Patents

Literature

68 results about "Fire-tube boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or (many) more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

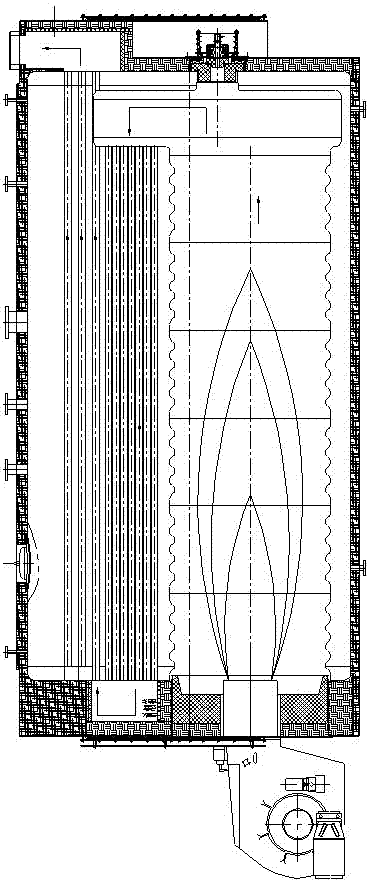

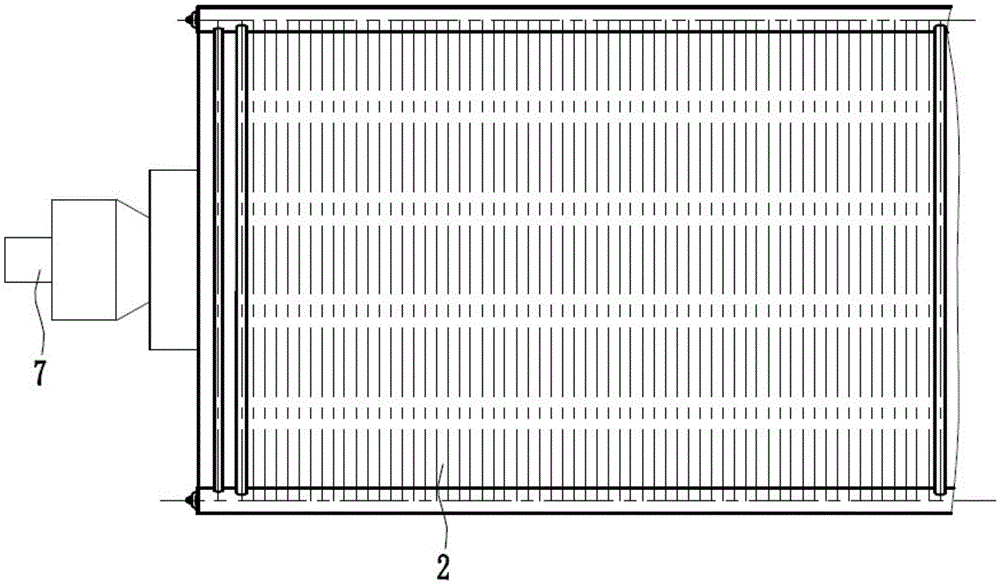

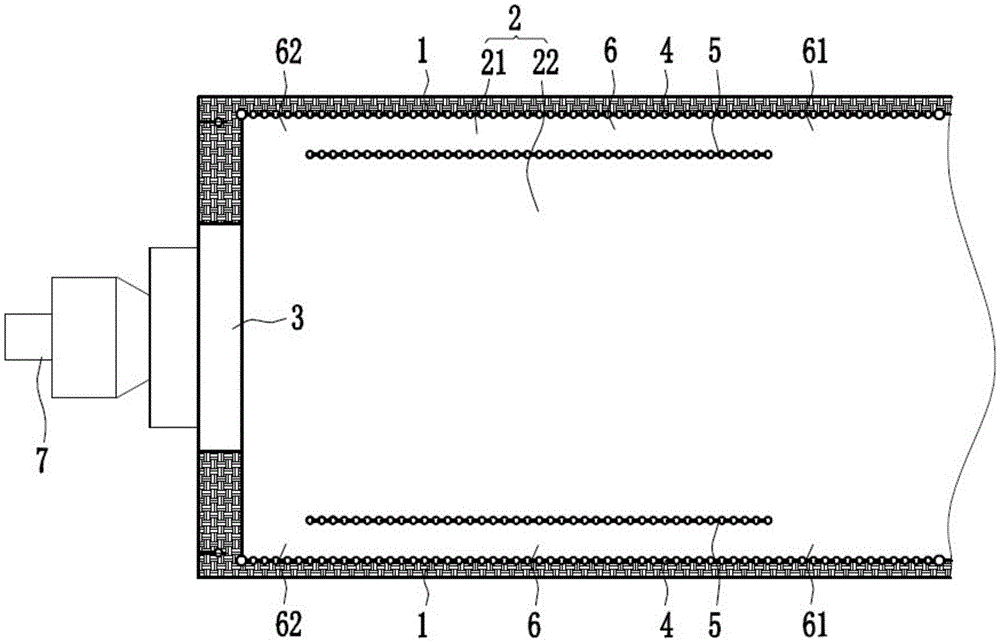

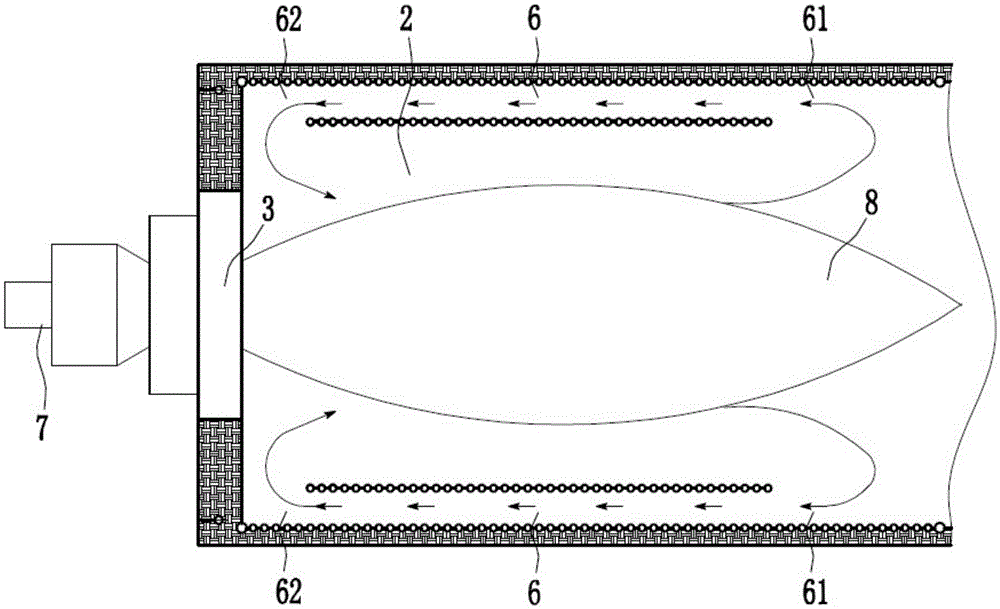

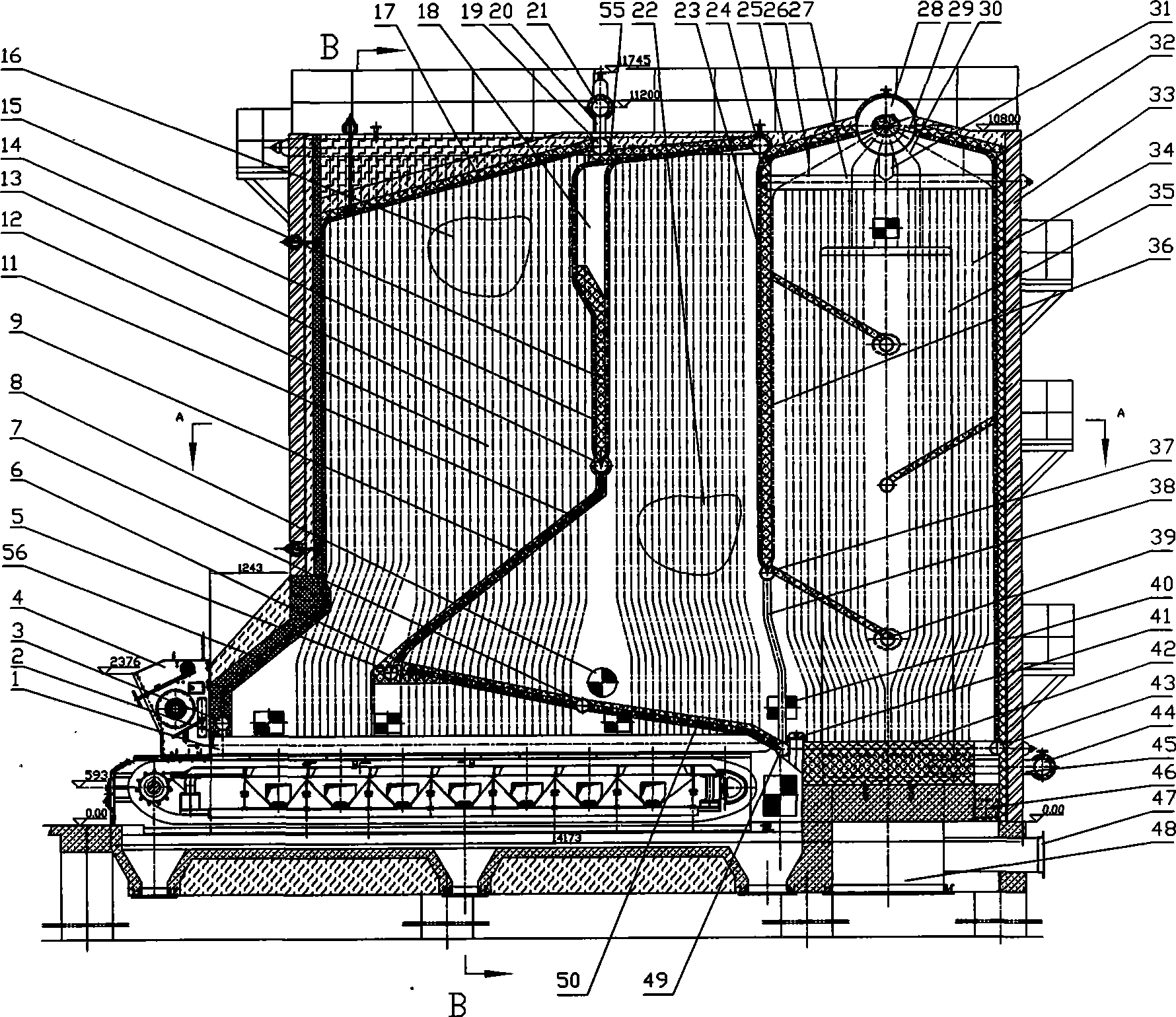

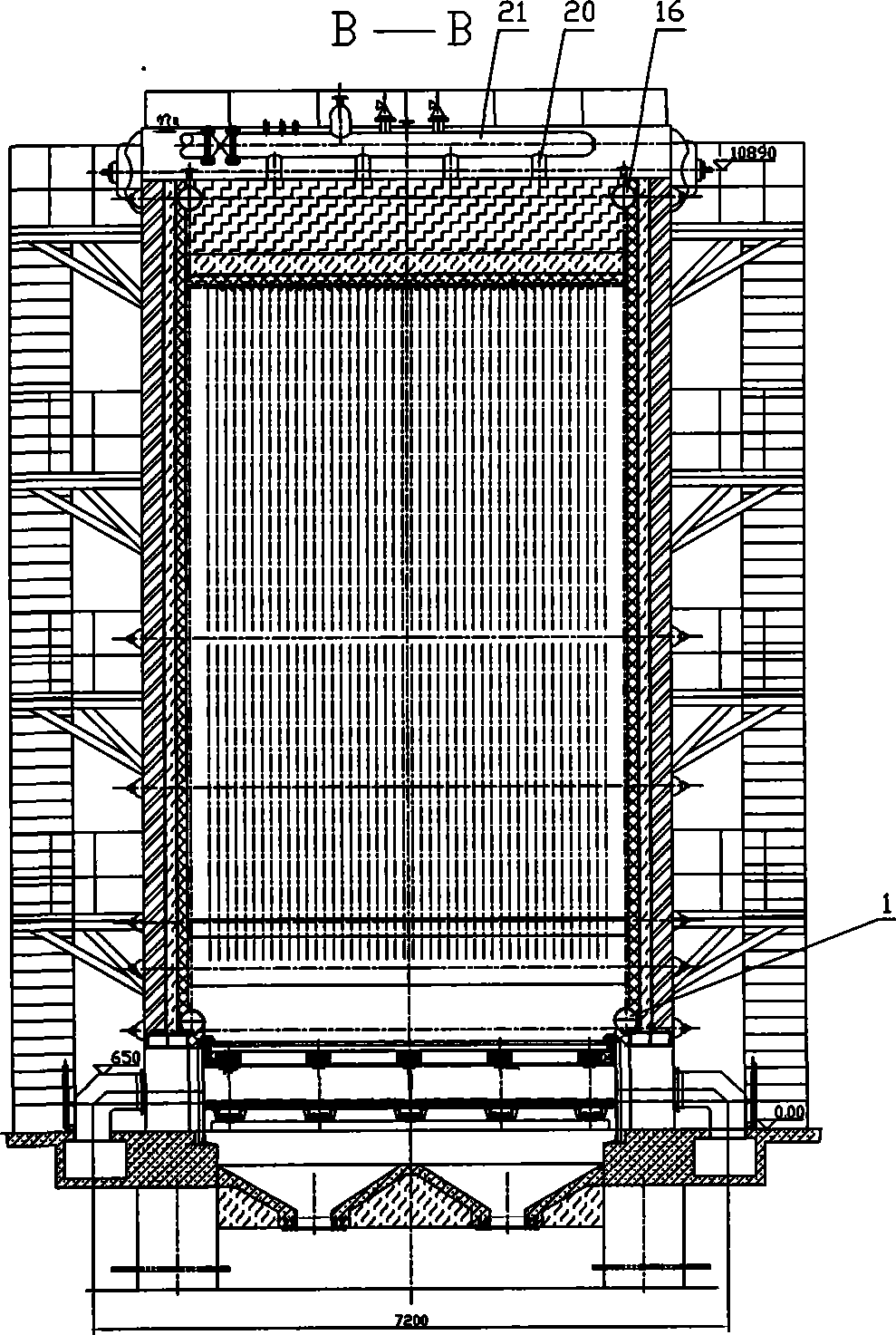

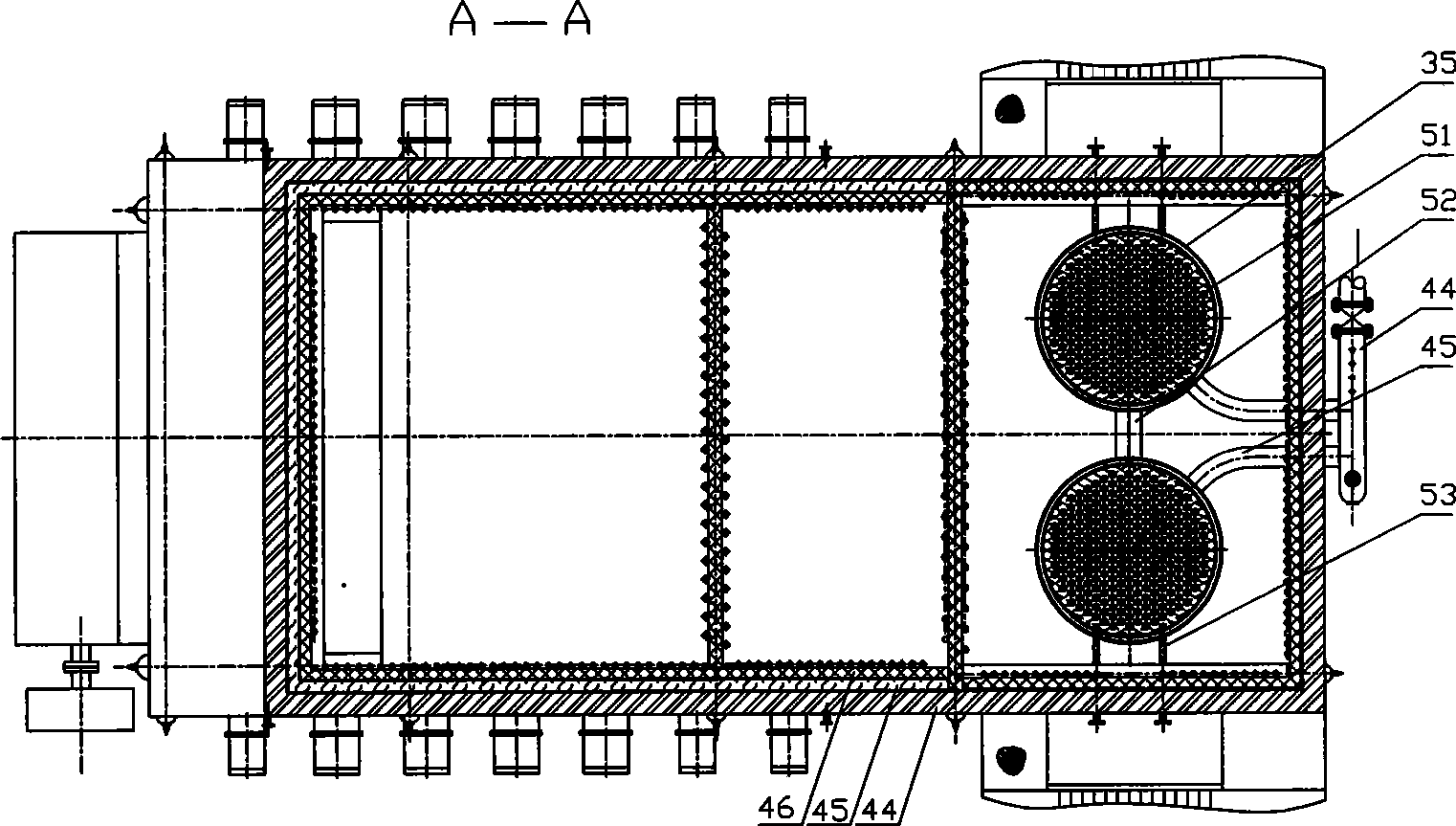

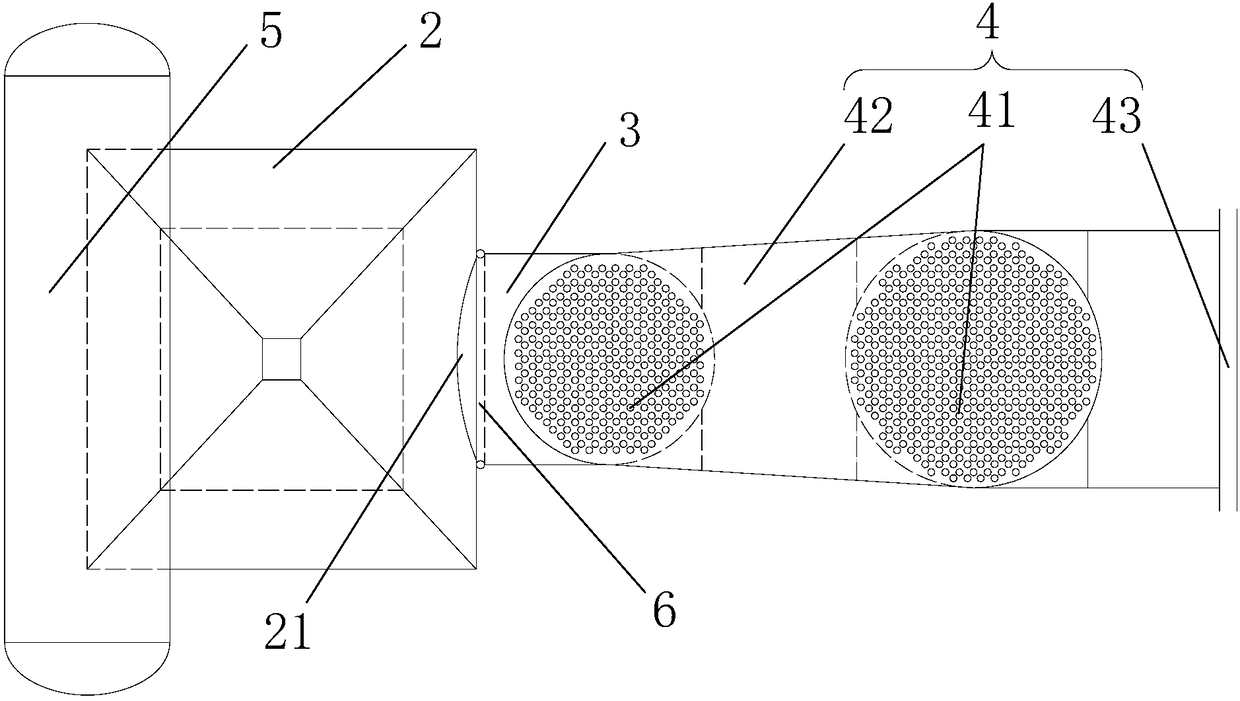

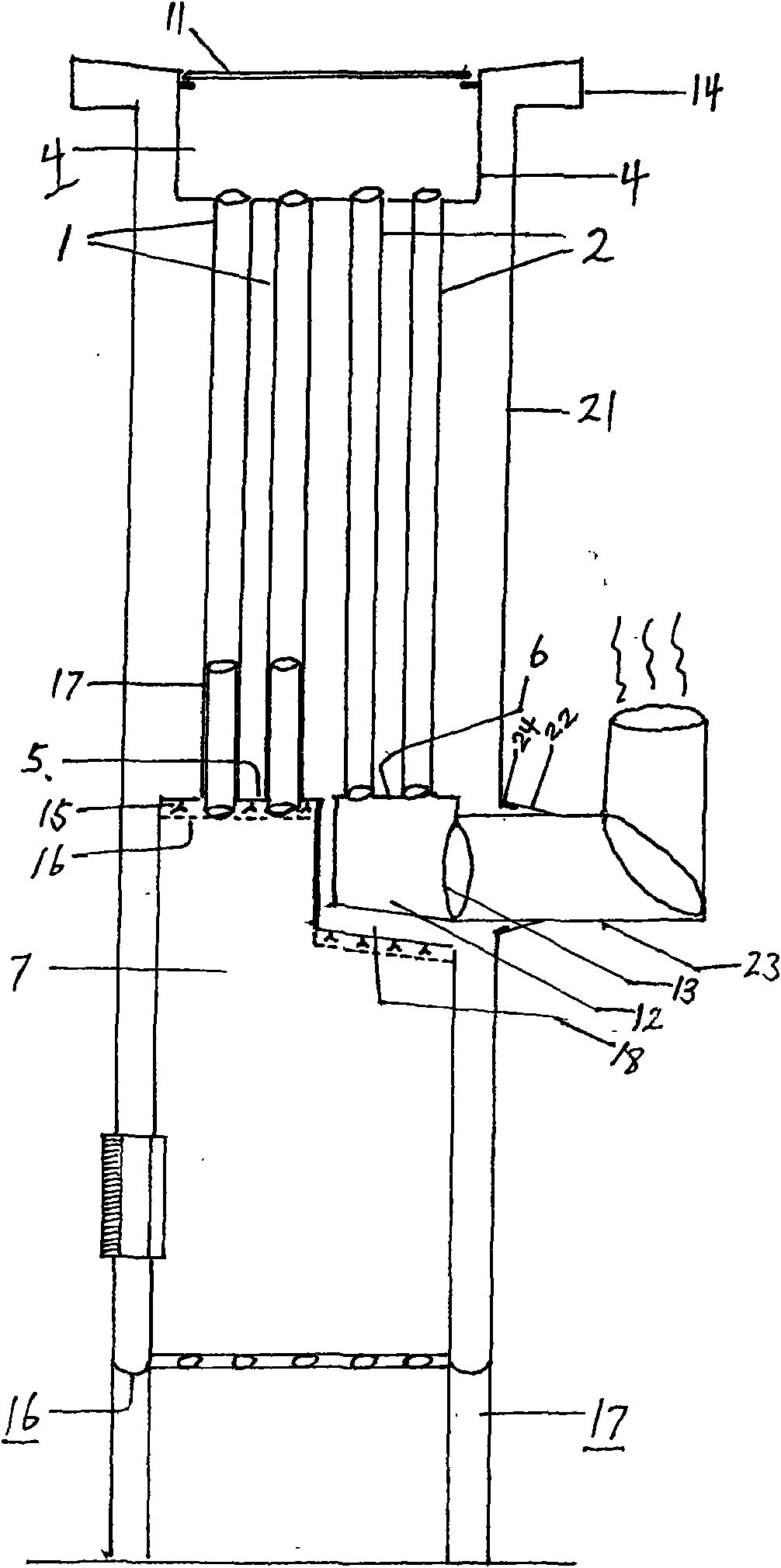

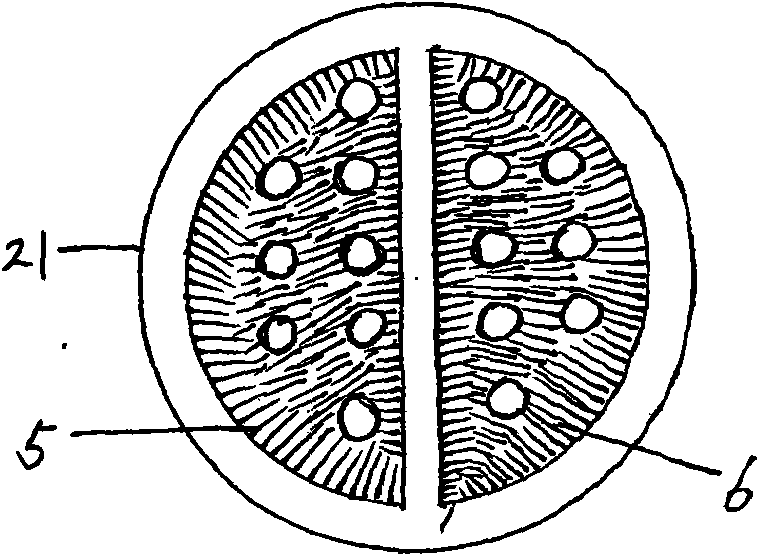

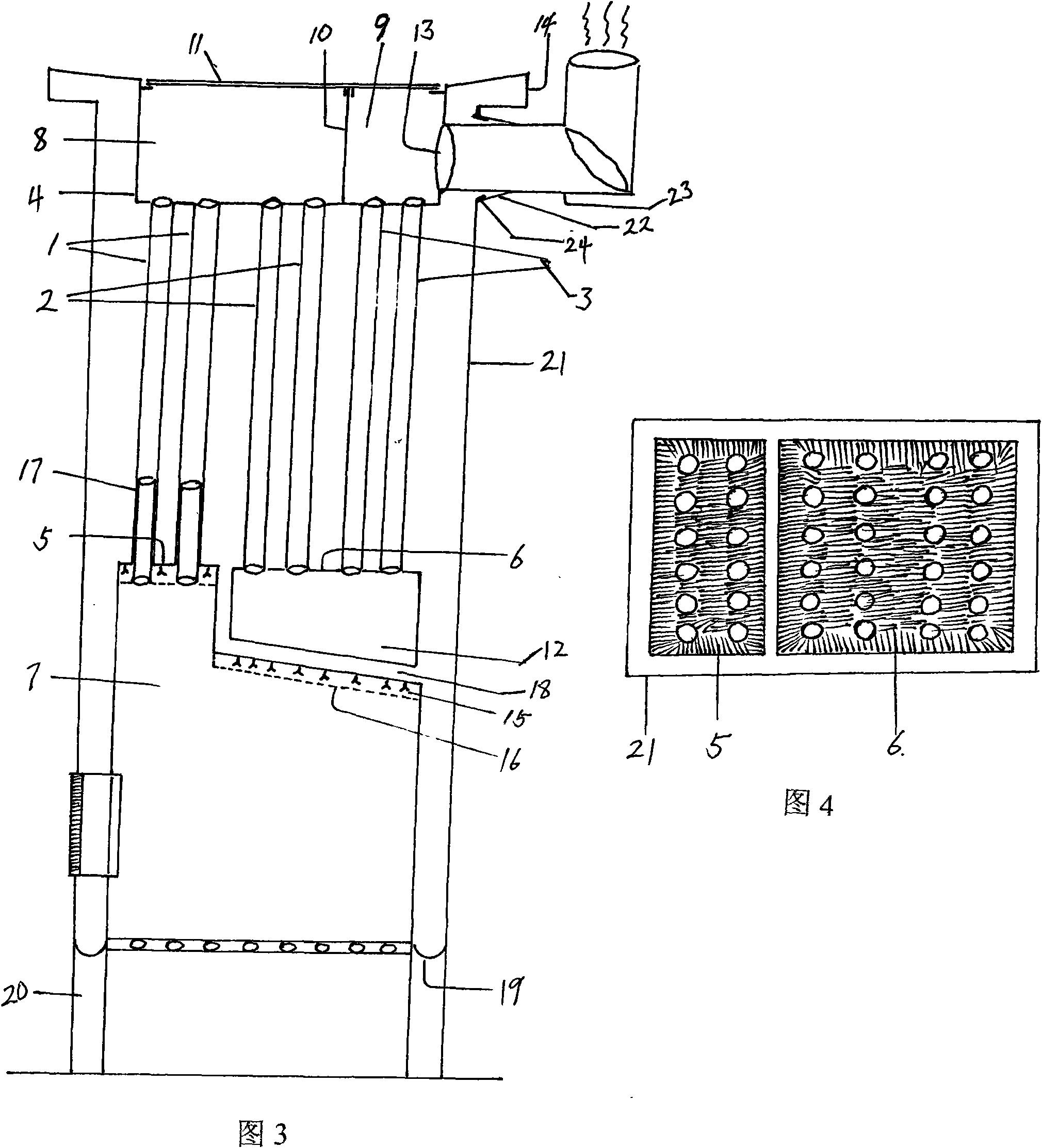

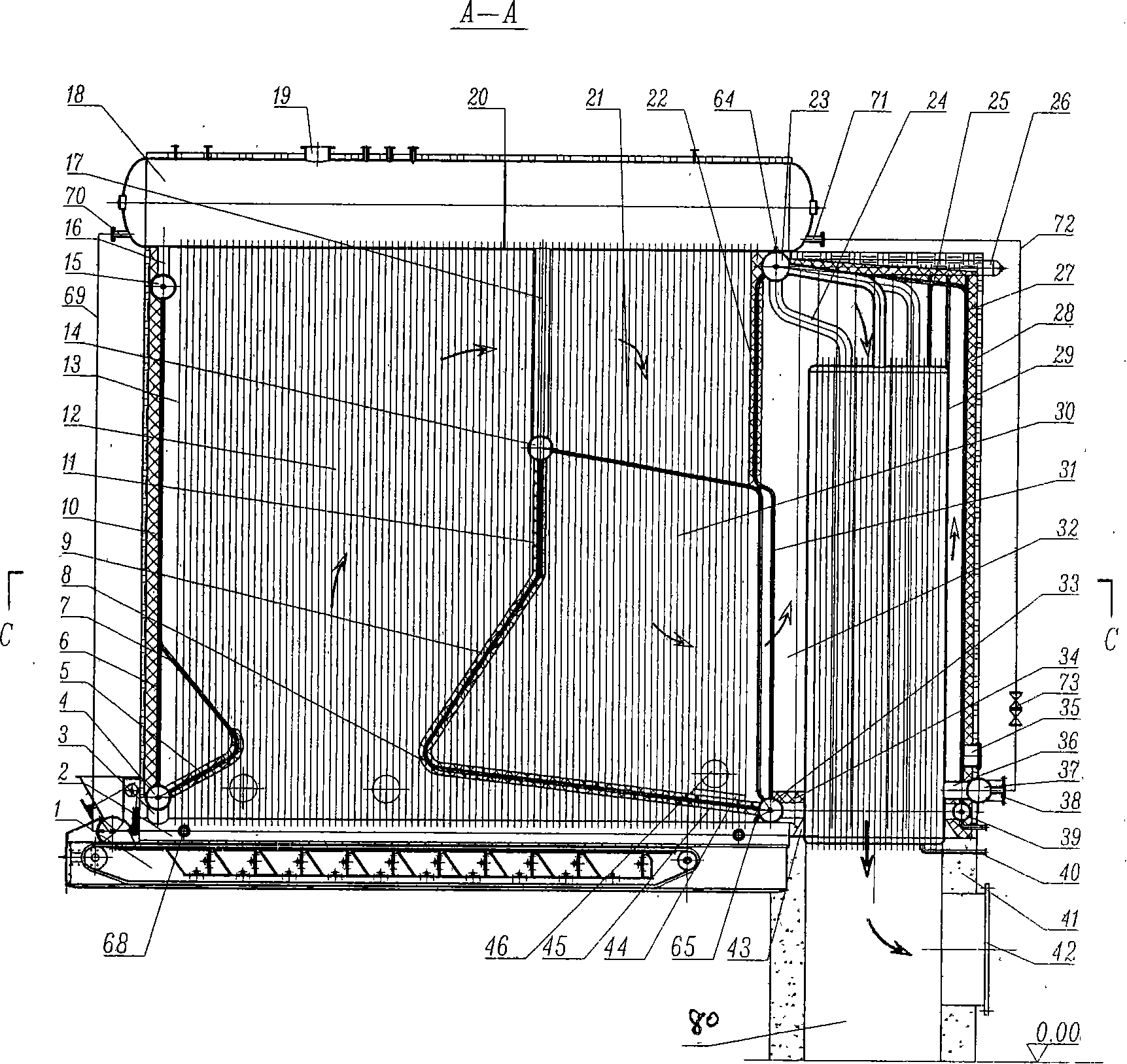

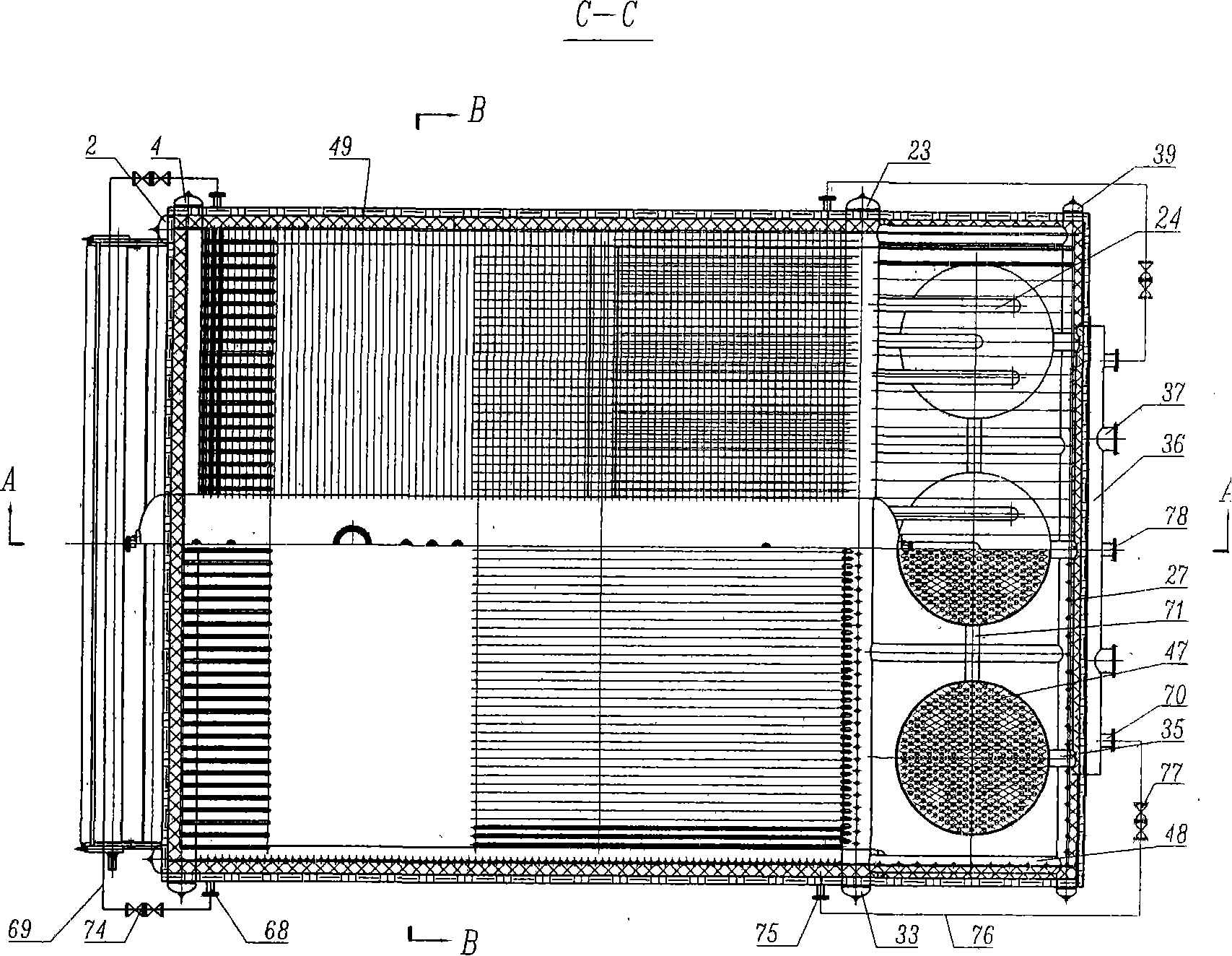

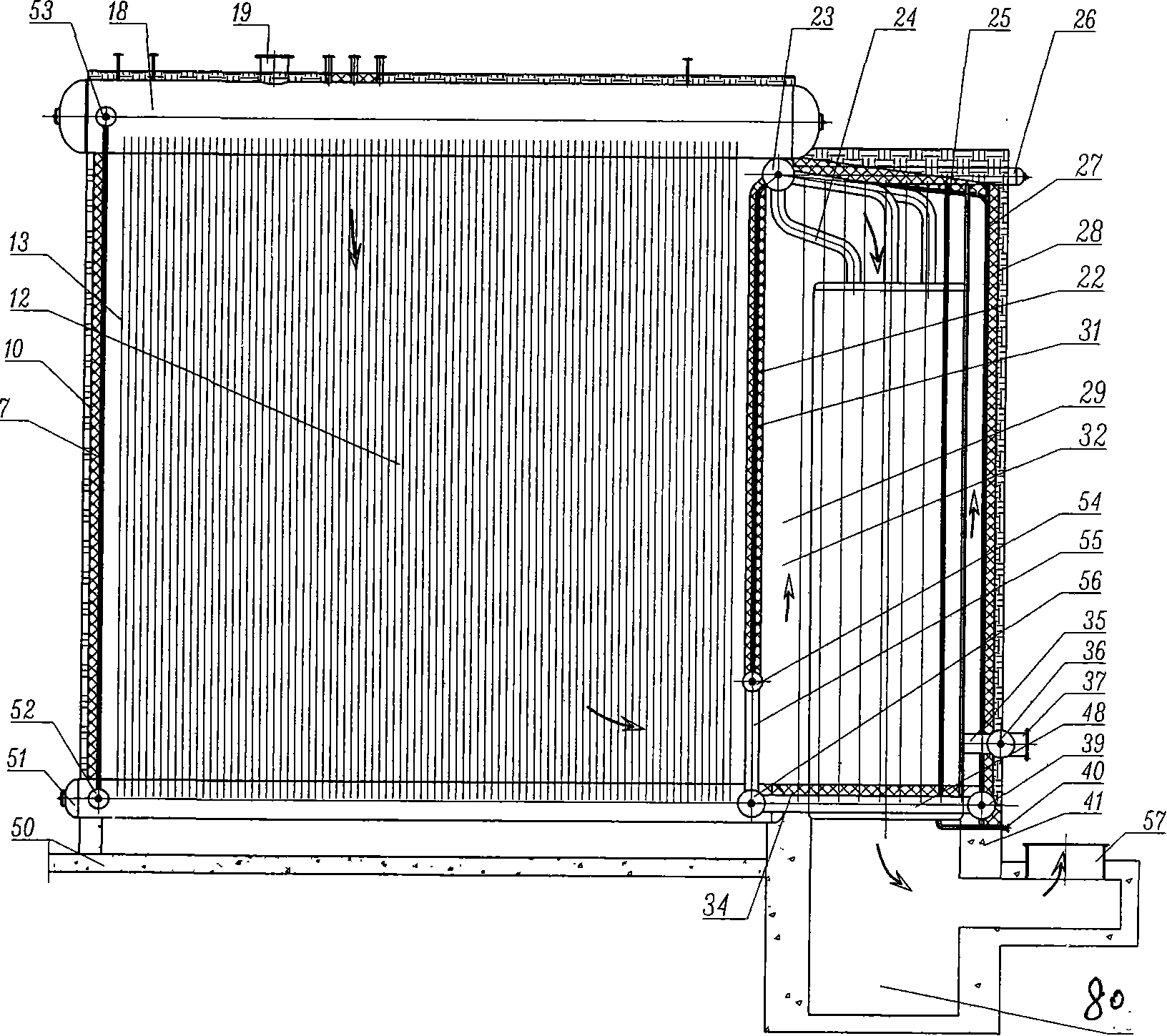

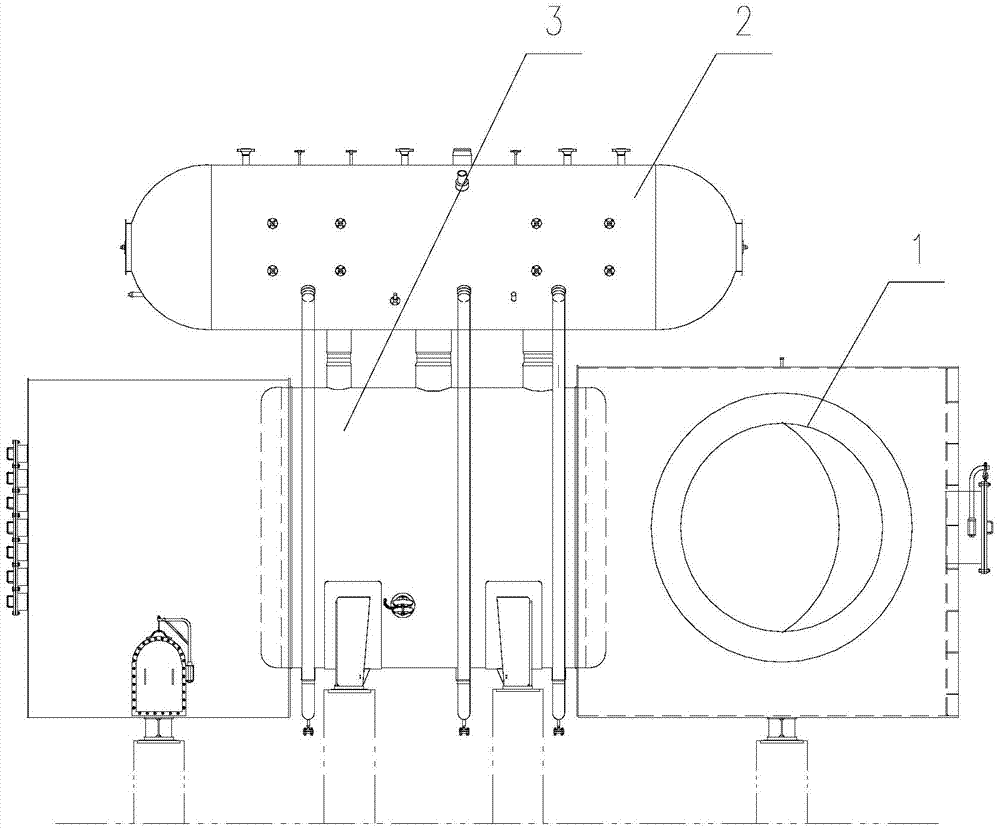

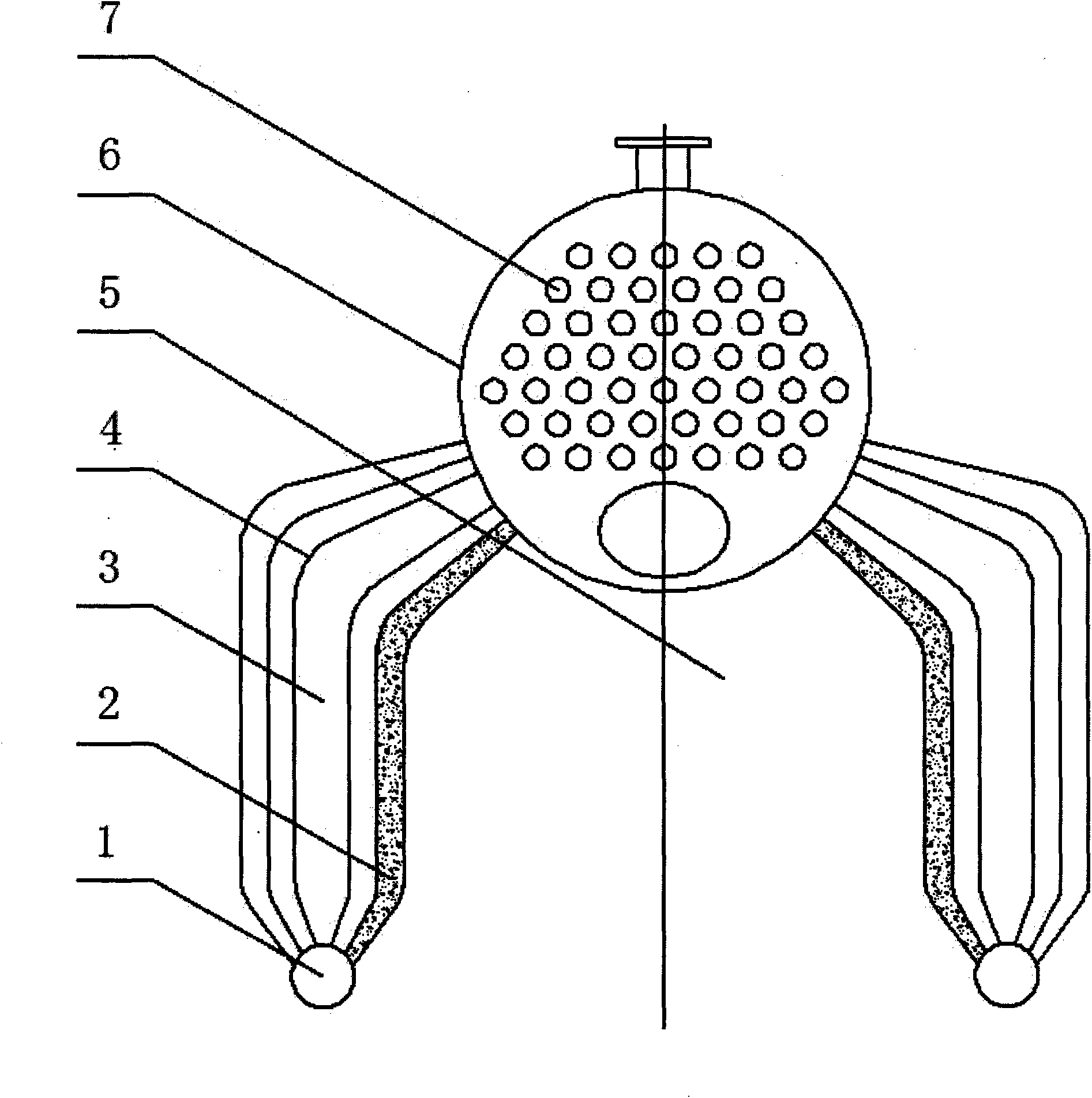

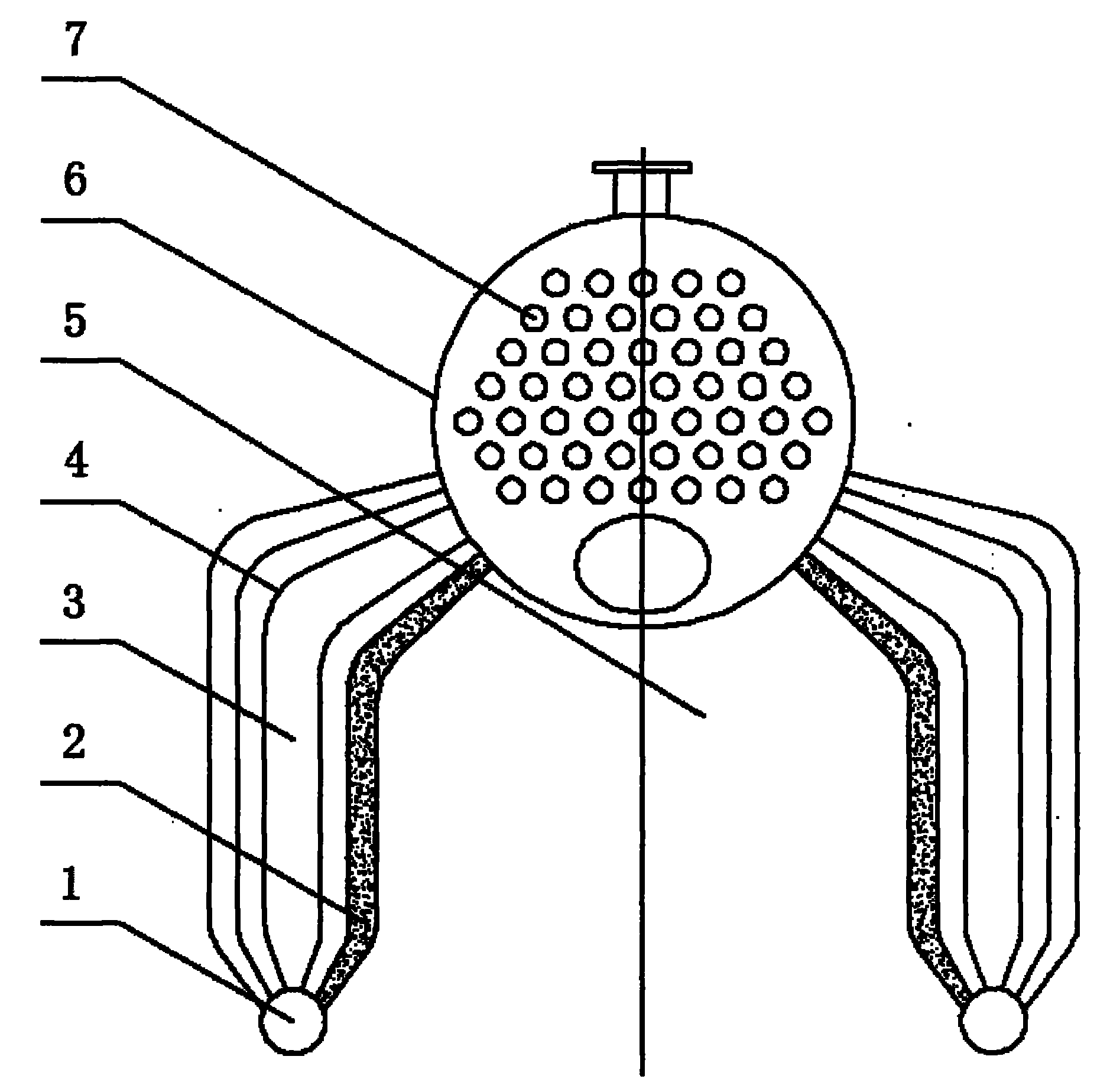

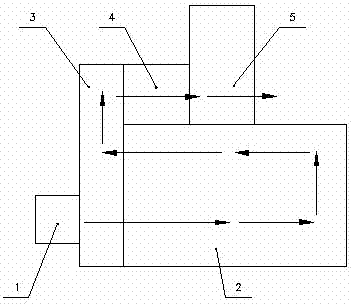

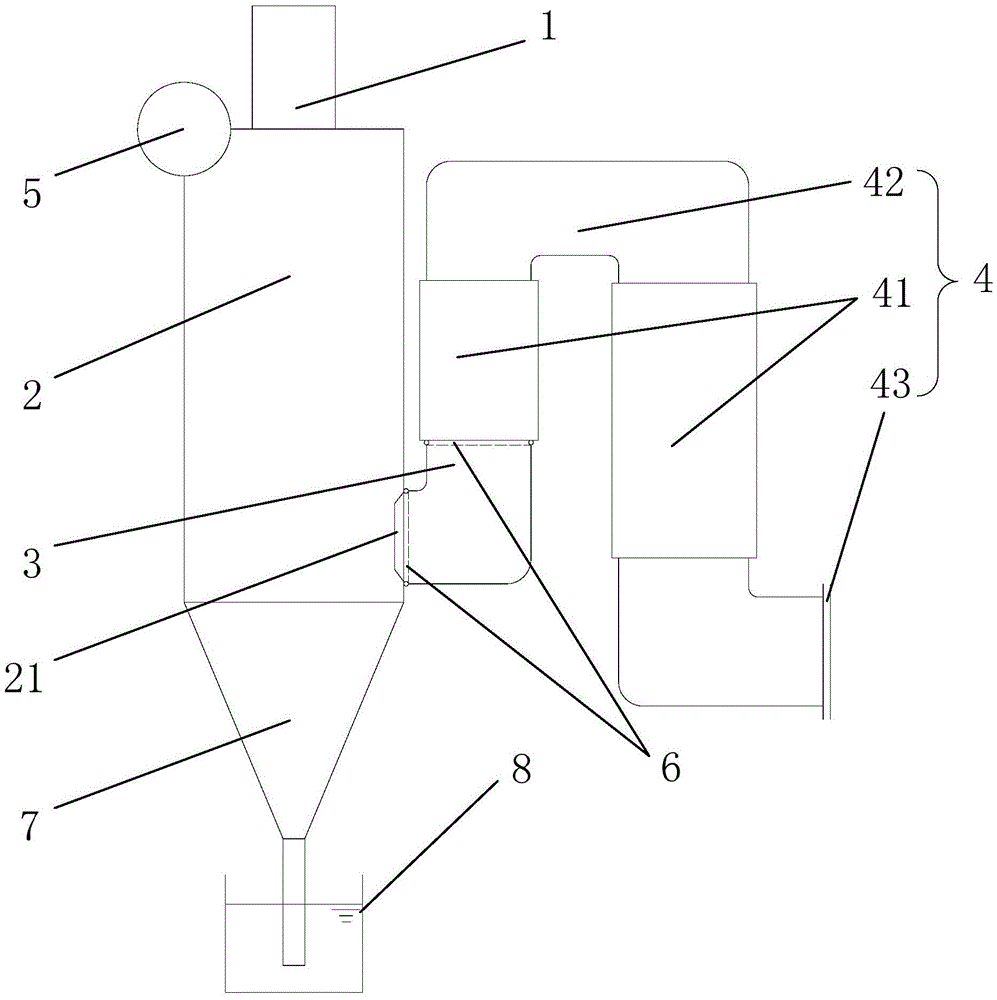

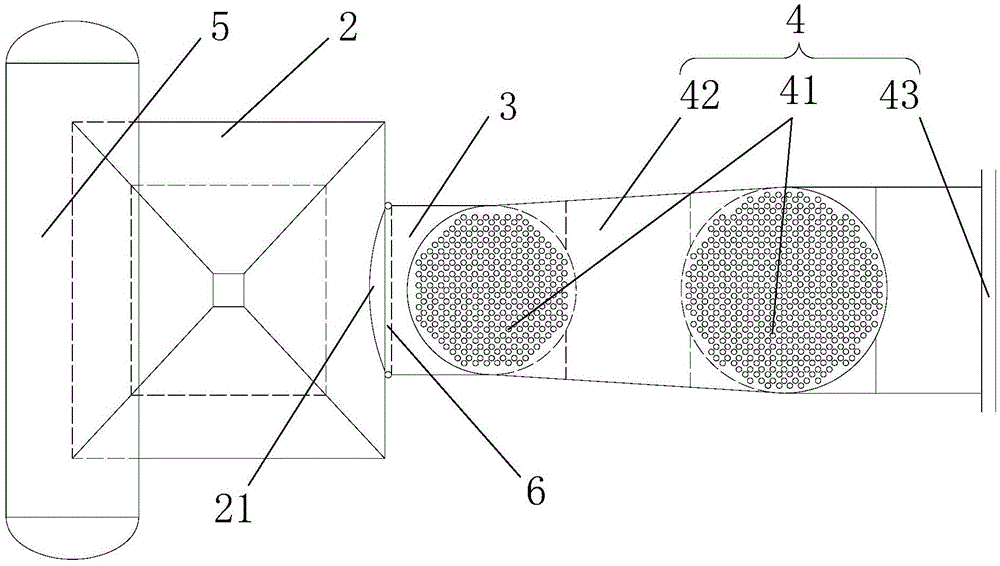

