Ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part

A field soil and micro-topography technology, applied in the field of agricultural machinery, can solve problems such as the inability to adjust the degree of soil compaction, and achieve the effect of solving the problem of soil adhesion, uniform compactness, and regular shape of small pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

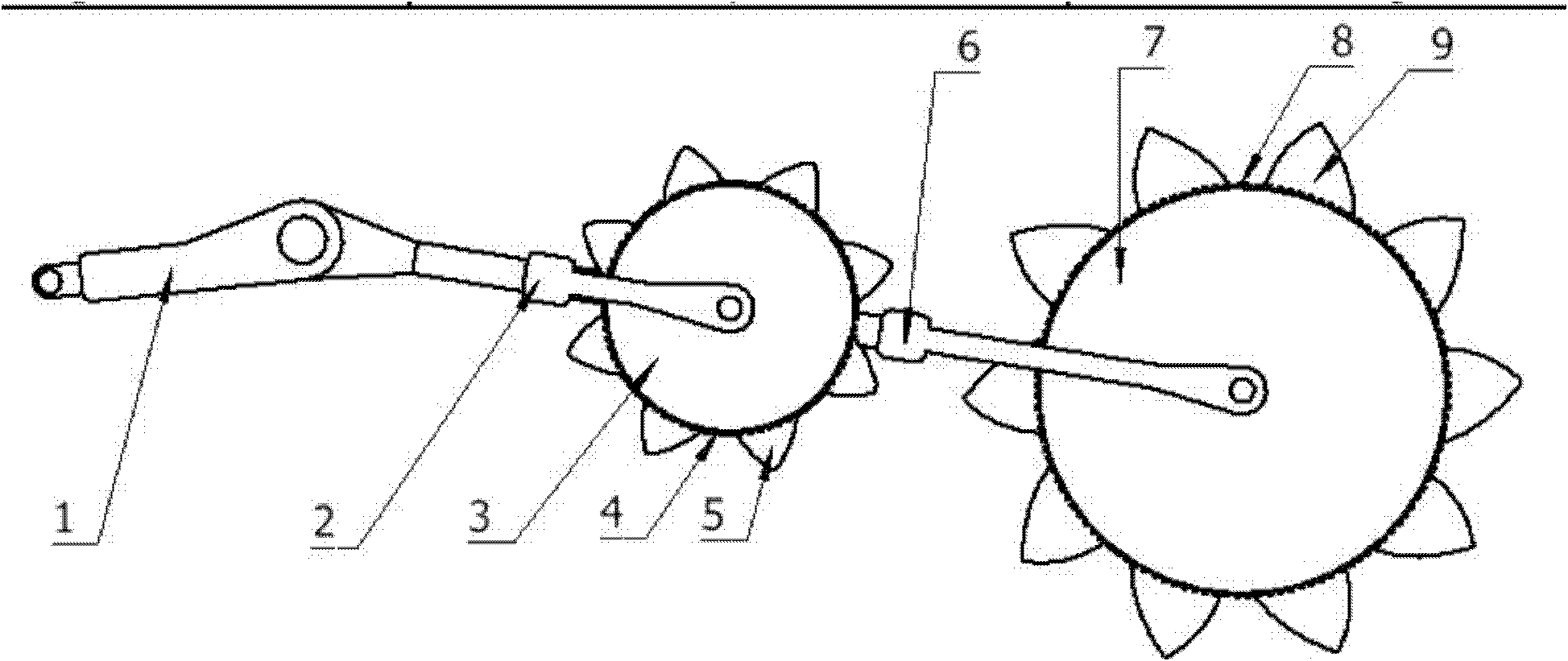

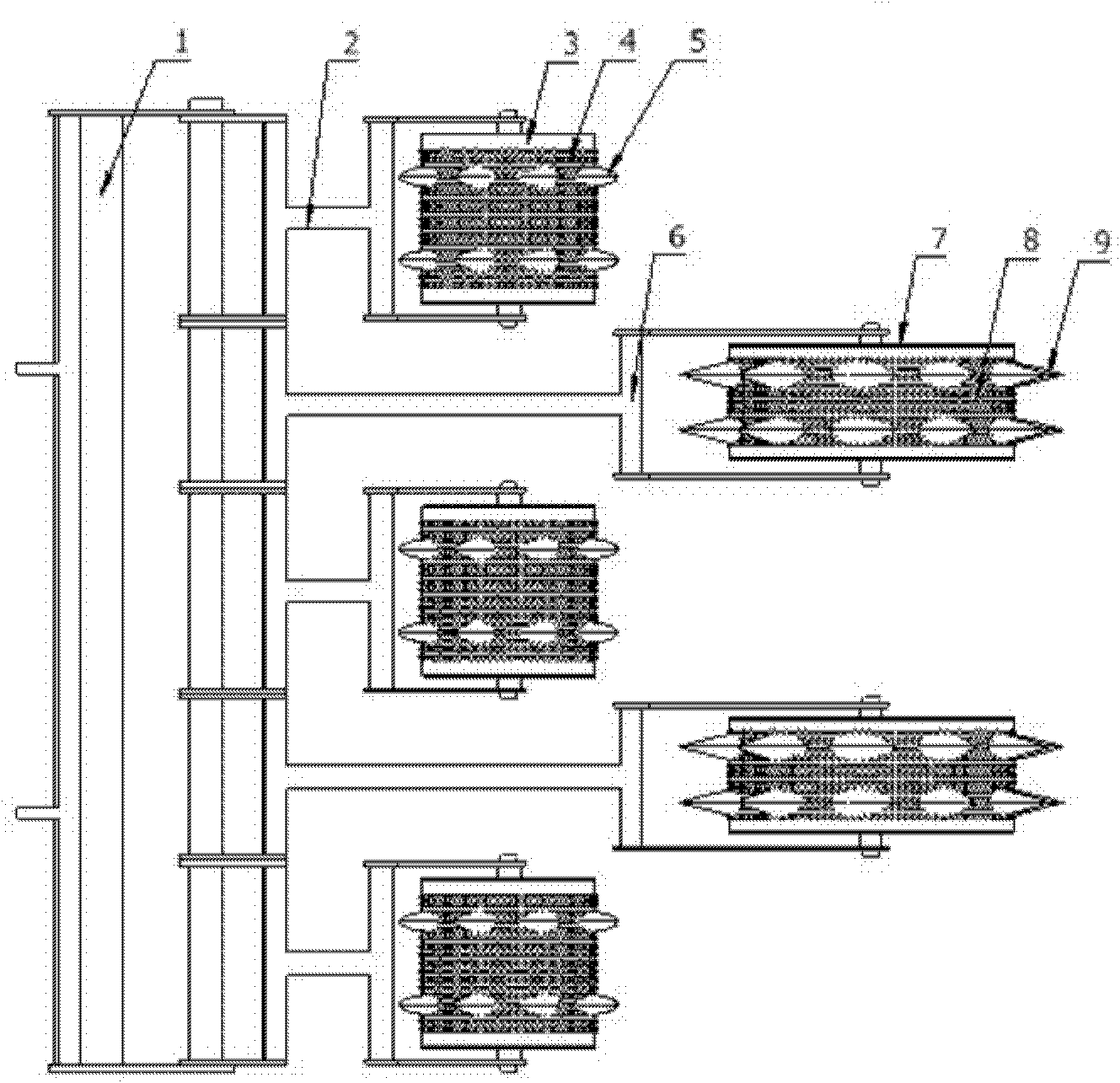

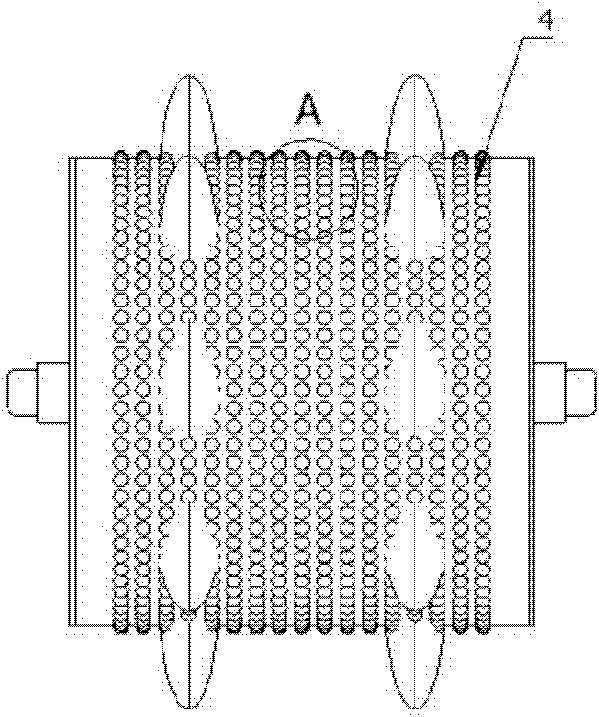

[0047]The specific structure of the rolling soil-touching parts of the bionic structure for processing the micro-topography of the soil surface in the field of ridge farming in this example is shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5 and Figure 6. The structural characteristics of the new rolling soil-contacting parts of this example are: it has the ridge roller 4 for suppressing the ridge and the furrow roller 7 for suppressing the furrow at the same time, which is different from the traditional suppression roller that can only suppress the ridge; There are roller teeth 3 and 6 with bionic geometric structure, which can process the micro-topography of the soil surface, which is different from the traditional pressure roller without teeth that cannot process the micro-topography of the soil surface; the surface of the ridge roller and the furrow roller has convex hulls, The bushing with bionic geometric structure of pits, ribs, steps and scales is made of UHMWP...

Embodiment 2

[0049] The specific structure of the rolling soil-touching parts of the micro-topography processing of the bionic structure in the ridge farming field soil surface in this example is shown in FIG. 8 . The biomimetic structure rolling soil-contacting parts for micro-topography processing of the field soil surface described in this example are different from Example 1 in that the rolling soil-contacting parts consist of 2 ridge rollers and 3 furrow rollers. The rest of the parts that are not described are the same as those described in Embodiment 1, and will not be repeated.

Embodiment 3

[0051] In this case, the specific structure of the furrow roller for the micro-topography processing of the soil surface in the ridge farming field is as follows: Figure 10 show. The difference between the furrow roller of the microtopography processing bionic structure rolling soil contacting parts in the ridge farming field described in this example and the example 1 and example 2 is that 8 roller teeth are distributed on each circumferential line of the furrow roller in this example, and each ridge The table roller or ditch roller axis is arranged with 3 rows of roller tooth groups. The other unmentioned parts are the same as those described in Embodiment 1 and Example 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com