Primary drying air control system and method for mechanical-grate garbage incinerator

A waste incinerator and mechanical grate technology, applied in the direction of combustion method, drying gas arrangement, drying, etc., can solve the problems of reducing the oxygen content of primary air, high equipment maintenance costs, incomplete waste combustion, etc., and achieve stable control , efficient and stable combustion, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

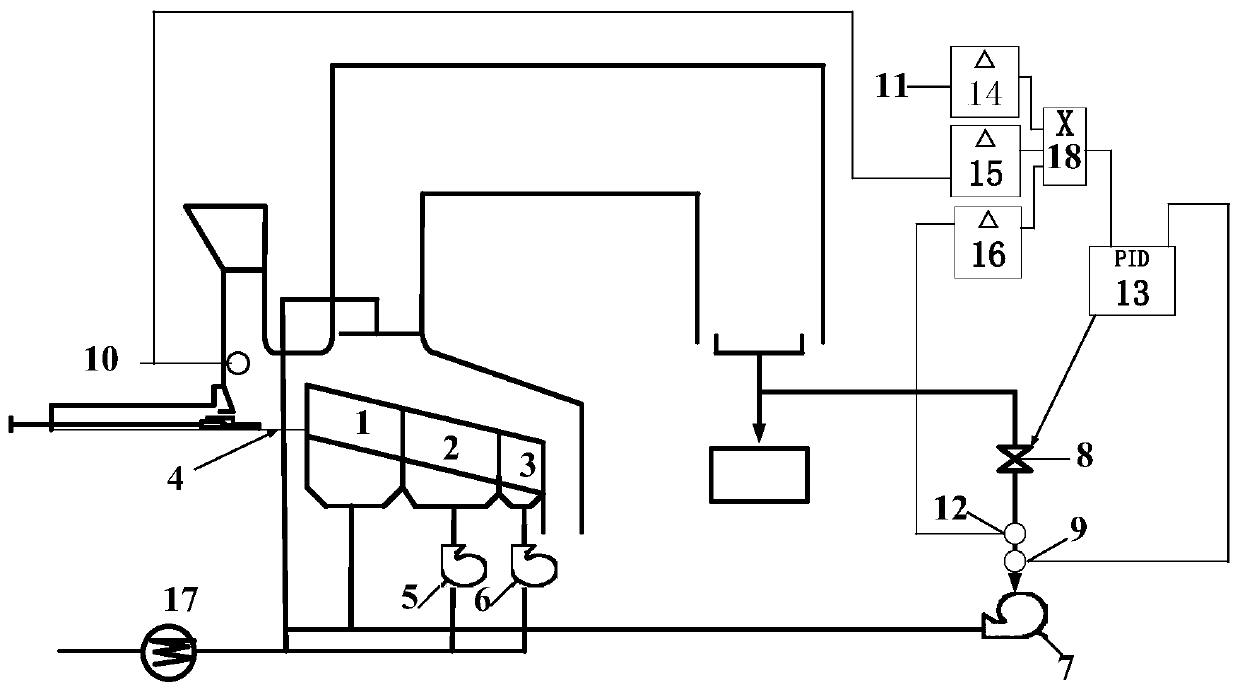

[0024] Such as figure 1 As shown, a mechanical grate waste incinerator primary drying air control system of the present invention includes a flue gas recirculation baffle 8 installed on a pipe connected to the boiler tail flue, and is installed on the flue gas recirculation baffle 8 The flue gas recirculation fan 7 at the outlet enables the flue gas at the boiler outlet to be throttled and regulated by the recirculation baffle 8, pressurized by the flue gas recirculation fan 7, and finally sent to the mechanical grate waste incinerator through the pipeline for drying. Section 1, to dry the garbage, together with the hot air sent to the gasification section 2 and the burnout section 3, is used as the primary air of the waste incineration grate boiler.

[0025]A primary drying air control system for a mechanical grate garbage incinerator of the present invention further includes a recirculation flue gas flow sensor 9 and a recirculation flue gas flow sensor 9 installed on the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com