High-reliability multiblade cold/hot air flow mixed spoiler

A technology of turbulence device and reliability, which is applied in the field of mixing turbulence device of hot and cold air, can solve the problems of large temperature gradient of the main circuit and auxiliary circuit, affecting the test results, etc., and achieves increased turbulence degree, compact overall structure, and uniform temperature. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

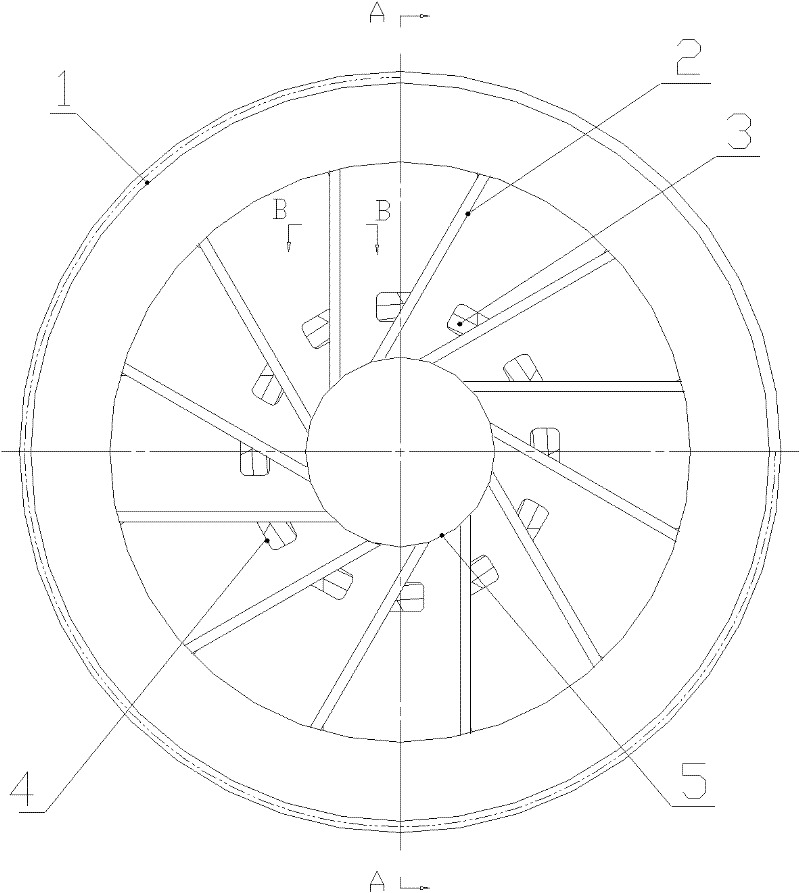

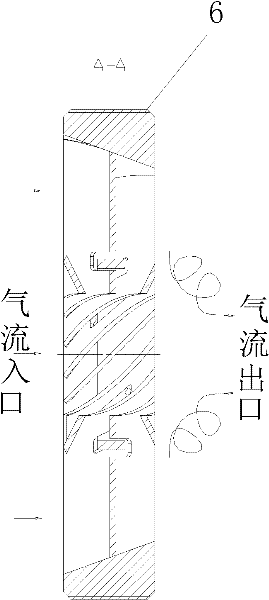

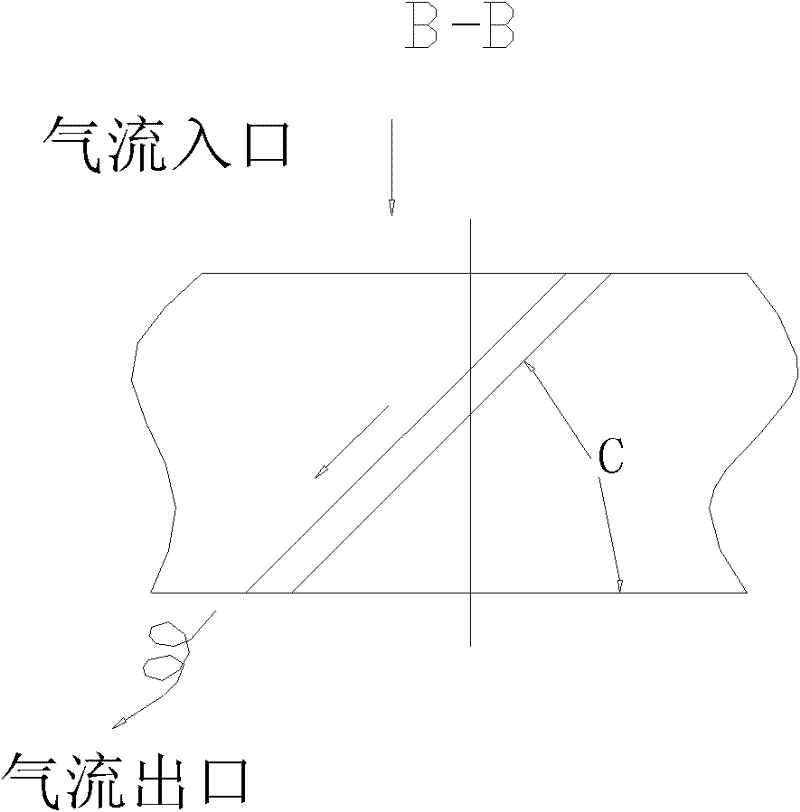

[0020] Such as figure 1 As shown, the high-reliability multi-blade hot and cold air flow mixing turbulence device of the present invention includes an outer ring 1 that can be threadedly connected to the inner wall of the pipeline, and a turbulence member arranged on the inner wall of the outer ring; the turbulence member includes a plurality of flat blades 2 and a limit ring 3; a plurality of flat blades 2 are evenly arranged along the inner wall of the outer ring 1 in the circumferential direction, and the blades 2 deflect the direction of the airflow to form a swirling flow. According to the flow rate and temperature of the mixed hot and cold airflow, blade schemes with different numbers and heights can be used. One end of the plurality of blades is welded on the inner wall of the outer ring and forms a certain angle with the direction of the incoming flow. The range of the angle is generally between 30° and 60°, preferably 45°. The other end of the plurality of blades is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com