Method for manufacturing bamboo beam

A production method and technology of bamboo beams, applied in the manufacture of tools, wood processing equipment, etc., can solve problems such as soil erosion, natural geographical ecological deterioration, etc., and achieve the effect of improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Embodiment A kind of manufacture method of bamboo beam, comprises the following steps:

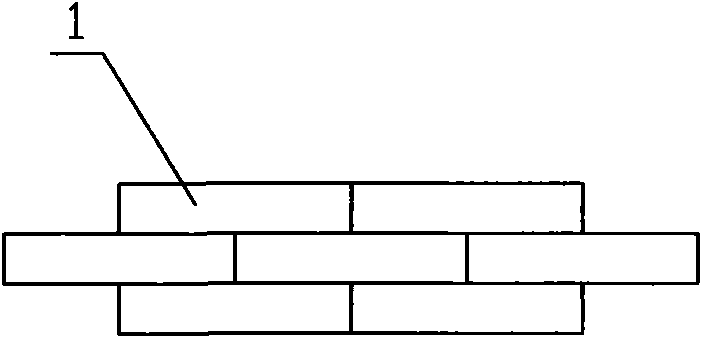

[0035] Step 1: Take a section of bamboo tube and split it longitudinally along its natural bamboo fiber interface to form several pieces of bamboo 1;

[0036] The second step: process and remove the bamboo joints and bamboo greens on the outside of each piece of bamboo slice 1, and the bamboo yellow inside, and smooth the bamboo slices;

[0037] The third step: drying the bamboo chips;

[0038] Step 4: Apply glue to the inner and outer surfaces of the bamboo slice 1 to make the inner and outer surfaces of the bamboo slice 1 sticky;

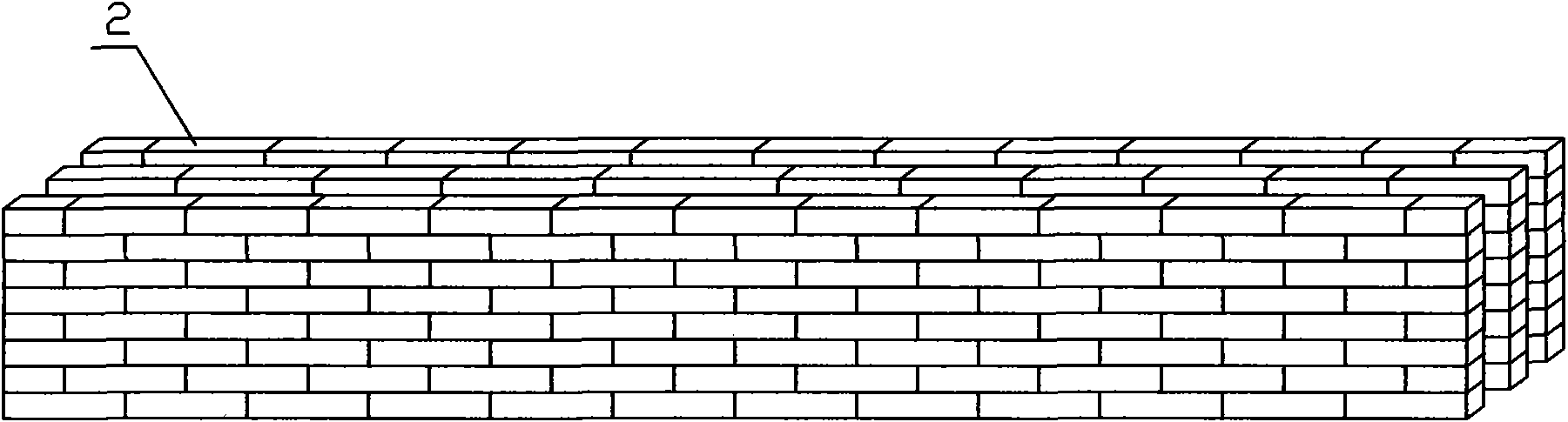

[0039] Step 5: Place the glue-coated bamboo slices 1 on a press for longitudinal dislocation pressing, and press them into rectangular bamboo slices 2;

[0040] The sixth step: sawing the redundant parts at both ends of the extruded bamboo sheet 2;

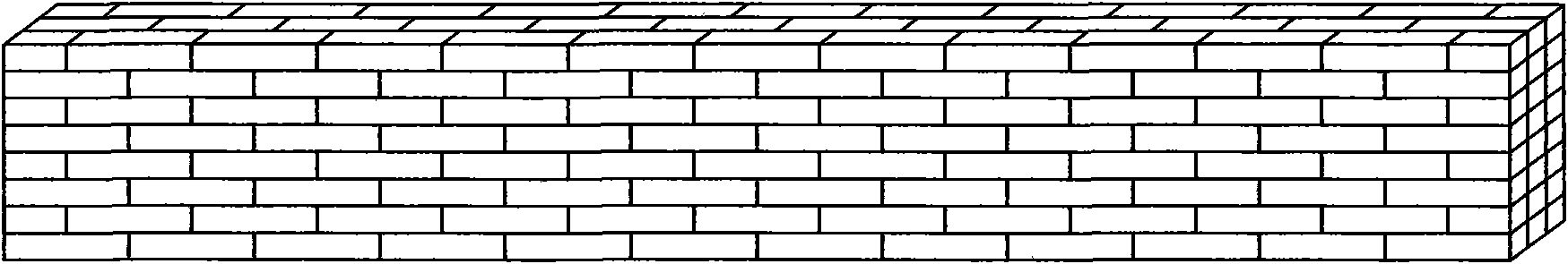

[0041] Step 7: Take the pressed and sawn bamboo boards 2, apply glue on the surface, place the glued ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com