Fire-tube boiler main fire tube heat exchange efficiency improving device and mounting method thereof

A technology of a fire tube boiler and an installation method, which is applied in the directions of water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high renovation cost, long construction period and low energy efficiency, so as to save the renovation cost and shorten the renovation construction period. , the effect of improving the energy saving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

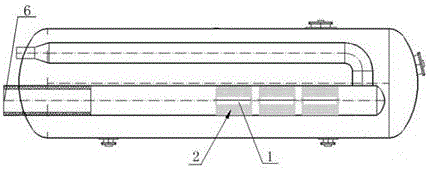

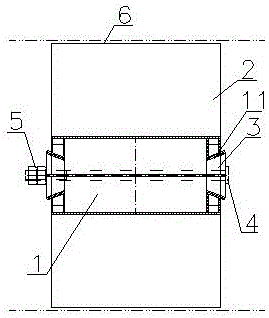

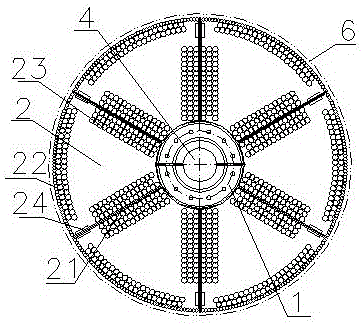

[0014] Embodiment 1: with reference to attached Figure 2-Figure 6 . A fire tube boiler main fire tube heat exchange enhancement device, including an expansion barrel 1 and a plurality of V-shaped heat storage nest net bucket assemblies 2, and the ports at both ends of the expansion barrel 1 are tapered openings 11 that are wide on the outside and narrow on the inside. And two tapered mouths 11 are respectively provided with a tapered slider 3, the size of the tapered mouth 11 matches the size of the tapered slider 3, the two tapered sliders 3 are provided with a pull bar 4 and the pull bar 4 is a The side end is provided with nuts 5, and the number of nuts 5 is 1 or 2; the outer surface of the expansion barrel 1 is surrounded by a plurality of V-shaped heat storage nest mesh bucket assemblies 2 and multiple V-shaped heat storage nest mesh bucket assemblies The sum of the included angles of the V-shaped heat storage nest buckets 21 in module 2 is 360°. The V-shaped heat stor...

Embodiment 2

[0015]Embodiment 2: on the basis of embodiment 1. A method for installing a fire tube boiler main fire tube heat exchange efficiency device, the first step is to remove the burner in the fire tube boiler 6 and carry out derusting and brushing strengthening agent treatment on the inner wall of the main fire tube; second The first step is to set the expansion bucket 1 with multiple V-shaped regenerative nest mesh bucket assemblies 2 around the outer circle in the main fire pipe after derusting, and turn the nut 5 to make the two tapered sliders on the pull rod 4 move in 3 directions. Moving inside, the expansion barrel 1 expands outward under the stretching of the two conical sliders 3 moving inwards and evenly tightens the multiple V-shaped heat storage nest mesh bucket assemblies 2 around the outer surface of the expansion barrel 1 The inner wall of the main fire tube. In the third step, the burner is packed back into the original position of the fire tube boiler 6 . Before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com