Device and method for producing compound yarn by compact siro spun

A siro spinning and compacting technology, which is applied to the device for producing strands by compact siro spinning, and in the field of compact siro spinning to produce strands, can solve problems such as unstable spinning performance, and achieve the expansion of production varieties, smooth surface, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

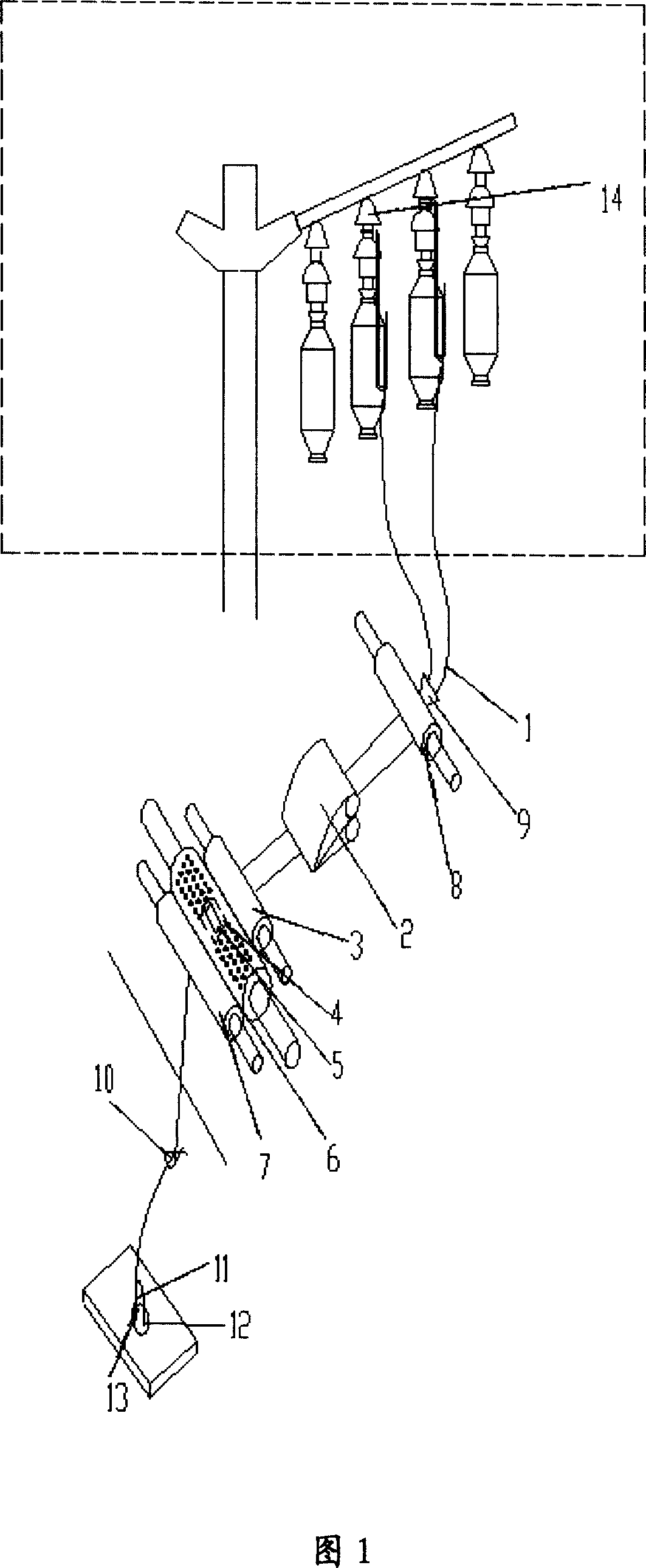

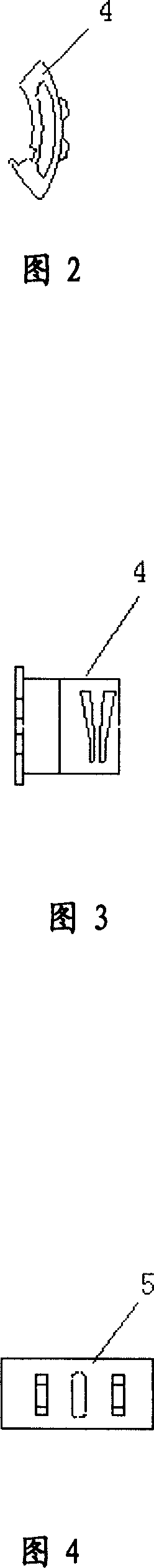

[0023] Referring to Fig. 1-Fig. 4, a kind of compact siro spinning device of the present invention produces strand, is made up of hanging spindle 14, two parallel rovings 1, rear road top roller 8, traverse guide yarn bell mouth 9, drafting Zone 2, front top roller 3, suction insert suction piece 4, air guide device pressing piece 5, accumulating roller 6, guide top roller 7, guide hook 10, traveler 13, spindle 11, bobbin 12. When the present invention was implemented, the installation of the siro spinning device was carried out on the basis of the compact spinning machine, and:

[0024] 1. Add two rows of hanging spindles 1, the distance between them is changed from 210mm to 140mm, and the forming diameter of the roving is 120mm.

[0025] 2. The traverse guide bell mouth 9 is changed from a single port to a double port, and the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com