Method for maintaining sustainable production capacity of greenhouse vegetable soils

A production capacity and soil technology, applied in the direction of soil preparation methods, fertilization methods, botanical equipment and methods, etc., can solve the problems that producers are difficult to fully grasp, affect the application effect, and fail to form sustainable production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

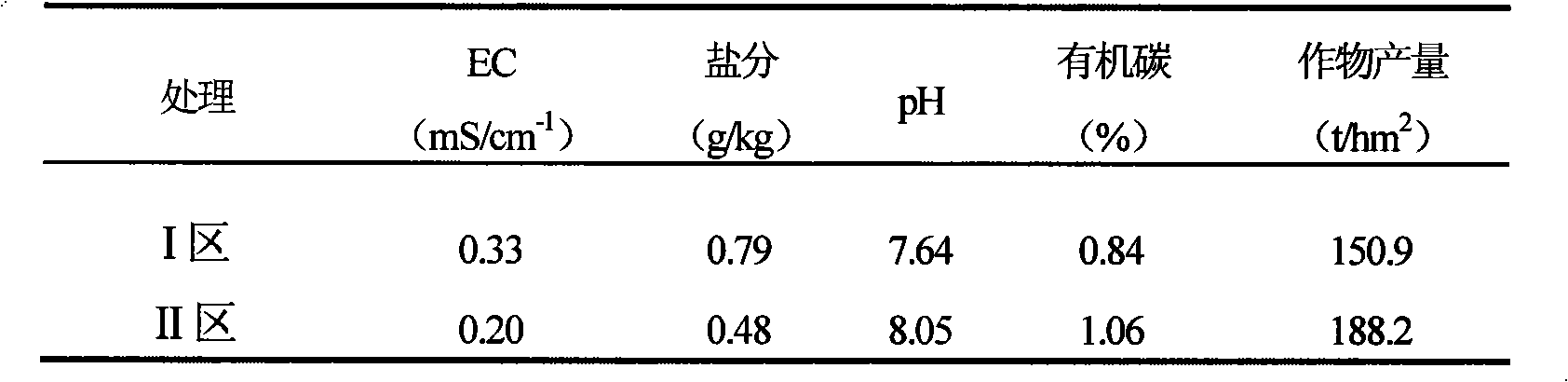

[0043] In Shouguang, Shandong Province, Daotian Town Experimental Base selects a solar greenhouse for planting cucumbers for many years. Half of the area of the greenhouse is the farmers' habitual planting area (recorded as I district), and the other half area is the application area of this embodiment (recorded as II district). The combination of steps A and D of controlling the soil C / N ratio and planting fill crops is adopted. Methods as below:

[0044] After the spring cropping cucumbers were pulled up on May 26, 2008, and the field residues were cleared in time, the fallow treatment was carried out in area I, and the idle corn (Lu Tianyu No. 1) was planted in area II on June 1, 2008. The planting density 3500 plants / mu, no fertilization during the entire growth period, harvested on August 12, and the growth period is 73 days. Until sweet corn was harvested, the electrical conductivity of the plow layer soil in Zone I and Zone II was measured (Table 1). After harvest...

