Turntable type dynamic sewage fermentation tank

A dynamic fermentation and fermentation tank technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of sewage purification treatment, slow fermentation process, laborious and laborious, etc., and achieve sewage Strong agitation, enhanced dissolved oxygen content, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

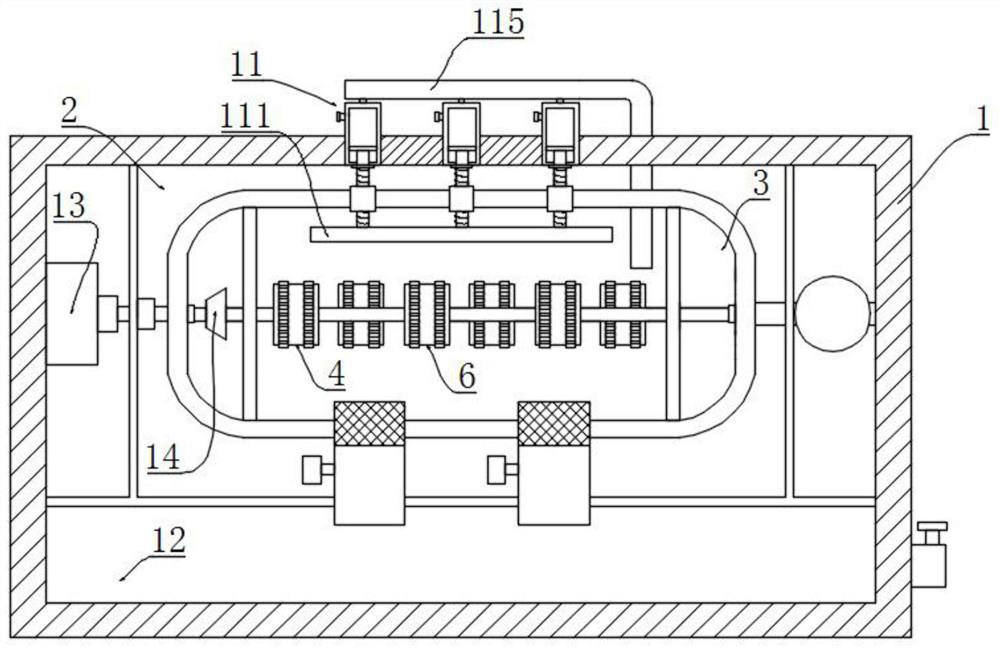

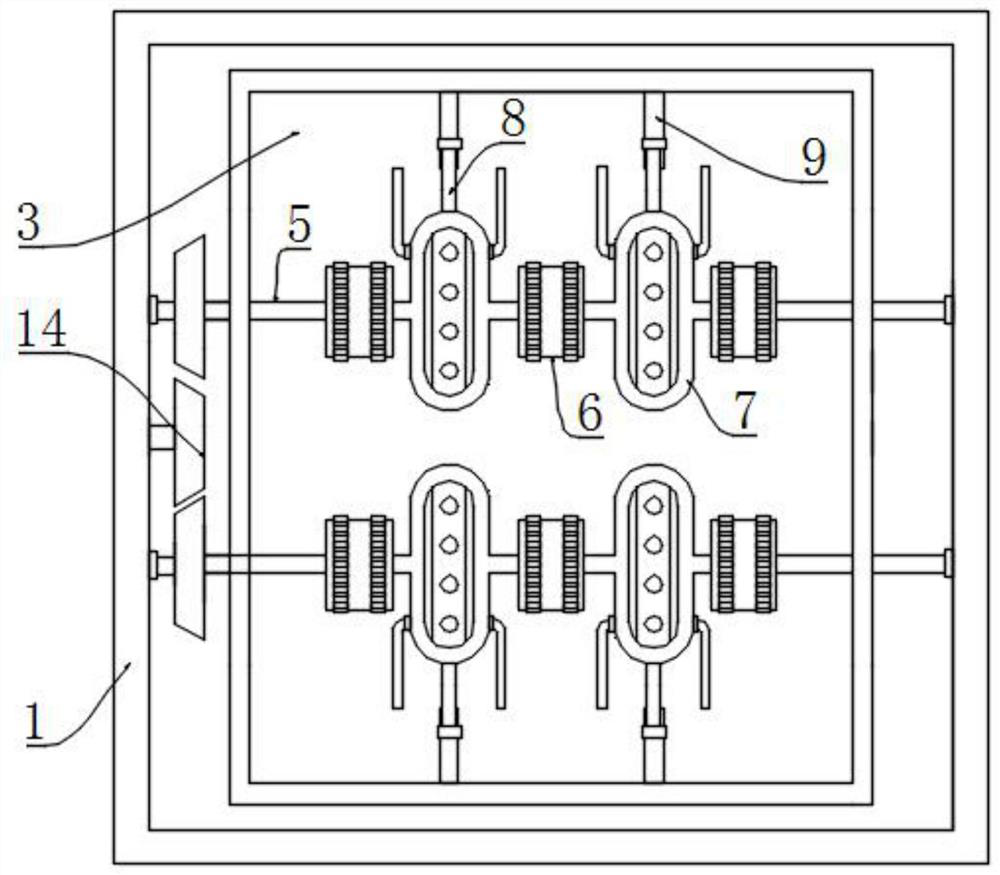

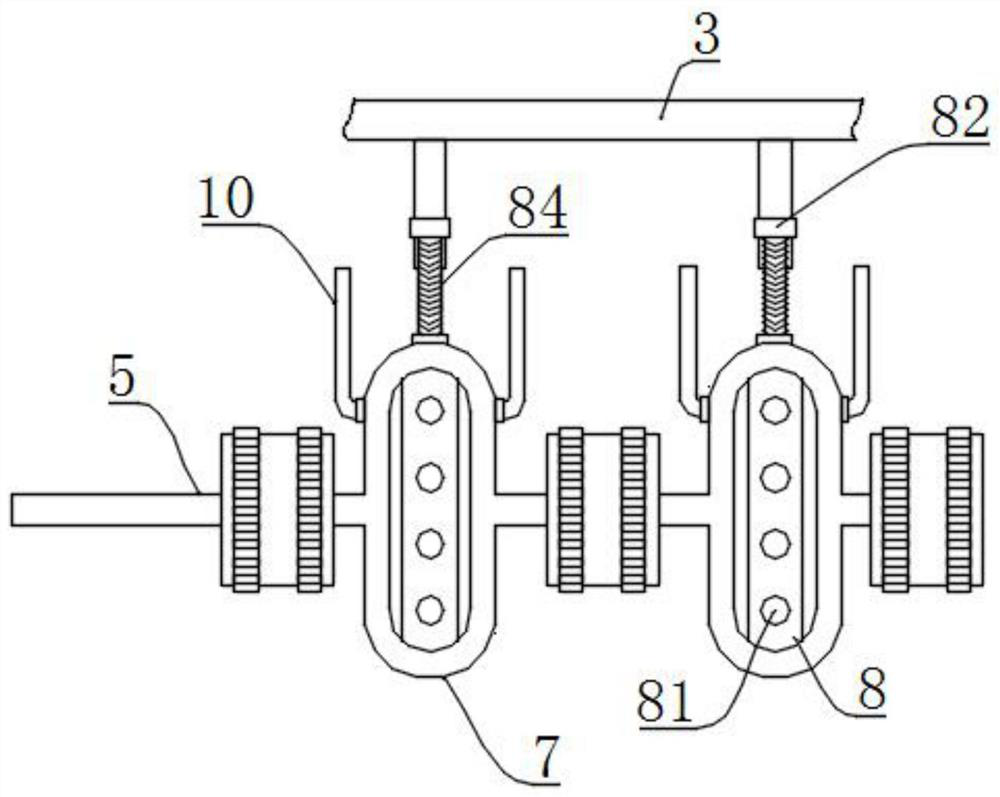

[0026] Example 1, please refer to Figure 1-6 As shown, the present invention provides a turntable type dynamic sewage fermentation tank, comprising a fermentation tank main body 1, a fermentation chamber 2 is provided in the fermentation tank main body 1, a driving motor 13 and a dynamic fermentation chamber 3 are provided in the fermentation chamber 2, and the dynamic fermentation chamber 3 rotates Connect the bending rotating part 5, and the end of the output shaft of the drive motor 13 is connected to the bevel gear set 14 rotating in different directions, and is transmitted by the bevel gear set 14 and the bending rotating part 5; the inner wall of the dynamic fermentation bin 3 is also provided with a second A crescent plate 9 and an upper air intake mechanism 11; the bending rotating part 5 includes a waist-shaped rotating ring 7 integrally formed with it, and the waist-shaped rotating ring 7 is provided with a first piston device 8 and a second crescent plate 10, and th...

Embodiment 2

[0032] Example 2, please refer to Figure 1-6As shown, the present invention provides a turntable type dynamic sewage fermentation tank, comprising a fermentation tank main body 1, a fermentation chamber 2 is provided in the fermentation tank main body 1, a driving motor 13 and a dynamic fermentation chamber 3 are provided in the fermentation chamber 2, and the dynamic fermentation chamber 3 rotates Connect the bending rotating member 5, and the end of the output shaft of the drive motor 13 is connected to the bevel gear set 14 rotating in different directions; the inner wall of the dynamic fermentation bin 3 is also provided with a first crescent plate 9 and an upper air intake mechanism 11; bending The rotating member 5 includes a waist-shaped rotating ring 7 integrally formed with it. The waist-shaped rotating ring 7 is provided with a first piston device 8 and a second crescent plate 10, and the first piston device 8 and the first crescent plate 9 are rollingly connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com