A kind of production method of utilizing acidic copper-containing etching waste liquid to produce electroplating grade copper sulfate

A production method, the technology of copper sulfate, applied in the direction of copper sulfate, etc., can solve the problems of high chloride ion content, high production cost, large energy consumption, etc., and achieve the effect of reducing processing cost, saving energy and cost, and eliminating processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

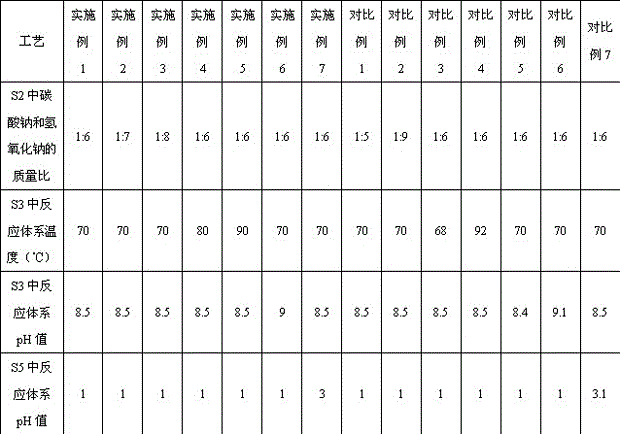

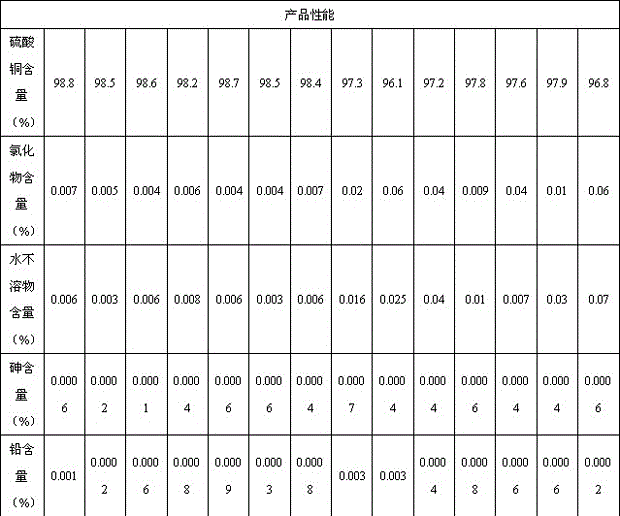

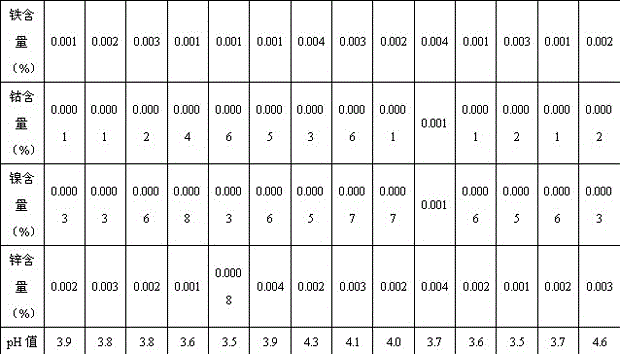

[0029] A kind of production method that utilizes acidic copper-containing etching waste liquid to produce electroplating grade copper sulfate, comprises the following steps:

[0030] S1. Impurity removal: inject 5m into the impurity removal kettle 3 Acidic copper-containing waste liquid for impurity removal;

[0031] S2. Alkali matching: 200kg sodium carbonate powder and 1.6m 3 Sodium hydroxide solution with a mass concentration of 50% is dissolved in 2m 3 In clear water, mix well; (i.e. the mass ratio of strong base, weak acid salt and strong base is 1:6) the mass concentration of lye is 30%;

[0032] S3. Continuous production: inject 3.5m into the reactor 3 Clean water, preheated to 70°C, preheated the acidic copper-containing waste liquid and mixed lye to 40°C respectively, and continuously added to the reaction kettle at the same time to start continuous production; keep the temperature of the reaction system at 70°C, pH 8.5;

[0033] After reacting for 2 hours, disch...

Embodiment 2

[0037] In addition to alkali matching, 200kg of sodium carbonate powder and 1.85m 3 Sodium hydroxide solution with a mass concentration of 50% is dissolved in 2.3m 3Except for clear water, the others are the same as in Example 1; (that is, the mass ratio of strong base, weak acid salt and strong base is 1:7) and the mass concentration of lye is 30%.

Embodiment 3

[0039] In addition to alkali matching, 200kg of sodium carbonate powder and 2.1m 3 Sodium hydroxide solution with a mass concentration of 50% is dissolved in 2.6m 3 Except for clear water, the others are the same as in Example 1; (that is, the mass ratio of strong base, weak acid salt and strong base is 1:8) and the mass concentration of lye is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com