Salt-resistant soil-improving slow release fertilizer and preparation method thereof

A slow-release fertilizer and fertilizer technology, which is applied to fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as affecting the normal growth of crops and the urgency of slow-releasing fertilizers, and achieve the advantages of simple and easy preparation method, significant effect, and reduced raw material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

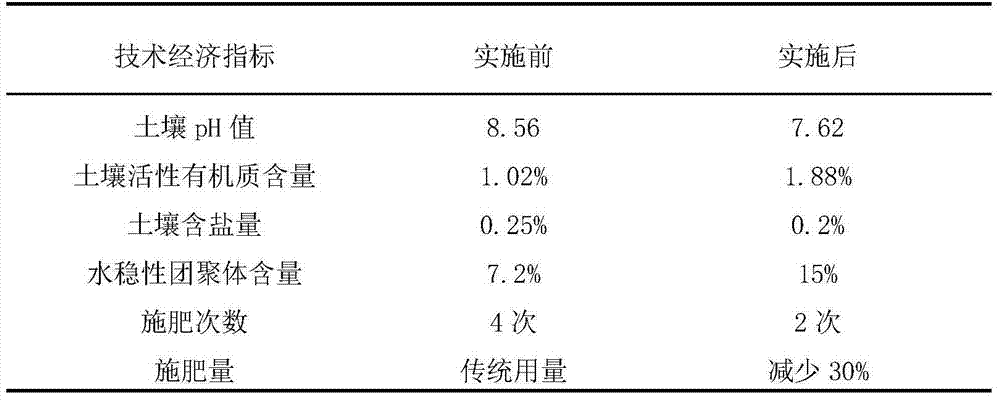

Examples

Embodiment 1

[0045] A salt-resistant slow-release fertilizer for saline-alkali soil improvement. The composition of raw materials in parts by weight is as follows: 10 parts of furfural slag, 30 parts of humic acid, 5 parts of montmorillonite, 5 parts of zeolite powder, 0.2 part of polyvinyl alcohol, and large particle size 10 parts of urea, 24 parts of monoammonium phosphate, and 16 parts of potassium sulfate.

[0046] (1) Take the above-mentioned humic acid, montmorillonite and zeolite powder according to the proportion and put them into a mixer and mix them evenly to obtain a mixture;

[0047] (2) Polyvinyl alcohol is configured into a 0.2-0.5wt% aqueous solution;

[0048](3) Put the nitrogen fertilizer in the drum of the granulator and heat it to 80-85°C, spread the mixture obtained in the step (1) evenly on the surface of the nitrogen fertilizer, then spray the aqueous solution of polyvinyl alcohol obtained in the step (2), and blast Dried until the surface forms a hard shell to obtai...

Embodiment 2

[0052] 15 parts of furfural residue, 25 parts of humic acid, 4 parts of montmorillonite, 6 parts of porous zeolite, 0.3 part of polyvinyl alcohol, 17 parts of large particle urea, 19 parts of monoammonium phosphate, and 14 parts of potassium sulfate. The preparation method is the same as in Example 1 .

[0053] The product of this embodiment is suitable for use as a slow-release fertilizer for moderate saline-alkali soil improvement against salt.

Embodiment 3

[0055] 20 parts of furfural slag, 20 parts of humic acid, 4 parts of montmorillonite, 6 parts of porous zeolite, 0.5 part of polyvinyl alcohol, 19 parts of large particle urea, 15 parts of monoammonium phosphate, and 16 parts of potassium sulfate; the preparation method is the same as in Example 1 .

[0056] The product of this embodiment is suitable for use as a slow-release fertilizer for salt-resistant soil improvement in severe saline-alkali soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com