Rice seedling raising substrate produced from plant straws and beer active sludge and preparation method thereof

The technology of plant straw and activated sludge is applied in the fields of botanical equipment and methods, planting substrates, preparation of organic fertilizers, etc., and can solve the problems of unfavorable rice seedling substrate promotion, large amount of soil borrowing, and increased mechanical work load, etc. To achieve the effect of promoting sustainable production, promoting the mechanization of the whole process, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a rice seedling-raising substrate produced from plant stalks and beer activated sludge, comprising the following steps:

[0026] Step 1: High-temperature aerobic fermentation, the plant straw is crushed into 5-10mm segments, and 50%-70% of the plant straw is mixed with 30%-50% of beer activated sludge by volume percentage, so that the initial Moisture is controlled at 50%-55%; 0.5%-1.5% straw decomposing agent and 1.5%-2.5% nitrogen fixer are added to the obtained mixture according to the mass ratio through a computer metering belt scale, and then carried out in a solar composting rapid heating device High-temperature aerobic fermentation, turning the heap 4-5 times, after 20-22 days, transfer to the aging workshop for secondary fermentation and decomposing;

[0027] Step 2: Secondary aerobic fermentation, adding cellulolytic bacteria to the organic material fermented in the first stage, using intermittent oxygen supply in the aging workshop, aero...

specific Embodiment

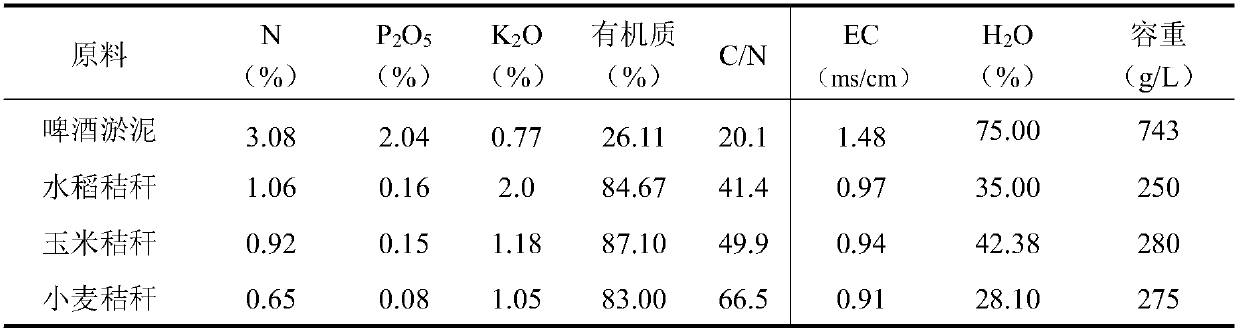

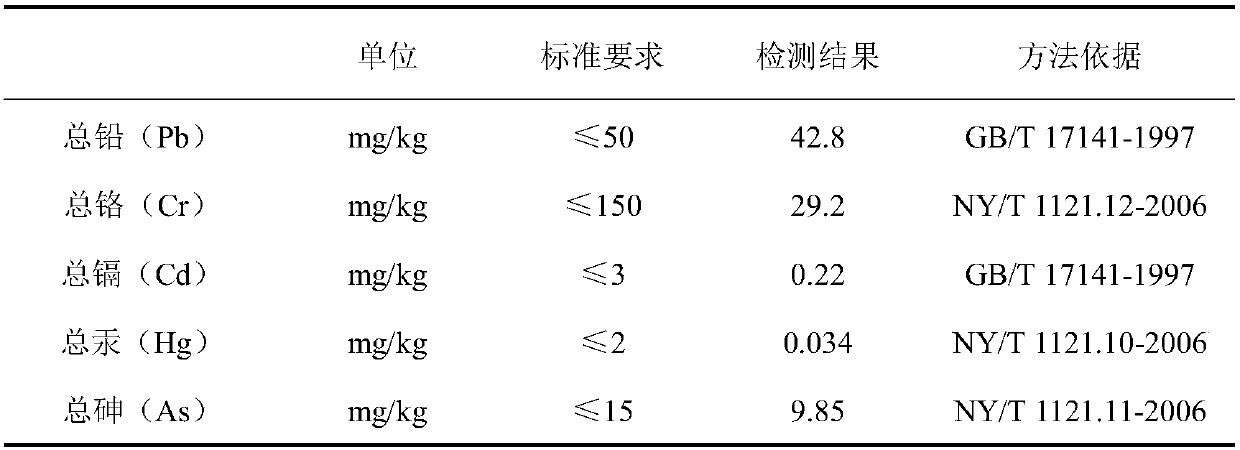

[0069] The test substrate is the rice seedling raising substrate produced by plant straw and beer activated sludge of the present invention. The nutrient, water and carbon-nitrogen ratio of compost materials are very important to the influence of compost fermentation. The suitable carbon-nitrogen ratio for microbial decomposition of organic materials is 25 The normal fermentation time is about 25 days. The raw materials selected in the test were averaged after several tests of their physical and chemical properties, and the results showed that the carbon-nitrogen ratio of crop straw was high, about 40 to 60 (Table 1); beer activated sludge refers to fermentation wastewater The activated sludge precipitated after treatment is mainly composed of waste yeast sludge that cannot be reused after several generations of fermentation. It contains 29.97% crude protein and its heavy metals are lower than the national standard (Table 2). The traditional treatment method is landfill Or sur...

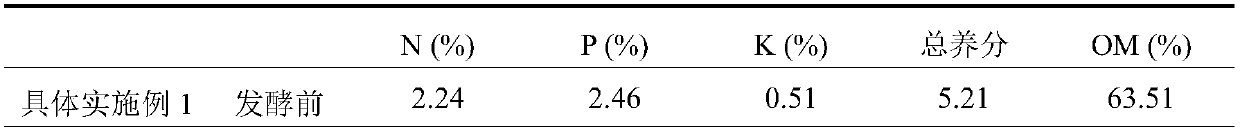

specific Embodiment 1

[0075] 1. Substrate raw materials: 50% plant straw + 50% beer sludge + 1% starter + 2% nitrogen fixer

[0076] 2. High temperature aerobic fermentation time: 20 days

[0077] 3. Secondary decomposing fermentation time: 10 days

[0078] 4. Acid regulator: 2.5% sulfur

[0079] 5. Inorganic materials: 5% pottery sand + 5% vermiculite

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com