Optical lens body temperature equalization structure based on cold shield radiation cover and flexible cold chain

A technology of optical mirrors and radiation shields, applied in optics, optical components, installation, etc., can solve problems affecting detection performance, optical mirror surface deterioration, thermal deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

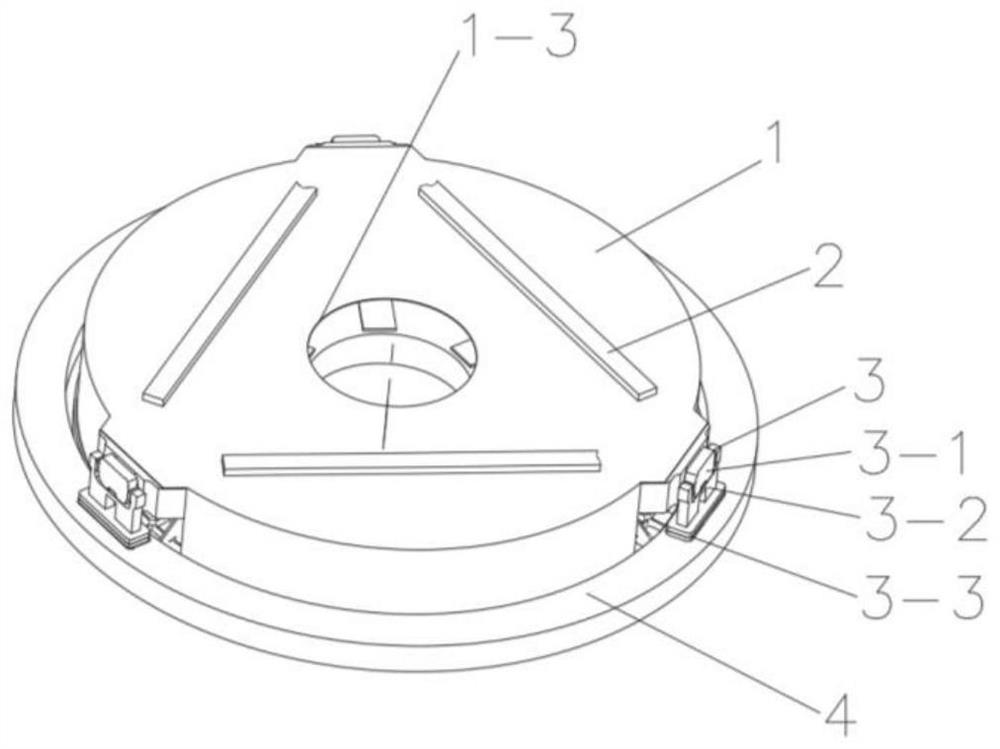

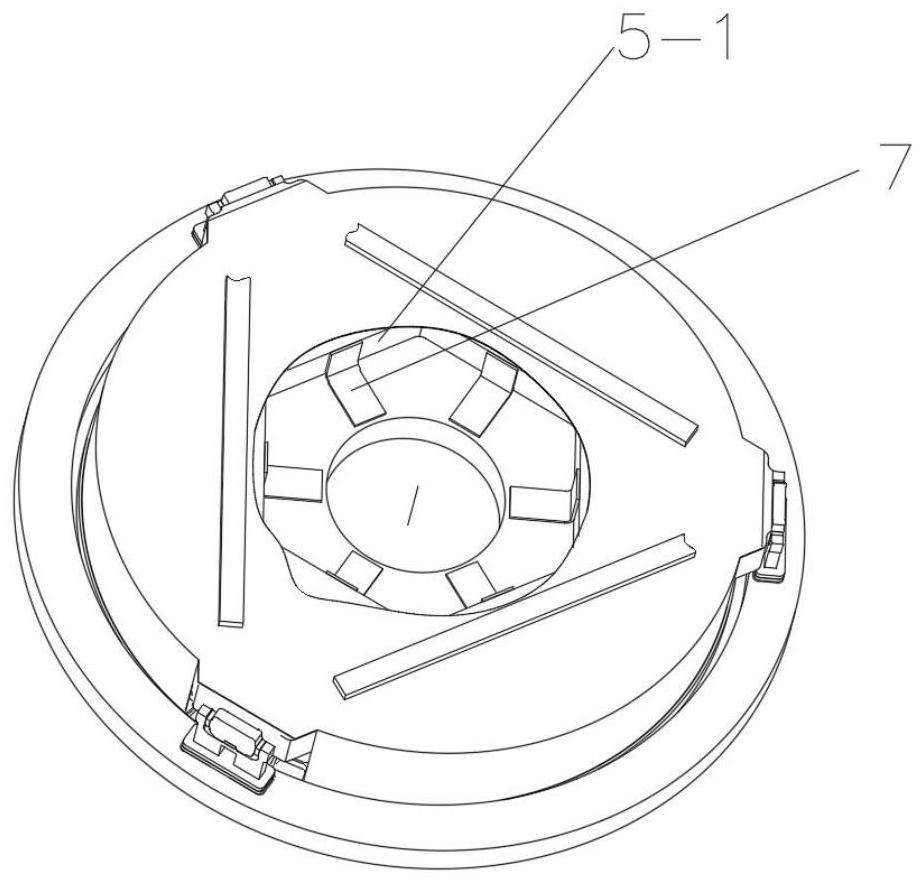

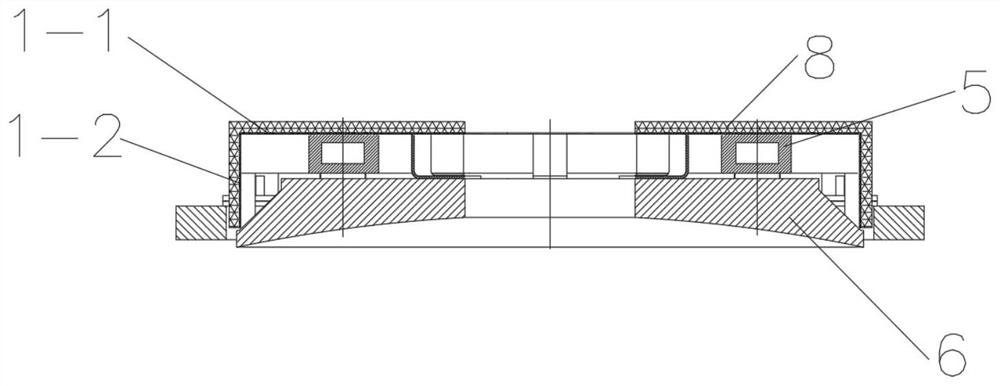

[0022] A specific embodiment of the temperature equalization structure of the optical mirror body based on the cold shield radiation cover and the flexible cold chain involved in the present invention is as follows:

[0023] 1. Connect the heat insulation component to the end of the main mirror back plate, adjust the installation accuracy of the three heat insulation components according to the optical design requirements, and then connect the heat insulation component to the installation base plate.

[0024] 2 Cut out 0.1mm thick graphite sheets according to the actual heat transfer requirements and design dimensions, and make a flexible cold chain according to the actual space layout requirements and the actual installation interface;

[0025] 3 Connect the two ends of the flexible cold chain to the inner wall of the back plate of the optical mirror body and the back of the large-diameter optical mirror body;

[0026] 4. Connect the cold shield radiation cover to the back pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com