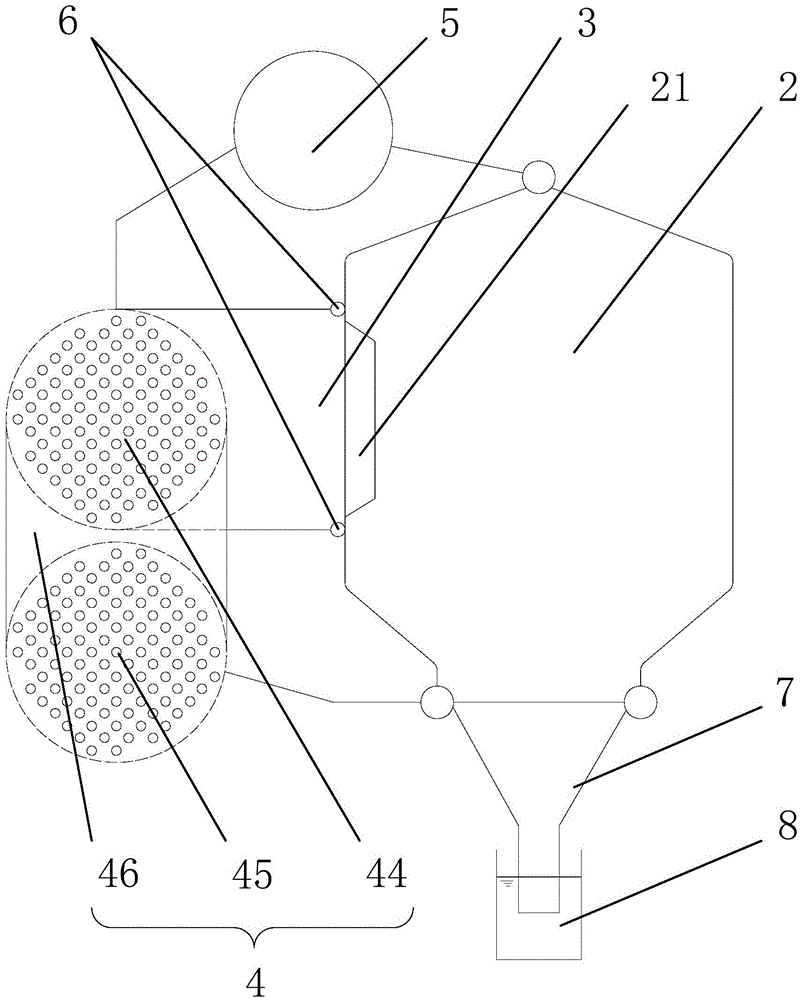

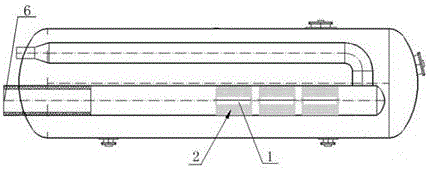

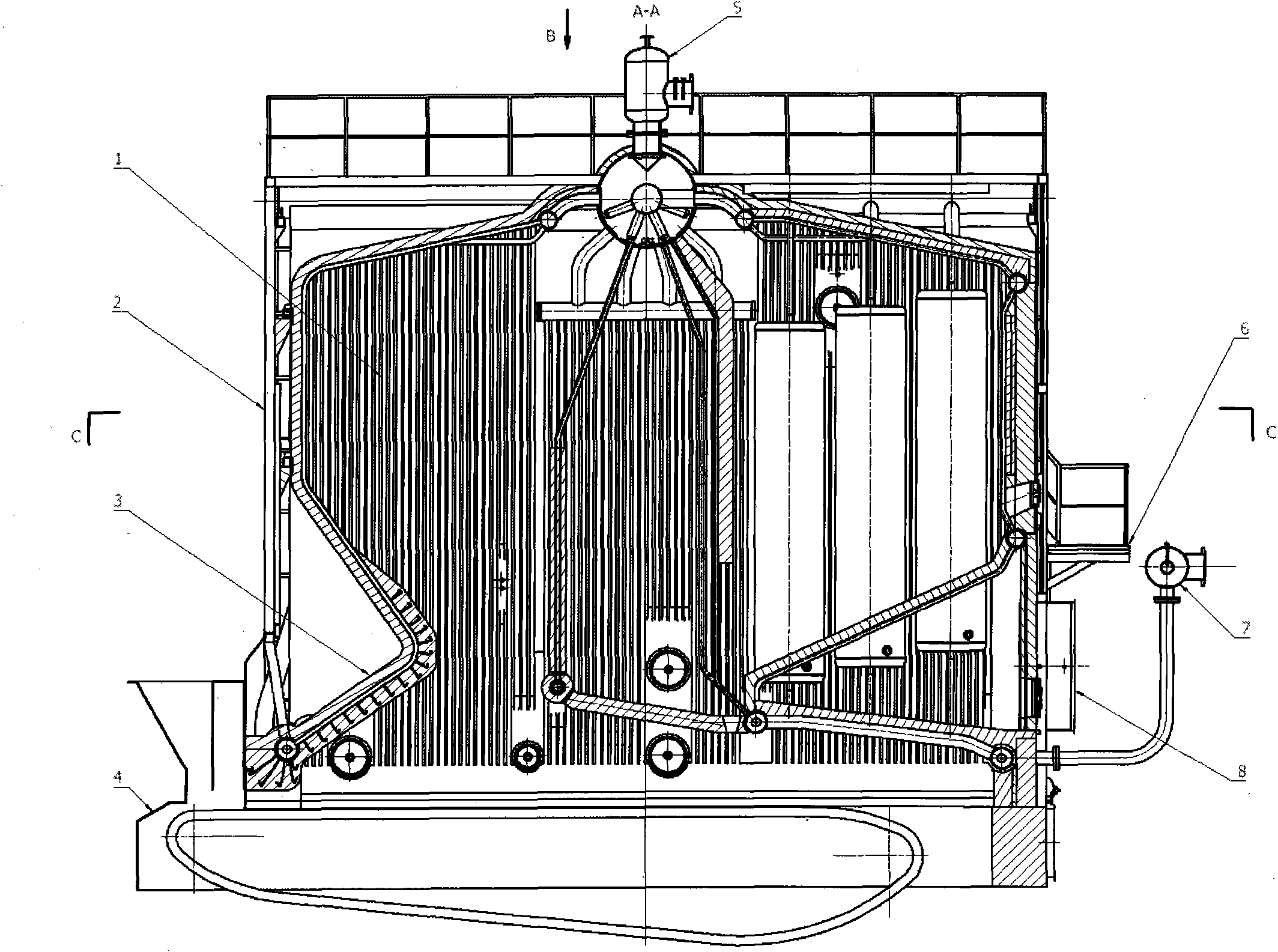

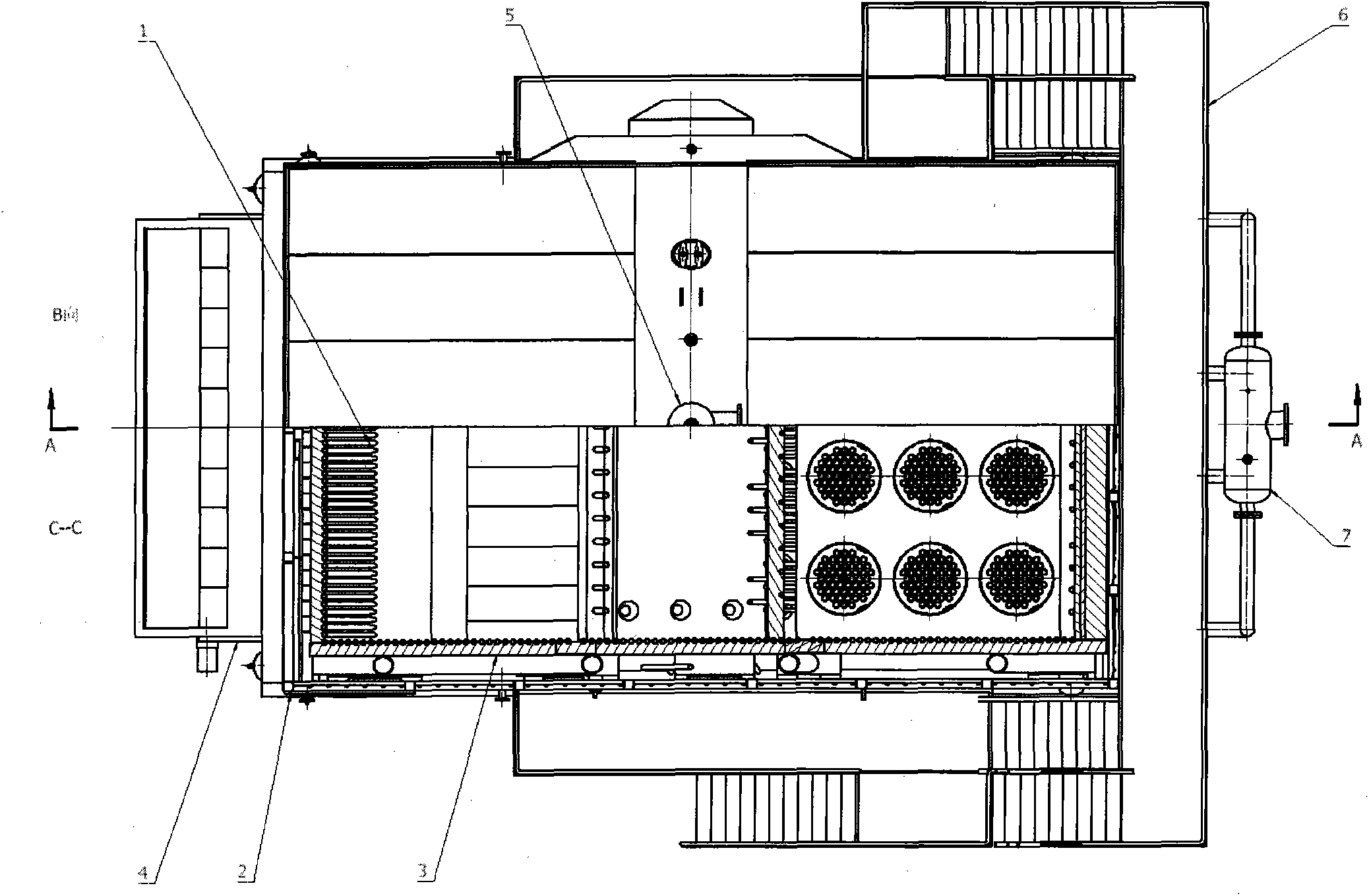

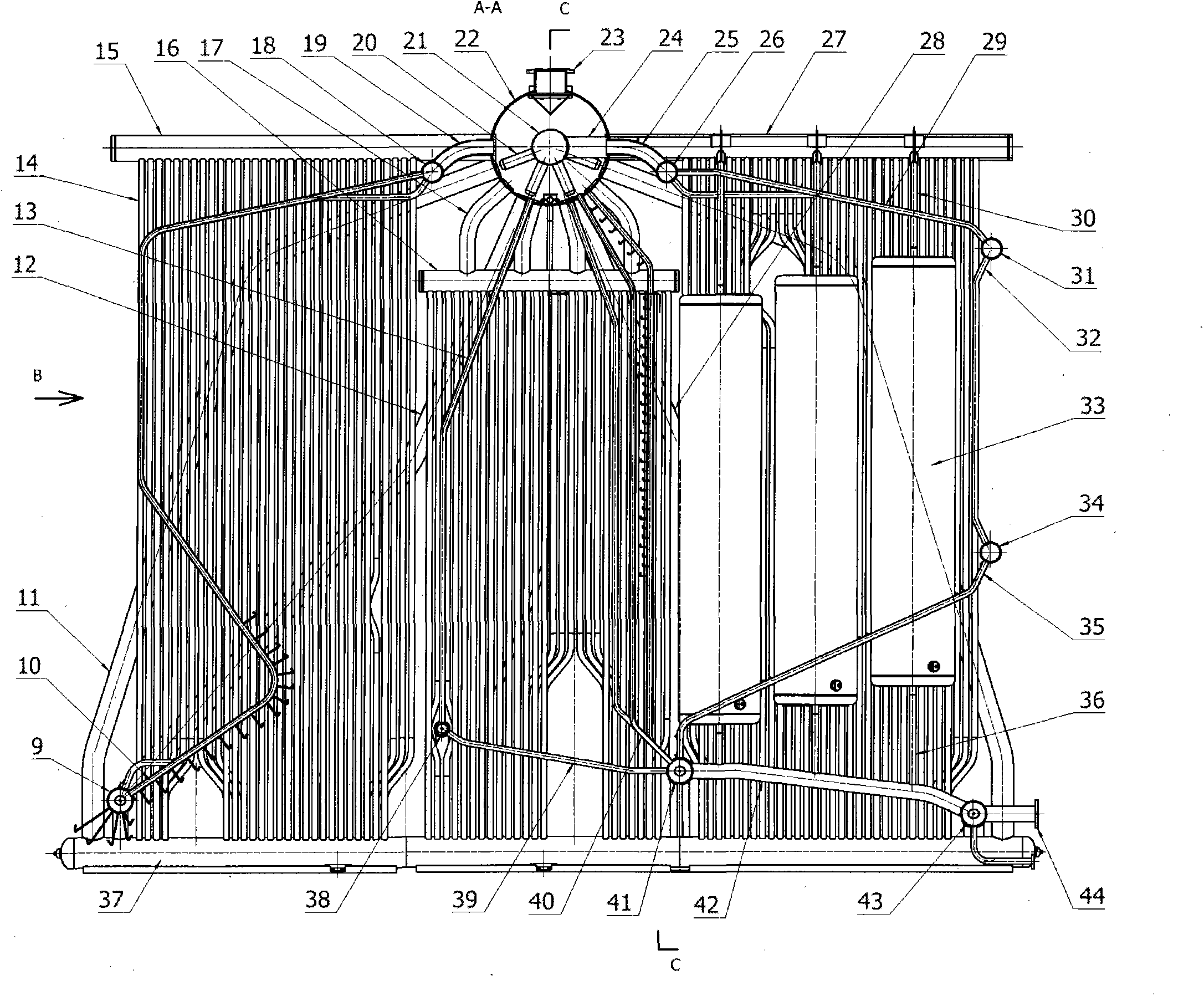

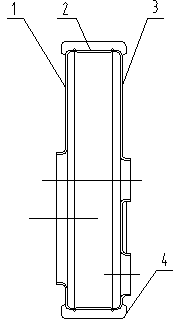

Large horizontal internally fired fire-tube hot-water boiler with external smoke-water heat exchanger

ActiveCN103398367ASmall diameterSave spaceWater-tube boilersFire-tube steam boilersBoiler furnaceProcess engineering

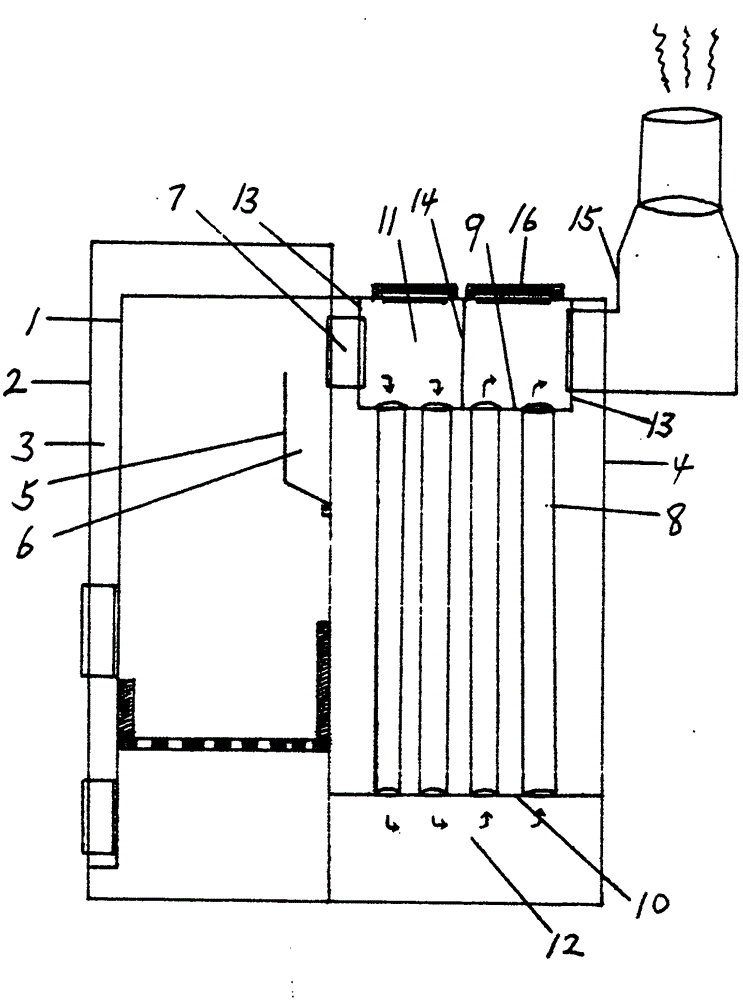

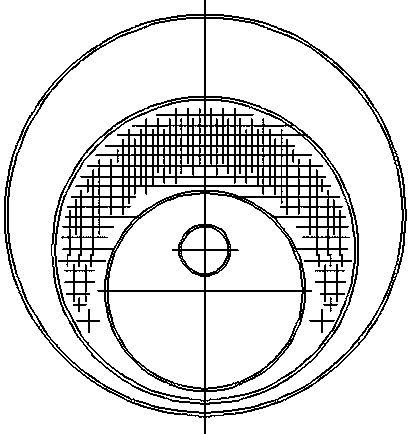

The invention relates to a large horizontal internally fired fire-tube hot-water boiler with an external smoke-water heat exchanger. The large horizontal internally fired fire-tube hot-water boiler comprises a boiler barrel (1), a boiler furnace (2) and a second return convection smoke tube (4). The boiler barrel (1) is horizontally arranged, and the boiler furnace (2) and the second return convection smoke tube (4) are arranged in the boiler barrel (1). The large horizontal internally fired fire-tube hot-water boiler is characterized in that the second return convection smoke tube (4) is arranged below the boiler furnace (2), a burnout chamber (3), a corner smoke chamber (5) and the smoke-water heat exchanger (6) are arranged on the outside of the boiler barrel (1), heat exchange tubes of the smoke-water heat exchanger are third return convection smoke tubes, the burnout chamber (3) is arranged at the rear of the boiler barrel (1), a shell side of the burnout chamber (3) is communicated with the boiler furnace (2) and the second return convection smoke tube (4), the second return convection smoke tube (4) is communicated with the corner smoke chamber (5), and the corner smoke chamber (5) is communicated with the third return convection smoke tubes of the smoke-water heat exchanger. The large horizontal internally fired fire-tube hot-water boiler has the advantages that the horizontal internally fired fire-tube boiler is large and is modularized.

