Jutecell underwear fabric and manufacture method thereof

A technology for underwear fabrics and production methods, which is applied in the directions of textiles and papermaking, weft knitting, and yarn, can solve the problems of non-characteristic appearance of fabrics, poor evenness, and excessive yarn hairiness, and achieves a more stylish appearance. Chic, bright color, low pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

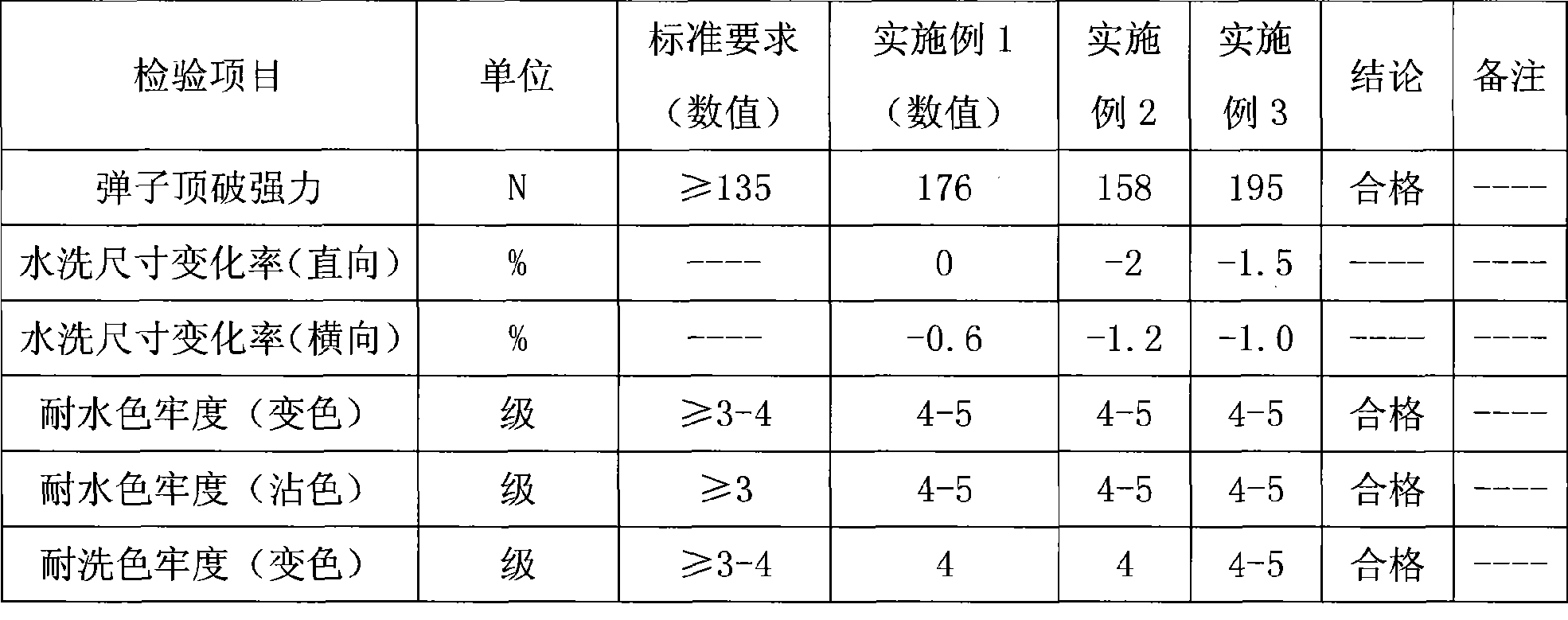

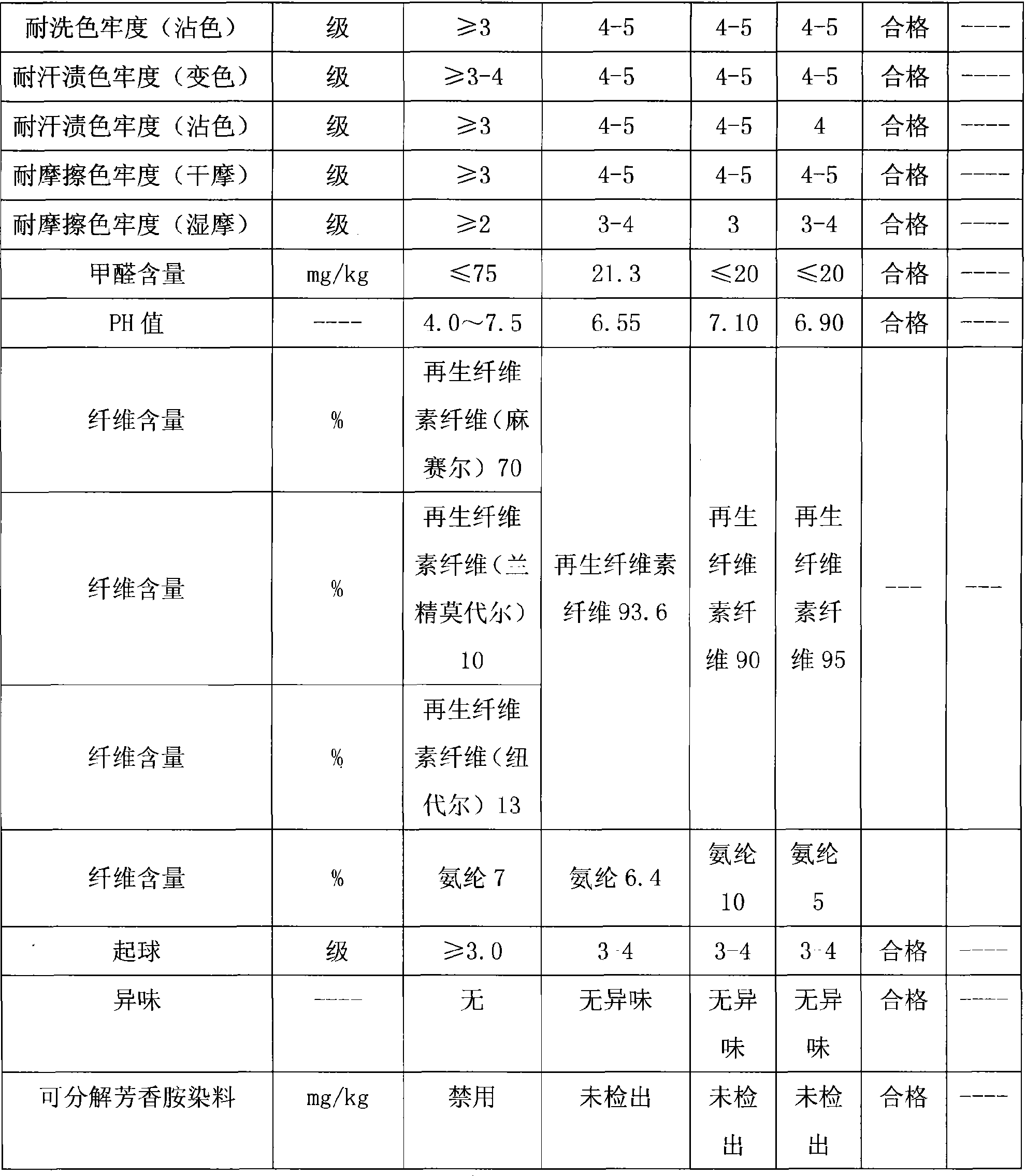

Embodiment 1

[0025] A Masail fiber underwear fabric is characterized in that it is composed of the following raw materials in parts by weight: 70 Masail fibers, 10 Modal fibers, 13 Newdale fibers and 7 spandex elastic fibers.

[0026] Maser fiber is produced by Shandong Hailong Co., Ltd., with a fineness of 1.67dtex and a length of 38mm; Modal fiber is produced by Austrian Lenzing Company, with a fineness of 1.33dtex and a length of 38mm; Newdale fiber is produced by Shandong Hailong Co., Ltd. , the fineness is 1.33dtex, and the length is 38mm; the spandex elastic fiber is the Elaspan elastic fiber of the former DuPont Company of the United States, which is now INVISTA, and the fineness is 33dtex.

[0027] The production method of above-mentioned hemp cell fiber underwear fabric, concrete steps are:

[0028] The first step: Spinning hexail fiber, modal fiber and newdale fiber into compact spinning yarn, the yarn count is 40 lbs, and the twist coefficient of spinning is 380;

[0029] The s...

Embodiment 2

[0069] Similar to the hemp fiber underwear fabric of Example 1, the difference is that it consists of the following raw materials in parts by weight: hemp fiber 50, modal fiber 20, newdale fiber 20 and spandex elastic fiber 10. The denier of the hemp fiber is 1.0dtex, and the length is 30mm. The fineness of the modal fiber is 1.0dtex, and the length is 30mm. The fineness of the Newdale fiber is 1.0dtex, and the length is 30mm. The denier of the spandex elastic fiber is 44dtex.

