Multi-combustion-mode ammonia fuel engine and control method thereof

A combustion mode and engine technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as insufficient power and low thermal efficiency, and achieve the effects of ensuring stability, efficient and stable combustion, and stable ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

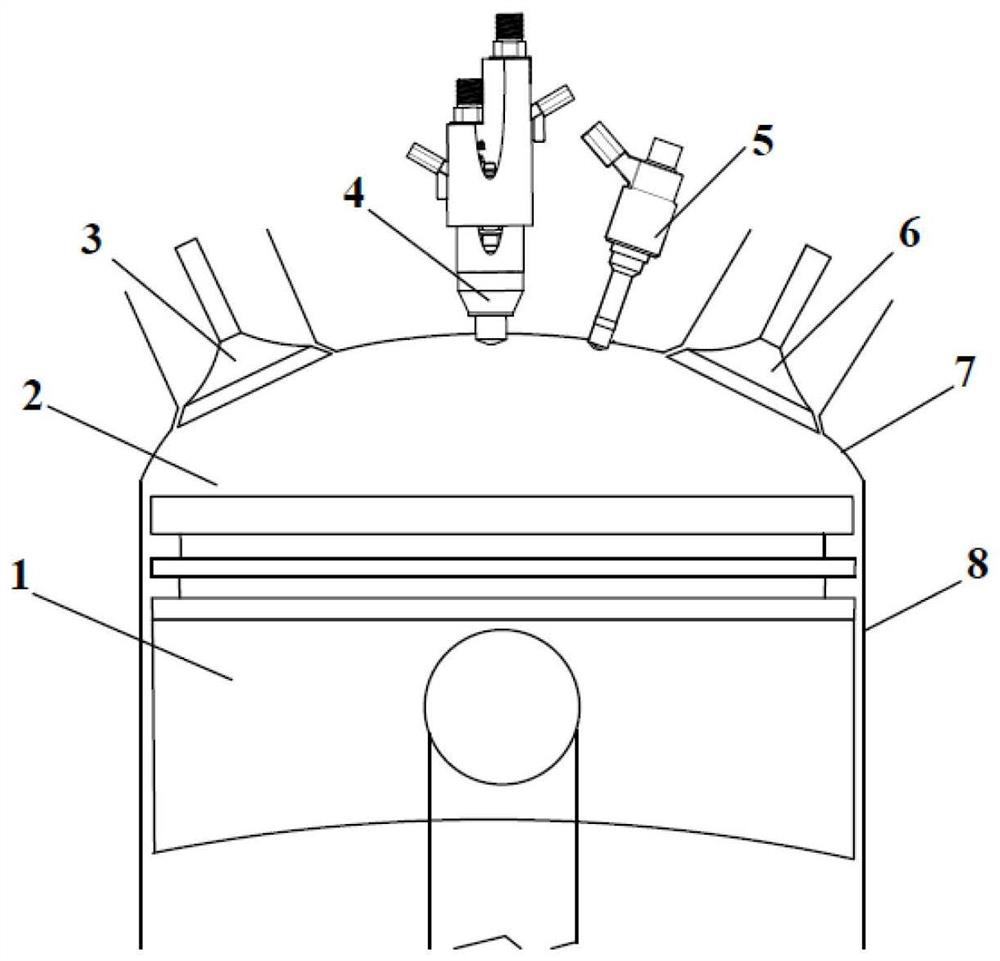

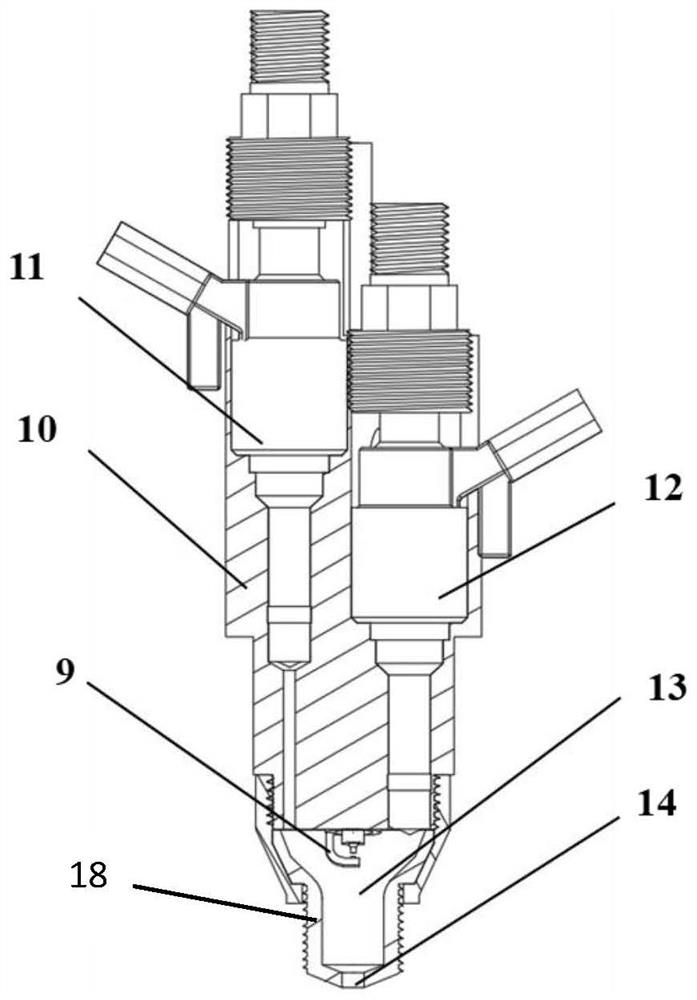

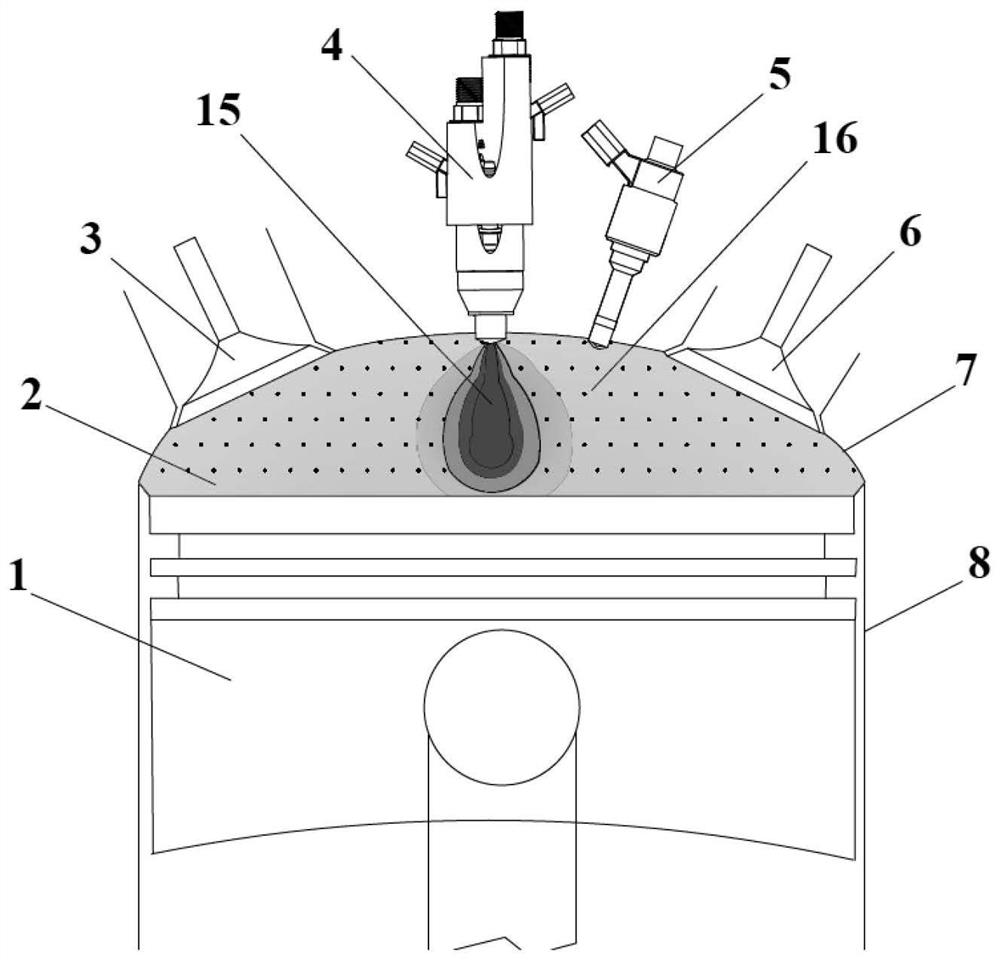

[0040] A multi-combustion mode ammonia fuel engine based on turbulent jet ignition. Its main feature is that the jet ignition device can promote the advantages of stable combustion in the cylinder. By advancing or delaying the ammonia injection time in the main combustion chamber, the ammonia fuel in the main combustion chamber can be adjusted. The timing of injection and pre-chamber jet generation can change the mixing state of the working fluid when the main combustion chamber combustion occurs, and finally form different combustion modes in the main combustion chamber: premixed combustion mode and diffusion combustion mode. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The implementation of the jet ignition device including the pre-chamber and the control method of multiple combustion modes will be further described below in conjunction with the accompanying drawings.

[0041] like figure 1 As shown, a multi-combustion mode ammonia fuel engine based on turbulent jet ign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com