Owner:JIANGSU SHUANGLIANG BOILER

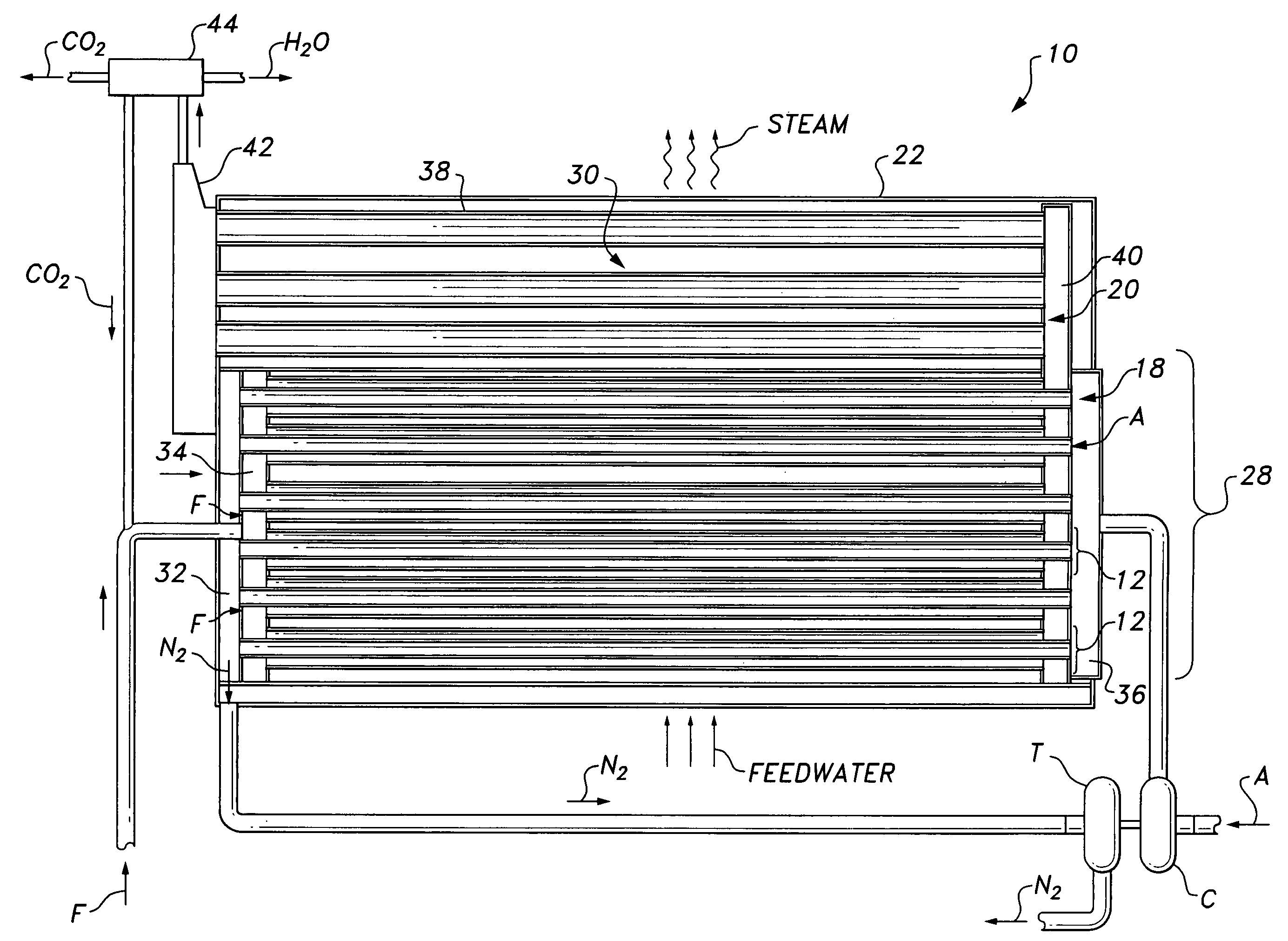

Carbon-free fire tube boiler

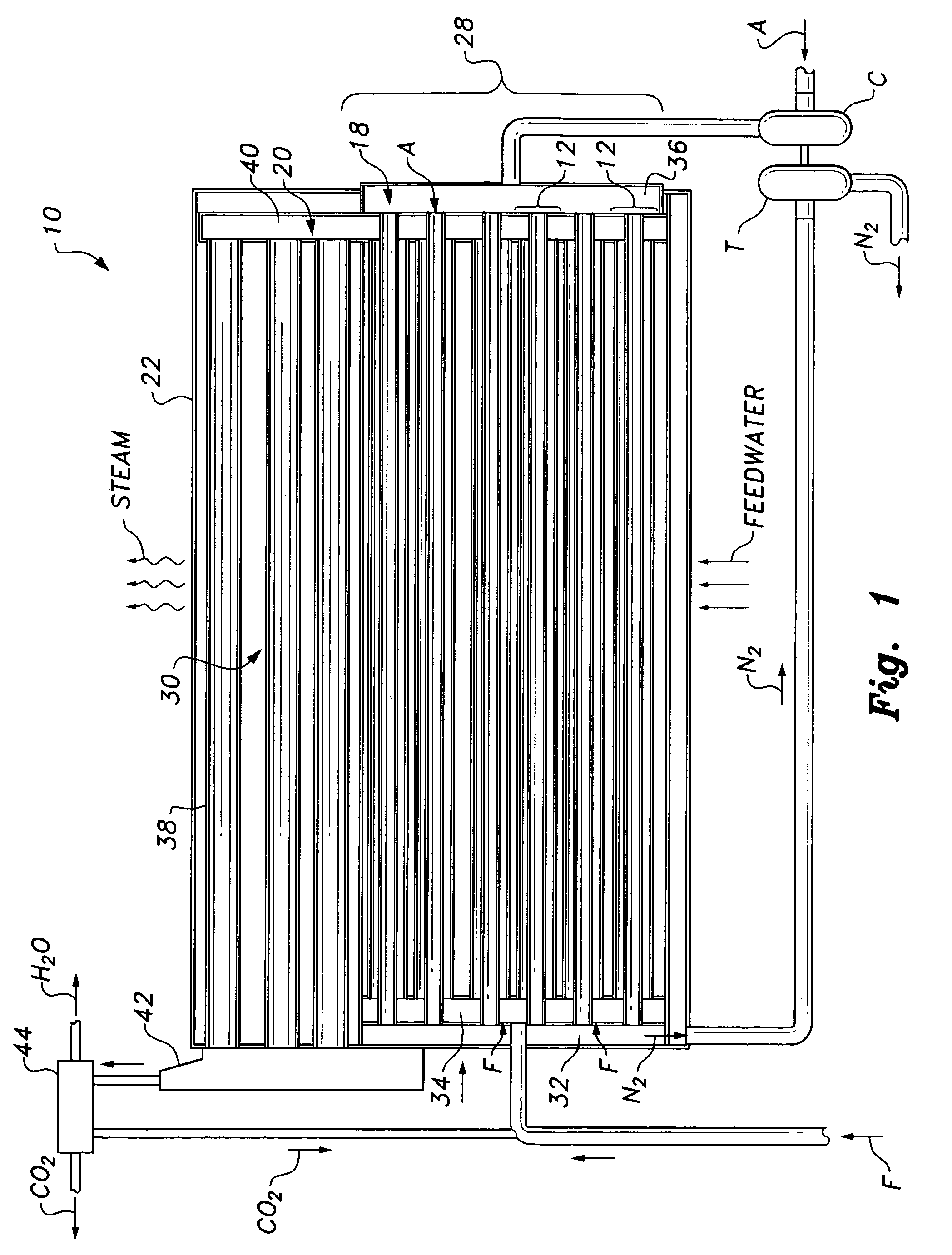

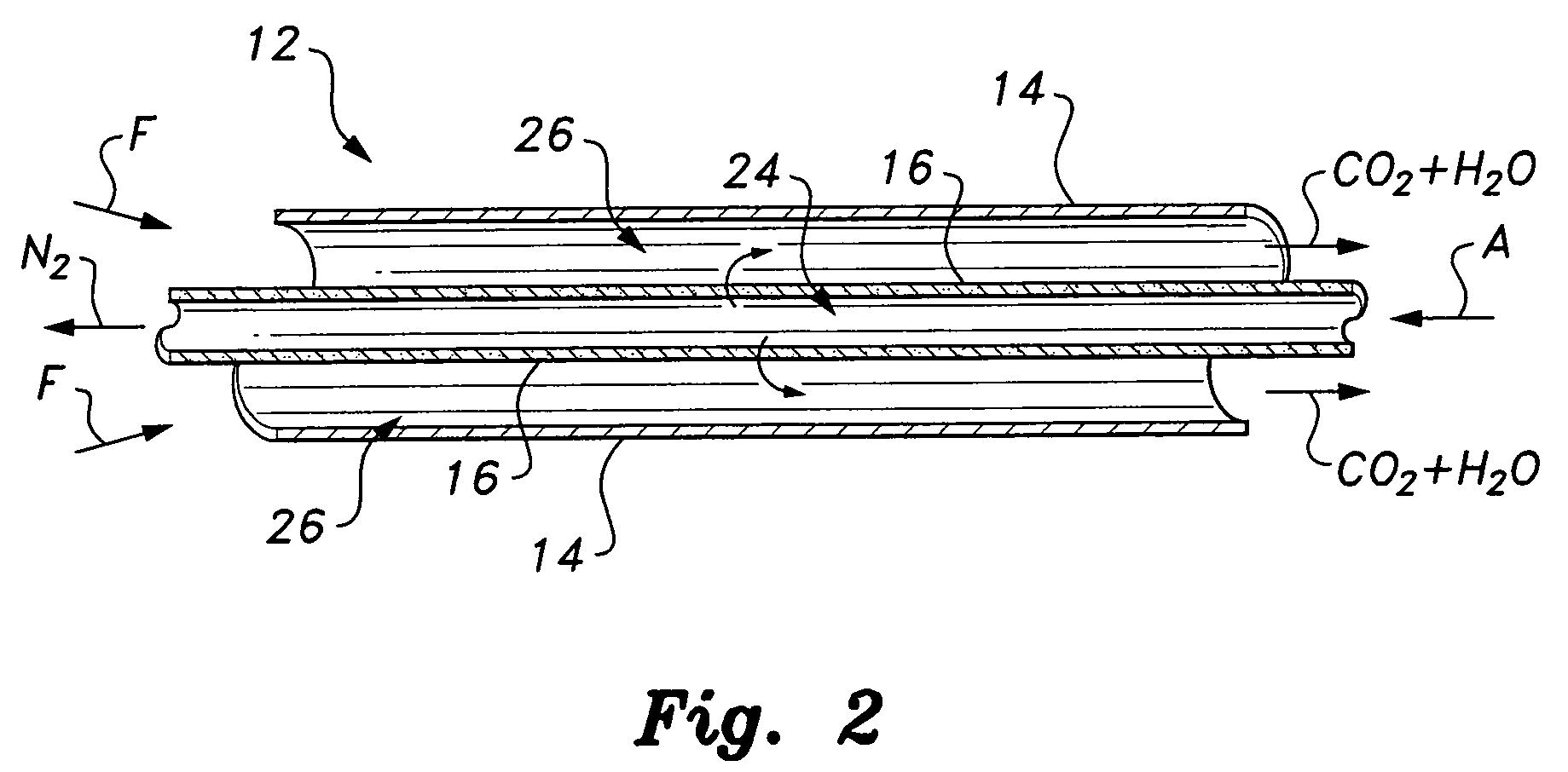

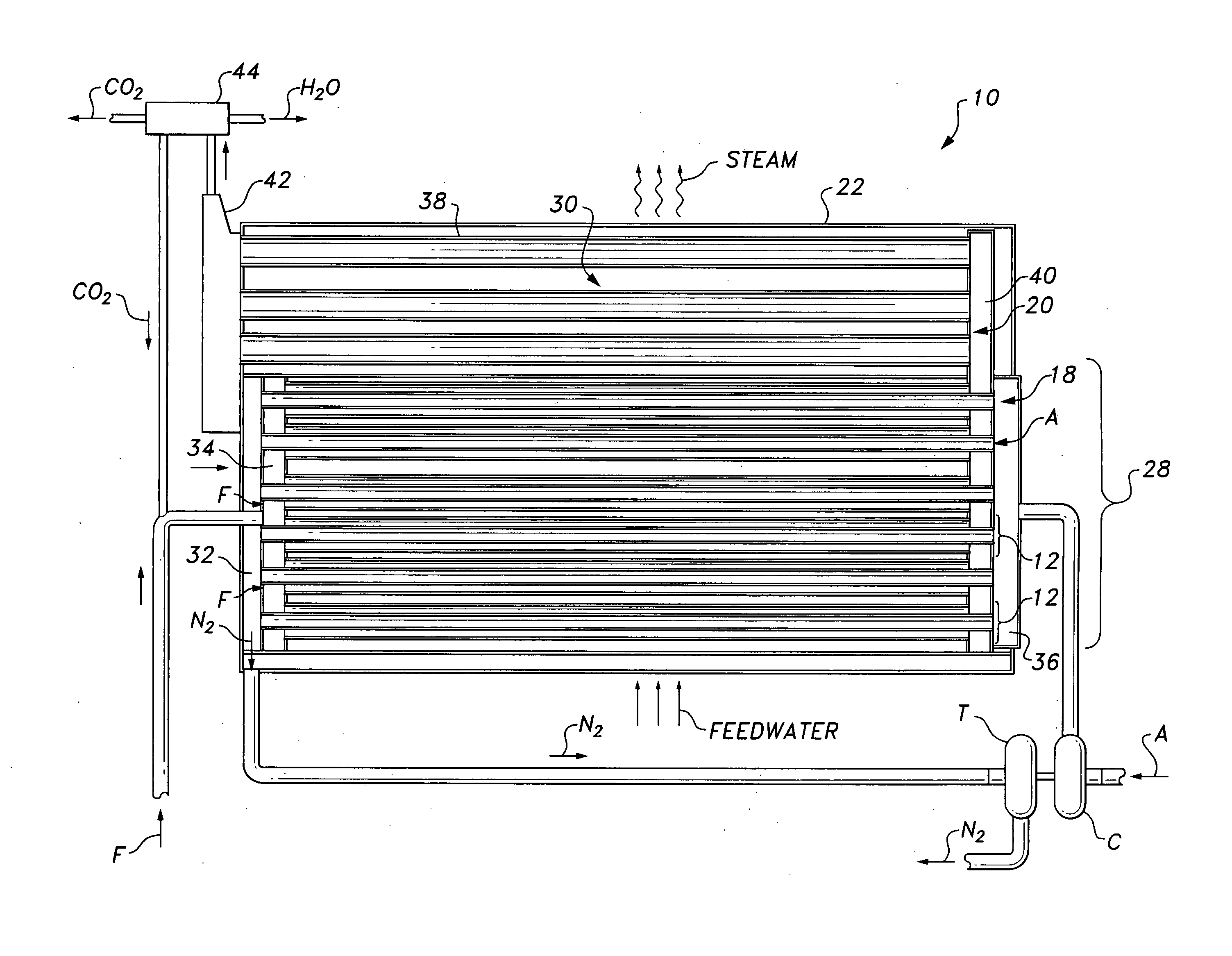

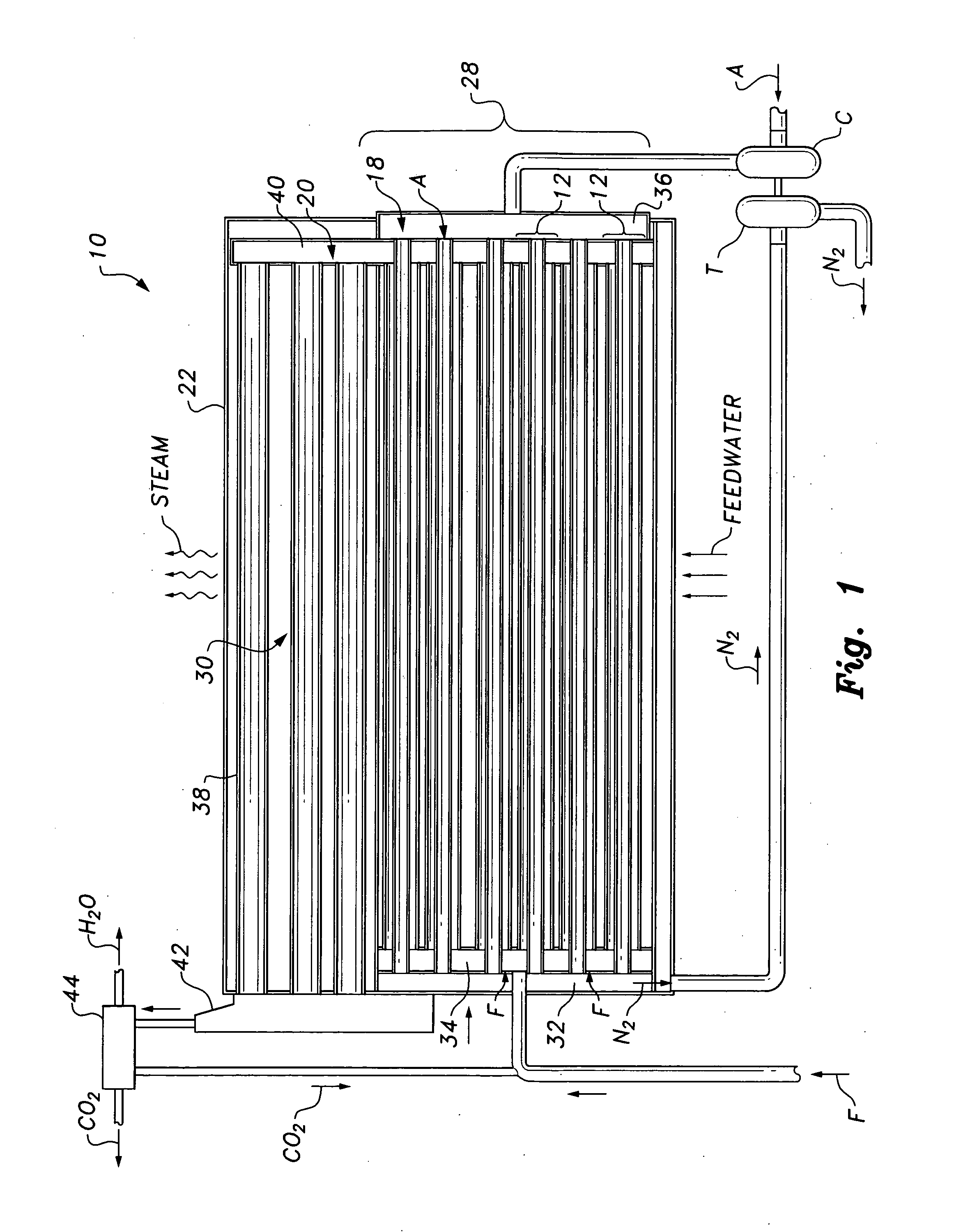

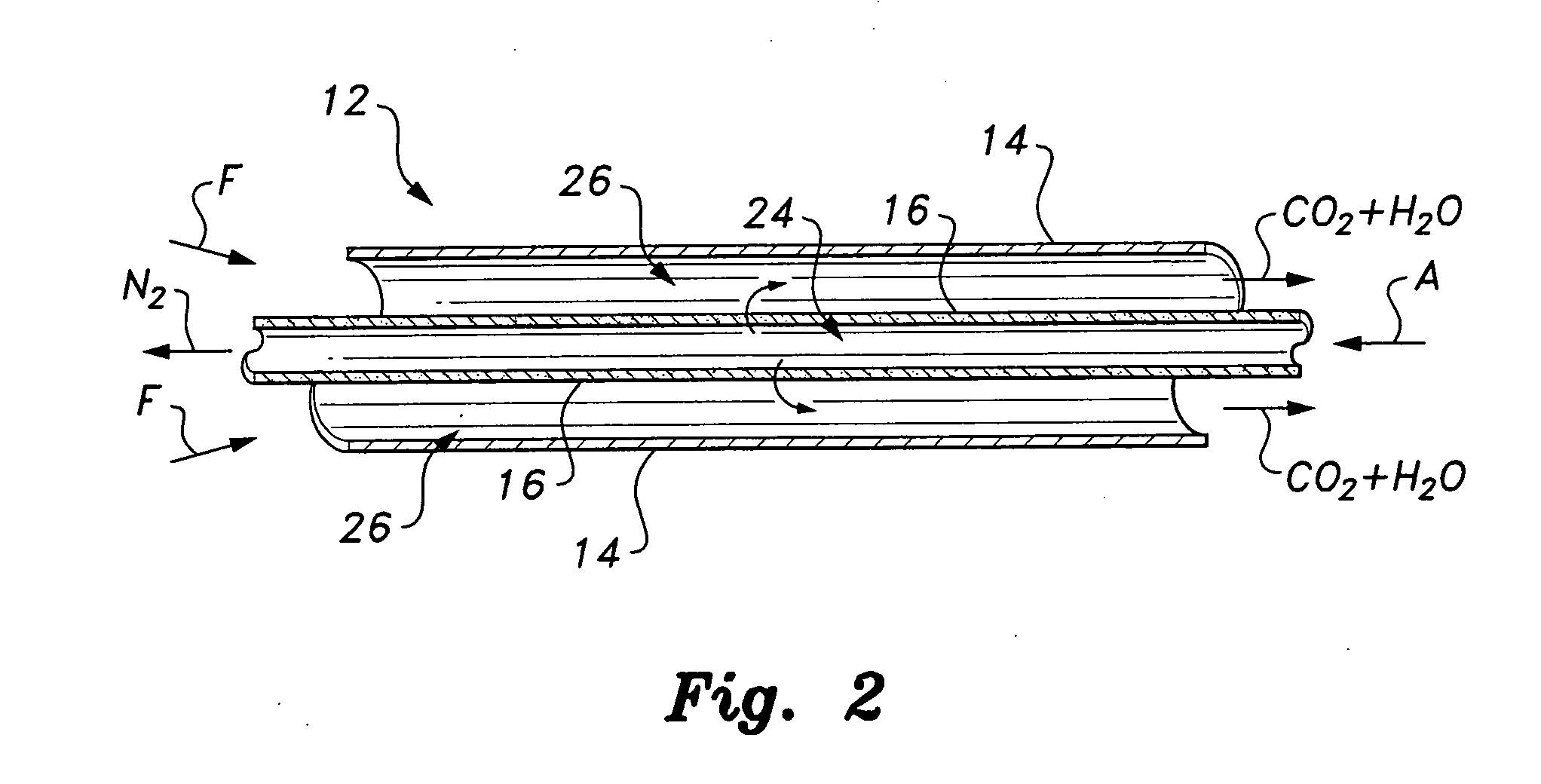

The carbon-free fire tube boiler is a boiler for heating water by combustion of hydrocarbon fuels with oxygen. The boiler includes a housing defining first and second heat transfer stages. At least one oxygen transport reactor is received within the first heat transfer stage. The oxygen transport reactor includes an outer wall and an inner cylindrical ion transport membrane. The membrane receives pressurized air and separates gaseous oxygen therefrom, transporting the oxygen into an annular region between the membrane and the outer wall. The gaseous hydrocarbon fuel is delivered into the annular region for combustion, producing gaseous carbon dioxide and water vapor. A water reservoir is defined within the first and second stages, with the at least one oxygen transport reactor and at least one transfer tube passing therethrough. The carbon dioxide and the water vapor are delivered through the at least one transfer tube for heating water contained therein.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Carbo-free fire tube boiler

InactiveUS20110132280A1Readily apparentFurnace-tube steam boilersCombustion enginesWater vaporOxygen delivery

The carbon-free fire tube boiler is a boiler for heating water by combustion of hydrocarbon fuels with oxygen. The boiler includes a housing defining first and second heat transfer stages. At least one oxygen transport reactor is received within the first heat transfer stage. The oxygen transport reactor includes an outer wall and an inner cylindrical ion transport membrane. The membrane receives pressurized air and separates gaseous oxygen therefrom, transporting the oxygen into an annular region between the membrane and the outer wall. The gaseous hydrocarbon fuel is delivered into the annular region for combustion, producing gaseous carbon dioxide and water vapor. A water reservoir is defined within the first and second stages, with the at least one oxygen transport reactor and at least one transfer tube passing therethrough. The carbon dioxide and the water vapor are delivered through the at least one transfer tube for heating water contained therein.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

