Gas fuel low-nitrogen combustor

A low-nitrogen burner, gas fuel technology, which is applied to gas fuel burners, combustion with multiple fuels, burners, etc., can solve the problems of insufficient nitrogen oxide emissions, insufficient combustion, and limited use of fuel quality. , to achieve the effect of inhibiting generation and emissions, reducing generation and emissions, and stable and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

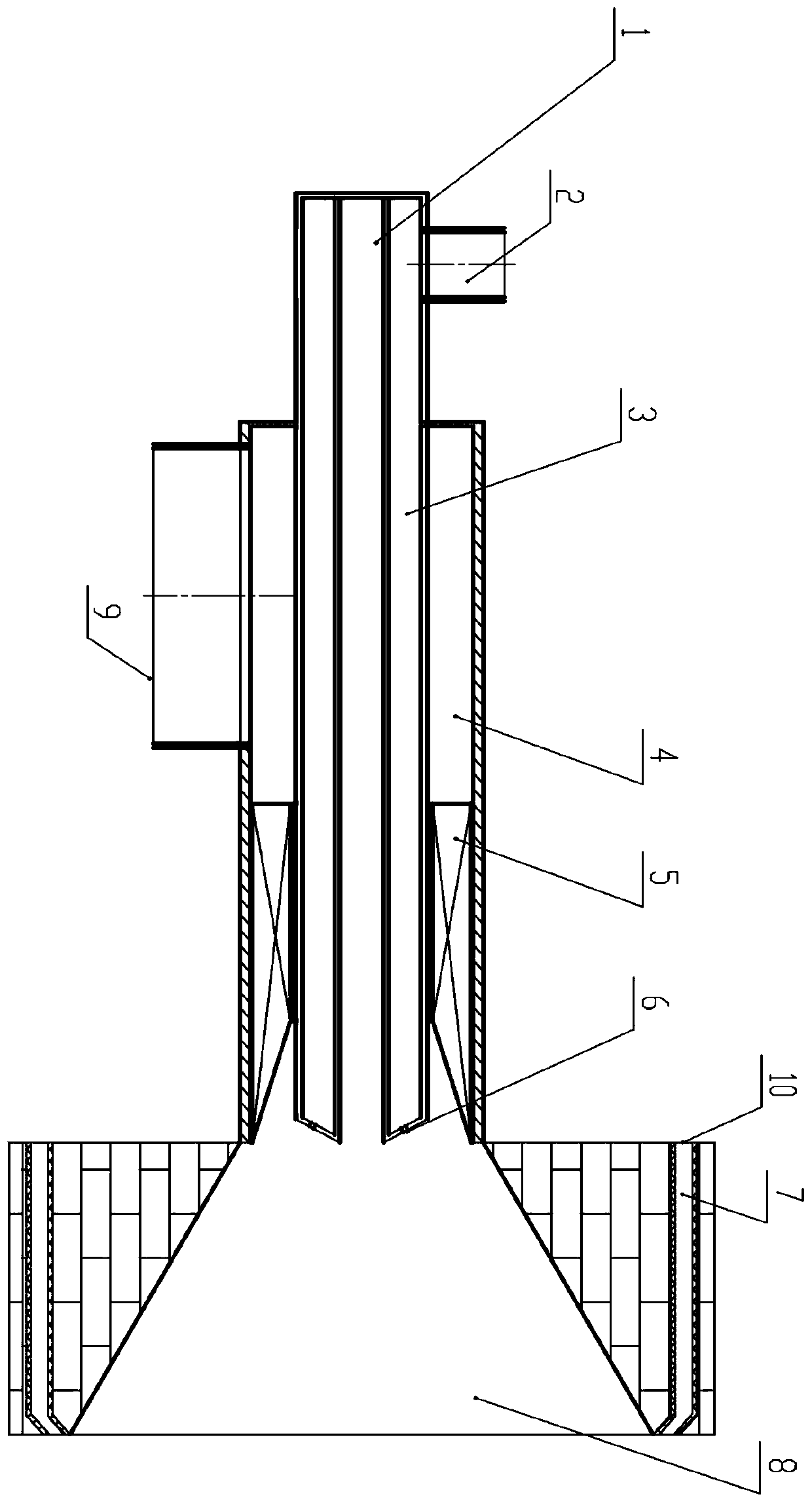

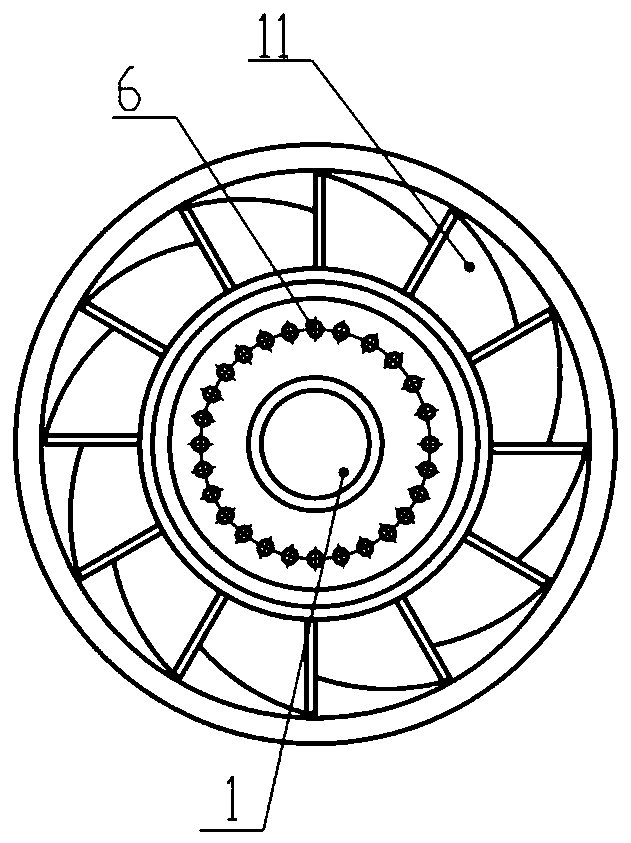

[0022] Please refer to Figure 1 to Figure 2 ,in, figure 1 It is a structural schematic diagram of a gas fuel low-nitrogen burner in an embodiment of the present invention; figure 2 It is a schematic structural diagram of a gas nozzle assembly in an embodiment of the present invention.

[0023] The invention discloses a gas fuel low-nitrogen burner, which comprises the following components:

[0024] 1. Preheating tube

[0025] The preheating pipe 1 is in the shape of a cylinder, and is arranged in the middle of the main body of the burner, coaxial with the center line of the burner. The front end of the preheating pipe 1 is closed, and the rear end is open to connect with the combustion chamber. The setting of the preheating pipe 1 can provide an internal circulation channel for the internal circulation in the furnace, so that the combustion products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com