Liquid oxygen methane thrust chamber injector

A liquid oxygen methane and thrust chamber technology, which is used in machines/engines, jet propulsion devices, indirect carbon dioxide emission reduction, etc. and other problems, to achieve the effect of energy partition release, compact structure and improved work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments do not limit the present invention.

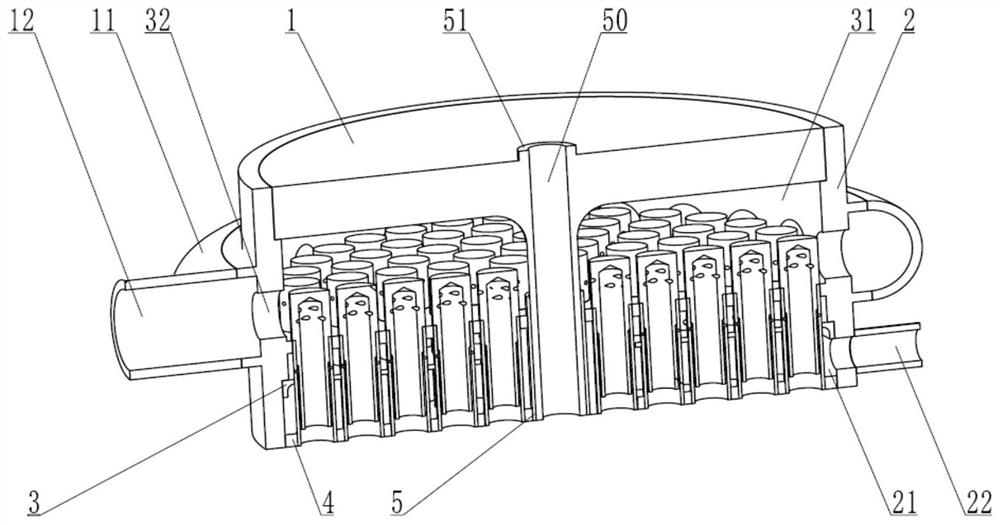

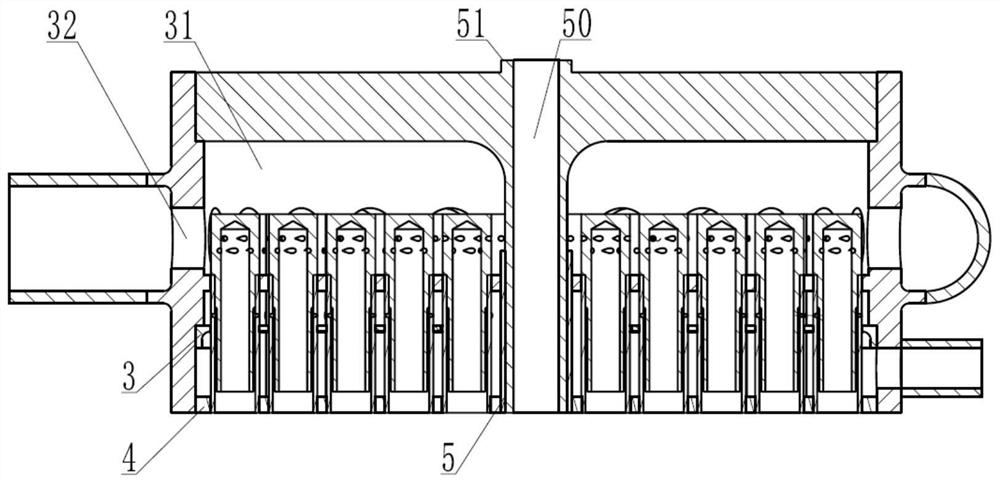

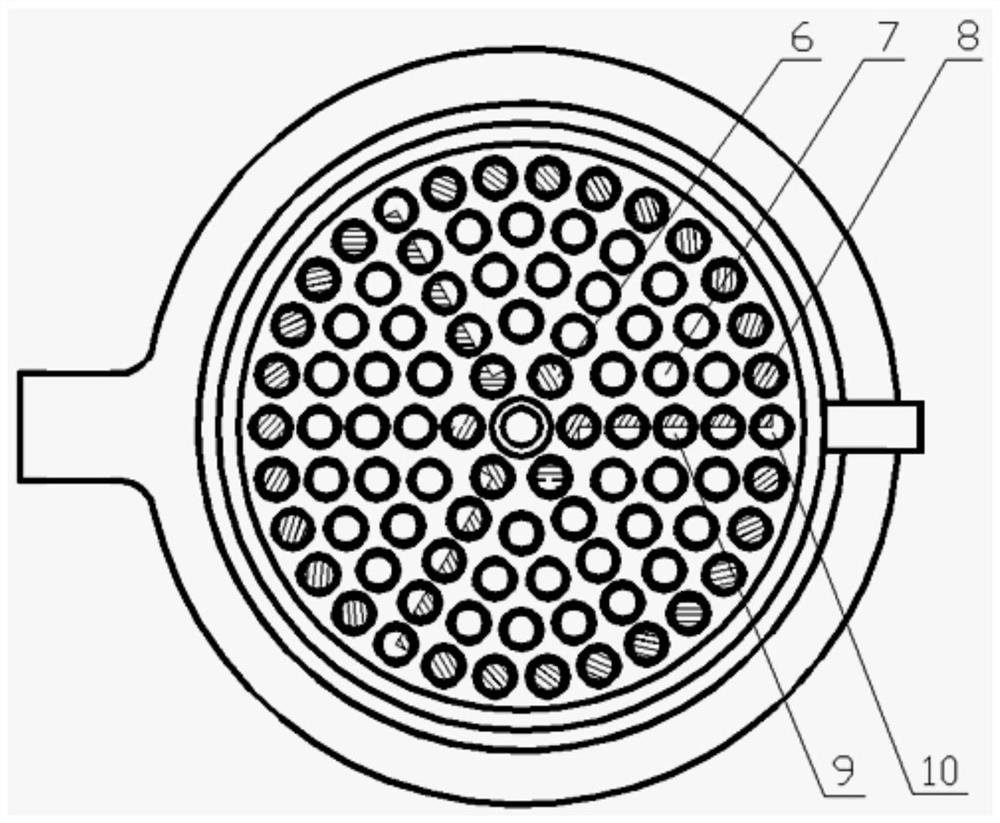

[0042] like figure 1 and figure 2 As shown, the liquid oxygen methane thrust chamber injector in this embodiment includes a plurality of injection units, a midsole 2, and a top cover 1, a deflector 3 and an inner bottom that are coaxially arranged on the midsole 2 in sequence. 4;

[0043] Multiple injection units are fixed on the midsole 2, the deflector 3 and the insole 4;

[0044] A liquid oxygen chamber 31 is formed between the top cover 1 , the midsole 2 and the plurality of injection units. The liquid oxygen chamber 31 is provided with a liquid oxygen inlet pipe 12 , and a collector is also provided on the liquid oxygen inlet pipe 12 . The liquid container 11; the midsole 2 is provided with an equalizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com