Clamping device for transverse deviation correction of ballastless track structure

A clamping device and technology of ballastless track, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of inability to apply ballastless track structure for lateral clamping, inability to adapt to non-parallel stress surfaces, and difficulty in spacing adjustment, etc. Achieve the effect of improving the convenience of operation, flexible organization and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The device provided by the present invention will be further specifically described below through specific embodiments with reference to the accompanying drawings.

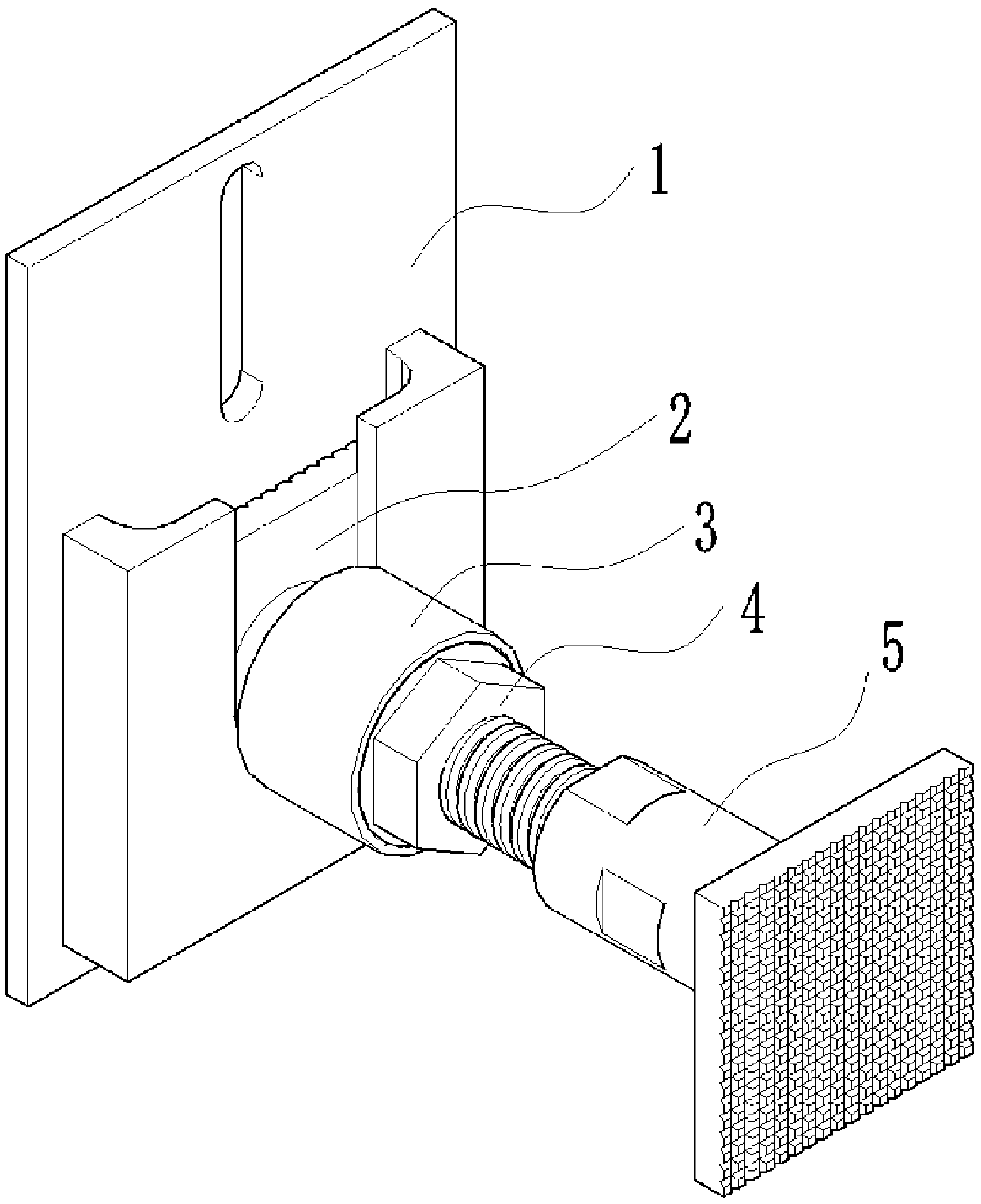

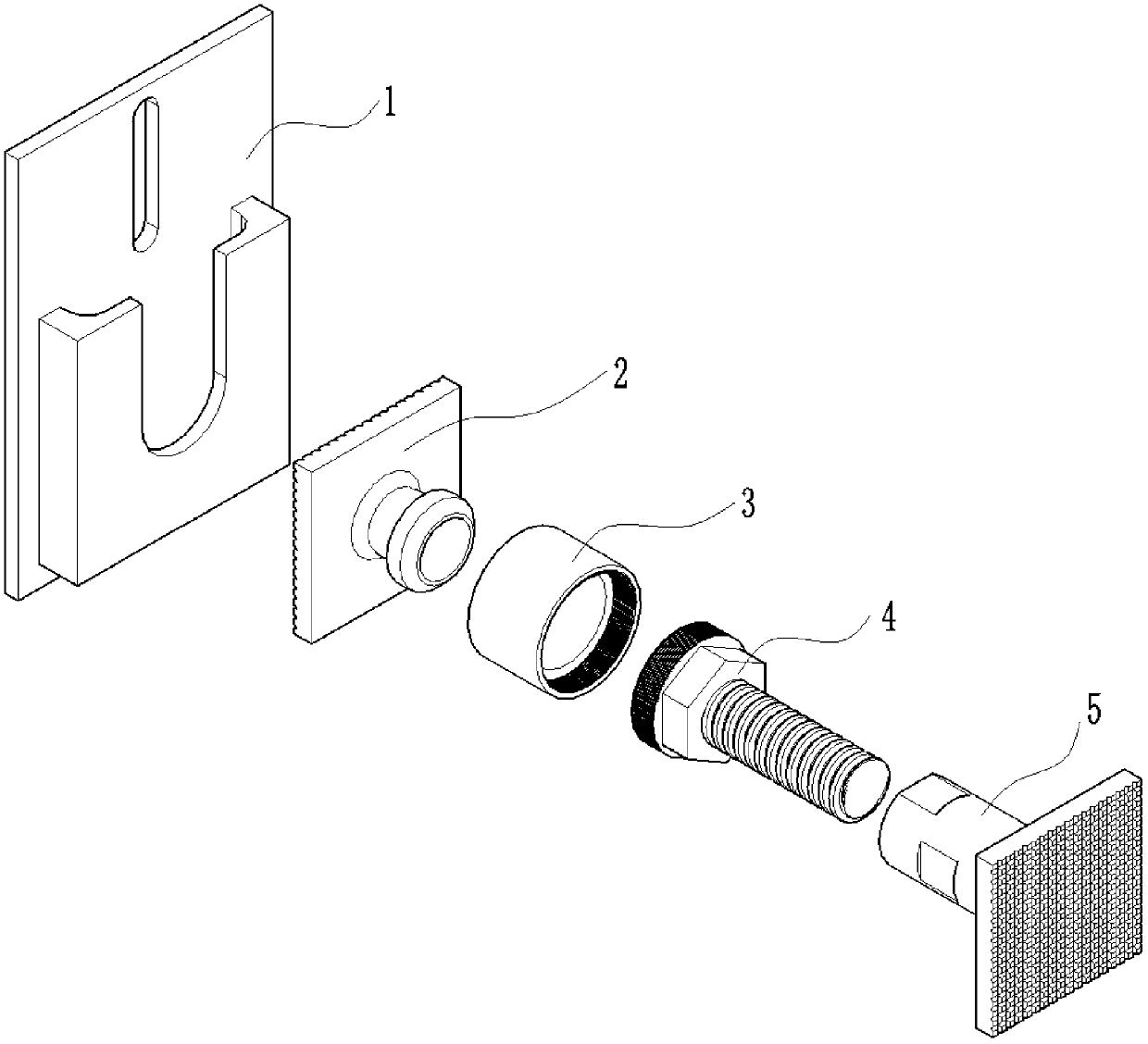

[0019] The clamping device for the lateral deviation correction of the ballastless track structure provided by the embodiment of the present invention includes an anti-falling frame 1 and a clamping push rod, wherein the clamping push rod is composed of a length adjusting sleeve 2, a length adjusting screw rod 3, and a connecting sleeve. Tube 4 and leveling end plate 5 are composed of four parts.

[0020] Before implementing the lateral correction of the ballastless track structure, the anti-falling frame 1 is installed on the side of the reaction force structure on both sides of the track structure on the side of the track structure through the oblong hole on its bottom plate by using expansion bolts.

[0021] The length-adjusting sleeve 2, the length-adjusting screw rod 3, the connecting sleeve 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com