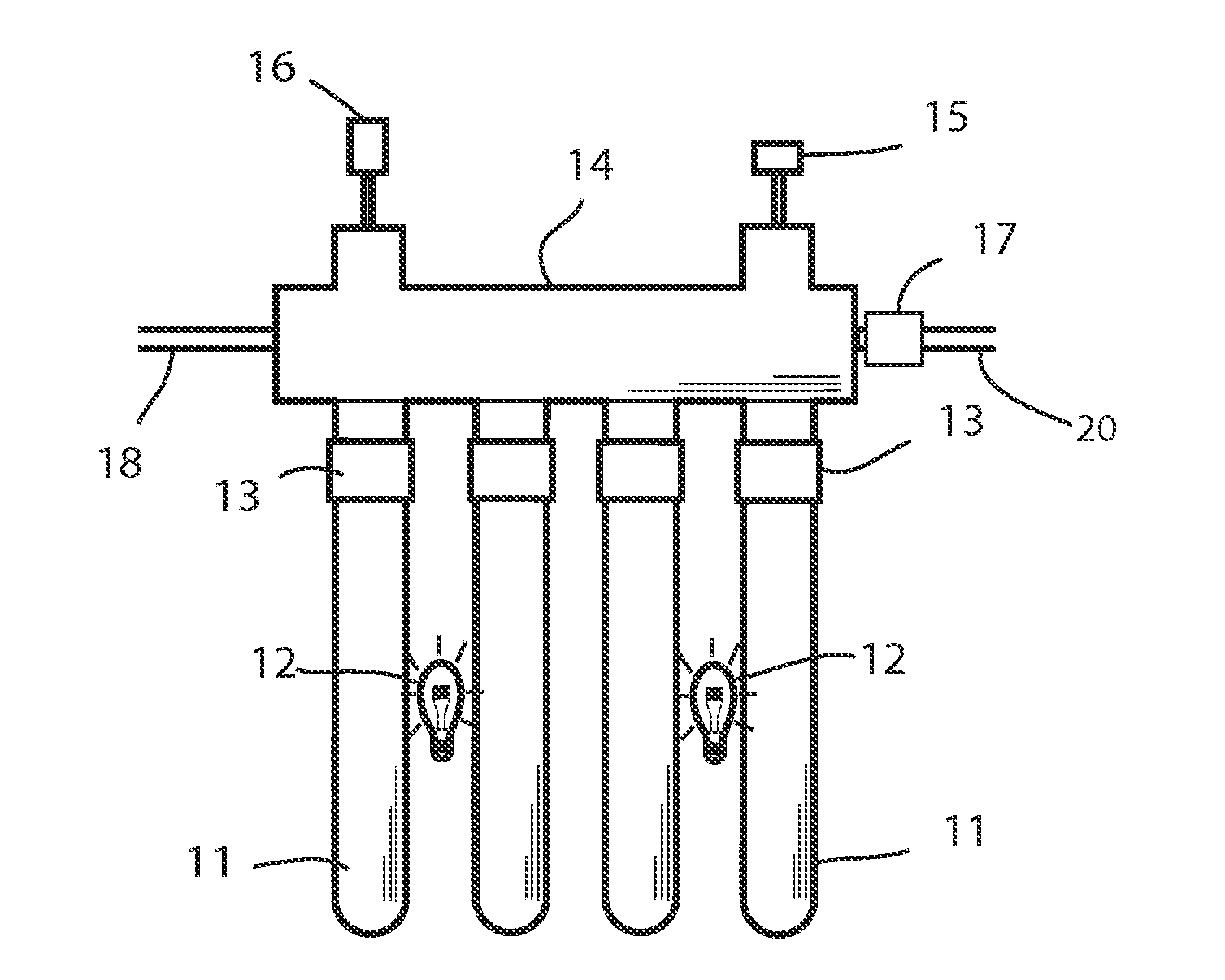

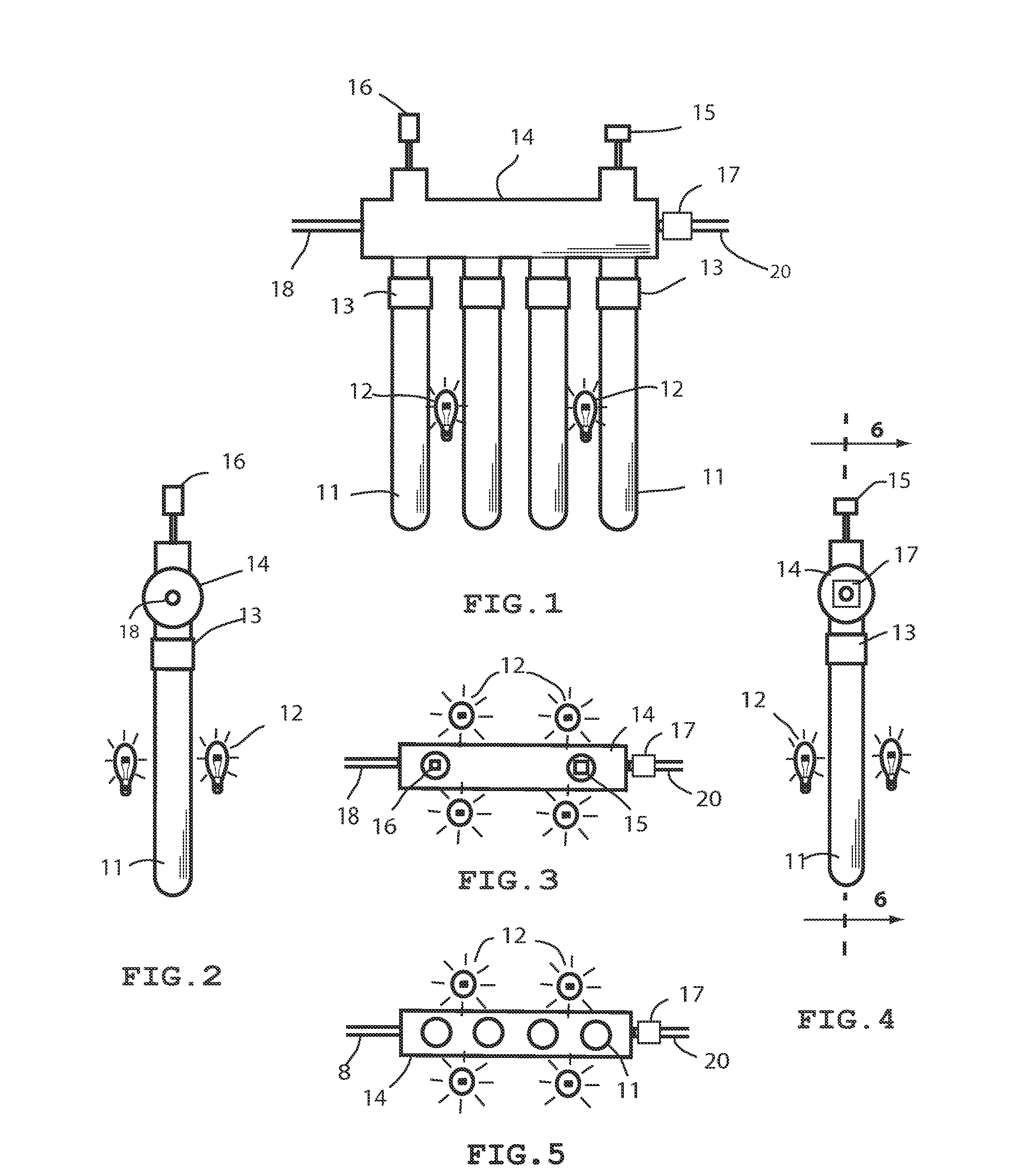

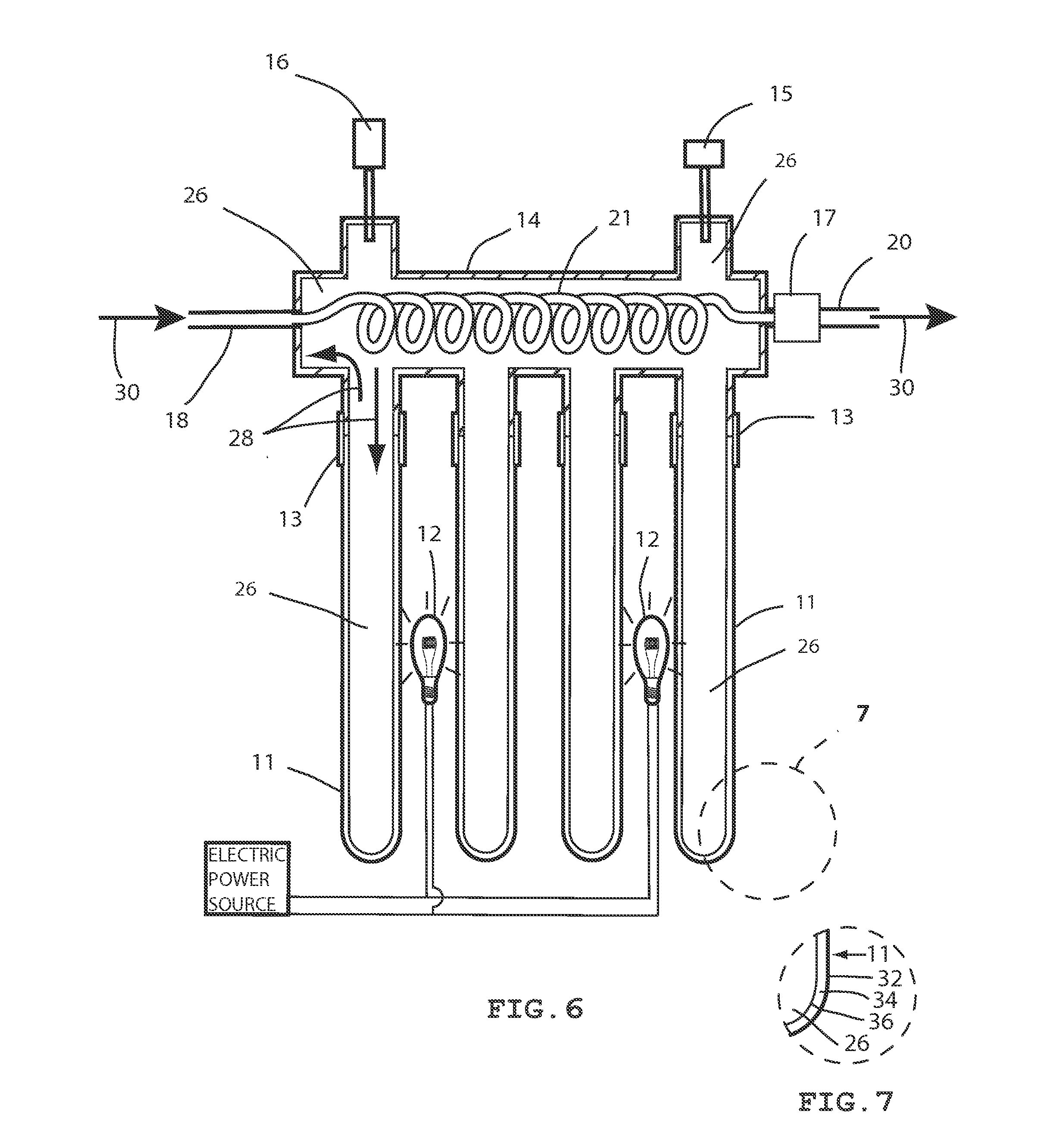

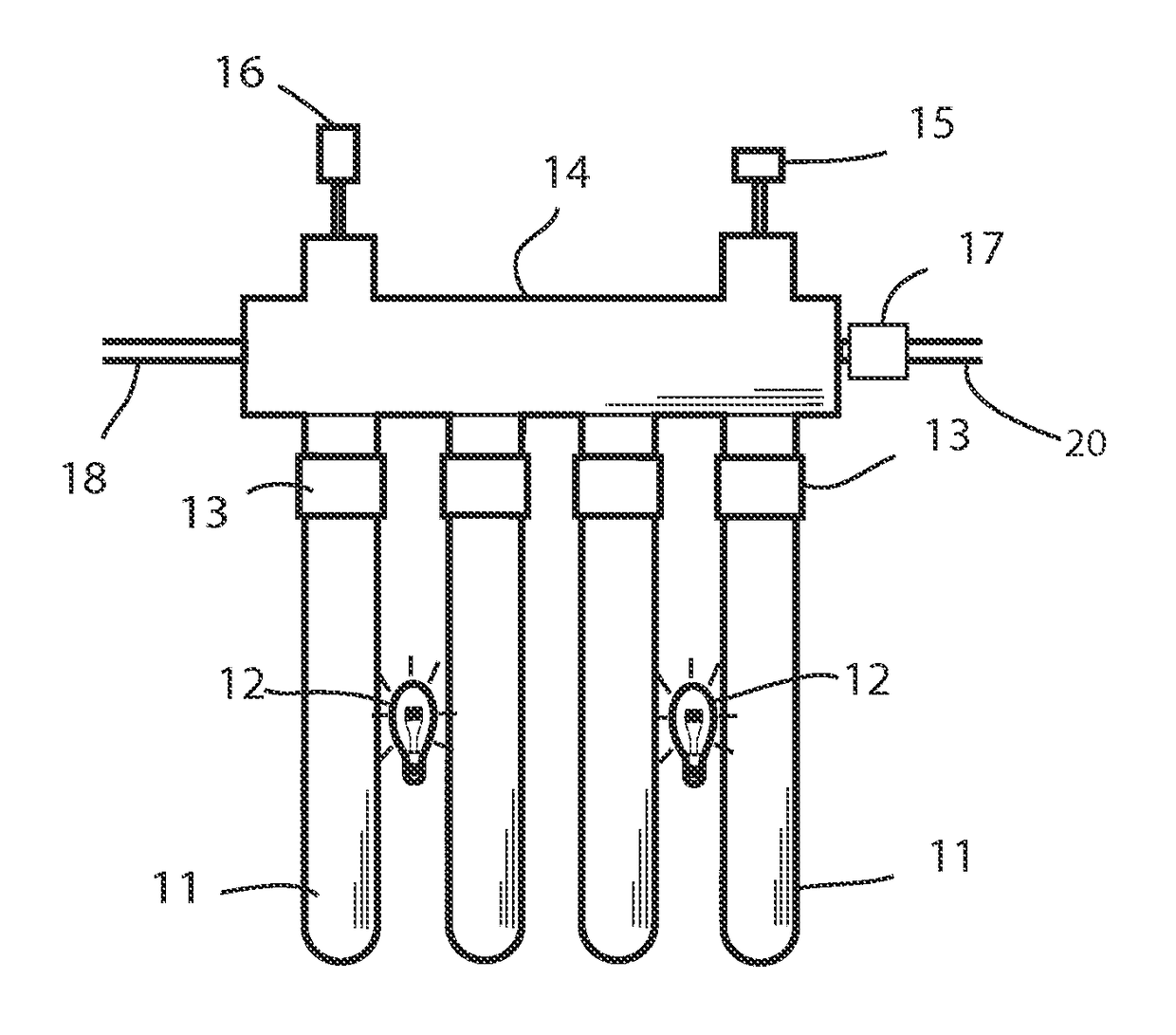

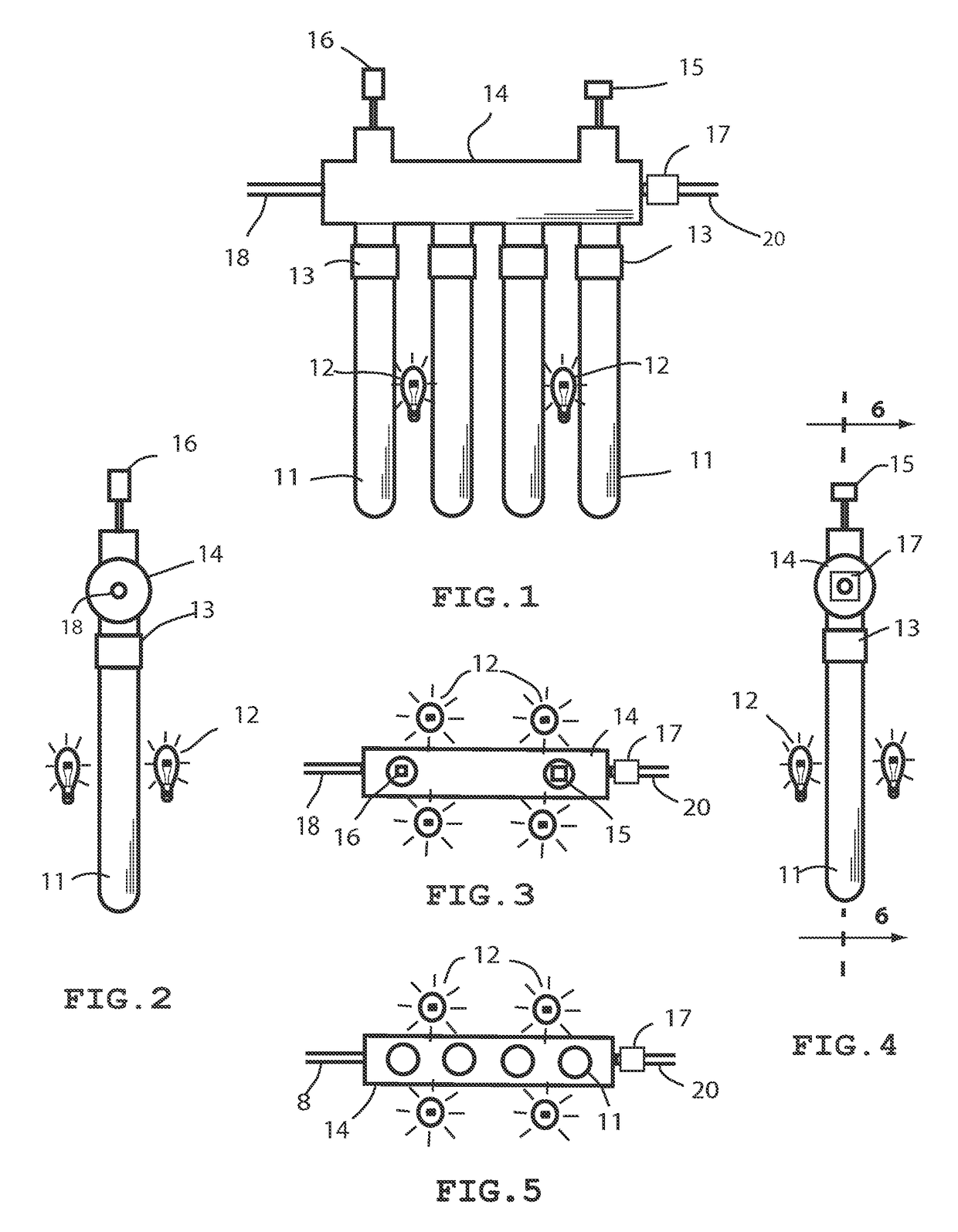

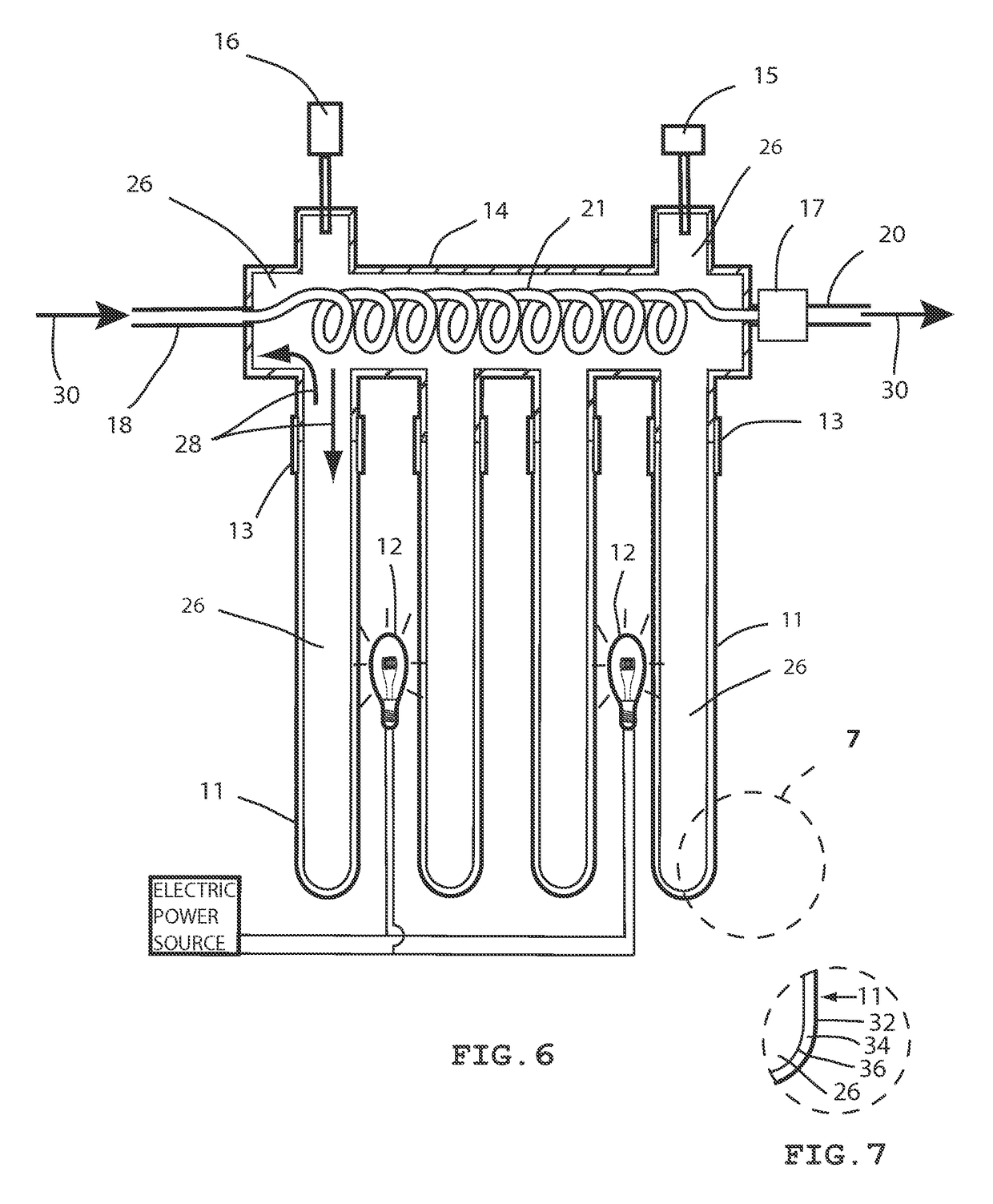

Artificial light and evacuated tube boiler

An evacuated tube boiler comprised of one or more evacuated tubes and a header, operatively connected to form a common internal volume. The internal volume further containing a first heating fluid. A conduit system conducting a second heating fluid through the header and first heating fluid. One or more artificial light sources in proximity to the evacuated tubes. In operation, the artificial light sources radiate light and / or thermal energy to the evacuated tubes whereby the first heating fluid is efficiently heated. The conduit system conducts the second heating fluid through the header and first heating fluid, whereby heat from the first heating fluid is transferred to the second heating fluid. The conduit system conducts the second heating fluid to the point of use. The apparatus may be used in a hydronic boiler heating system for heating a dwelling.

Owner:DUNN BRIAN

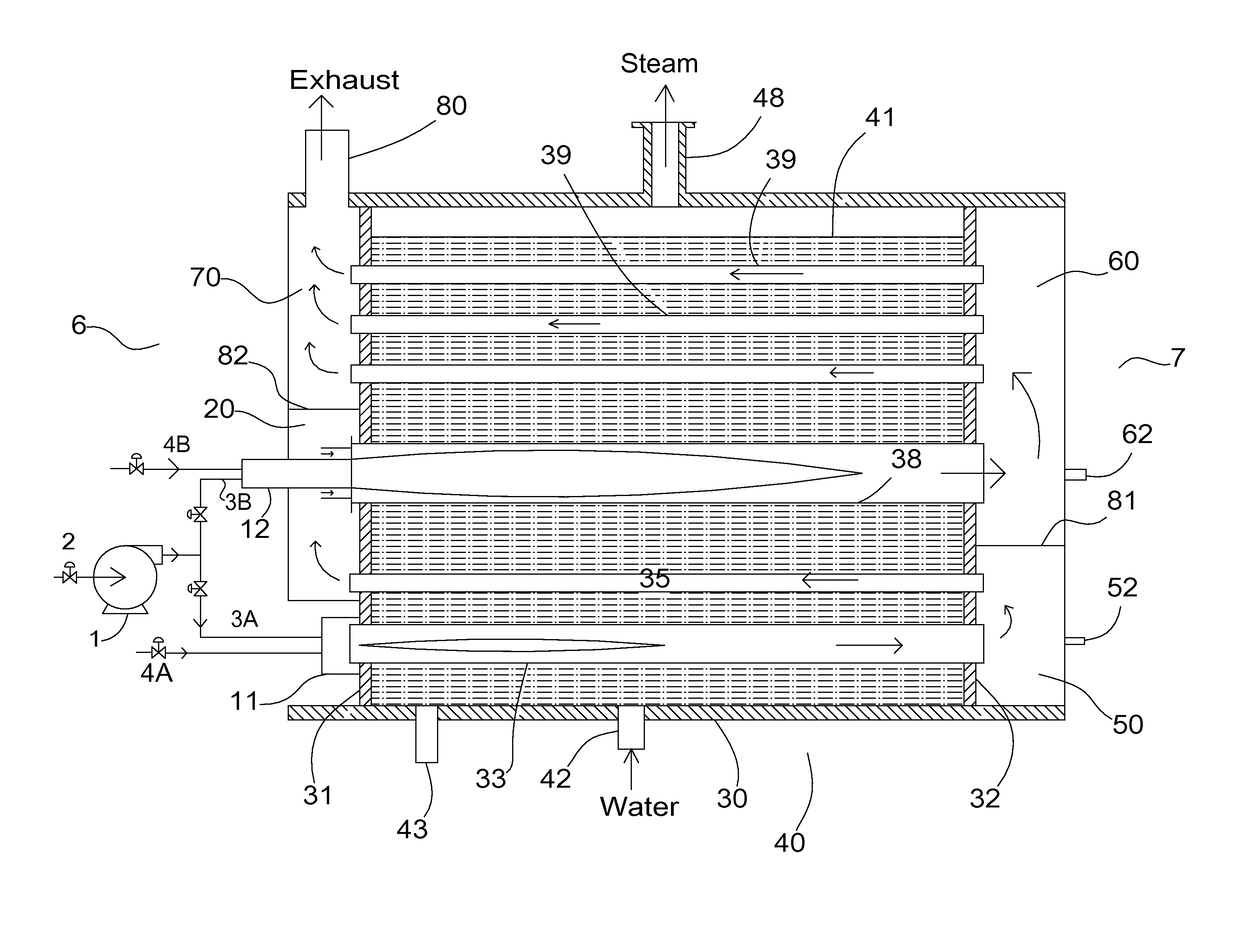

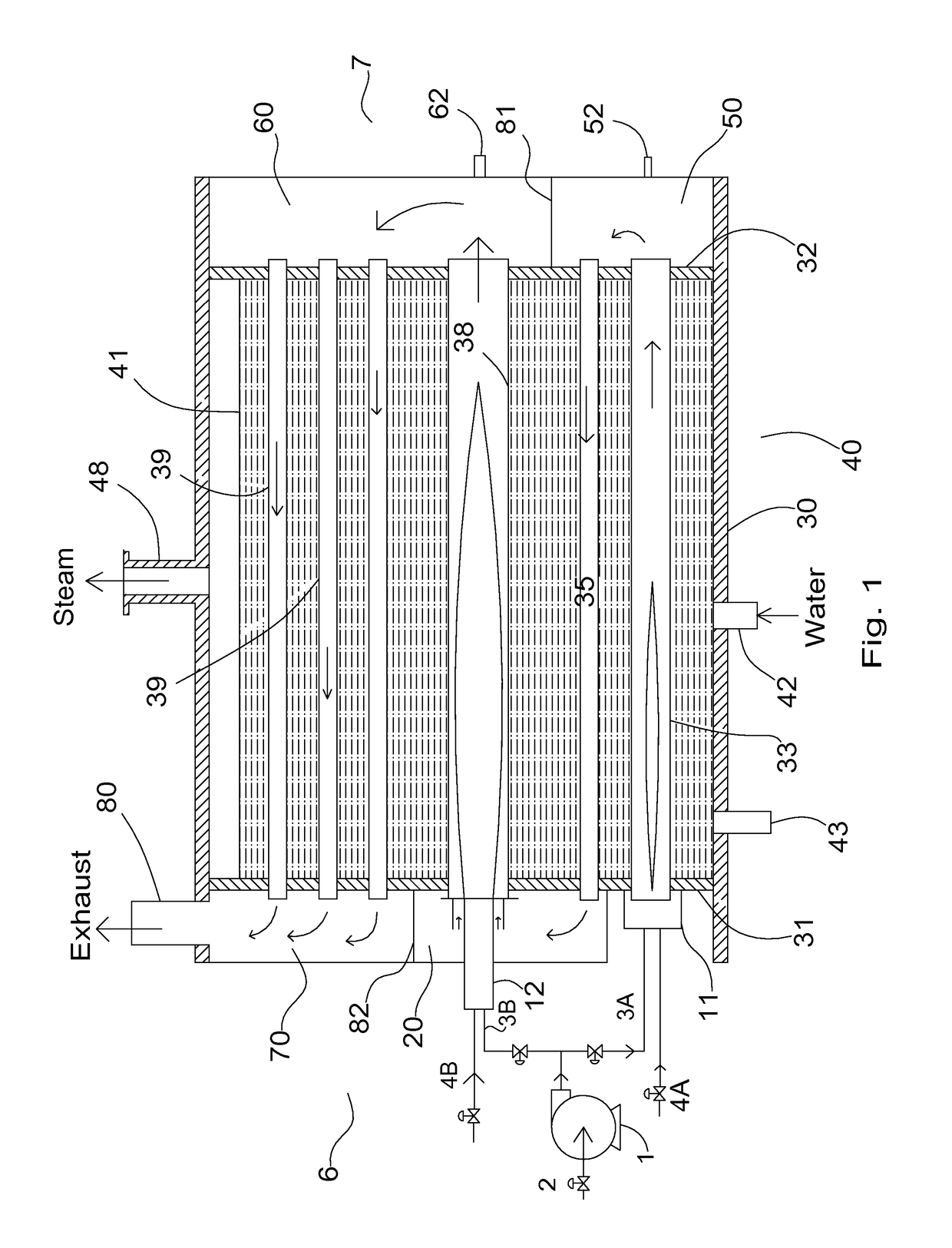

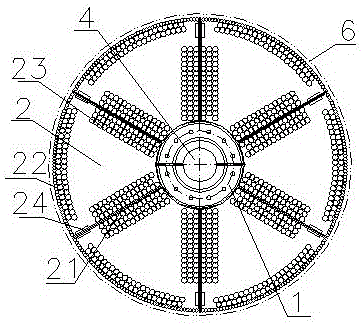

Water-tube boiler achieving internal circulation of flue gas and low-nitrogen combustion control method

ActiveCN105485897AReduce generationWill not increase the loadWater heatersCombustion regulationCombustorLow nitrogen

The invention relates to the technical field of boilers, in particular to a water-tube boiler achieving internal circulation of flue gas and a low-nitrogen combustion control method. The water-tube boiler achieving internal circulation of the flue gas comprises a boiler wall and a boiler chamber which is communicated with an outlet of a combustor, an outer side water-cooling wall is installed on the side wall of the boiler chamber, an inner side water-cooling wall is installed in the boiler chamber, and a water-cooling interlayer is formed between the outer side water-cooling wall and the inner side water-cooling wall; a flue gas backflow inlet is formed in the end, far away from the outlet of the combustor, of the water-cooling interlayer, and a lower-temperature flue gas backflow outlet is formed in the end, close to the outlet of the combustor, of the water-cooling interlayer; a low-temperature flue gas backflow zone is formed by the water-cooling interlayer, and a high-temperature flue gas radiation zone is formed by the portion, located on the inner side of the inner side water-cooling wall, of the boiler chamber. According to the water-tube boiler achieving internal circulation of the flue gas and the low-nitrogen combustion control method, by means of the circulation mode of flue gas in the boiler chamber, decreasing of combustion temperature is facilitated, generation of nitrogen oxides is reduced, the load of an induced draft fan cannot be increased, the system is easy to control, and combustion stability is good.

Owner:QINGDAO QUANNENG ENERGY SAVING ENVIRONMENTAL PROTECTION BOILER CO LTD

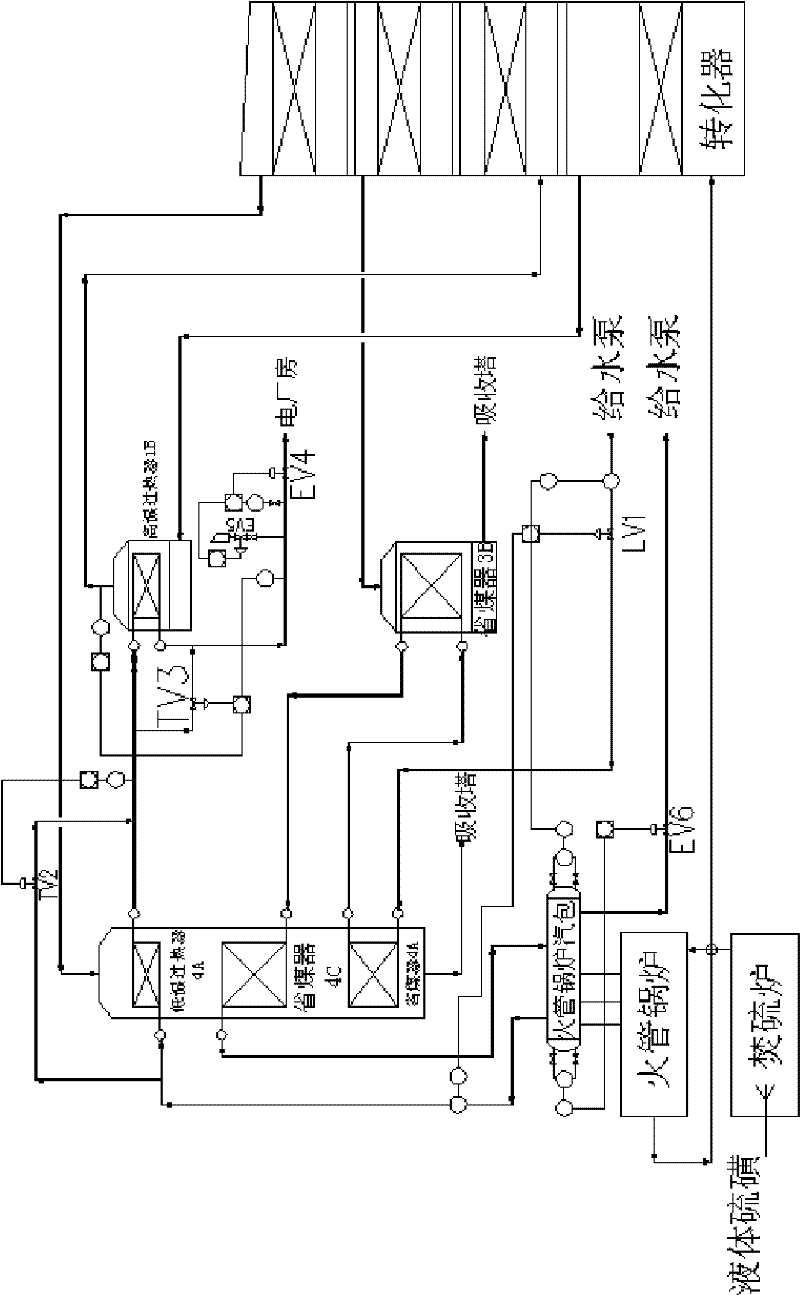

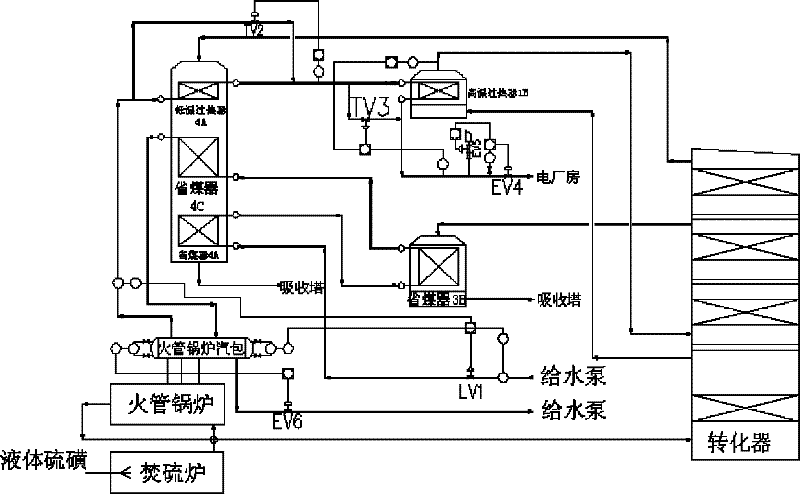

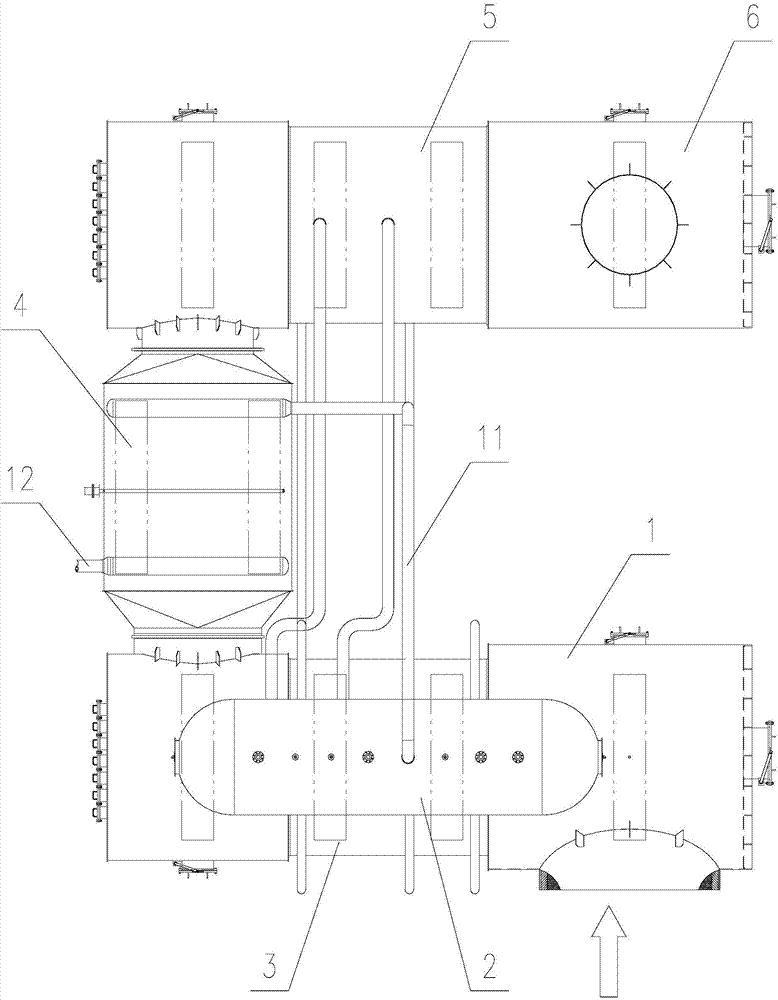

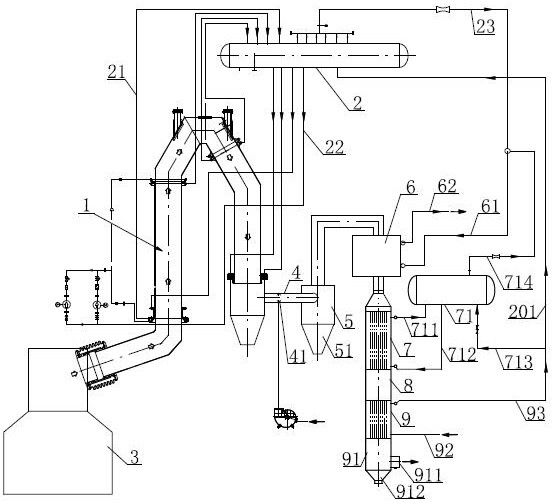

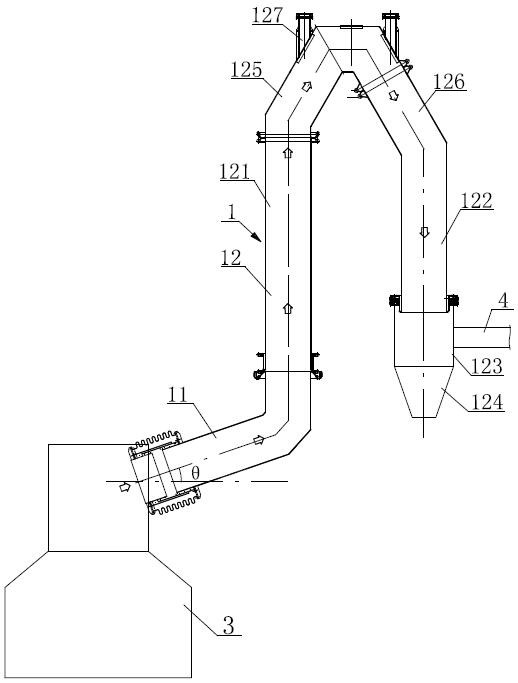

Automatic control high temperature waste heat recovery system used in process of preparing acid by sulphur

InactiveCN102444883AEnsure safetyGuaranteed reliabilityChemical industryIncinerator apparatusChemical industryAutomatic control

The invention relates to the fields of chemical industry, energy saving and environment protection, in particular to an automatic control high temperature waste heat recovery system used in the process of preparing acid by sulphur. The automatic control high temperature waste heat recovery system used in the process of preparing the acid by the sulphur comprises a fire tube boiler, a fire tube boiler steam drum, an economizer 4A, an economizer 3B, an economizer 4C, a low temperature superheater 4A, a high temperature superheater 1B and a connecting pipeline valve for forming the system. Compared with the prior art, the automatic control is adopted and the automatic control high temperature waste heat recovery system used in the process of preparing the acid by the sulphur has high technical requirements on both the arrangement among recovery equipment and the reasonableness of forming the system, is more suitable for the requirements for recovering waste heat generated by a device for preparing the acid by the sulphur in a large scale, has the advantages of investment saving, high heat recovery efficiency, long using period of equipment and capacity of adapting to the requirement of a chemical process device on continuous operation for years, is matched with an automatic control system and has high safety and reliability.

