Dust collector chip separation baffle

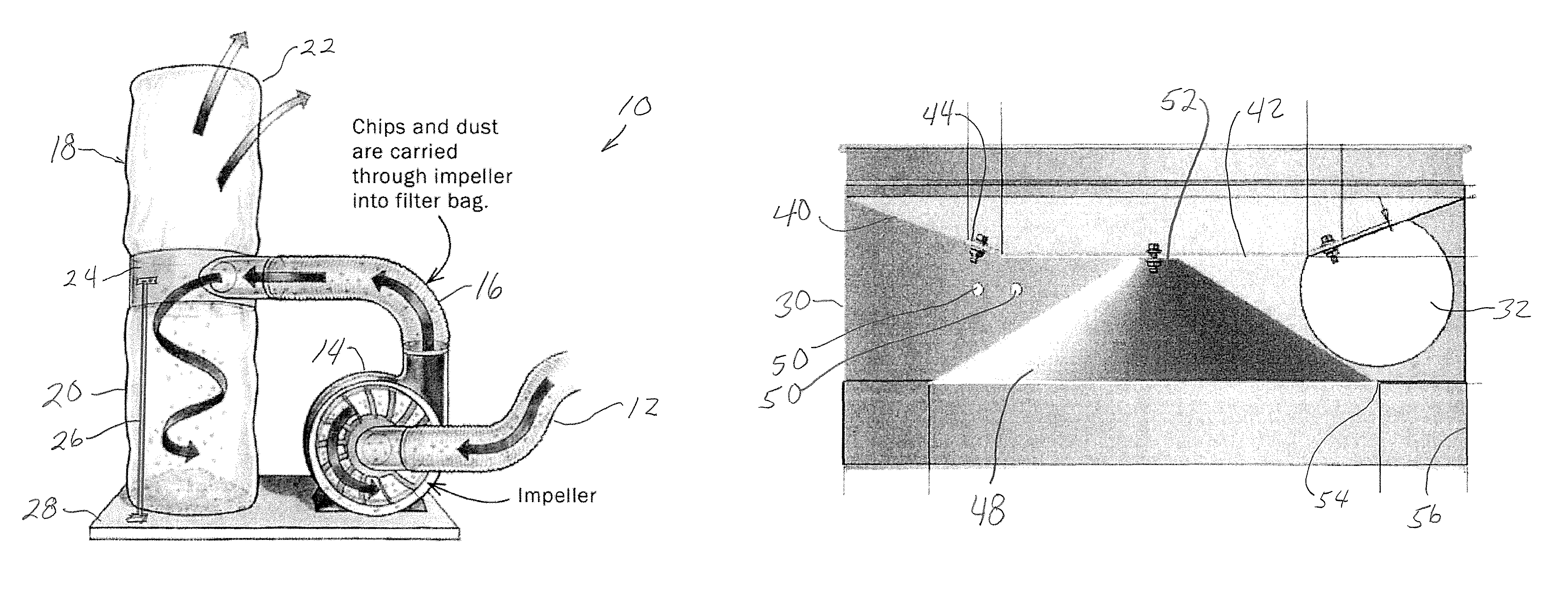

a technology of dust collector and baffle, which is applied in the field of baffle for dust collector, can solve the problems of reducing the capacity forming and shaping tools generate a substantial quantity of dust and wood chips, and reducing the efficiency of the dust collector, so as to reduce the loading and blockage of the air filter, less frequent cleaning of the air filter element, and the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

