Counter current heat exchanging water-fire tube boiler capable of saving energy and protecting environment

An energy-saving and environmentally friendly countercurrent heat exchange technology, which is applied to fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of countercurrent heat exchange energy-saving and environmental protection water-fire tube boilers that have not been seen yet, and achieve the reduction of incomplete combustion of solids Heat loss, energy saving is obvious, and the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

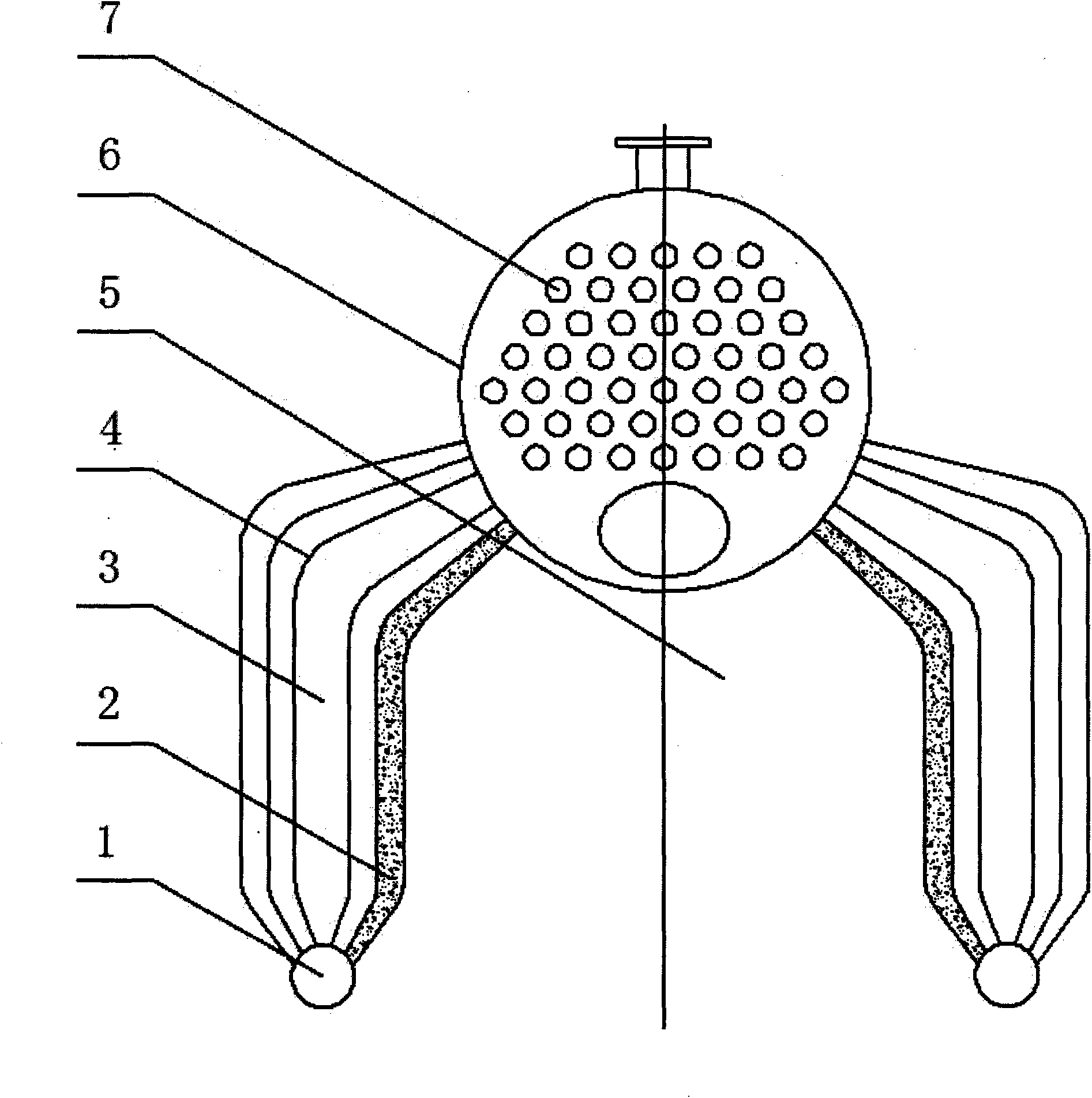

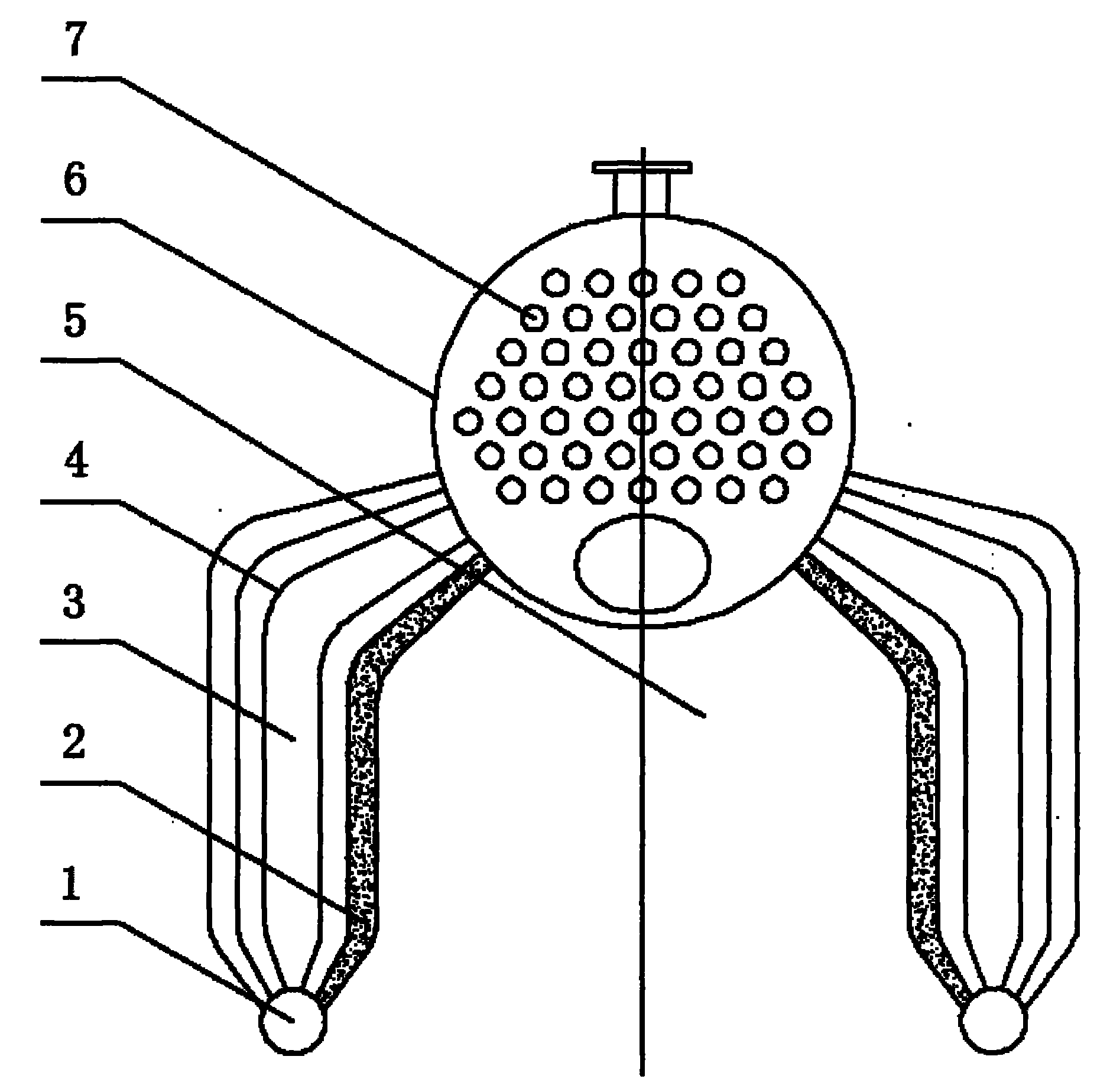

[0008] The specific structure of the present invention will be described in detail according to the drawings. The structure of the countercurrent heat exchange, energy-saving and environment-friendly water-fire tube boiler is shown in the figure. It is composed of a pot shell 6, a header 1, a convection pipe 4, a pyrotechnic pipe 7, a smoke partition wall 2, a combustion chamber 5, and a convection pipe flue 3. It is characterized in that the high-temperature flue gas of the second return passes through the pyrotechnic pipe in the pot shell first. 7 The part with higher water temperature on the water side performs heat exchange, and then the flue gas with lower temperature in the three returns passes through the convection pipe flue 3 and the convection pipe 4 with lower water temperature on the water side for heat exchange, and the flue gas is discharged out of the boiler body after heat exchange. Completely change the original downstream heat exchange method, realize counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com