Guide pulley device with lifting steel wire rope pre-tightening function

A technology for hoisting steel wire ropes and guide pulleys, which is applied in hoisting devices, cranes, transportation and packaging, etc. It can solve the problems of cumbersome installation and disassembly of hoisting wire rope elastic ropes and empty hook pretensioning devices, and achieve the goal of avoiding disassembly cumbersome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

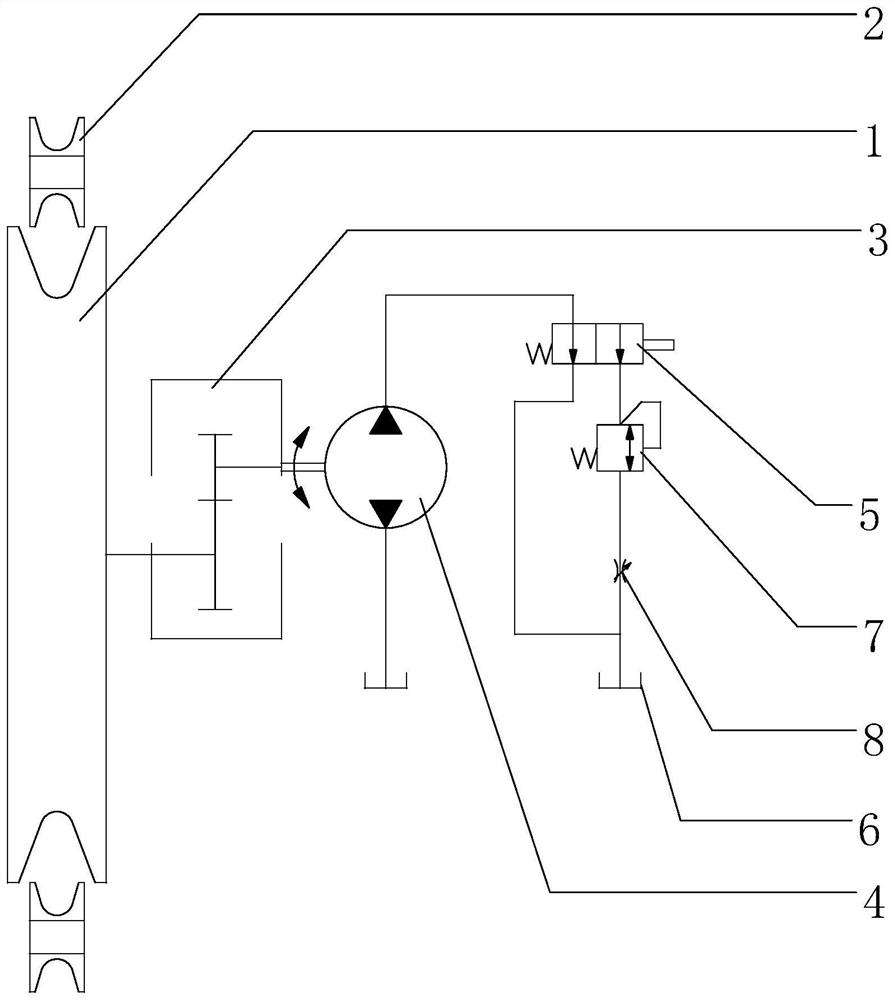

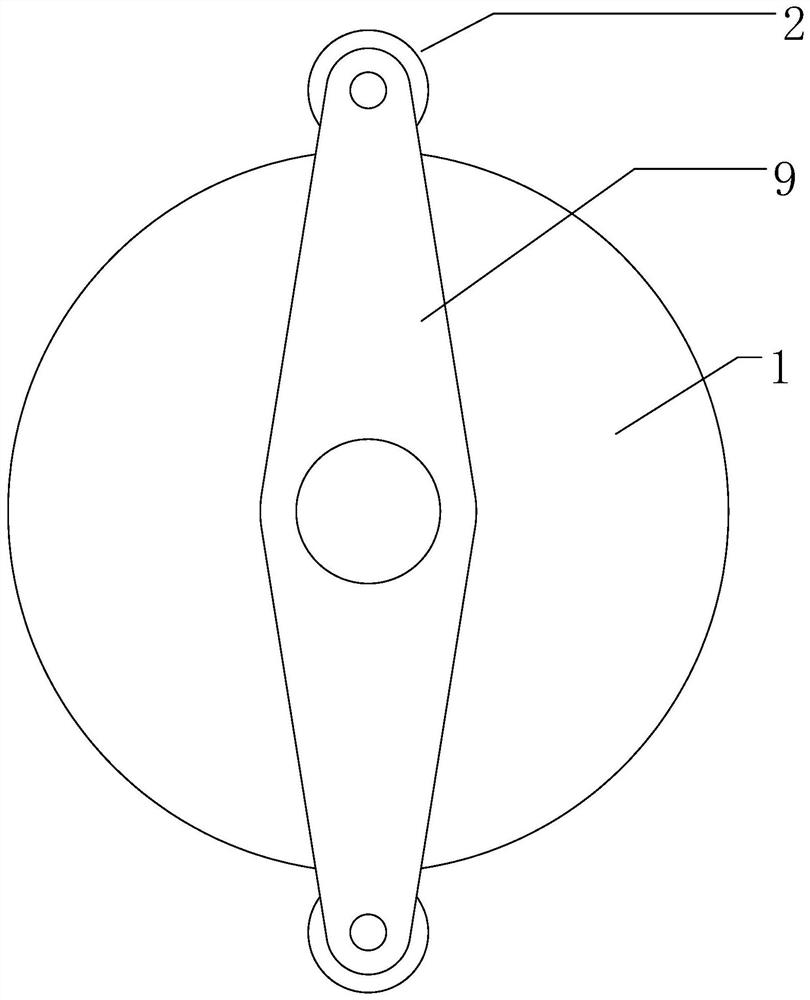

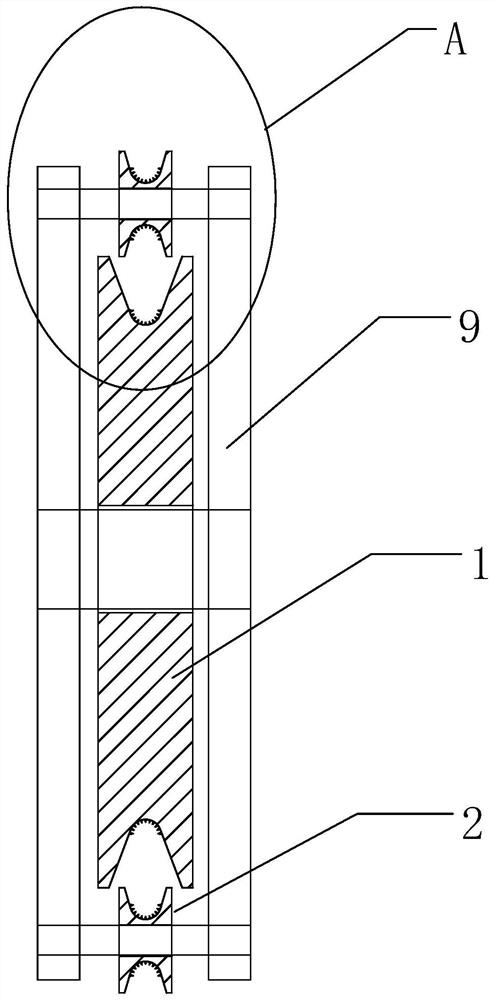

[0019] figure 1 It is a structural schematic diagram of a guide pulley device with the function of pre-tightened hoisting wire rope in the present invention; figure 2 It is the assembly drawing of the guide pulley, the pressure roller and the fixed splint; image 3 It is a structural schematic diagram of the guide pulley, the pressure roller and the fixed splint; Figure 4 for image 3 The enlarged schematic diagram at A. like figure 1 , figure 2 , image 3 and Figure 4 As shown, the structure of the present invention is a guide pulley device with the function of pre-tightening the hoisting wire rope, including a guide pulley 1 installed on the boom head of the crane, and a number of pressing rollers 2 are arranged on the side of the guide pulley 1, A hoisting wire rope is clamped between the pressing roller 2 and the guide pulley 1, and the guide pulley 1 is connected with a deceleration mechanism, and the deceleration mechanism is used to control the torque of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com