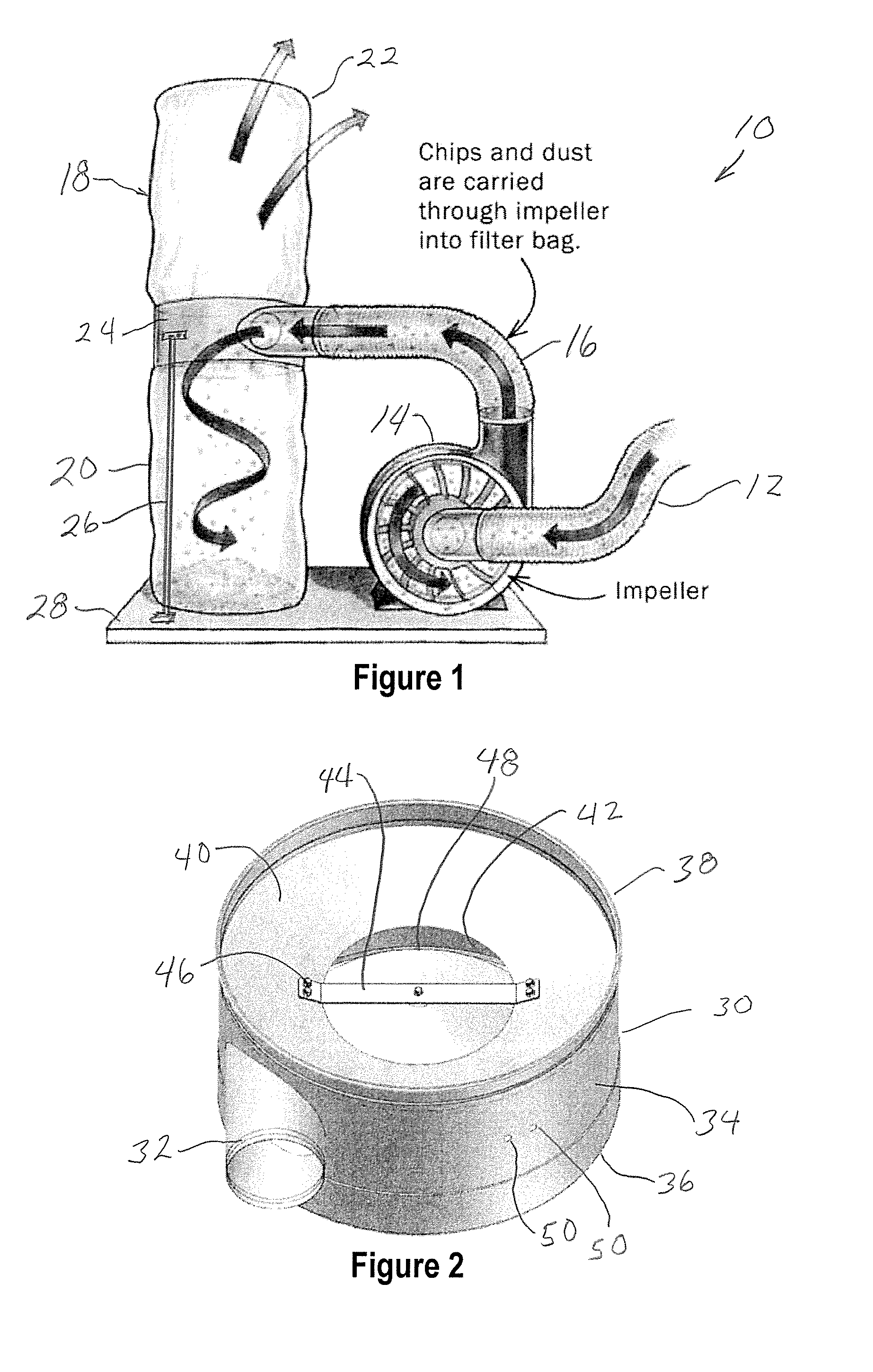

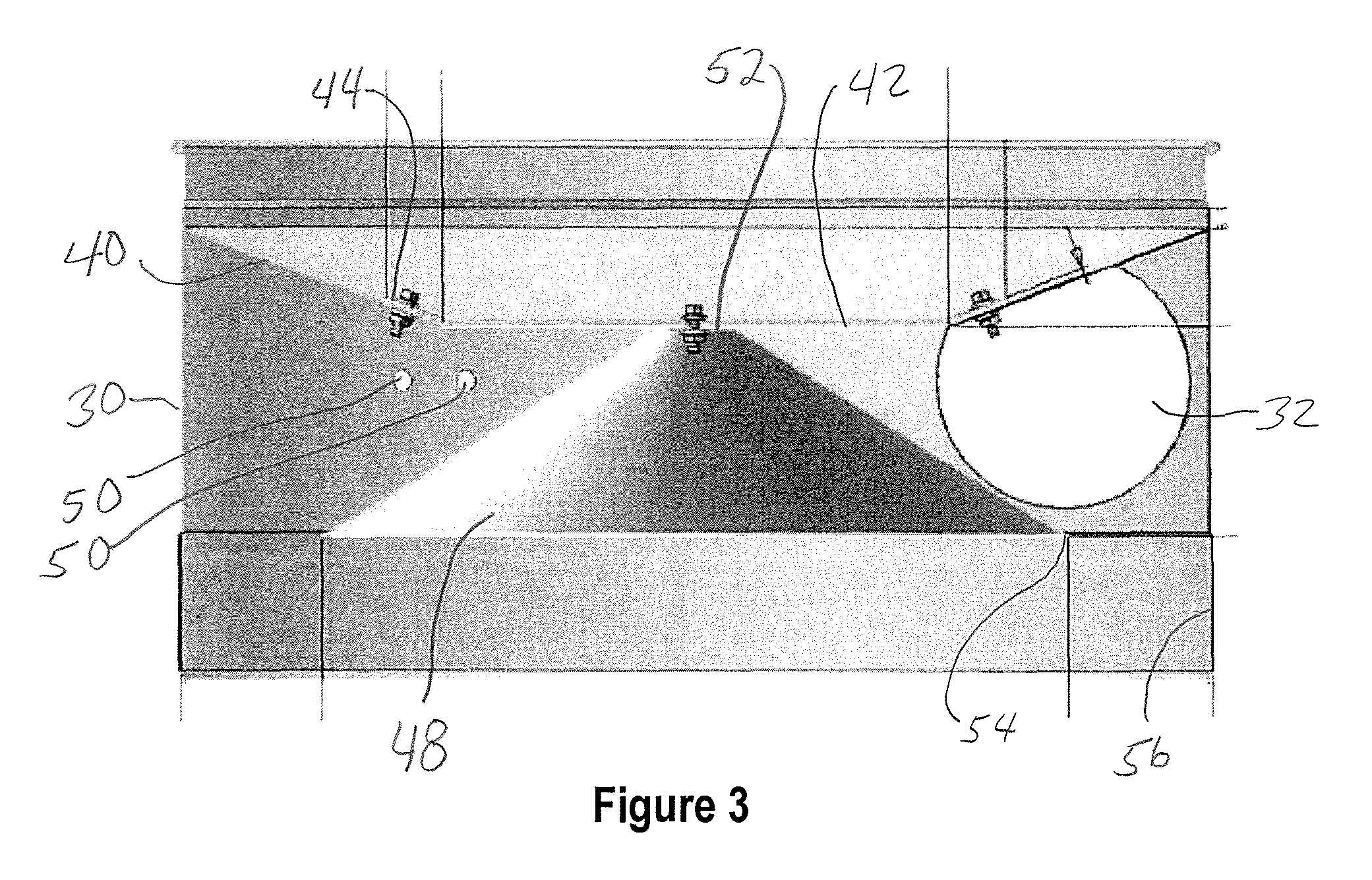

[0016]An embodiment of the invention is shown in FIG. 2 including an inlet ring or dust separator 30 for a dust collector, such as the dust collector 10 of FIG. 1, although use in other dust collectors are possible. The inlet ring 30 includes a inlet opening 32 to which a tube, conduit or other air flow carrying member may be connected. The inlet opening 32 is tangentially disposed relative to a circular side wall 34 of the inlet ring 30. The inlet ring 30 has a bottom end 36 for connection to a particle reservoir and a top end 38 for connection to a filter membrane or filter element. The filter element of the dust collector may be a fabric bag, for example, having a 30 micron filter rating, or in a preferred embodiment, a 1 micron rated filter element. Other size and types of filters are of course possible.

[0017]Within the inlet ring 30 is a ring wall 40 that extends inwardly from the interior of the circular side wall 34 and defines a central opening 42. The reference to the inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com