China hemp native fiber multicomponent blended yarn and preparing method thereof

A hemp primary fiber and multi-component technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of high hard sliver rate of ultra-long fibers, poor spinnability, thick and short fibers, etc., to achieve improved evenness, Less hairiness and better evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

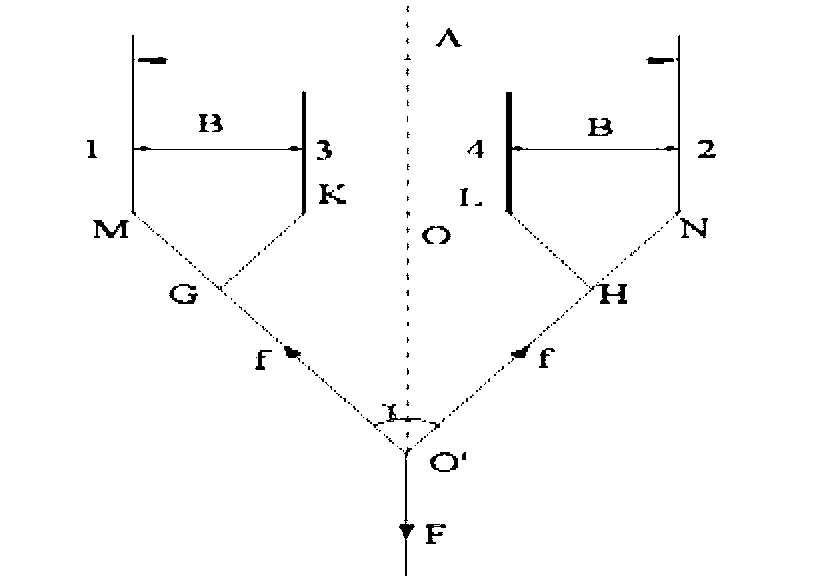

Method used

Image

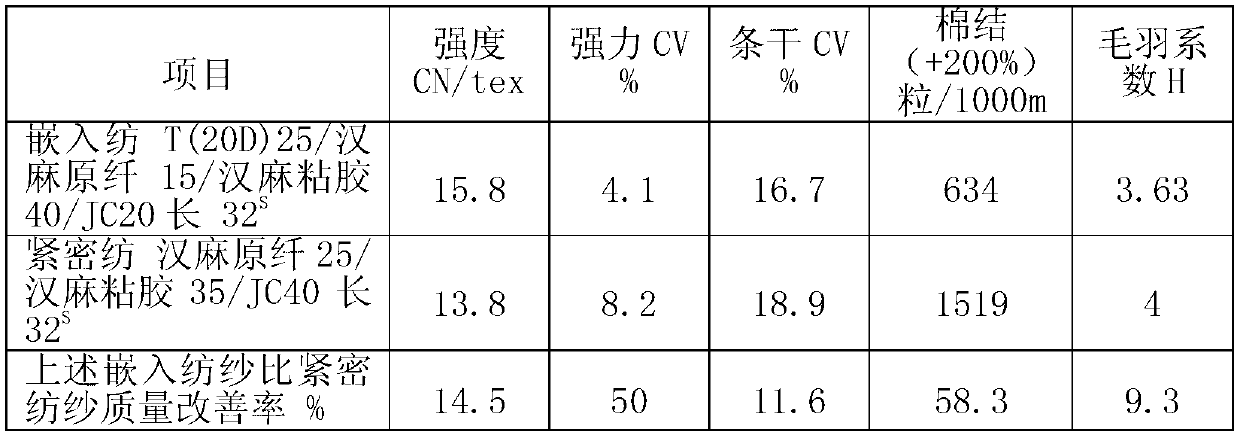

Examples

Embodiment 1

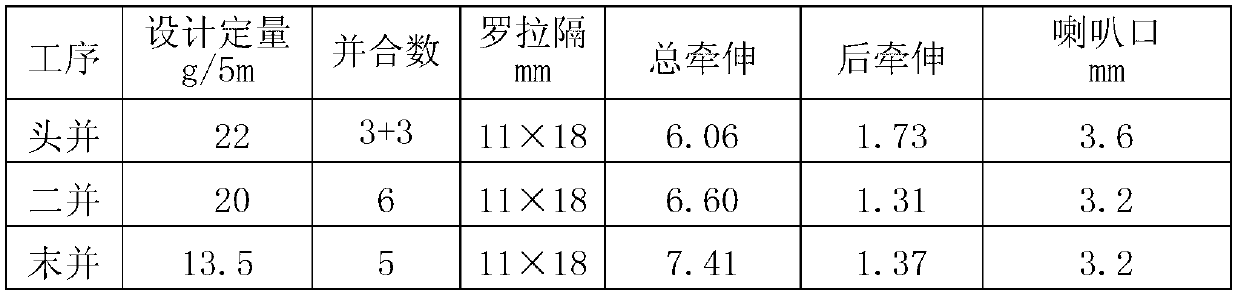

[0114] 1. Spinning process

[0115] 1. Main performance indicators of raw materials:

[0116] The length of hemp fiber is 55.34mm, the linear density of hemp fiber is 3.01D, the metric count is 2695Nm, the rate of hard strips is 1.5%, the rate of hemp grains is 35 grains / g, the rate of extra long fibers is 1.8%, and the moisture regain rate is 8.7%. The hemp viscose is selected from Shandong Hailong Co., Ltd. 1.5D×38mm cotton-type staple fiber, the long-staple cotton is selected from 137A Xinjiang long-staple cotton, the filament is selected from 20D polyester filament, and 32S blended yarn is spun with embedded spinning.

[0117] 2. Process flow:

[0118] ① Hemp raw fiber health pretreatment → cleaning and carding pretreatment: FA002A cotton grabbing machine (hemp raw fiber is fed separately) → A035E mixed cotton opener → FA106 cotton opener → A092A cotton feeder → A076C lapping machine → A186D Carding machine (not into sliver, collecting cotton web for packing) →

[0119]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com