Two-wheel slotter

A double-wheel milling and grooving machine technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of high maintenance costs, high manufacturing precision requirements, disassembly and maintenance Difficulty and other problems, to achieve the effect of low maintenance cost, reduced production cost, simple and convenient processing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

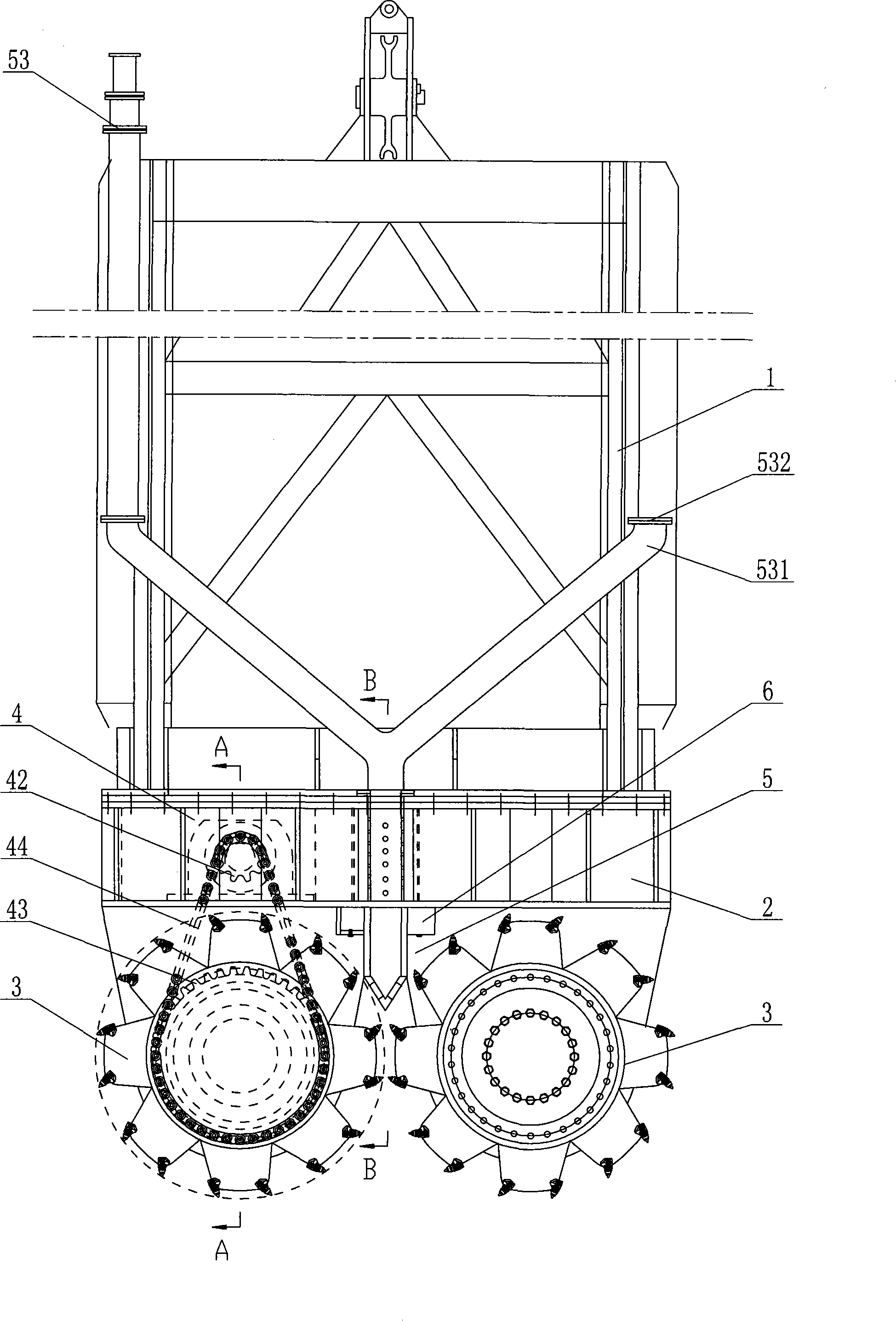

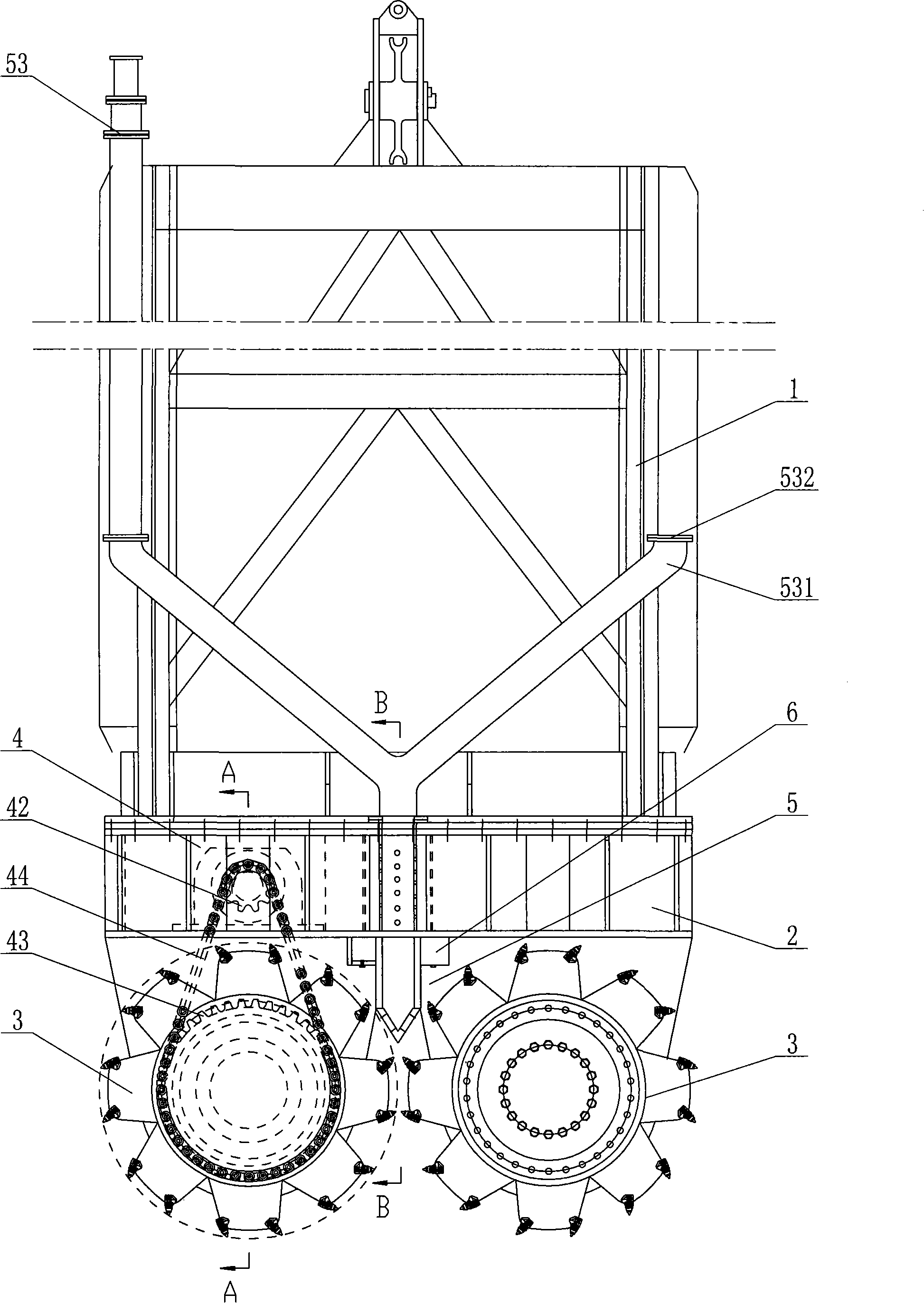

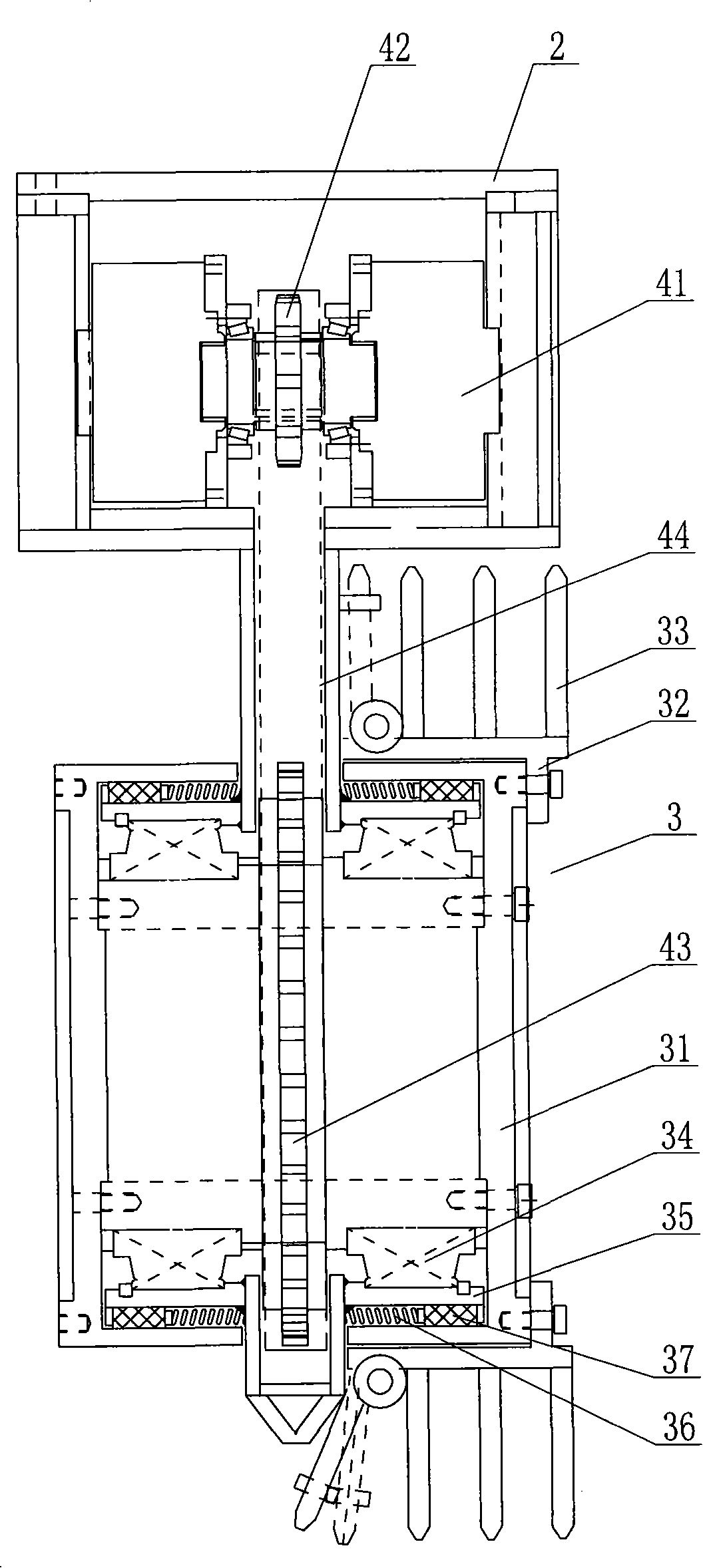

[0019] As shown in Figures 1 to 4, the double-wheel milling machine according to the present invention includes a guide frame 1, a sealed box 2 installed at the bottom of the guide frame 1, a driving device 4 installed in the sealed box 2, and a device Two milling wheels 3 with several milling cutter heads 33 are arranged on the lower part of the sealed box body 2, which can carry out forward and reverse milling on the soil layer and the rock layer. The low speed in the body 2, the large torque hydraulic motor 41 and the small sprocket 42 installed on the output shaft of the hydraulic motor 41, the large sprocket 43 for driving the rotation of the milling wheel 3 and the connection of the small sprocket 42 and the large chain The speed change transmission mechanism that the chain 44 of wheel 43 forms. The double-wheel milling machine is hoisted, put in place, and lowered by crawler belts, and the high-pressure oil supply system is started. The driving device 4 drives the milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com