[0070] Similar to the production method of the hempcell fiber underwear fabric of embodiment 1, the difference is:

[0071] In the first step, masaier fiber, modal fiber and newdale fiber are spun into compact spinning yarn, and the yarn count is 32 lbs, and the twist coefficient of spinning is 360;

[0072] In the second step, the machine number of the loom is 22G, the loop length of the compact spinning yarn is 35cm / 100 needles, and the loop length of the spandex elastic fiber is 11cm / 100 needles....

Embodiment 3

[0074] Similar to the hemp fiber underwear fabric of Example 1, the difference is that it consists of the following raw materials in parts by weight: hemp fiber 65, modal fiber 20, new dale fiber 10 and spandex elastic fiber 5. The denier of the hemp fiber is 1.8dtex, and the length is 45mm. The fineness of the modal fiber is 1.8dtex, and the length is 45mm. The fineness of the Newdale fiber is 1.8dtex, and the length is 45mm. The denier of the spandex elastic fiber is 22dtex.

[0075] Similar to the production method of the hempcell fiber underwear fabric of embodiment 1, the difference is:

[0076] In the first step, Masaier fiber, Modal fiber and Newdale fiber are spun into compact spinning yarn, the yarn count is 60 British branches, and the twist coefficient of spinning is 400;

[0077] In the second step, the machine number of the loom is 36G, the coil length of the compact spinning yarn is 24cm / 100 needles, and the coil length of the spandex elastic fiber is 8cm / 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com