Embodiment 2

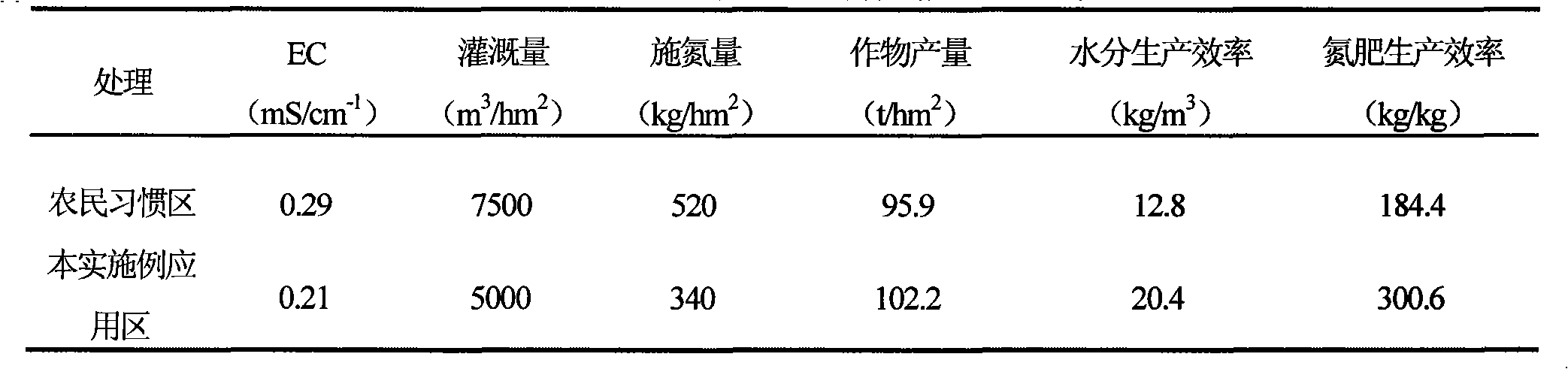

[0048] In the Gucheng Town Experimental Base of Shouguang City, Shandong Province, two same-type solar greenhouses were selected to plant autumn and winter stubble tomatoes, and the tomato variety for testing was Baili. One of the solar greenhouses is the customary planting area of farmers, and the other solar greenhouse is the application area of this embodiment.

[0049] The application area of this example adopts the combination of the control of soil C / N ratio in steps A, B and C, precise control of nitrogen fertilizer and water-saving irrigation. The method is as follows:

[0050] Before A tomato planting, apply the decomposed matter (conditioner material) mixed with wheat straw and cow dung in equal amounts, and the amount of application is 1000kg / mu, and the soil C / N ratio is regulated;

[0051] B In terms of fertilizer application, the controlled application of farmyard manure and the precise regulation of nitrogen fertilizer are adopted. 3 per mu, the applicati...

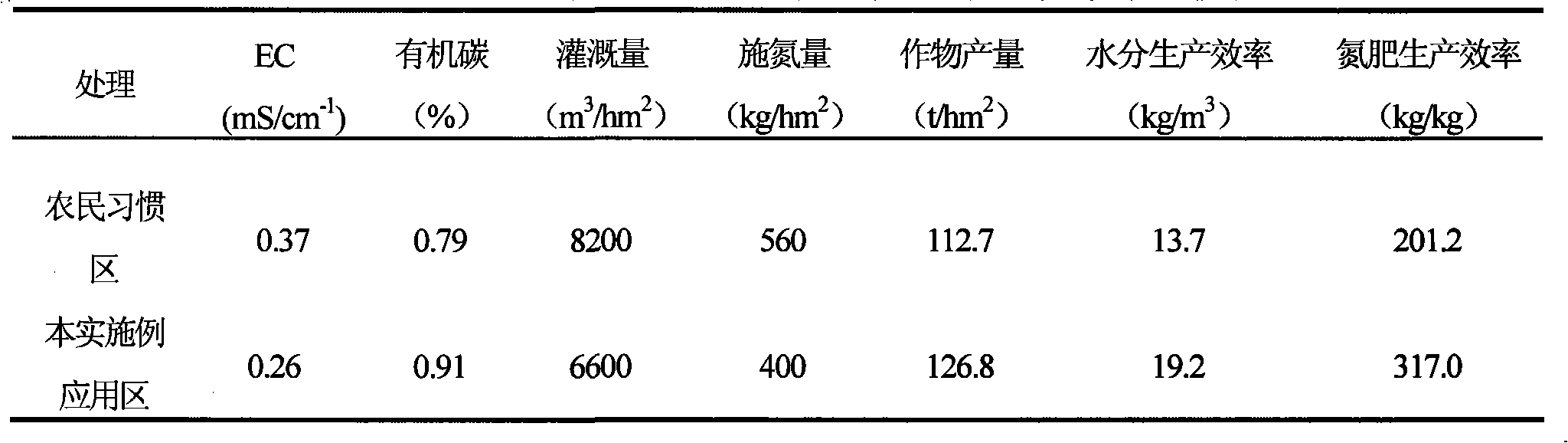

Embodiment 3

[0059] In the solar greenhouse, after harvesting cucumbers, which are the previous crops, the field residues are removed in time. Half of the greenhouse area is a leisure area, and the other half is an idle crop area. Other management measures are the same. Sweet corn (Lu Tianyu No. 1) was planted in the idle crop area on May 26, 2009, with a planting density of 3,800 plants / mu. No fertilization was applied throughout the growth period, but conventional irrigation was carried out according to crop demand. It was harvested on August 10, and the growth The period is 77 days. By the time the sweet corn is harvested, the soil conductivity in the fill crop area will be 0.25mS·cm compared with the fallow area. -1 Reduced to 0.19mS·cm -1 , decreased by 24.0%, and the accumulation of nitrate nitrogen in the 0-120cm soil layer decreased by 130kg·hm -2 The above indicated that planting sweet corn during the fallow period in the greenhouse can effectively reduce the threat of nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com