A powder feeder

A material distributor and powder technology, applied in chemical instruments and methods, mixers, dissolving and other directions, can solve the problems of dust generation, unreachable milk tea powder, material blocking, etc., and achieve the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

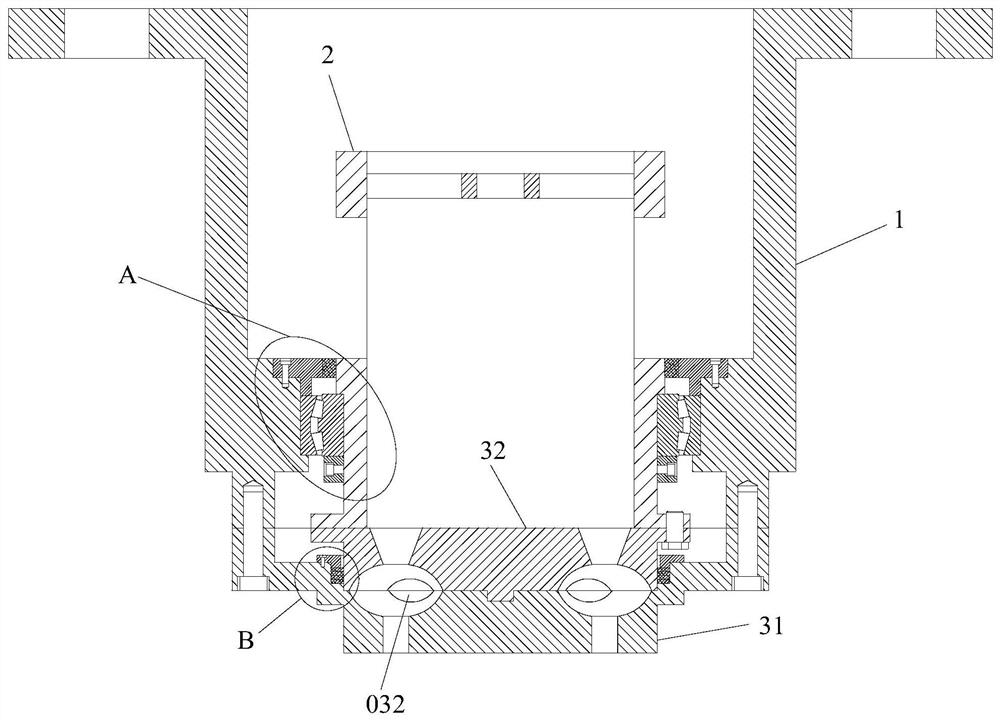

[0045] The invention provides a powder feeder, such as Figure 16 As shown, the distributor is set at the outlet of the powder mixing equipment, combined with figure 1 As shown, the distributor includes a flange sleeve 1 connected to the discharge port of the powder material mixing equipment. The flange sleeve 1 is provided with a rotatable feeding cylinder 2, and the end of the flange sleeve 1 is provided with a discharge Unit 3, wherein the feeding cylinder 2 is a cylinder with openings at both ends, and a pair of feeding notches 21 are provided on the side wall of the feeding cylinder 2 (such as Figure 12 shown);

