Liraglutide sustained-release microsphere preparation and preparation method thereof

A slow-release microsphere preparation, the technology of liraglutide, applied in the field of biomedicine, can solve the problem of low encapsulation efficiency of liraglutide sustained-release microspheres, difficulty in determining the formulation of sustained-release preparations, and inactivation of liraglutide and other problems, to achieve the effect of uniform particle size, round surface and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

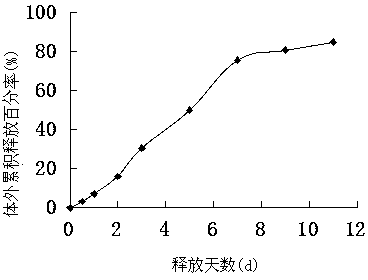

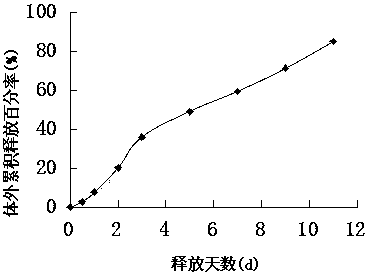

Image

Examples

Embodiment 1

[0042] (1) Pretreatment: The liraglutide API is in a freeze-dried powder state, and the impurities in the analysis and detection content meet the USP requirements and then refrigerated for later use;

[0043] (2) Dissolve 30mg of liraglutide in 1ml of water for injection, and add 3mg of lysine at the same time to prepare the inner water phase; the mass-volume concentration of liraglutide in the inner water phase is 30mg / mL, and lysine The solubility of the acid in the internal aqueous phase is 3%;

[0044] (3) Dissolve 100 mg of poly(lactic-co-glycolic acid) copolymer (the ratio of polylactic acid to glycolic acid in the poly(lactic-co-glycolic acid) copolymer is 1:1, Mw=15000) in 2ml of dichloromethane to obtain an oil phase; The mass-volume concentration of lactic acid glycolic acid copolymer in oil phase is 300mg / mL;

[0045] (4) Mix the inner water phase in step (2) with the oil phase in step (3), and mix and sonicate for 30s under a 100w sonicator to obtain colostrum W ...

Embodiment 2

[0049](1) Pretreatment: The liraglutide API is in a freeze-dried powder state, and the impurities in the analysis and detection content meet the USP requirements and then refrigerated for later use;

[0050] (2) Dissolve 40mg of liraglutide in 1ml of water for injection, and add 8mg of glycine at the same time to obtain the inner water phase; the mass-volume concentration of liraglutide in the inner water phase is 40mg / mL, and glycine in the inner water The mass-volume concentration in the phase is 8 mg / ml;

[0051] (3) Dissolve 300mg of poly(lactic-co-glycolic acid) copolymer (the ratio of polylactic acid to glycolic acid in the poly(lactic-co-glycolic acid) copolymer is 3:1, Mw=10000) in 4ml of dichloromethane to obtain an oil phase; The mass-volume concentration of lactic acid glycolic acid copolymer in oil phase is 300mg / mL;

[0052] (4) Mix the inner water phase in step (2) and the oil phase in step (3), and mix and sonicate for 10 seconds under a 200w ultrasonic breaker...

Embodiment 3

[0056] (1) Pretreatment: The liraglutide API is in a freeze-dried powder state, and the impurities in the analysis and detection content meet the USP requirements and then refrigerated for later use;

[0057] (2) Dissolve 60mg of liraglutide in 1ml of water for injection, and add 30mg of histidine at the same time to prepare the inner water phase; the mass-volume concentration of liraglutide in the inner water phase is 60mg / mL, histidine The solubility of the acid in the internal aqueous phase is a mass-volume concentration of 30 mg / ml;

[0058] (3) Dissolve 500mg of poly(lactic-co-glycolic acid) copolymer (the ratio of polylactic acid to glycolic acid in the poly(lactic-co-glycolic acid) copolymer is 1:3, Mw=15000) in 5ml of dichloromethane to obtain an oil phase; The mass-volume concentration of lactic acid glycolic acid copolymer in oil phase is 300mg / mL;

[0059] (4) Mix the inner water phase in step (2) and the oil phase in step (3), and mix and sonicate for 10 seconds u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com