Acrylic polyester-type hyperdispersant and preparation method and application thereof

An acrylic polyester and hyperdispersant technology, applied in applications, household appliances, coatings, etc., can solve the problems of insufficient dispersion stability of low-temperature construction performance, limited storage and use of dispersion systems, and reduced viscosity of dispersion systems. To achieve the effect of good storage and use performance, low viscosity, and improved flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of m-pentadecylphenyl acrylate

[0043] In a 250mL four-neck flask, add an appropriate amount of solvent, m-pentadecylphenol and cuprous chloride (500PPM), then add acryloyl chloride and ionic liquid, and slowly add the acid-binding agent III with constant pressure dropping funnel under stirring. Ethylamine, sealed with a balloon over the reflux condenser. The molar ratio of acid chloride / pentadecylphenol was 1.15, and the temperature was raised to 57°C. After 8.25 hours of reaction, the generated triethylamine hydrochloride was removed by filtration while it was hot. The filtrate was diluted with chromatographic grade methanol and analyzed by liquid phase to determine the reaction yield. After the filtrate was washed with water, the solvent was removed by rotary evaporation to obtain the crude m-pentadecylphenyl acrylate, which was recrystallized to obtain the pure product.

Embodiment 1

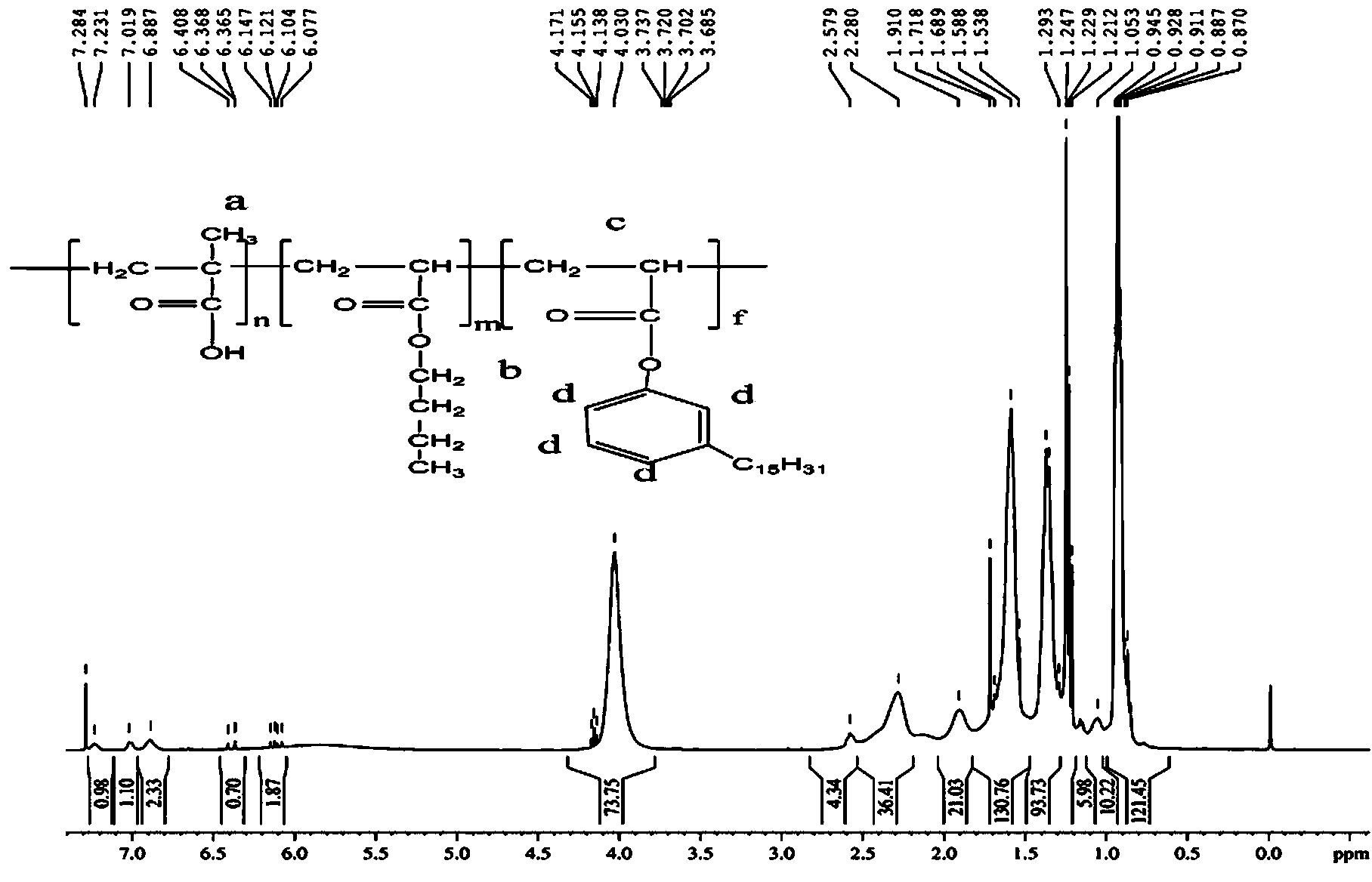

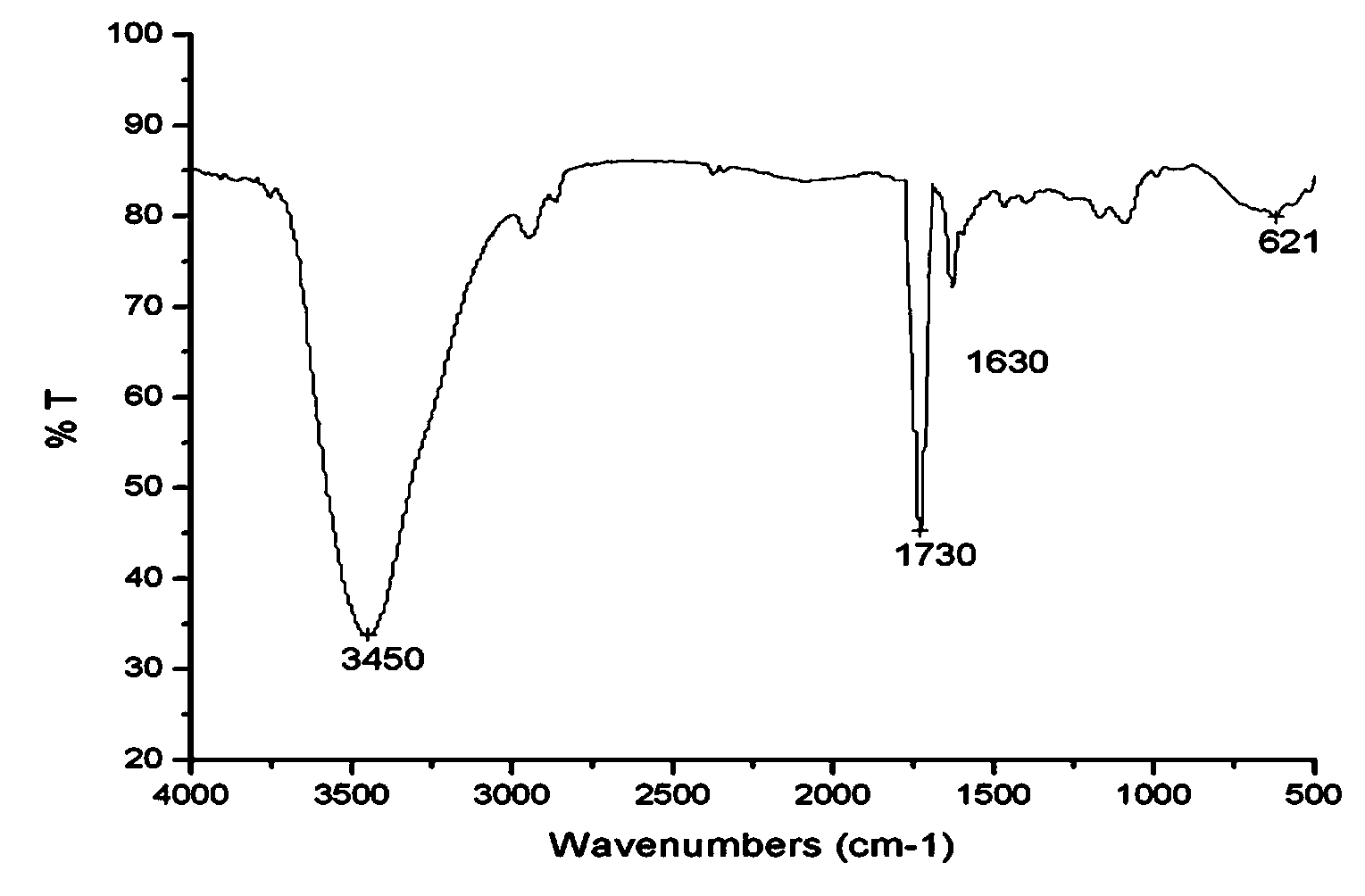

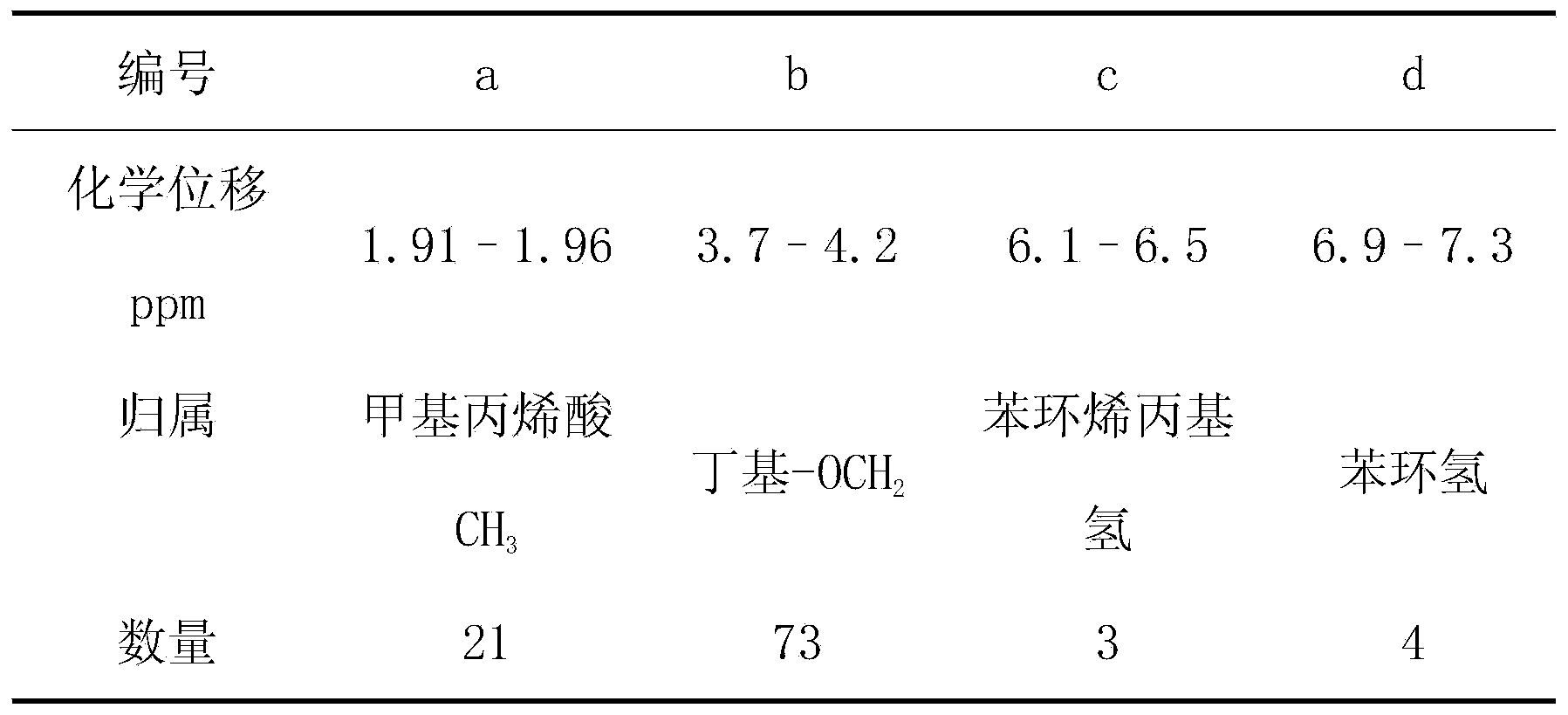

[0045] Weigh 1 part of methacrylic acid, 8.5 parts of butyl acrylate, 0.5 part of pentadecyl phenyl acrylate and 0.1 part of chain transfer agent mercaptoacetic acid (the same below), 0.1 part of initiator AIBN, 25 parts of acetone and isopropanol (The mass ratio of the two is 1:1, the same below). The solvents are pre-mixed, and a part (not strictly limited, half can be added first) is added to a four-necked flask with a thermometer, and then placed in a pre-heated to 70°C In an oil bath, turn on the mixer. After 2 hours of reaction, the remaining mixture was added using a constant pressure dropping funnel. Then the reaction solution was kept at 70° C. for 4 h, and after cooling down, tetrahydrofuran was added for dilution. Finally, the reaction liquid is poured into the mixed solution of methanol and water to precipitate the polymer, and the precipitate is vacuum-dried to obtain the acrylic polyester hyperdispersant. GPC detection weight average molecular weight is 20000. ...

Embodiment 2

[0047] Weigh 1 part of methacrylic acid, 8.5 parts of butyl acrylate, 0.5 part of pentadecyl phenyl acrylate and chain transfer agent, 0.15 part of AIBN initiator, 25 parts of acetone and isopropanol solvents are mixed in advance, and a part is added to the belt Into the four-neck flask of the thermometer, put nitrogen into the oil bath pan preheated to 80°C, and turn on the stirrer. After 2 hours of reaction, the remaining mixture was added using a constant pressure dropping funnel. Then the reaction solution was kept at 80° C. for 4 h, and after cooling down, tetrahydrofuran was added for dilution. Finally, the reaction liquid is poured into the mixed solution of methanol and water to precipitate the polymer, and the precipitate is vacuum-dried to obtain the acrylic polyester hyperdispersant. GPC detection weight average molecular weight is 10000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com