Method of preparing meat-flavor essence from duck meat processing wastes

A meat flavor and waste technology, which is applied to the field of preparing meat flavor from duck meat processing waste, can solve problems such as resource waste, and achieve the effects of protecting the environment, increasing added value, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

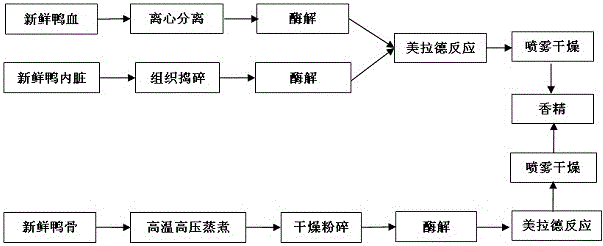

[0011] (1) The process of preparing meat flavor essence from duck blood, as attached figure 1 ;

[0012] 1. Fresh duck blood pretreatment: ⑴ anticoagulation, fresh duck blood, 1:4 ( v / v ) Add 3.8% sodium citrate solution; (2) Centrifuge at 4000r / min for 15min to separate the crude duck plasma;

[0013] 2. Preparation of enzymatic hydrolysis solution: (1) Enzymolysis, add 30000U / 100ml alkaline protease to plasma, adjust pH to 8.0, and react for 3 hours at 60°C; (2) Inactivate enzyme, heat at 100°C for 10 minutes;

[0014] 3. Maillard reaction: (1) mixed reaction, mix the enzymatic hydrolysis solution with xylose and cysteine at a ratio of 1:1:0.2 (solid content ratio), adjust the pH to 7.5, and react at 110°C for 2 hours;

[0015] 4. Drying: Pass the Maillard reaction product through a spray dryer (control the inlet air temperature at 180°C-200°C, and the outlet air temperature at 85°C-90°C) to obtain dry essence powder;

[0016] 5. Detection: Detect the physical and ch...

Embodiment 2

[0030] (1) The process of preparing meat flavor essence from duck blood, as attached figure 1 ;

[0031] 1. Fresh duck blood pretreatment: ⑴ anticoagulation, fresh duck blood, 1:4 ( v / v ) Add 3.8% sodium citrate solution; (2) Centrifuge at 4000r / min for 15min to separate the crude duck plasma;

[0032] 2. Preparation of enzymatic hydrolysis solution: (1) Enzymolysis, adding 50000U / 100ml of alkaline protease to the plasma, adjusting the pH to 8.0, and reacting at 60°C for 3 hours; (2) Inactivating the enzyme, heating at 100°C for 10 minutes;

[0033] 3. Maillard reaction: (1) mixed reaction, mix the enzymatic solution with xylose and cysteine at a ratio of 1:1:0.2 (solid content ratio), adjust the pH to 8.5, and react at 120°C for 2 hours;

[0034] 4. Drying: Pass the Maillard reaction product through a spray dryer (control the inlet air temperature at 180°C-200°C, and the outlet air temperature at 85°C-90°C) to obtain dry essence powder;

[0035] 5. Detection: Detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com