Owner:中江能源回收(上海)有限公司

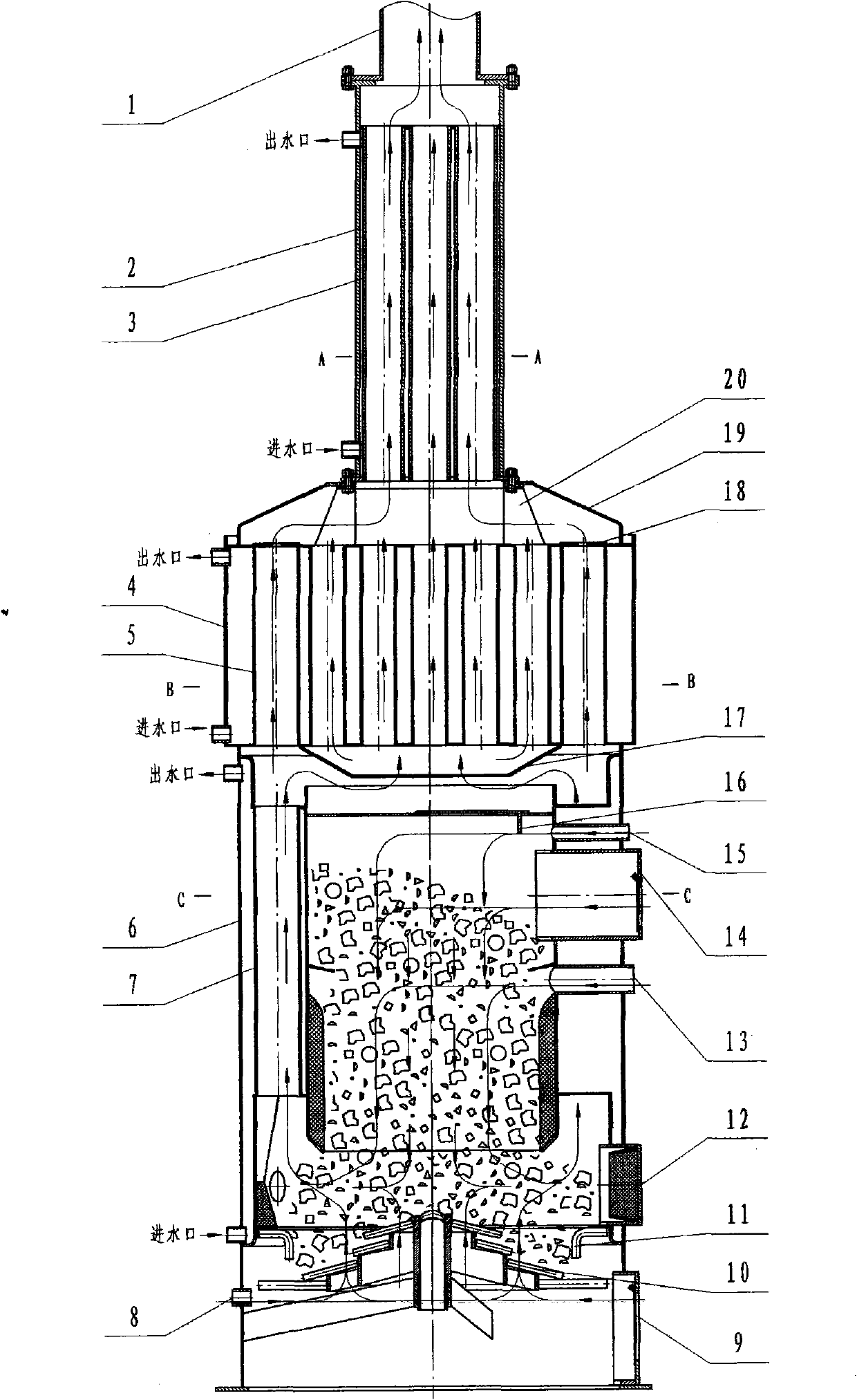

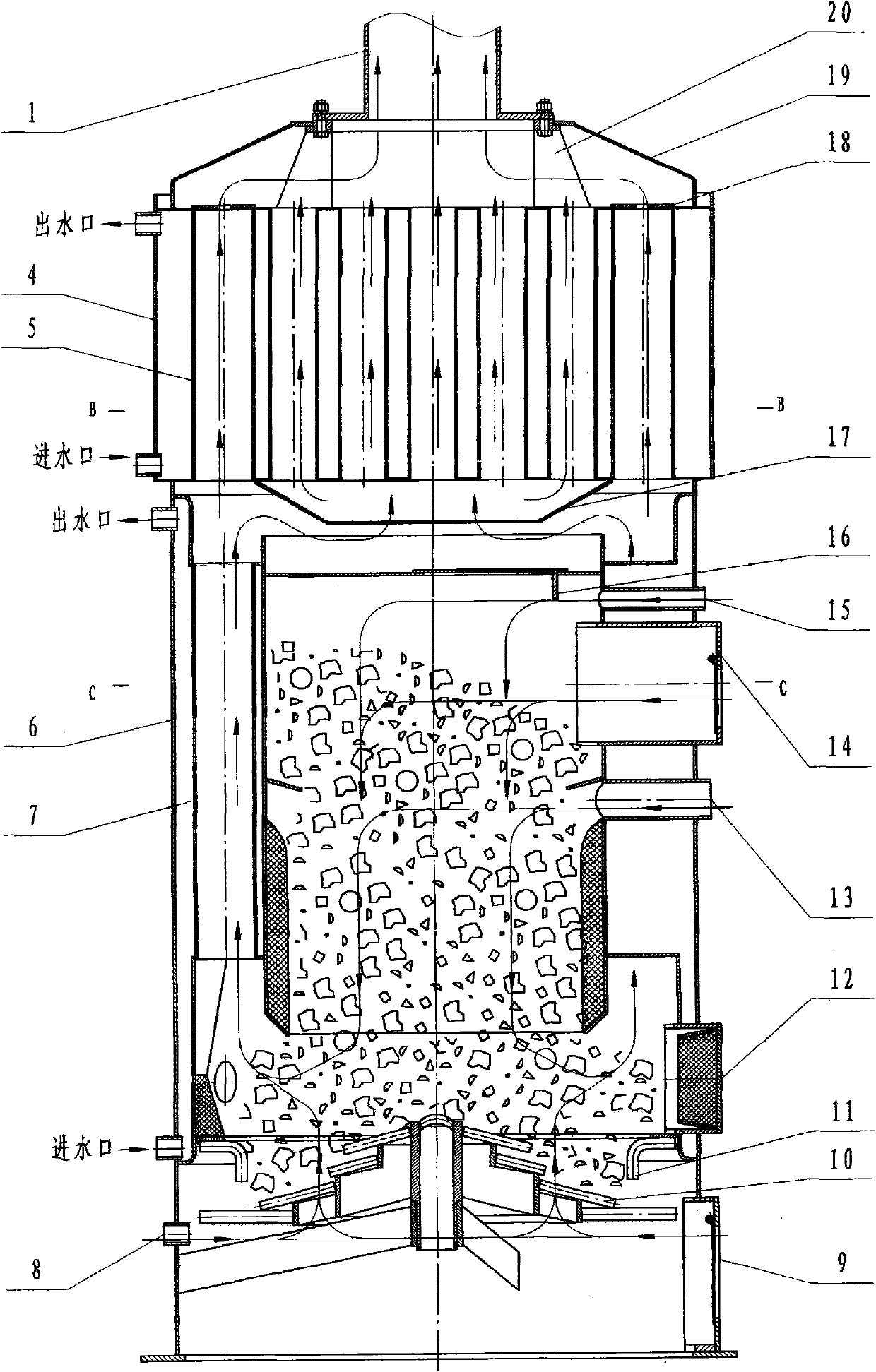

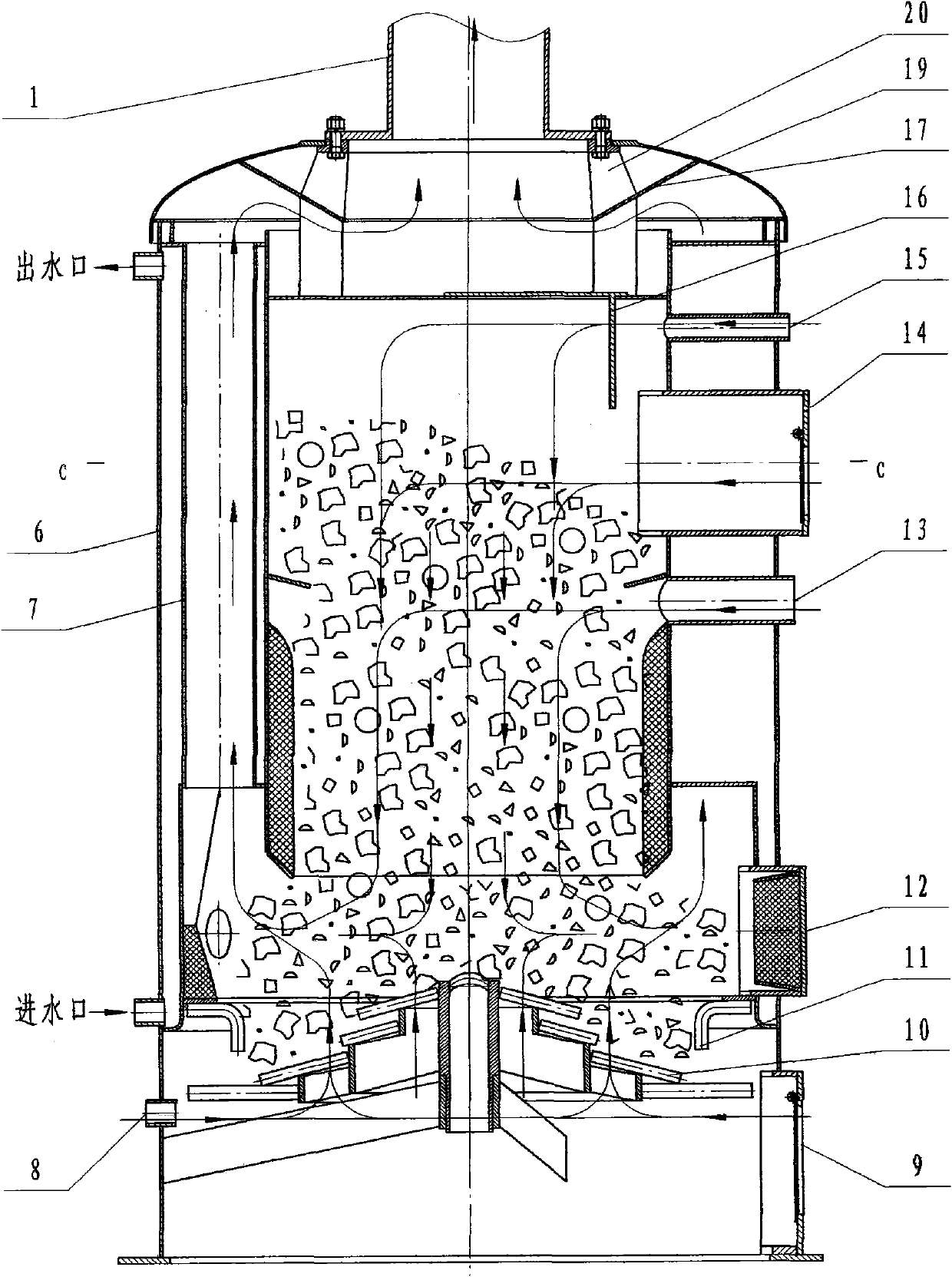

Low discharge high energy efficiency vertical shell type water-fire tube boiler

InactiveCN101187501AIncrease the lengthShorten the lengthWater heatersSteam boilersHigh energyCogeneration

A water-fire tube boiler of a low discharging high-performance vertically-arranged boiler casing type relates to eight boiler series, namely a large or middle water-fire tube grate firing, a chamber combustion, hot-water, steam, and phase-change and distributed type cogeneration boiler. The invention comprises a longitudinal barrel, a crossbar collecting box, a wall-cooling tube, a vertically-arranged boiler casing, a screw-thread fire tube and the like. The invention changes flue direction of current water-fire tube boilers from a longitudinal flue which is horizontally returned in front and back direction to a transversal flue which is vertically returned in up and down direction. Twice large dilatancies are naturally realized before smoke enters into the flue, and the vertically-arranged boiler casing is entirely barely heated in the rear portion of the flue of the boiler. The volume of a furnace and the flue and a radiative-convective heating surface are significantly enlarged with same size and same quantity of steel consumption, a five return journey of a whole forced-circulating waterway for coal and hot water is only provided with a baffle board, and a three journey of a whole forced-circulating waterway for gas (oil) is not provided with any baffle boards. Inlet water roses slowly after entering into the boiler casing, and firstly washes an upper tube sheet, and then enters into a rising tube. The invention eliminates tube explosion, tube-plate fracture and flue abrasion, the initial discharging concentration of smoke is greatly reduced, and consumption of steel and electricity is decreased.

Owner:王森

United acid manufacturing method by utilizing sulfuretted hydrogen and sulphur

ActiveCN103030115AImprove efficiencyAvoid Dew Point CorrosionSulfur compoundsHydrogenProcess equipment

The invention relates to a united acid manufacturing method by utilizing sulfuretted hydrogen and sulphur. The method is characterized in that in a united acid manufacturing production process by utilizing the sulfuretted hydrogen and the sulphur, a fire-tube boiler is adopted at a third section of outlet of a converter and behind an intermediate temperate superheater; the evaporating pressure of the boiler is controlled to be 5.1-5.6Mpa, and the saturation temperature is 265-271 DEG C, the inner wall temperature of a fire tube is improved, and the temperature of the fire tube wall is 265.5-271.4 DEG C, so that the condition that the temperature of the fire tube wall is higher than the dew point temperature of sulfuric acid in the gas is guaranteed, and the dew point temperature in a whole sulfuretted hydrogen working condition is 263 DEG C, so that the dew point corrosion is avoided; meanwhile, two acid manufacturing working conditions of a wet method and a dry method are considered, two fire tube boilers are adopted to be connected in series for operation; when the acid is manufactured by the wet method, the pressure of the two boilers is controlled to be 5.1-5.6Mpa; when the acid is manufactured by a dry method, the dew point of the sulfuric acid in the gas is about 155 DEG C according to the test of the dew point of the sulfuric acid in gas; the two boilers are separated to operate; the pressure of the first boiler is controlled to be 4.0-4.8Mpa; the pressure of the second boiler is controlled to be 1.0-1.8Mpa; and low-pressure steam is directly produced, and the heat is further recovered. With the adoption of the method provided by the invention, the dew point corrosion is avoided, and the use efficiency of process equipment is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

Low discharging and high-energy effect novel industrial boiler

InactiveCN101457981ARaise the outlet temperatureReduce carbon contentWater-tube boilersWater heatersHigh energyCogeneration

The invention discloses a novel industrial boiler with low emission and high energy efficiency, and relates to the series of twenty boilers which are different in fuels and mediums, namely large-scale grate firing: scattered coal, moulded coal and biomass and chamber firing: fuel gas, oil-fired hot water, steam, phase-conversion heat exchange and distributed heat and power cogeneration boilers. The novel industrial boiler comprises a transverse boiler, a transversal and longitudinal container, a water wall tube, a vertical boiler shell, a thread smoke tube, and the like. The invention integrates the advantages of a water-tube boiler, a water-fire tube boiler and a corner-tube boiler, more particularly solves the different defects of three types of boilers; namely, the water-tube boiler has the defects of complicated technology as well as large volume and steel consumption; the water-fire tube boiler has the defects of tube plate crackle, tube explosion, smoke tube abrasion, and the like; the corner-tube boiler has the defects that the technology is complicated technology and the dust deposition at the tail part is difficult to be eliminated; and the invention also greatly improves the difficult problems of the three types of boilers that the initial emission concentration of smoke and dust is higher generally. The invention has the advantages of advanced installation technology and extremely obvious energy conservation and emission reduction.

Owner:王森

A full membrane wall water fire tube boiler

The invention relates to a full-film type wall water-fire tube boiler. The boiler comprises a hearth which is of a full-film type wall structure, a burner which is fixedly connected to one end of the hearth, a turning smoke chamber which is of a full-film type wall structure, a heat exchanger and a steam drum. An outlet smokestack is arranged on one side of the hearth. One end of the turning smoke chamber is connected with the outlet smokestack, and the other end of the turning smoke chamber is connected with the heat exchanger. The connecting joint between the turning smoke chamber and the outlet smokestack and the connecting joint between the turning smoke chamber and the heat exchanger are each provided with an annular header. A film type wall water-cooled tube of the turning smoke chamber communicates with a shell of the heat exchanger through the annular header located at the position of the heat exchanger. The steam drum communicates with the film type wall water-cooled tube of the turning smoke chamber through the annular header located at the position of the outlet smokestack. Meanwhile, the steam drum directly communicates with a film type wall water-cooled tube of the hearth and forms a circulation heat exchange channel. The full-film type wall water-fire tube boiler includes various structures, boiler capacity covers the full industrial boiler range, and thus the boiler can be widely applied to various conditions where water-fire tube boilers are needed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

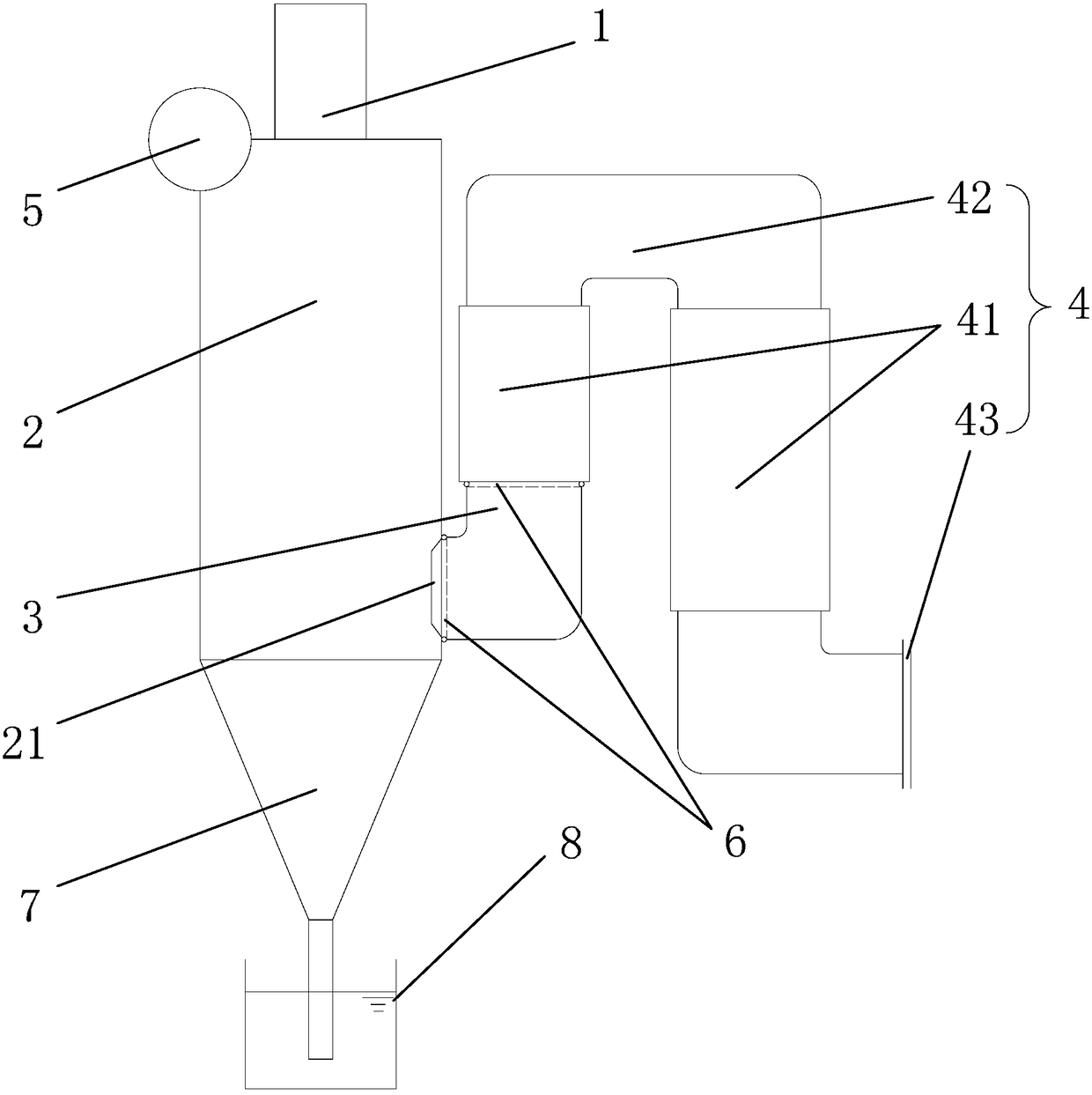

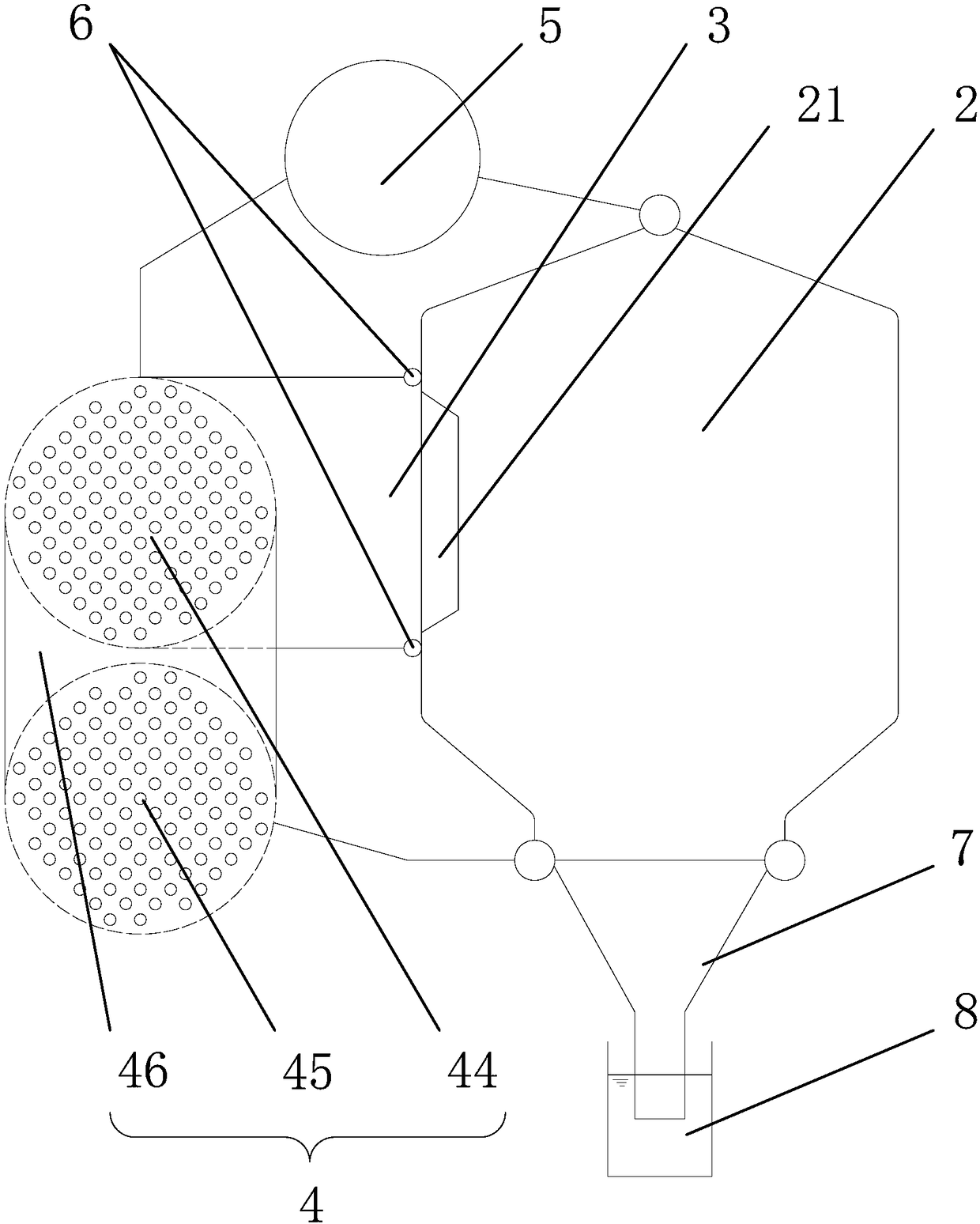

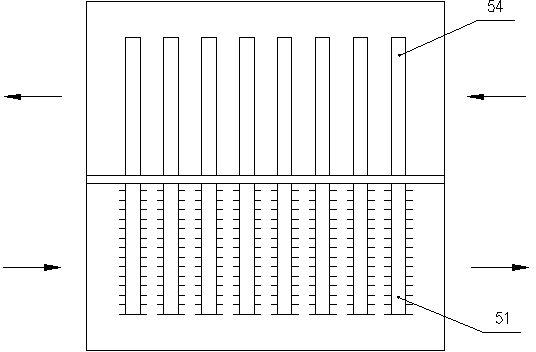

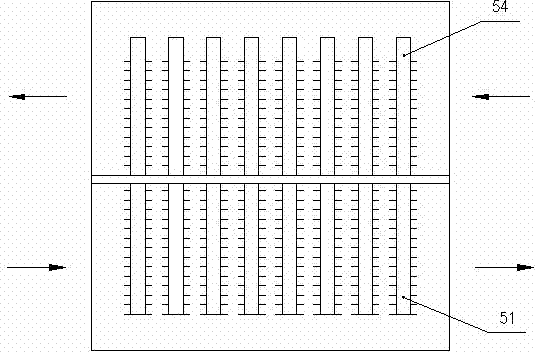

Horizontal fire tube boiler with tail provided with gas-water heat tube heat exchange tube

InactiveCN104110670ALower exhaust gas temperatureHigh thermal efficiencyWater heatersSteam boilersCombustorWater flow

The invention relates to a horizontal fire tube boiler with the tail provided with a gas-water heat tube heat exchange tube and belongs to the technical field of heating equipment. The horizontal fire tube boiler comprises a burner (1), a boiler body (2), a turning smoke chamber (3) and a coal economizer (4). The burner (1) is arranged at the front end of the boiler body (2), and the coal economizer (4) is arranged at the top of the boiler body (2). The horizontal fire tube boiler is characterized in that a gas-water heat tube heat exchanger (5) is arranged at the back of the coal economizer (4) and is also arranged at the top of the boiler body (2). According to the horizontal fire tube boiler, the flue gas temperature can be further reduced, even flue gas condensation is achieved, latent heat of vaporization is released, boiler efficiency is improved, the water inflow temperature of the boiler rises, and fuel consumption is reduced. Besides, the problem that blowing down overhauling occurs due to gas-water flow communication when a heat tube is damaged is solved. The horizontal fire tube boiler can be independently arranged based on existing boiler energy saving technology transformation.

Owner:JIANGSU SHUANGLIANG BOILER

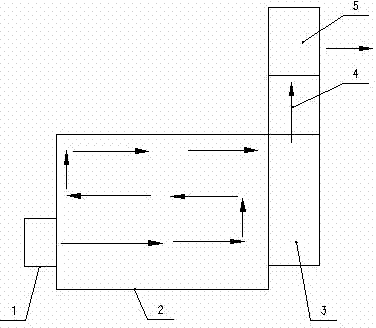

High efficient boiler

InactiveCN102418915AEasy to clean upHigh thermal efficiencyBoiler drums/headersBoiler supporting/setting arrangementsCombustion chamberEngineering

The invention relates to a high efficient fire standpipe boiler, which generally consists of a boiler housing, a boiler flue, a boiler flue top, an internal upper smoke chamber, a smoke-fire standpipe, a lower smoke chamber, a boiler base and the like. A smoke-fire standpipe bundle is orderly arranged between an upper pipe plate and a lower pipe plate, the smoke-fire standpipe bundle consists of a plurality of metal standpipes, the upper pipe plate and the internal upper smoke chamber are arranged above the smoke-fire pipe bundle, a sealing cover plate which can be opened and is provided with a heat preserving layer is arranged above the upper smoke chamber, a combustion chamber is arranged below the lower pipe plate of a first travel-route smoke-fire pipe bundle, the lower smoke chamber is arranged below the other travel-route smoke-fire pipe bundles, the orientation and the travel route of the smoke are decided by the existence of separating plates inside the upper and the lower smoke chambers and the quantity of the separating plates, and the boiler can be divided into a two-travel-route heat absorption structure, a three-travel-route heat absorption structure and a multi-travel-route heat absorption structure according to the orientation of the smoke in the smoke-fire pipe bundle. Due to the adoption of the smoke-fire pipe bundle consisting of the multi-travel-route metal standpipes, the accumulated charcoal and the water scale can be convenient to clear, the smoke exhaustion temperature can be effectively reduced, and the boiler heat efficiency can be improved; and due to the solving of the local high temperature and the heat expansion stress problems, the overall durability of the boiler can be improved, and the service life of the boiler can be prolonged.

Owner:蒋恩良

Low discharge high energy efficiency vertical shell type water-fire tube boiler

InactiveCN101187467AIncrease the lengthShorten the lengthSteam generation plantsHigh energyCogeneration

A vertically-arranged spiral-cased water-gas-tube boiler which is low discharge and high energy efficiency relates to the thirties big boilers series, namely that large-size and middle-sized water-gas-tube grate firing boilers of loose coal, molded coal and biological energy, or gas and fuel oil of boilers in household, and comprises a hot-water boiler, a vapor boiler, a phase-change heat transfer hot-water boiler and a distributed thermo-electricity cogeneration boiler. The invention comprises a longitudinally-arranged barrel, a crossbar collection chamber, a wall-cooling pipe, a vertically-arranged spiral casing, and a thread flue tube and the like. The invention changes the flue way of a current water-gas-tube boiler from a longitudinal flue way which horizontally returns front and rear to a transverse flue way which vertically returns up and down. Smoke is naturally realized two large flashes before entering the flue tube. The vertically-arranged spiral casing is totally exposed and heated in the tail flue way of the boiler. With the same volume of the boiler and steel consumption, the invention significantly enlarges the capacities of a hearth and the flue way and radiating convection heating area. Only one baffle is arranged in five returns of a coal-fired hot water total forced-circulation waterway, and three returns of a gas-fired total forced-circulation waterway is not provided with a baffle, which not only completely eliminates tube explosion, tube plate crack and fuel tube abrasion, but also a smoke sedimentation chamber is arranged on the front bottom portion of a smoke-discharge mouth, which largely reduces the initial discharge concentration of smoke.

Owner:王森

Horizontal hot water boiler

InactiveCN102721170AIncrease heat absorption areaReduce the burden onWater heatersEngineeringThermal expansion

A horizontal hot water boiler belongs to the technical field of boilers. According to the boiler, the running time and the running distance of high-temperature smoke before entering a heat absorber of a smoke and fire tube are prolonged, so that fuels can be burned sufficiently; the phenomenon that accumulated carbon falls on a fuel bed and is smoky in a vertical fire tube boiler can be avoided when the accumulated carbon is removed; and during the initial running period of the horizontal hot water boiler, the phenomenon that condensate water falls on the fuel bed so as to affect the burning can not occur, an upper smoke chamber selects a water cooling structure, and a lower smoke chamber selects a non-water-cooling structure, so that the rear of a lower tube plate is obviously larger than that of an upper tube plate, a smoke tube positioned on the lower tube plate is far away from the edge of the tube plate, so that the stress caused by thermal expansion can be alleviated. A vertical baffle plate is additionally arranged on the upper smoke chamber of the heat absorber, so that two strokes of the high-temperature smoke in the heat absorber are realized. A hand hole door for removing accumulated carbon is arranged on the upper surface of the upper smoke chamber with two strokes of smoke tube bundles, the hand hole door for removing accumulated carbon can be opened to remove the accumulated carbon, and the accumulated carbon can be removed without opening the hand hole door for removing the accumulated carbon by adopting a pre-embedded smoke tube brush structure.

