Rear-placed combustor with annular porous medium head for ultramicro turbojet engine

A technology of turbojet engine and porous media, applied in combustion chambers, continuous combustion chambers, machines/engines, etc., can solve the problems of low combustion efficiency in combustion chambers, short residence time of gas, poor flame stability, etc., to achieve improved combustion efficiency, Overcoming the effect of short residence time and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

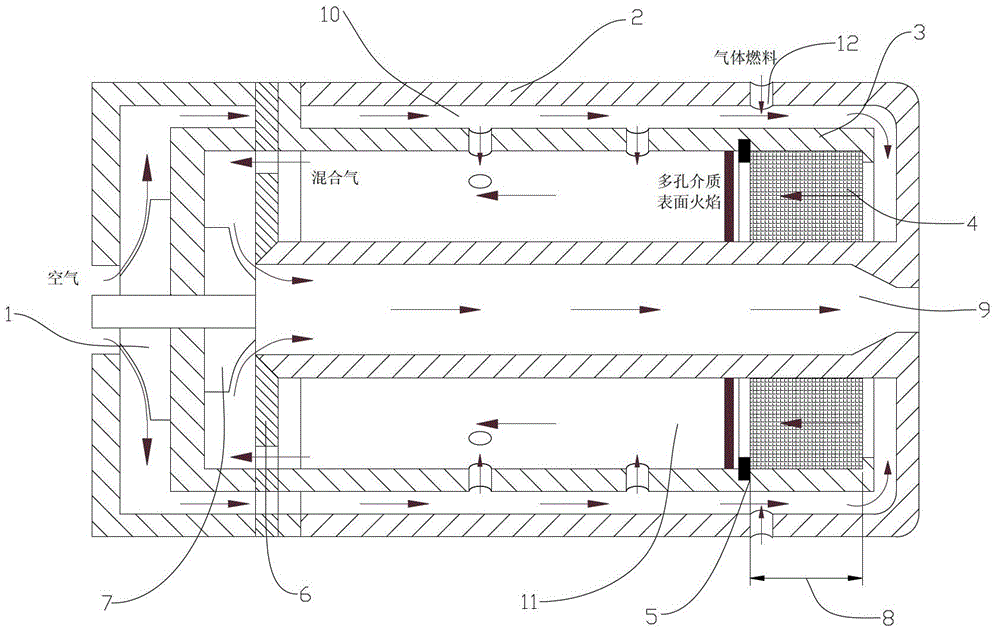

[0031] like figure 1 As shown, the ultra-micro turbojet engine combustion chamber of the annular porous medium head of the embodiment of the present invention adopts acetylene as gas fuel, and consists of the combustion chamber casing 2, the flame tube wall 3, the combustion chamber outlet 6 and the annular porous medium head Combustion chamber casing 2, flame tube wall 3 and combustion chamber outlet 6 are sintered with alumina ceramic material.

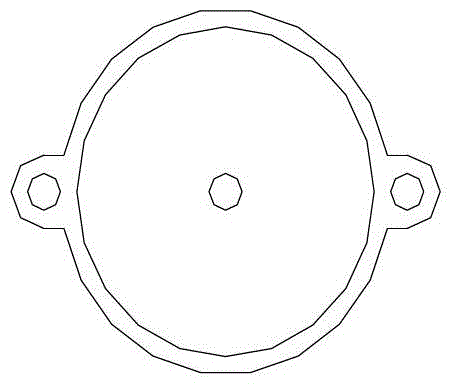

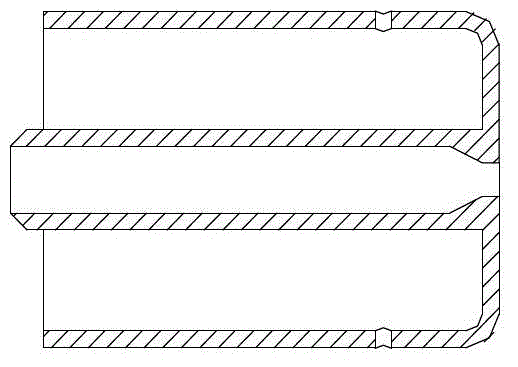

[0032] like Figure 2a , Figure 2b , Figure 2c As shown, the combustor case 2 includes two parts, the outer ring and the inner ring, and the space contained in the inner ring of the combustor case 2 is the exhaust passage 9; Flame cylinder wall 3, the structure is as Figure 3a , Figure 3b , as shown, between the flame tube wall 3 and the outer ring of the combustion chamber casing 2 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com