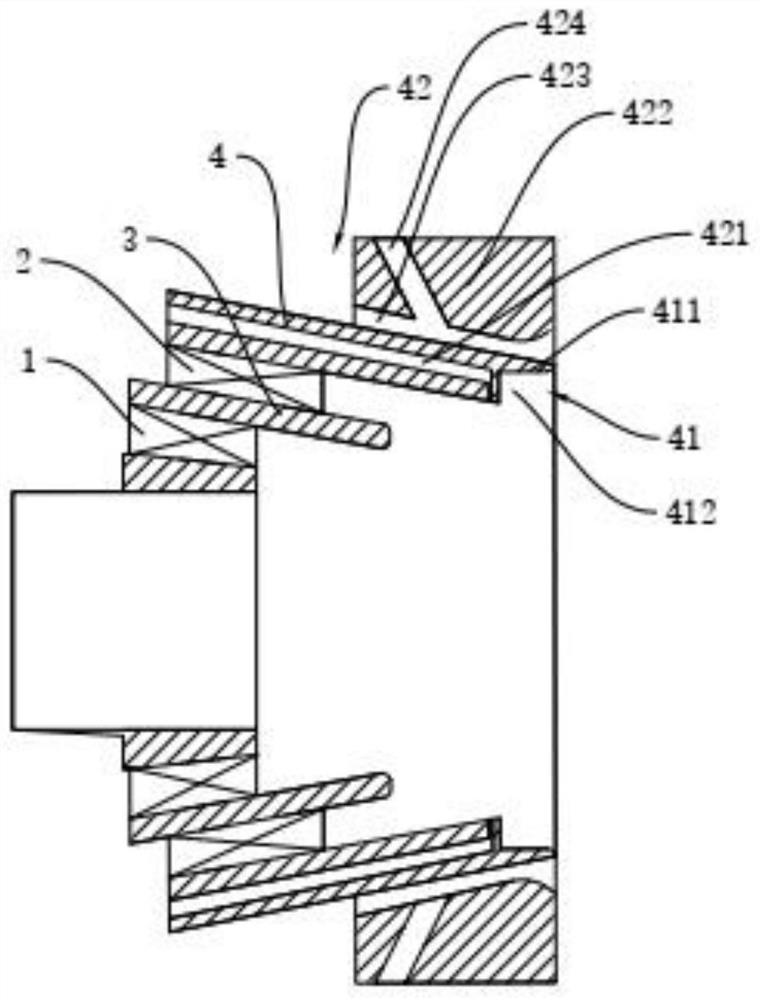

Two-stage axial swirler and aero-engine with cavity enhanced oil and gas mixing

A two-stage swirler and swirler technology, applied in the field of aero-engines, can solve the problems of unstable precession flow of the vortex core, reduced flame stability of the combustion chamber, unfavorable flame stability, etc. Improved outlet temperature distribution, improved blending and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

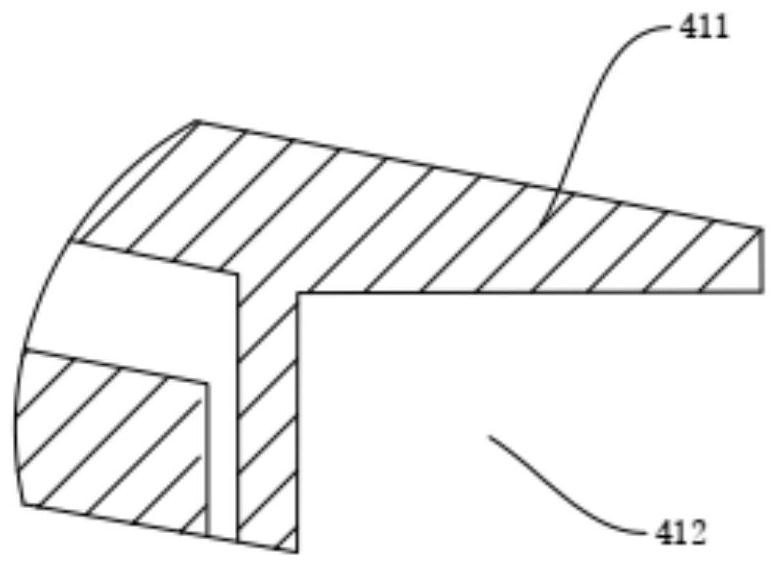

[0047] refer to image 3 , the difference between this embodiment and Embodiment 1 is that the end of the guide ring 411 is arranged vertically, the guide ring 411 is installed and used in conjunction with the flame tube of the aero-engine during installation, and the end of the guide ring 411 is vertically arranged, It has the effect of positioning installation.

Embodiment 3

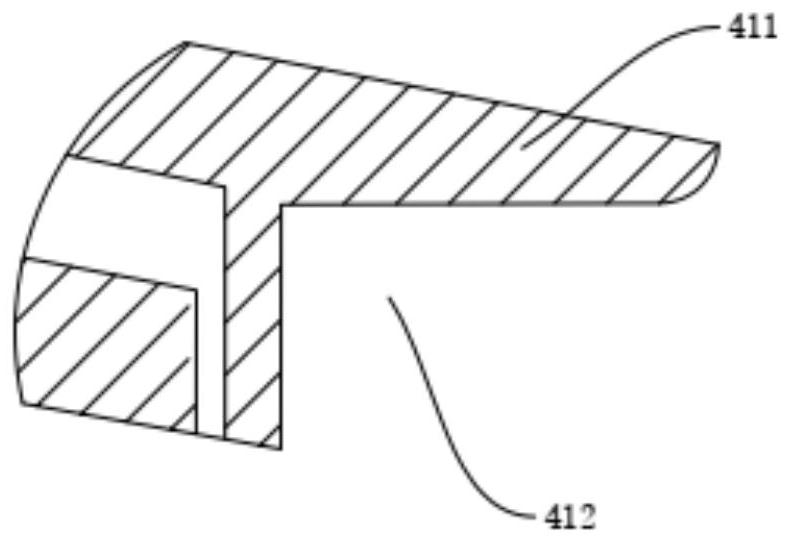

[0049] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the end of the guide ring 411 is chamfered, and the end of the guide ring 411 is chamfered to reduce the adsorption of oil and gas at the end of the guide ring 411, and by chamfering the end of the guide ring 411 The end of the ring 411 is chamfered, which reduces the weight of the aero-engine while cooling the cyclone casing, and the chamfering at the end of the guide ring 411 is convenient when processing the guide ring 411. Machining.

Embodiment 4

[0051] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the angle between the inner wall of the guide ring 411 and the end of the sleeve 4 is 135°, and the angle between the inner wall of the guide ring 411 and the end of the sleeve 4 is set to 135° , the angle between the guide ring 411 and the sleeve 4 is set to 135°, so that the oil and gas mixed in the cavity vortex 412 can smoothly enter the flame tube for combustion, and pass through the guide ring 411 and the end of the sleeve 4. The inclined setting between the first is to reduce the adsorption of oil and gas, the second is to increase the mixing residence time of fuel and air, and the mixing effect is strengthened, and the third is to reduce the weight of the sleeve 4. The aero-engine is a precision mechanical equipment and is equipped with aeroplanes to work. When designing aero-engine parts, it is necessary to consider the influence of weight, and it is necessary to reduce the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com