Owner:蒋恩良

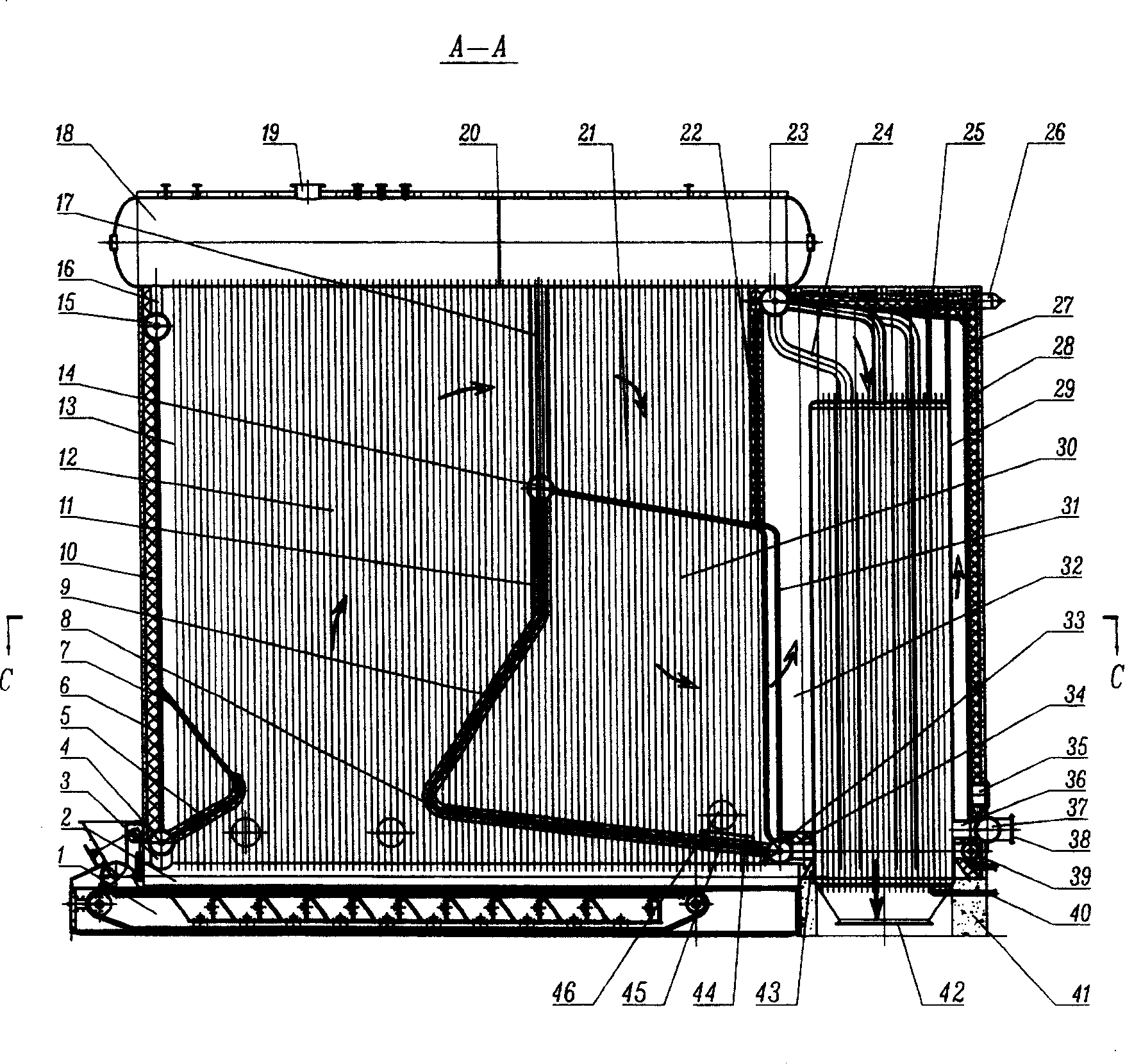

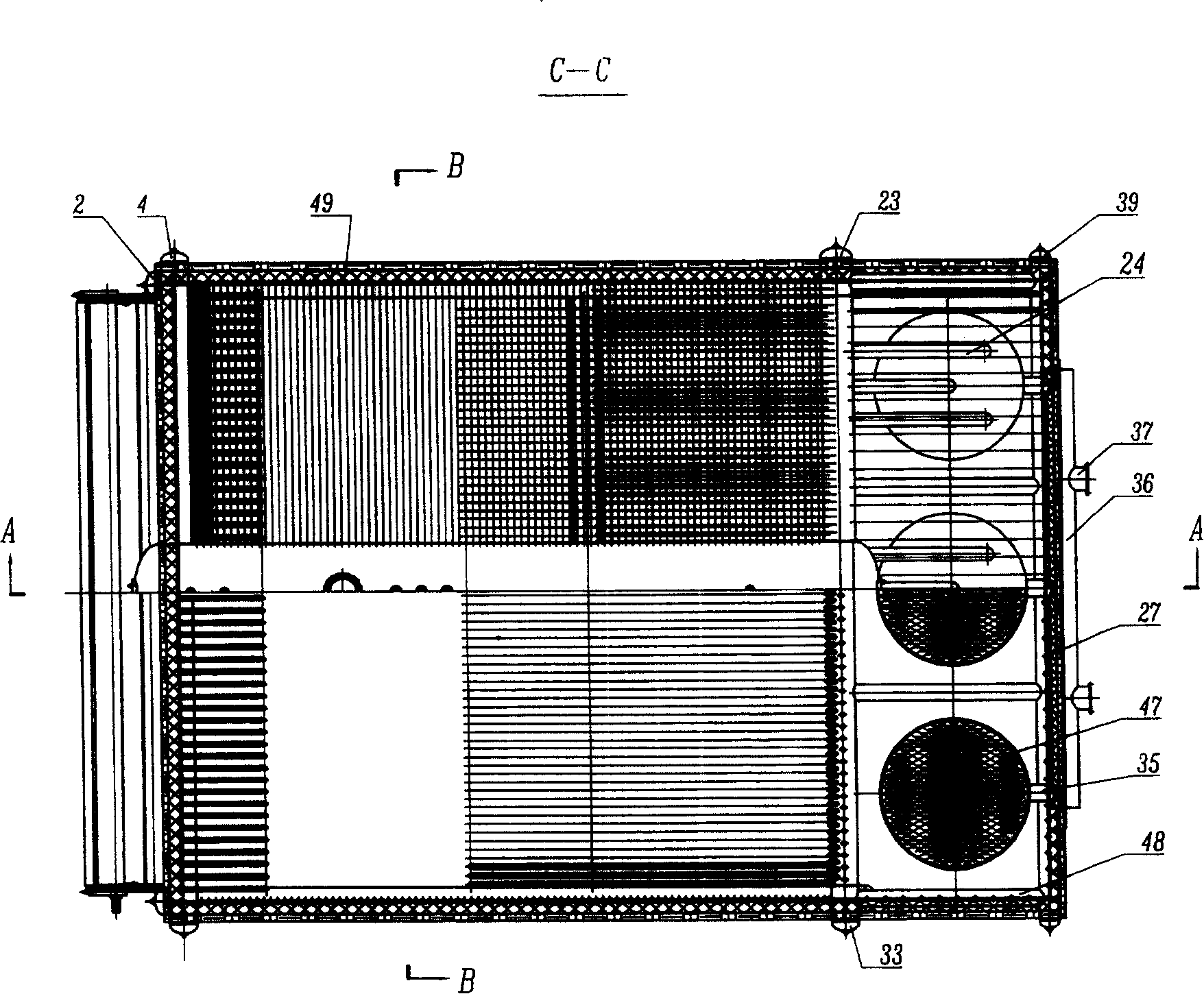

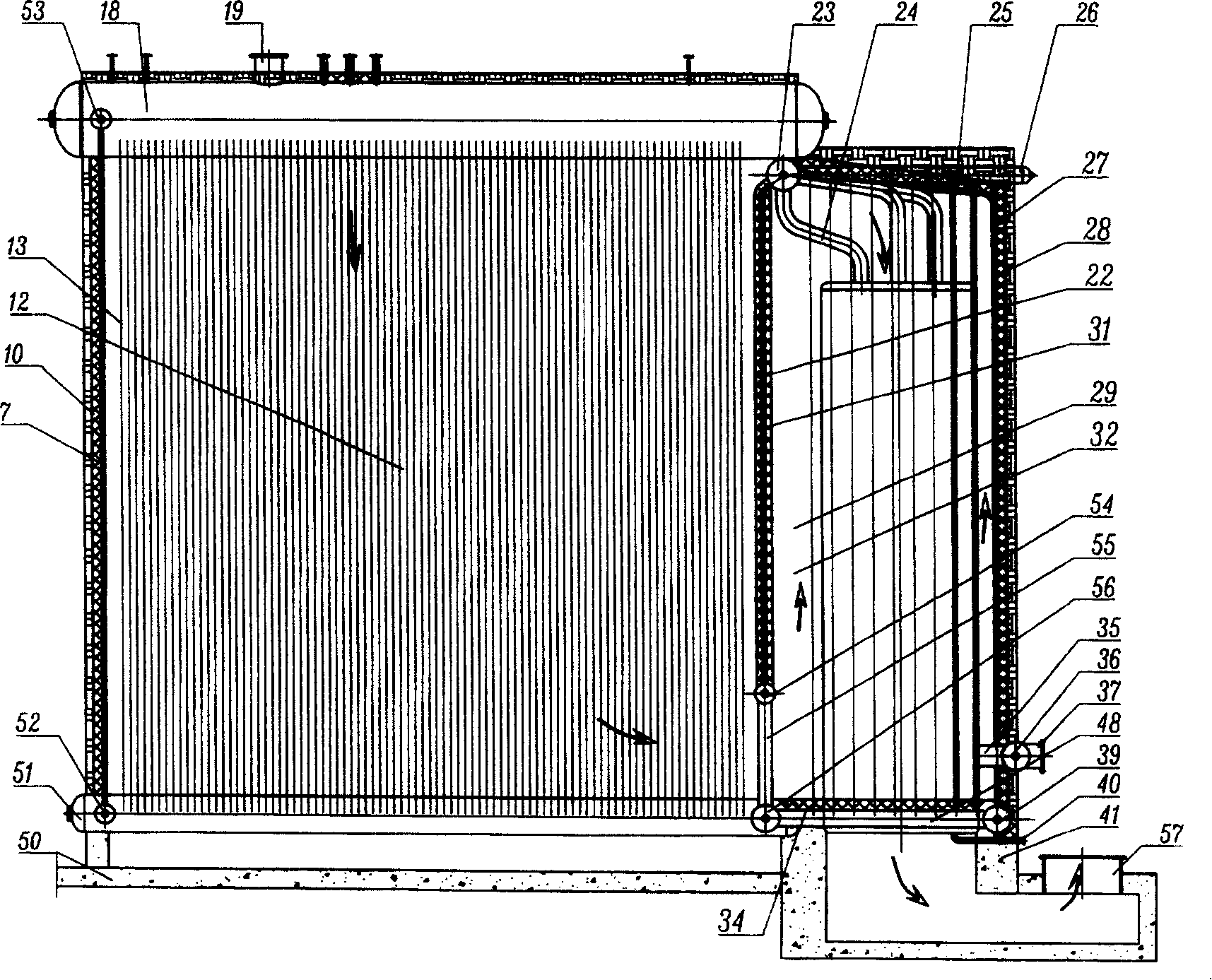

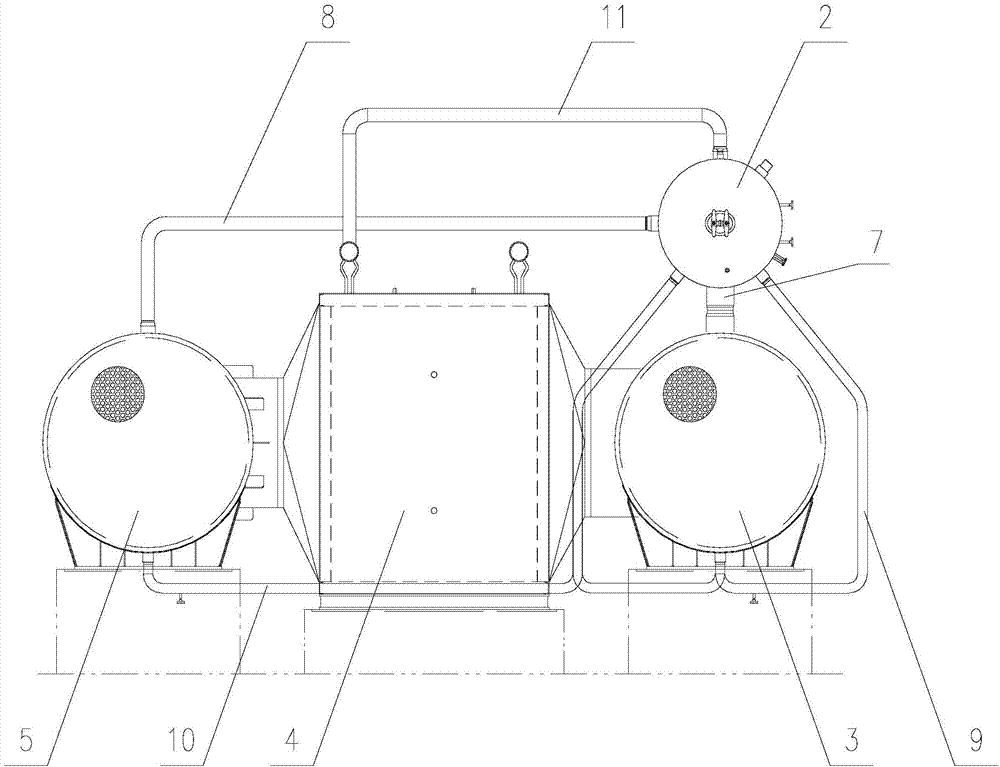

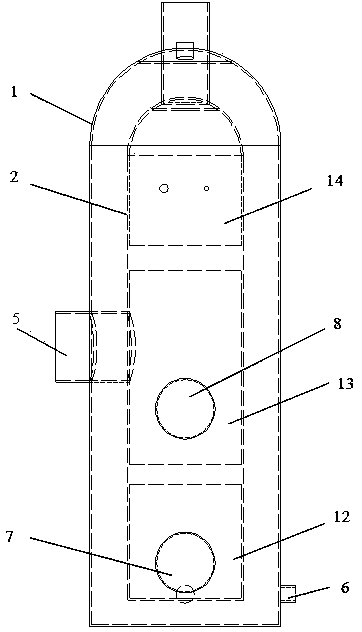

Boiler shell middle sectional type sulfur acid producing fire-tube boiler with superheater

InactiveCN103672840AReduce heat transfer areaLower working temperatureFire-tube steam boilersSteam superheatersHeat transmissionWorking temperature

The invention relates to the technical field of sulfur acid production, in particular to a boiler shell middle sectional type sulfur acid producing fire-tube boiler with a superheater. The boiler shell middle sectional type sulfur acid producing fire-tube boiler with the superheater comprises a steam drum, the superheater, a boiler shell, an inlet smoke box and an outlet smoke box. The boiler shell middle sectional type sulfur acid producing fire-tube boiler with the superheater is characterized in that the boiler shell comprises a high-temperature boiler shell section and a low-temperature boiler shell section, one end of the inlet smoke box is connected with one end of the high-temperature boiler shell section, the other end of the high-temperature boiler shell section is connected with one end of the superheater, the other end of the superheater is connected with one end of the low-temperature boiler shell section, the other end of the lower-temperature boiler shell section is connected with one end of the outlet smoke box, and the steam drum is arranged above the high-temperature boiler shell section. Compared with the prior art, the boiler shell is divided into the two sections, and the superheater is arranged between the two sections of the boiler shell. The superheater is arranged in front of the low-temperature boiler shell, and thus the heat transmission temperature difference of the steam side and the smoke side of the superheater is improved greatly; the superheater is arranged behind the high-temperature boiler shell, the working temperature of the superheater is reduced greatly, and the safety of the superheater is improved.

Owner:中江能源回收(上海)有限公司

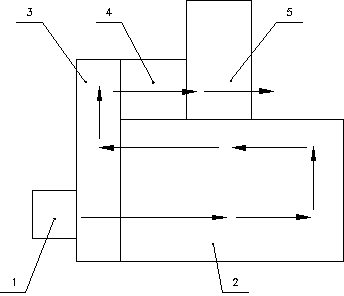

Counter current heat exchanging water-fire tube boiler capable of saving energy and protecting environment

InactiveCN102116526AReduce incomplete combustionReduce lossesWater heatersCombustion chamberFlue gas

The invention relates to a counter current heating exchanging water-fire tube boiler capable of saving energy and protecting the environment, which comprises a boiler shell, a containing box, a convection tube, a smoke-fire tube, a smoke separating wall, a combustion chamber and a convection tube flue, wherein high-temperature flue gas with two return trips firstly passes through a position with higher water temperature at the water side of the smoke-fire tube in the boiler shell for exchanging heat, then lower-temperature flue gas with three return trips passes through the convection tube with lower temperature at the water side of the convection tube flue for exchanging heat, and the flue gas is discharged out of the boiler body after the heat exchange; the original downstream heat exchanging means is completely changed; counter current heat exchange is realized; energy sources are saved; carbon dioxide emission is reduced; the purposes of saving energy and protecting the environment are achieved; the counter current heating exchanging water-fire tube boiler can be produced by adopting a normal boiler production technology; and the reconstruction of an existing boiler can be realized by only changing the flow of the flue gas.

Owner:陈雅华

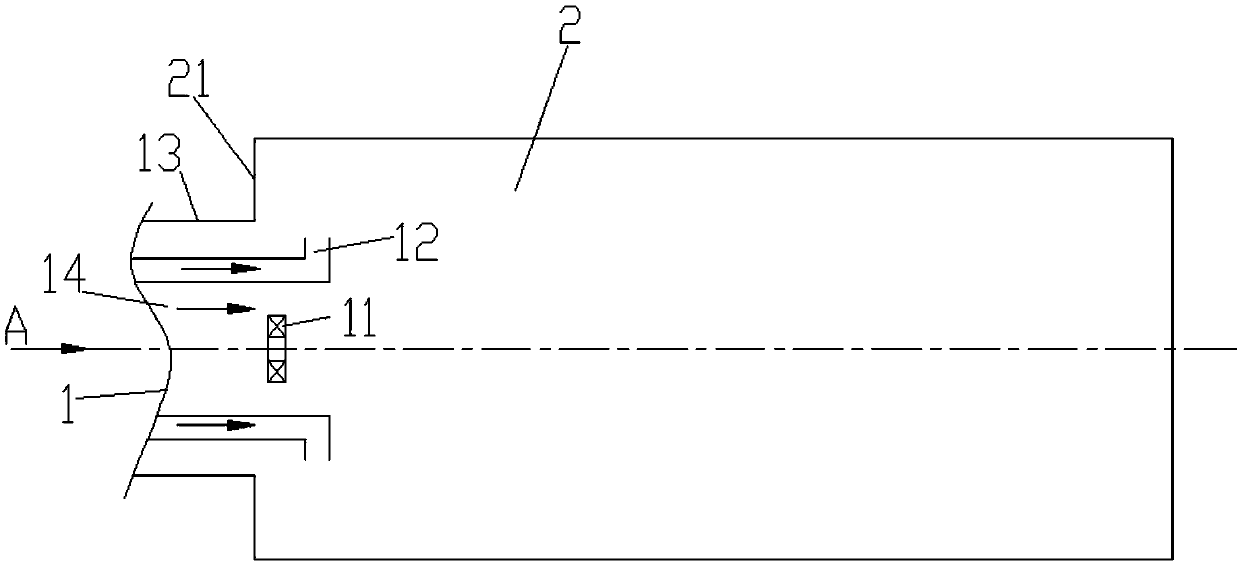

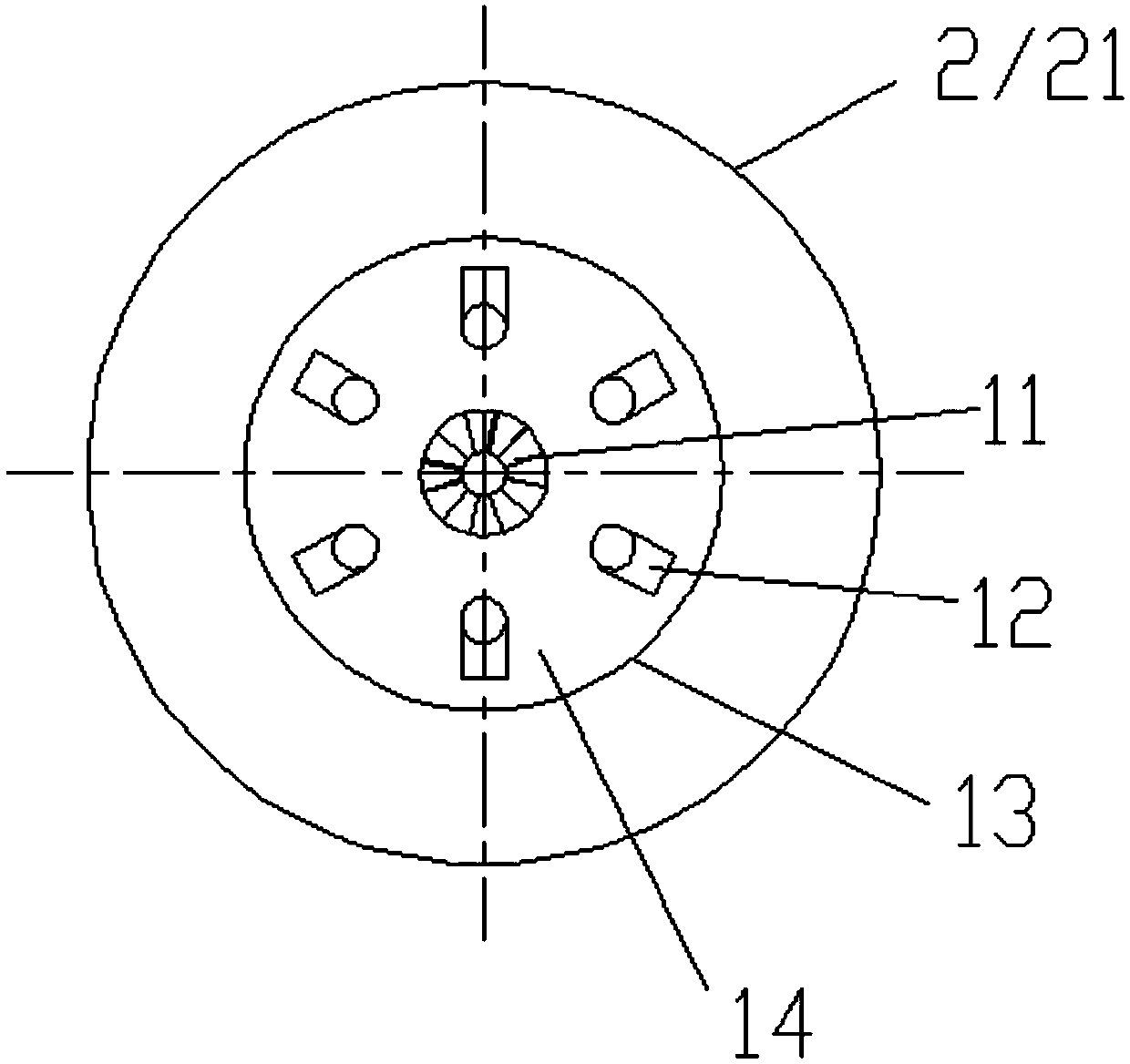

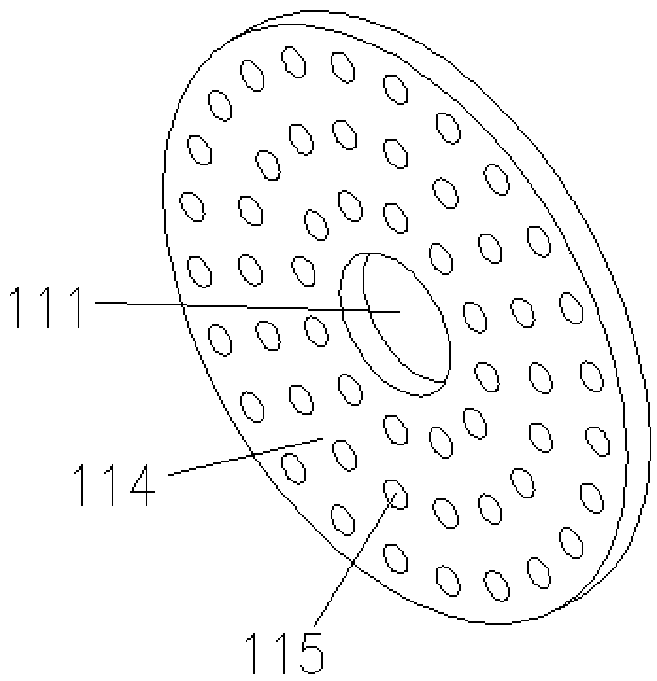

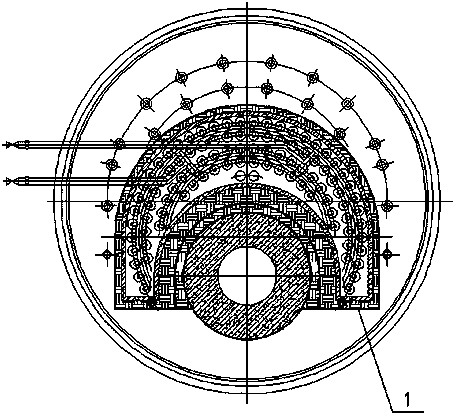

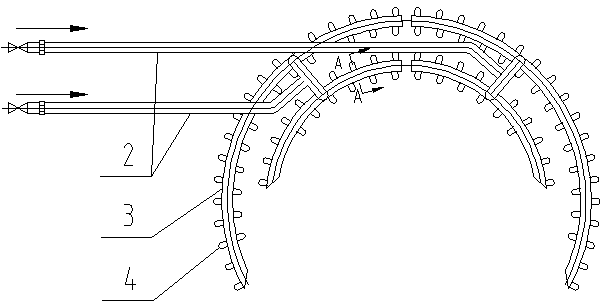

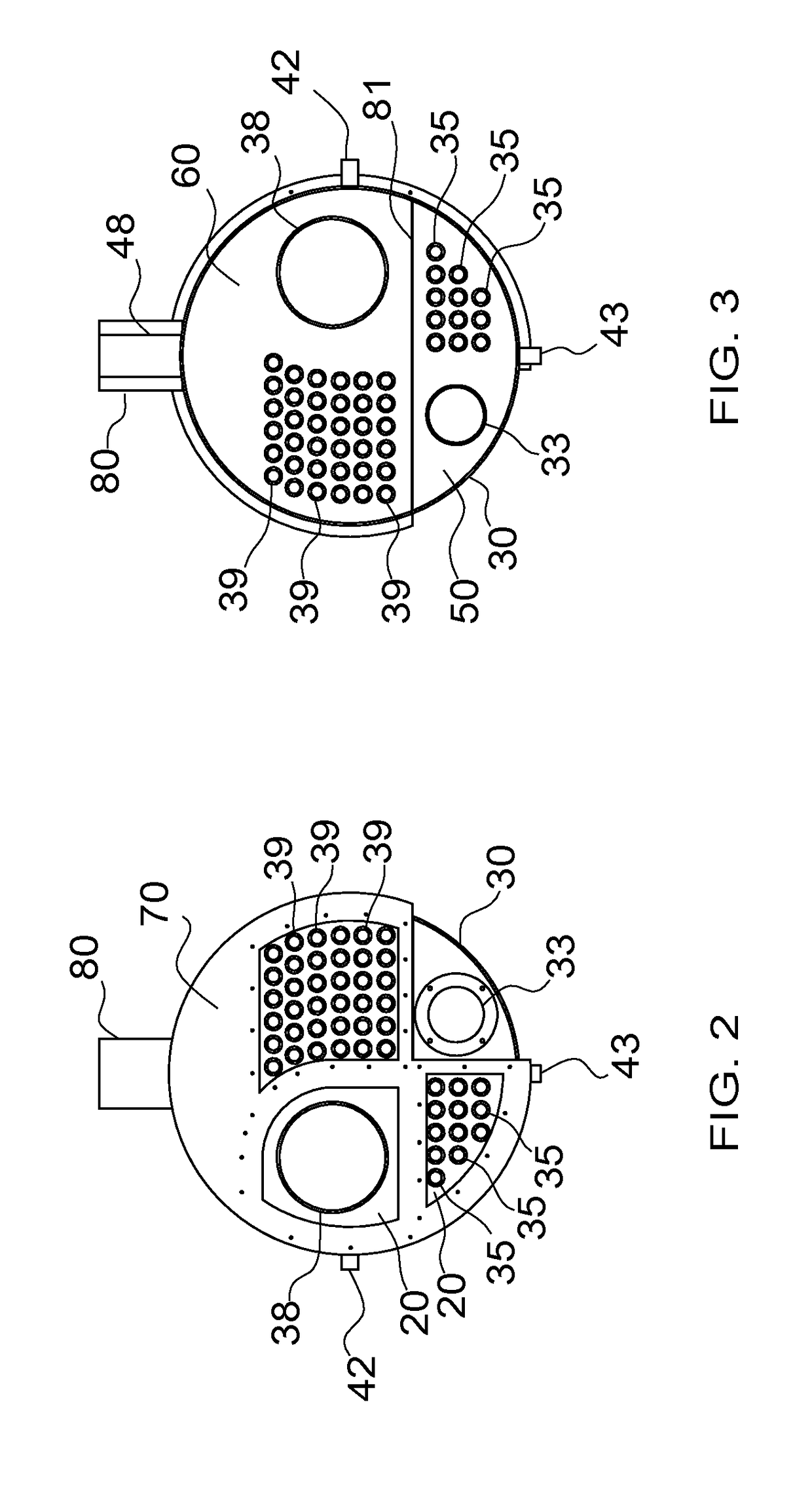

Fuel gas combustion system suitable for fire tube boiler

PendingCN109611847AStrong burning abilityExpand coverageGaseous fuel burnerCombustion systemNitrogen

The invention discloses a fuel gas combustion system suitable for a fire tube boiler, relates to the technical field of ultralow nitrogen combustion of gas-fired boilers, and aims to solve the technical problem of effectively reducing the NOx emission concentration of the fire tube boiler. The fuel gas combustion system is characterized in that a few of air guns are arranged in the center of a flame stabilizing disc; a plurality of stable combustion air channels are arranged on the periphery of the flame stabilizing disc; a fuel gas gun is arranged on the outer side of the flame stabilizing disc; and the spray orifice of the fuel gas gun stretches out of the throat of a combustor and is outwards in the radial direction. The fuel gas combustion system has the following advantages: the combustion system has excellent stable combustion capacity; the fuel gas sprays outwards in the radial direction to enlarge the covering range of flame and reduce the flame peak temperature by utilizing the boiler hearth to the maximum; and in addition, exhaust gas recycling is generated in the boiler, so that the recycling usage amount of external exhaust gas is reduced, and 30 mg and even less NOx isdischarged.

Owner:SHANGHAI WISEBOND TECH +1

Energy-saving emission-reducing vertical fire-tube boiler capable of using water as oxidant

InactiveCN102563854AAchieve smokeless combustionIncrease burn rateWater heatersOxygen deprivationChemical reaction

The invention relates to an energy-saving emission-reducing vertical fire-tube boiler capable of using water as oxidant. A plurality of water jackets (water containers) are serially connected, a vertical fire tube heating mode is adopted, the water can be used as the oxidant, combustion efficiency is high, the quantity of consumed oxygen is low, accordingly, a heat exchange effect is improved, heat efficiency is enhanced, and energy is saved. A combustion principle of the energy-saving emission-reducing vertical fire-tube boiler includes that hydrogen and carbon are used as energy carriers, and energy can be exchanged between hydrogen and carbon. The carbon or hydrocarbon and water realize 'oxygen deprivation' reaction in a high-temperature environment, namely high-temperature steam is used as the oxidant to realize thermal chemical reaction with the carbon or the hydrocarbon, and hydrogen-rich gas is generated. Energy is absorbed during hydrolysis while energy is released during oxidation of the carbon, and energy is exchanged between the carbon and the hydrogen. The high-temperature environment is required when the energy is exchanged between the carbon and the hydrogen, and the energy is only consumed to maintain the high-temperature environment required by the thermal chemical reaction. Accordingly, by the aid of the energy-saving emission-reducing vertical fire-tube boiler, smokeless combustion of coal can be realized, and biomass fuel containing a large amount of water, domestic garbage and industrial and agricultural combustible waste are suitable to be used as energy sources.