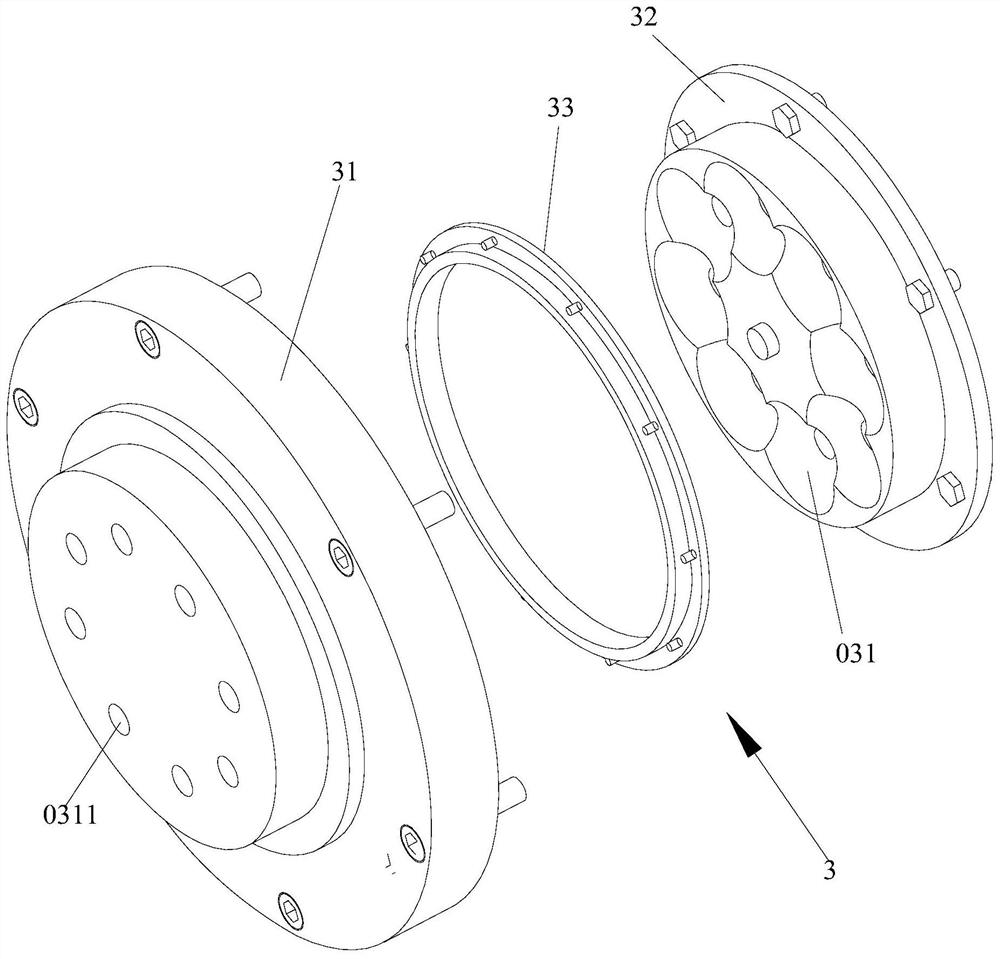

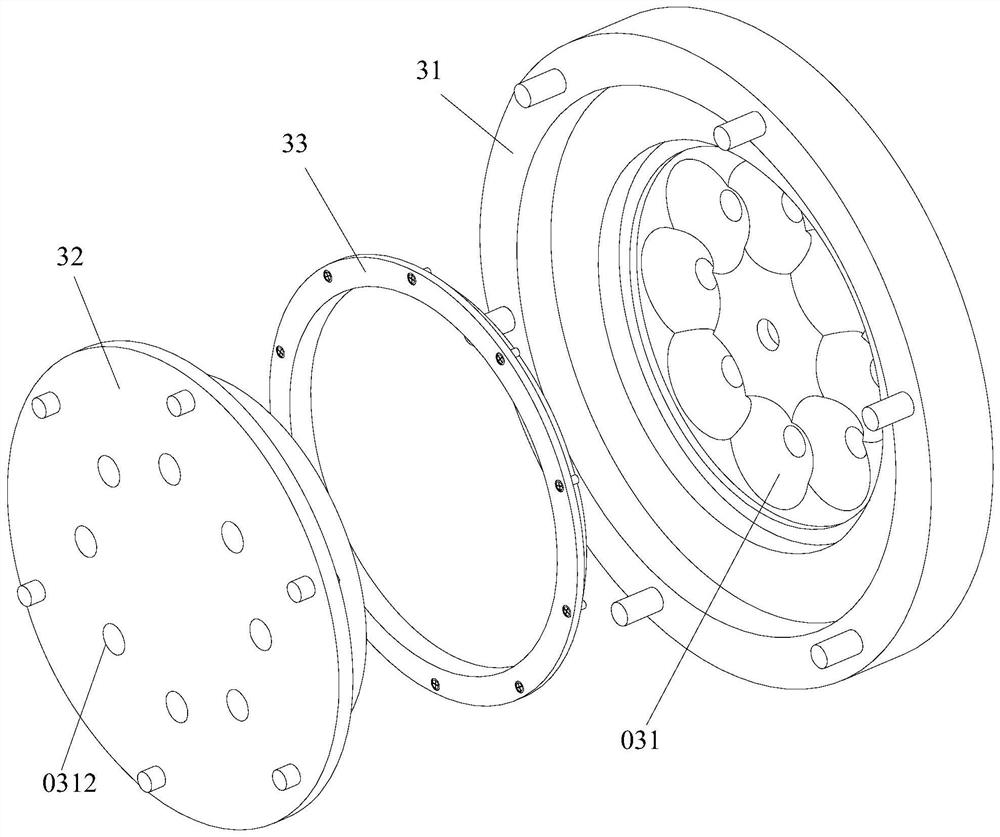

[0046] Such as figure 2 and image 3As shown, the discharge unit 3 includes a second disc body 32 coaxially rotating with the feed cylinder 1 and a first disc body 31 fixed on the flange sleeve 1, the first disc body 31, the second disc body 32, the method The flange sleeve 1 and the feeding cylinder 2 are coaxially arranged; between the feeding cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com