High-pressure and low-frequency autooscillation pulse gas-liquid jet nozzle

A jet nozzle and nozzle technology, applied in the field of high-pressure and low-frequency self-vibrating pulsed gas-liquid jet nozzles, can solve the problems of little structural research, enhanced striking force, and differences in optimal cavity length, so as to expand the radial action range and improve the instantaneous Impact force, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

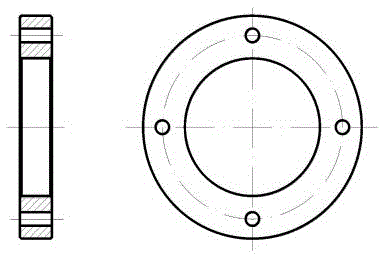

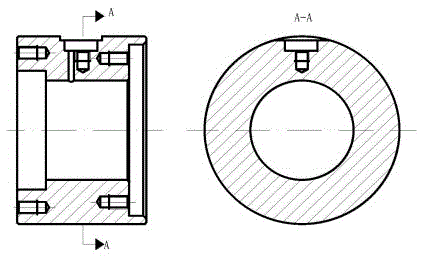

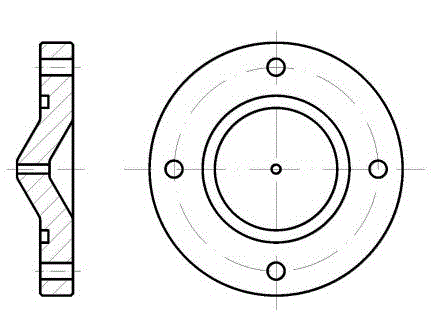

[0017] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-5 As shown, a frequency-adjustable high-pressure low-frequency self-vibrating pulse gas-liquid jet nozzle consists of an upper nozzle (1), a connecting seat (2), a cavity (3), O-rings (4) and (8), a lower The nozzle (5), cylindrical screws (6) and (9) and the air volume regulating valve (7) are composed of seven parts. The high-pressure pipe is threaded to the left end of the upper nozzle, and the connecting seat is also threaded to the middle of the upper nozzle. The through hole set on the connecting seat and the countersunk hole on the cavity are fixedly connected by cylindrical screws, and the upper and lower nozzles and the cavity are all equipped with high-precision clearance fit, the purpose is to ensure that the outlet of the upper nozzle and the inlet of the lower nozzle are aligned at the same time. axis. When working, the cavity and the lower nozzle can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com