Owner:王振孝

Low NOx fire tube boiler

The invention discloses a fire tube boiler which includes a perforated flame holder configured to hold a combustion reaction that produces very low oxides of nitrogen (NOx).

Owner:美一蓝技术公司

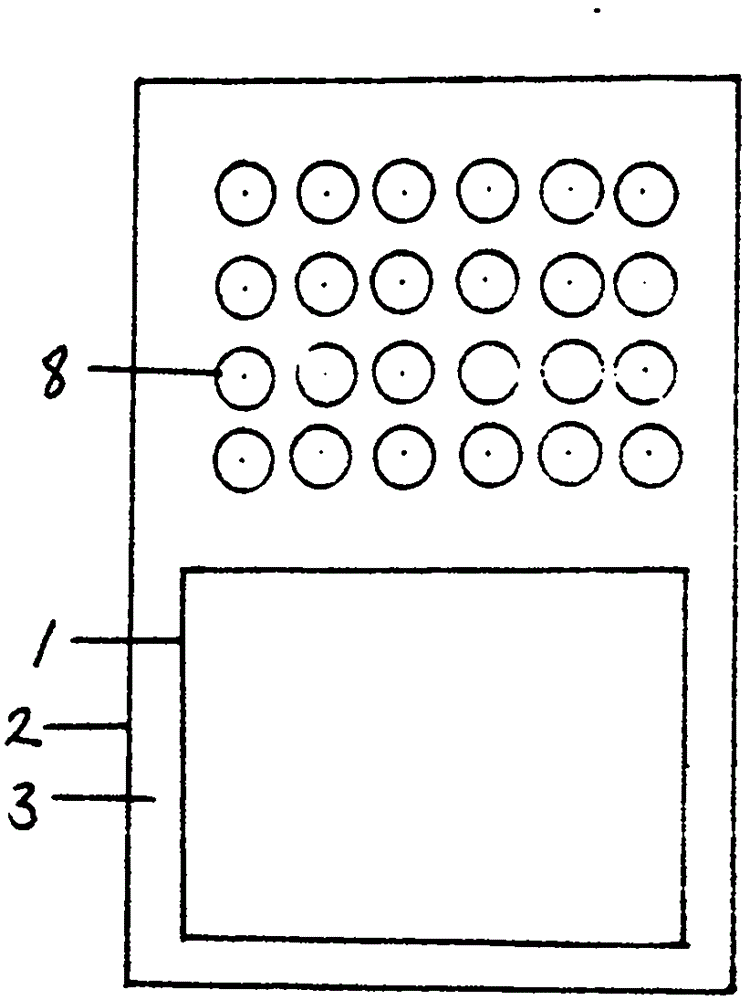

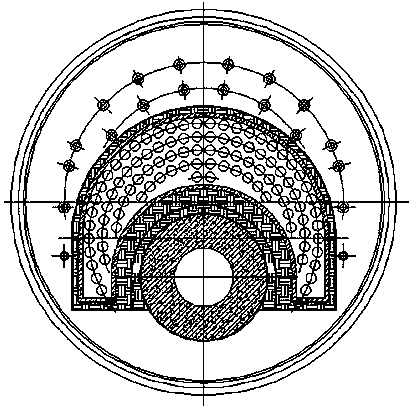

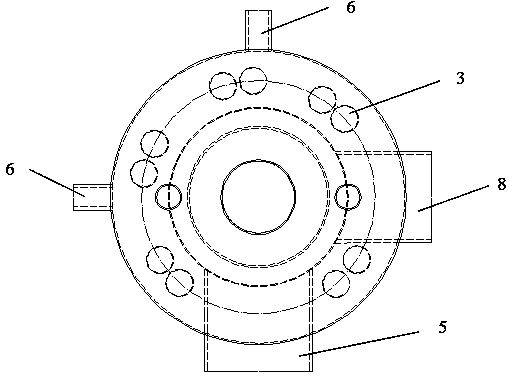

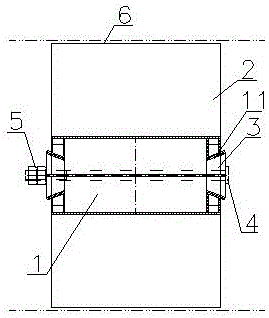

Built-in smoke box type soot blower for horizontal type fire tube boiler

The invention relates to a built-in smoke box type soot blower for a horizontal type fire tube boiler. The built-in smoke box type soot blower is mainly used for boiler soot blowing of fuels such as burning heavy oil and coke oven gas which are high in ash content. The soot blower is arranged in a front smoke box or a rear smoke box of the horizontal type fire tube boiler and comprises a main pipe (2), branch pipes (3) and nozzles (4). The main pipe (2) is connected with the branch pipes (3), a plurality of rows of branch pipes (3) are annularly arranged, the arrangement positions of the branch pipes (3) correspond to the positions of each row of smoke pipes in the front smoke box or the rear smoke box of the horizontal type fire tube boiler, each row of branch pipes (3) are provided with a plurality of nozzles (4), and the arranging position of each nozzle (4) on the branch pipe (3) corresponds to the inlet position of each smoke pipe in the front smoke box or the rear smoke box of the horizontal type fire tube boiler. According to the built-in smoke box type soot blower, high-speed gas is utilized to blow deposited soot in the longitudinal smoke pipes to the other end of each pipe, and collection and tidying of the deposited soot are facilitated.

Owner:JIANGSU SHUANGLIANG BOILER

Vertical small-capacity fire-tube boiler

InactiveCN103808006AImprove heat transfer efficiencyImprove thermal efficiencyWater heatersCombustorHeat conservation

The invention relates to hot water boilers, in particular to a vertical small-capacity fire-tube boiler. The vertical small-capacity fire-tube boiler is mainly composed of a boiler shell, a smoke exhaust tube, a combustor, a fire tube, an exhaust gas chamber and the like. A traditional water tube and a traditional fire tube are changed innovatively, namely the traditional water tube is replaced with the mode that an outer cavity between a heat preservation outer shell and a heat preservation inner shell is filled with water, so that the area of the heating surface is largely enlarged, no tube explodes, and the service life of the boiler is prolonged relatively. The traditional mode that the fire tube extends back and forth horizontally in the transverse mode is changed into the mode that the fire tube extends back and forth vertically in the longitudinal direction, and the fire tube is almost completely exposed in the water, so that the exhaust smoke flow is lengthened, the heat transfer area is enlarged largely, and the heat transfer efficiency of the boiler is improved exponentially. Exhaust smoke in the boiler can completely wash the inner wall of the fire tube rapidly and longitudinally, and therefore the purposes of economical efficiency, energy conservation, the compact structure, high heating efficiency and the like are achieved.

Owner:JIANGSU UNIV

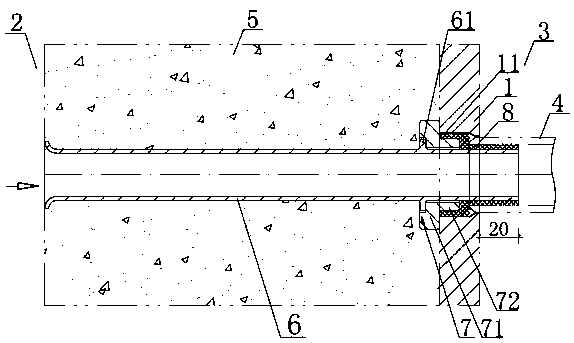

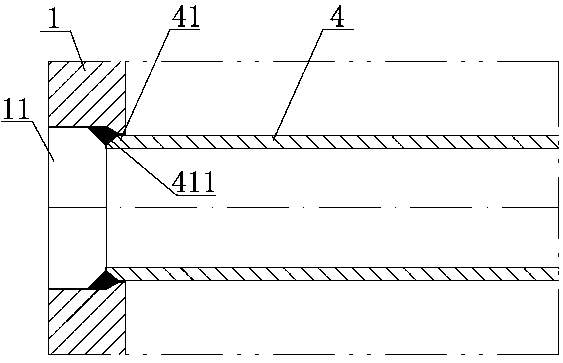

Smoke gas inlet structure of fire tube boiler

PendingCN109579600AGuaranteed uptimeAvoid LeakageHeat exchanger casingsFire-tube steam boilersEngineeringWeld seam

The invention discloses a smoke gas inlet structure of a fire tube boiler. The smoke gas inlet structure comprises a tube plate, wherein one side of the tube plate is a smoke box side, the other sideof the tube plate is a water path side; the tube hole of each heat exchange tube at the water path side extends into a tube hole of the tube plate; the tube hole of each heat exchange tube is welded,sealed and fixed with the tube hole correspondingly; the tube hole of each heat exchange tube extends into one end, close to the water path side, of the tube hole; the tube hole of each heat exchangetube is welded, sealed and fixed with the inner wall, close to the water path side, of the tube hole; a high-temperature fire-resistant cast layer is arranged between the tube plate and the smoke box;ceramic sleeves which are in one-to-one correspondence to the heat exchange tubes are embedded and fixed in the high-temperature fire-resistant cast layer; one end of each ceramic sleeve communicateswith the smoke box, and the other end of each ceramic sleeve extends into the corresponding heat exchange tube; a ceramic protective sleeve is further arranged in each tube hole; and each ceramic protective tube sleeves the ceramic sleeve in each tube hole. The smoke gas inlet structure has the advantages that a welding seam between the tube plate and the heat exchange tube can be effectively protected, and the fire tube boiler can be guaranteed to safely and reliably operate.

Owner:SUZHOU HAILU HEAVY IND

Waste heat recovery system matched with HISMELT smelting reduction ironmaking system

The invention discloses a waste heat recovery system matched with an HISMELT smelting reduction ironmaking system. The waste heat recovery system comprises a cooling flue and a flue steam pocket, the outlet end of the cooling flue is provided with a connecting flue, the outlet of the connecting flue is connected to a separator, the inlet section of the cooling flue is connected to a reacting furnace, and a cooling medium is introduced into the connecting flue to cool flue gas; a smoke outlet of the separator is connected with a steam superheater, a superheater smoke outlet of the steam superheater is connected with a fire-tube boiler, a boiler ascending tube and a boiler descending tube of the fire-tube boiler are connected to a boiler drum, the fire-tube boiler is connected with a fire-tube economizer, and a smoke exhaust barrel is arranged at the bottom of the fire-tube economizer. An economizer water outlet pipe on the fire tube economizer supplies water to the fire tube boiler drum and the flue drum, steam output by the flue drum and the fire tube boiler drum is conveyed to the steam superheater, and a superheated steam output pipe is arranged on the steam superheater. The slag-bonding phenomenon can be effectively avoided, and the heat efficiency is greatly improved.

Owner:SUZHOU HAILU HEAVY IND +1

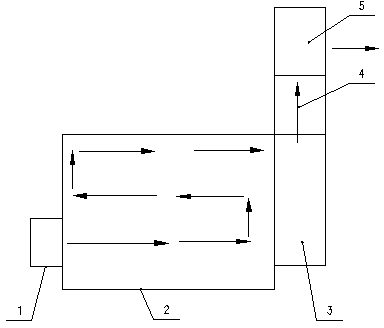

Horizontal fire tube boiler with gas-gas heat tube heat exchange tube arranged on tail

InactiveCN104121569ARaise the exhaust gas temperatureLower exhaust gas temperatureCombustion processIndirect carbon-dioxide mitigationCombustorEngineering

The invention relates to a horizontal fire tube boiler with a gas-gas heat tube heat exchange tube arranged on the tail and belongs to the technical field of heating equipment. The horizontal fire tube boiler comprises a combustor (1), a boiler body (2), a cornering smoke chamber (3) and a coal economizer (4), wherein the combustor (1) is arranged at the front end of the boiler body (2), and the coal economizer (4) is arranged on the top of the boiler body (2). The horizontal fire tube boiler is characterized in that a gas-gas heat tube heat exchanger (5) is additionally arranged behind the coal economizer (4), and the gas-gas heat tube heat exchanger (5) is also arranged on the top of the boiler body (2). By means of the horizontal fire tube boiler, the temperature of smoke can be further lowered, smoke condensation can be even achieved, the latent heat of vaporization is released, the efficiency of the boiler is improved, the temperature of combustion air is increased, and the consumption of fuel is reduced. Furthermore, people do not need to worry about the problem of shutdown overhaul due to gas-gas flow path communication caused by the damage of heat tubes, and the horizontal fire tube boiler can be independently arranged through transformation of the energy-saving technology for an existing boiler.

Owner:JIANGSU SHUANGLIANG BOILER

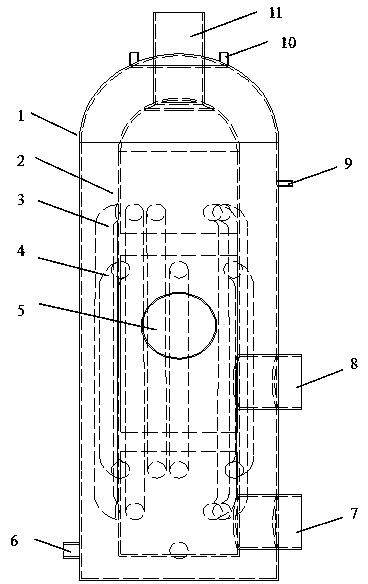

Full-film type wall water-fire tube boiler

ActiveCN105588100AGuaranteed air tightnessGuaranteed StrengthWater-tube boilersCombustorPlate heat exchanger

The invention relates to a full-film type wall water-fire tube boiler. The boiler comprises a hearth which is of a full-film type wall structure, a burner which is fixedly connected to one end of the hearth, a turning smoke chamber which is of a full-film type wall structure, a heat exchanger and a steam drum. An outlet smokestack is arranged on one side of the hearth. One end of the turning smoke chamber is connected with the outlet smokestack, and the other end of the turning smoke chamber is connected with the heat exchanger. The connecting joint between the turning smoke chamber and the outlet smokestack and the connecting joint between the turning smoke chamber and the heat exchanger are each provided with an annular header. A film type wall water-cooled tube of the turning smoke chamber communicates with a shell of the heat exchanger through the annular header located at the position of the heat exchanger. The steam drum communicates with the film type wall water-cooled tube of the turning smoke chamber through the annular header located at the position of the outlet smokestack. Meanwhile, the steam drum directly communicates with a film type wall water-cooled tube of the hearth and forms a circulation heat exchange channel. The full-film type wall water-fire tube boiler includes various structures, boiler capacity covers the full industrial boiler range, and thus the boiler can be widely applied to various conditions where water-fire tube boilers are needed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Artificial light and evacuated tube boiler

Owner:DUNN BRIAN

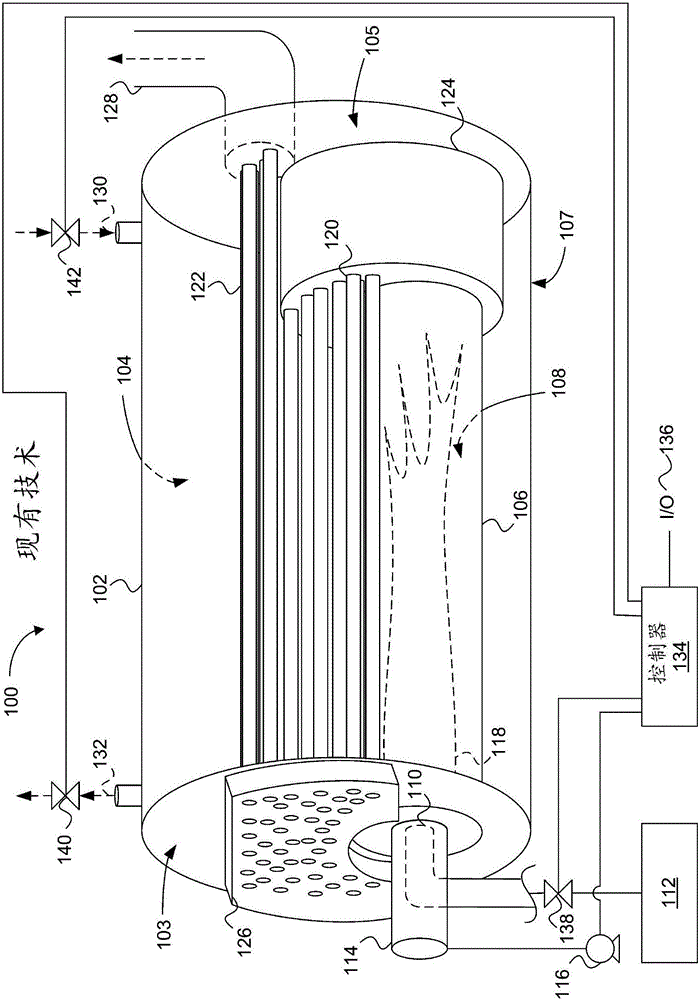

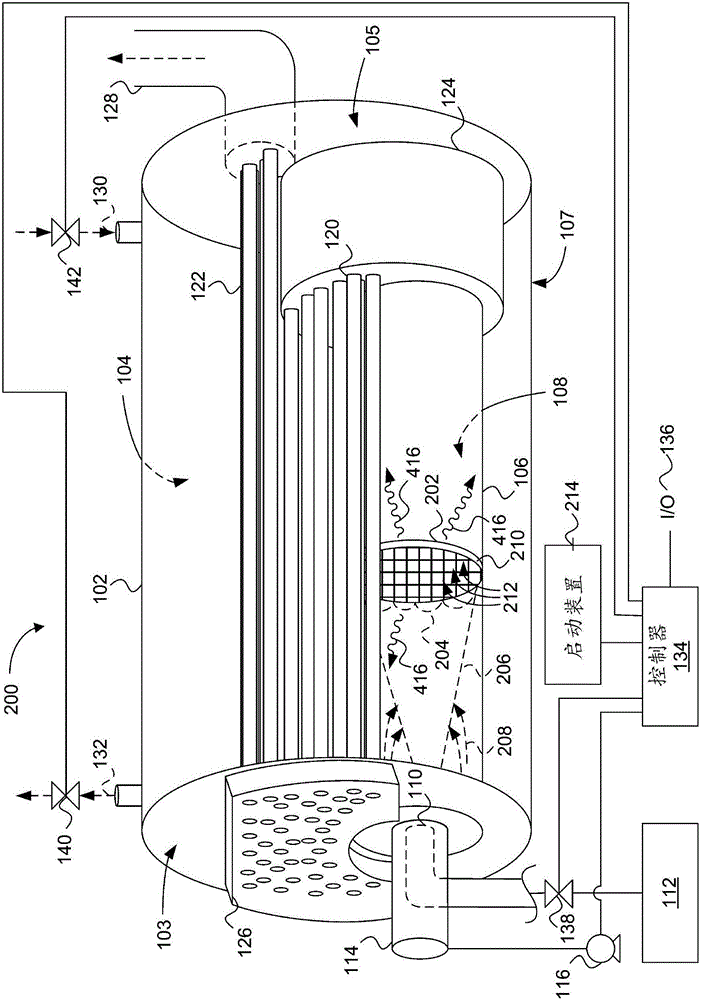

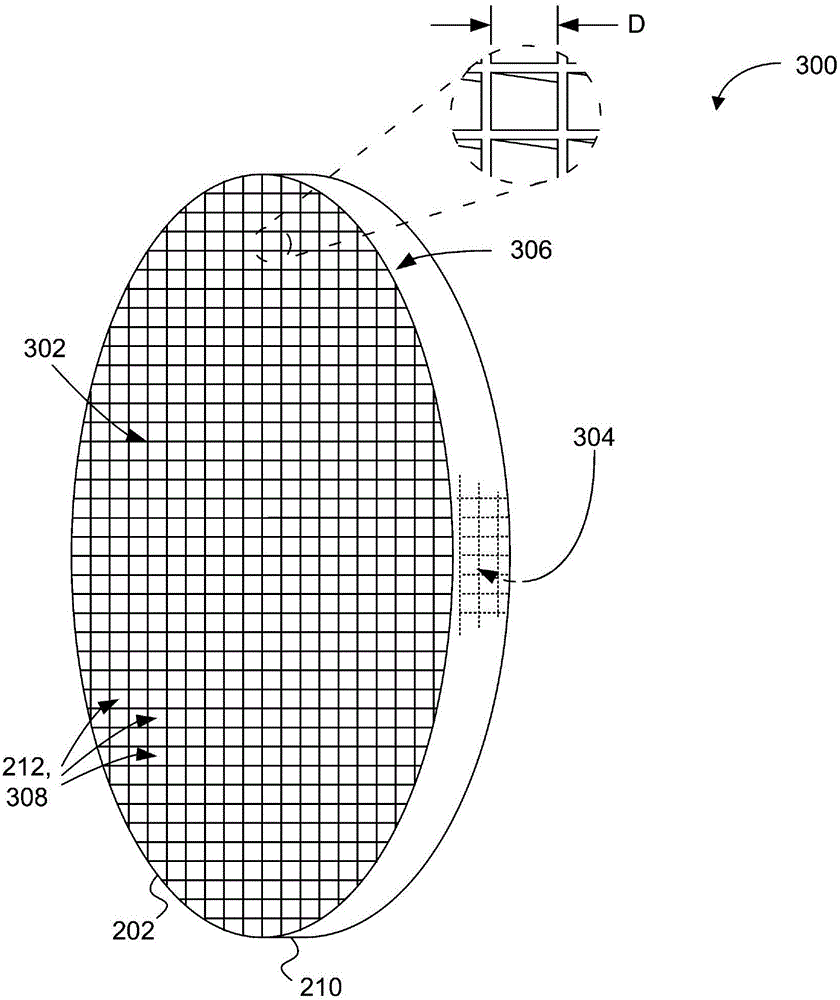

Method and Apparatus for Firetube Boiler and Ultra Low NOx Burner

ActiveUS20180128479A1Reduce nitrogen oxide emissionsReduce consumptionFurnace-tube steam boilersFire-tube steam boilersCombustorFlue gas

The current invention disclose a method and apparatus for production of hot water or steam in a firetube boiler, said method comprising the steps of producing a first flue gas using a first stage of a burner in a first pass of a firetube boiler; passing at least a portion of said first flue gas through a second pass of said boiler, wherein said second pass comprises a plurality of firetubes; routing said portion of said first flue gas to a second stage of said burner to reduce NOx emissions from said second stage of said burner; producing a second flue gas from said second stage of said burner in a third pass of said boiler; passing said second flue gas through a fourth pass of said boiler, wherein said fourth pass comprises a plurality of firetubes.

Owner:PREFERRED UTILITIES MFG

Fire-tube boiler main fire tube heat exchange efficiency improving device and mounting method thereof

ActiveCN106524492AShort renovation periodHigh energy saving rateWater heatersEngineeringCircular surface

The invention relates to a fire-tube boiler main fire tube heat exchange efficiency improving device and a mounting method thereof. The fire-tube boiler main fire tube heat exchange efficiency improving device is good in energy saving effect and does not need to change the main structure and using mode of an existing traditional fire-tube boiler after being mounted. The fire-tube boiler main fire tube heat exchange efficiency improving device comprises an expansion barrel and a plurality of V-shaped heat storage net hopper assemblies. The end openings at the two ends of the expansion barrel are both conical openings with the outer sides wider than the inner sides, and a conical sliding block is arranged in each conical opening. A pull rod is arranged between the two conical sliding blocks, and a nut is arranged at the end of one side of the pull rod. The V-shaped heat storage net hopper assemblies surround the outer circular surface of the expansion barrel, and the sum of the included angles of V-shaped heat storage net hoppers in the V-shaped heat storage net hopper assemblies is 360 degrees. The fire-tube boiler main fire tube heat exchange efficiency improving device has the advantages that firstly, the main structure and using mode of the existing traditional fire-tube boiler do not need to be changed after the heat exchange efficiency improving device is mounted, the modification period of the traditional fire-tube boiler is shortened, and the modification cost is saved; and secondly, the heat exchange efficiency improving device can conduct sufficient heat exchange with high-temperature smoke, and thus the energy saving rate of the modified fire-tube boiler is increased by 20%-30%.

Owner:杭州帕沃节能设备有限公司

Combined screwed pipe water-fire tube boiler

InactiveCN103759241AImprove sealingReduce weightBoiler flue tubes/fire tubesWater-tube boilersPipe waterMaterial consumption

The invention provides a combined screwed pipe water-fire tube boiler and relates to an industrial boiler taking screwed pipes as main heat convection heating surface. The combined screwed pipe water-fire tube boiler comprises a body, a steel frame backplate, a oven wall liner heat preservation, a chain grate stoker, an air collector, a backwater allocating header and a boiler exhaust gas outlet. The body comprises a drum, a left and right side water wall tube assembly, a front arch tube assembly, a back arch tube assembly and a combined screwed pipe assembly. After the backwater allocating header is communicated with the body via a pipe, an total water return pipe of the boiler is conveyed into the boiler via the backwater allocating header and the combined screwed pipe assembly, the boiler allocates a side water wall tube circulating loop comprising left and right side water wall tube assemblies, a front arc-shaped tube circulating loop comprising front arc-shaped tube assemblies and back arc-shaped tube circulating loop comprising back arc-shaped tube assemblies to circulate back to the boiler, the air collector extracts out and pipelines are utilized to transport to users. The combined screwed pipe assemblies composed by high efficient heat exchanger element screwed pipes to an upright arrangement is adopted in convection heat exchanging area on the tail portion of the boiler, material consumption is reduced, module production is adopted in plants, production quality is easy to control, the weight of single assembly unit is light, field mounting is convenient and project duration is short.

Owner:鄂尔多斯市高原实业有限责任公司

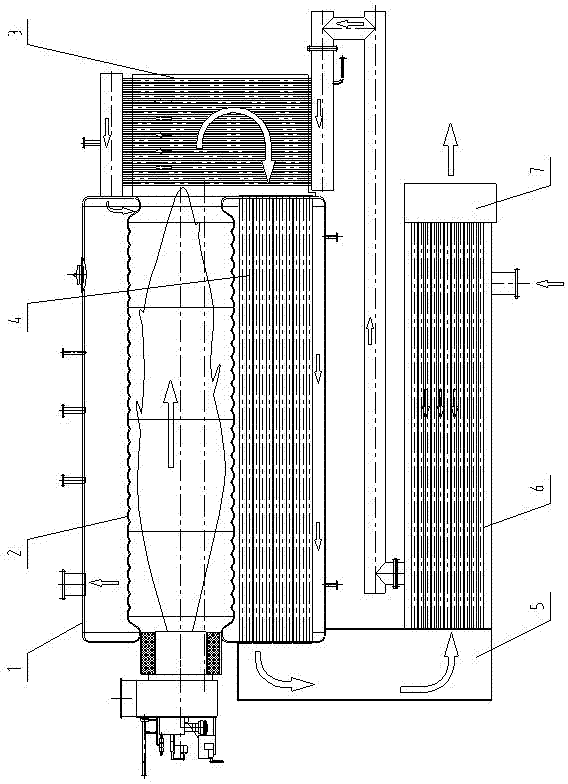

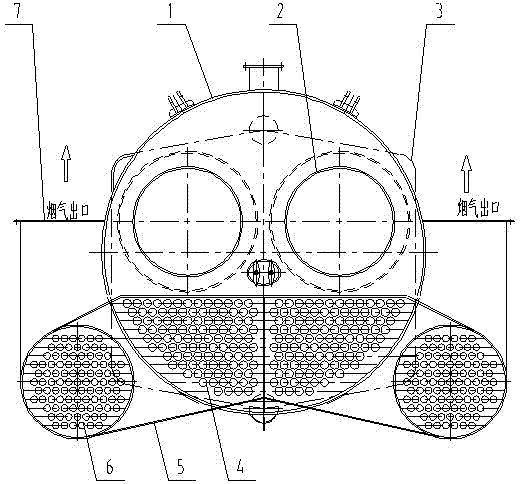

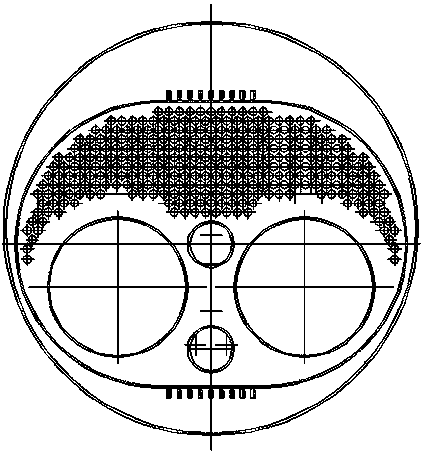

Double-flue reversal chamber of large horizontal fire-tube boiler

InactiveCN104110673AMeet specification requirementsSmall diameterSteam boilersSteam boilers componentsButt weldingCombustion

The invention relates to a double-flue reversal chamber of a large horizontal fire-tube boiler and belongs to the technical field of heating equipment. The double-flue reversal chamber comprises a cylinder (2), a front tube sheet (1) and a back tube sheet (3). The front tube sheet (1) and the back tube sheet (3) are respectively in butt welding with the cylinder (2). The double-flue reversal chamber is characterized in that the cylinder (2), the front tube sheet (1) and the back tube sheet (3) are all oval and two round holes are symmetrically formed in the left and the right of the front tube sheet (1) and correspond to double flues in a barrel of the horizontal fire-tube boiler respectively. The reversal chamber can not only meet a limiting condition of wall thickness but utilize internal space of the barrel to the utmost extent and accordingly make the output of 35t / h (29MW) possible to the horizontal internal-combustion fire-tube boiler.

Owner:JIANGSU SHUANGLIANG BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com