Preparation method for obtaining kilogram-grade high temperature alloy undercooled melt

A technology for supercooled superalloys and supercooled melts, which is applied in the field of preparation of kilogram-level supercooled superalloys. The effect of good structure uniformity, good fluidity and low solid phase ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

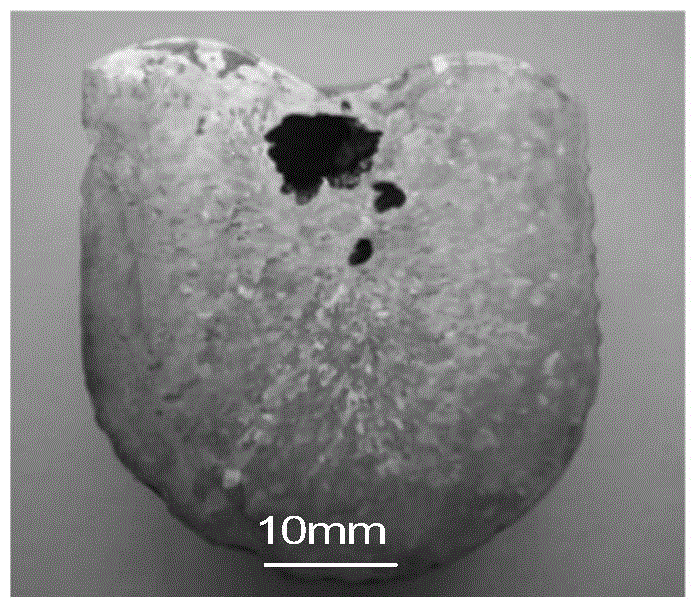

[0039] This embodiment is a preparation method for obtaining a supercooled melt of a kilogram-level superalloy with a solid-liquid two-phase region of 30-80°C. The superalloy is K4169 superalloy, and the mass of the K4169 superalloy is 0.5Kg. The specific implementation is carried out in the intermediate frequency induction power supply, and its specific steps are:

[0040] Step one, the selection of induction power frequency. The conductor resistivity ρ and the conductor magnetic permeability μ are obtained according to the superalloy manual, and according to formula (1) and formula (2), the frequency of the intermediate frequency power supply is finally determined to be 30KHz.

[0041] ΔH=d / n, (1)

[0042] In the formula, n is a constant. According to the formula (1), the current penetration depth △H of the intermediate frequency induction power supply is determined.

[0043] f = ρ μ ( ...

Embodiment 2

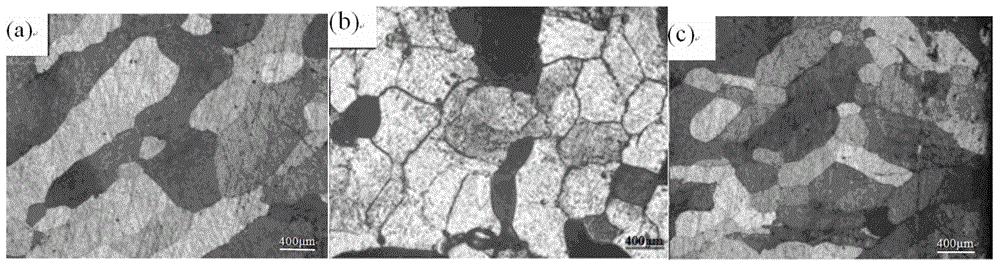

[0057] The specific implementation process of this example is as follows: This example is a preparation method of a 2Kg Ni-22Cr-18W-1Mo superalloy supercooled melt.

[0058] The material involved in this example is a Ni-22Cr-18W-1Mo superalloy, which is a self-developed nickel-based deformed superalloy that is solid solution strengthened and carbide dispersion strengthened. The Ni-22Cr-18W-1Mo superalloy was disclosed in the paper "Secondary M23C6 Precipitation Behavior of Ni-22Cr-18W-1Mo-based Superalloy" by Bai Guanghai et al. in 2009.

[0059] Step one, the selection of induction power frequency. The conductor resistivity ρ and conductor magnetic permeability μ are obtained from the superalloy handbook, and according to formula (1) and formula (2), the frequency of the intermediate frequency power supply is finally determined to be 4KHz.

[0060] ΔH=d / n, (1)

[0061] In the formula, n is a constant. According to the formula (1), the current penetration depth △H of the in...

Embodiment 3

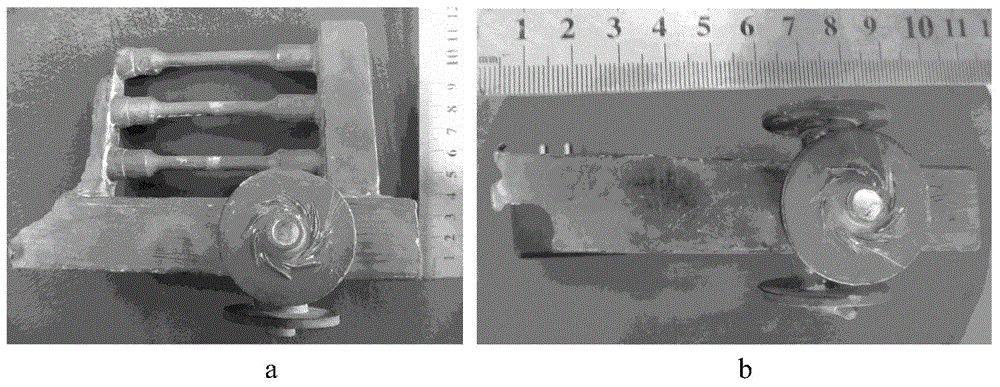

[0076] The specific implementation process of this example is: The specific implementation process of this example is: This embodiment is a preparation method of a 30Kg Ni-22Cr-18W-1Mo superalloy supercooled melt.

[0077] Step 1, the selection of induction power frequency. The conductor resistivity ρ and the conductor magnetic permeability μ are obtained from the superalloy handbook, and according to formula (1) and formula (2), the frequency of the intermediate frequency power supply is finally determined to be 400 Hz.

[0078] ΔH=d / n, (1)

[0079] In the formula, n is a constant. According to the formula (1), the current penetration depth △H of the intermediate frequency induction power supply is determined.

[0080] f = ρ μ ( 5030 ΔH ) 2 - - - ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com