Bionic asphalt-based crack pouring glue material and preparing method thereof

An asphalt-based, joint-filling glue technology, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve the problems of rapid failure, poor adhesion between the joint-filling glue and the crack wall, and short validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

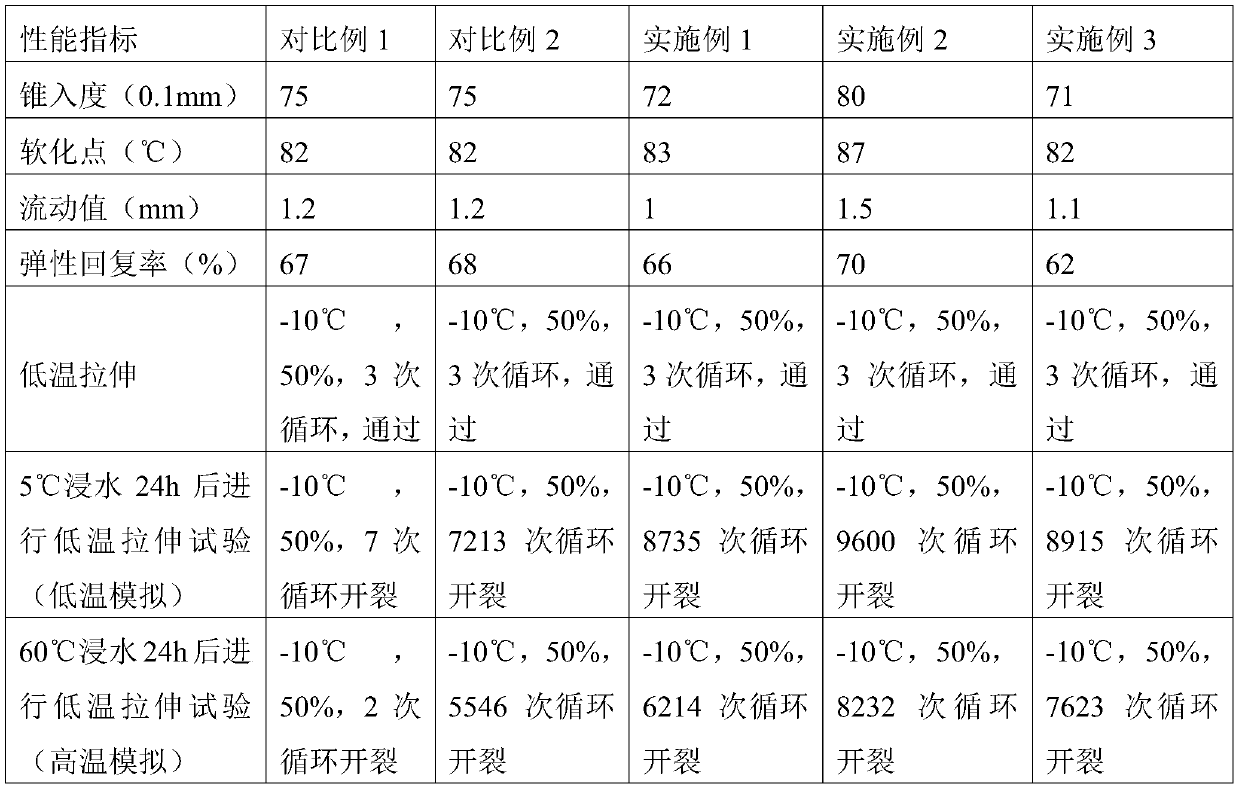

Embodiment 1

[0031] Add 0.1 mol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) to 100 mL of phosphate buffer, then adjust the pH to 5, and then add Add 0.1 mol of polyethyleneimine and 0.3 mol of 3,4-dihydroxybenzoic acid, stir slowly at room temperature for 3 hours, after the reaction is over, let it stand for stratification to get water-containing catechol structural unit A multi-component polymer, this multi-component polymer is dried at 80°C and -53.9KPa for half an hour to obtain an anhydrous multi-component polymer containing catechol structural units, and anhydrous The multi-component polymer continues to keep warm at 80°C for later use.

[0032] Select 100 parts of heavy traffic road asphalt AH-70 and heat it to a fluid state at 120°C, add 0.1 part of adhesive synergist (nano cesium tungsten oxide, cesium / tungsten = 30 / 70) under stirring conditions (speed 80rpm) , 1 part of tackifier (terpene resin) and 1 part of polymer modifier (SBS), cut at 5000rpm for 30m...

Embodiment 2

[0038] Add 0.1mol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) to 100mL of phosphate buffer, then adjust the pH to 5.5, and then add Add 0.1 mol of polyethyleneimine and 0.3 mol of 3,4-dihydroxyphenylacetic acid, stir slowly at room temperature for 3 hours, after the reaction is over, let it stand for stratification to get water-containing catechol structural unit A multi-component polymer, this multi-component polymer is dried at 80°C and -53.9KPa for half an hour to obtain an anhydrous multi-component polymer containing catechol structural units, and anhydrous The multi-component polymer continues to keep warm at 80°C for later use.

[0039] Select 100 parts of heavy traffic road asphalt AH-90 and heat it to a fluid state at 110°C, and add 0.5 parts of adhesive synergistic additive (nano-antimony tin oxide, tin / antimony=50 / 50) under stirring conditions (speed 80rpm) , 3 parts of tackifier (terpene resin) and 5 parts of polymer modifier (SBS), cut 60m...

Embodiment 3

[0041] Add 0.1mol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) to 100mL of phosphate buffer, then adjust the pH to 4.5, and then add Add 0.1 mol of polyethyleneimine and 0.3 mol of 3,4-dihydroxyphenylpropionic acid, stir slowly at room temperature for 3 hours, after the reaction is over, let it stand for stratification to obtain a hydrous catechol-containing structure Unit multi-component polymer, after drying this multi-component polymer at 80°C and -53.9KPa for half an hour, an anhydrous multi-component polymer containing catechol structural units is obtained, and the The multi-component polymer of water continues to keep warm at 80°C for later use.

[0042]Select 100 parts of heavy traffic road asphalt AH-70 and heat it to a fluid state at 130°C, and add 0.3 parts of adhesive synergistic additive (nano cesium tungsten oxide, cesium / tungsten = 40 / 60) under stirring conditions (speed 80rpm) , 2 parts of tackifier (terpene resin) and 3 parts of polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com