Crude oil reduced pressure distillation method for eliminating choke point in pressure reduction process

A distillation method and technology of a vacuum distillation tower, which are applied in the field of petroleum refining, can solve problems such as the inability to eliminate the processing bottlenecks of the vacuum furnace and the vacuum tower, the large operating load of the vacuum distillation tower, and the large load of the vacuum furnace, and achieve The effect of increasing the flash volume at the top of the vacuum flash evaporation tower, increasing the economic benefits of the device, and reducing the amount of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method of the invention is used in the design of a new crude oil atmospheric and vacuum distillation unit.

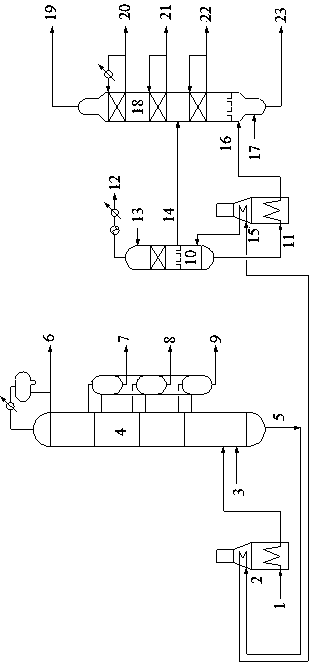

[0029] The pretreatment and atmospheric distillation part are the same as the conventional atmospheric and vacuum device, and the process flow of the vacuum distillation part is as attached figure 1 shown. The processing capacity of the vacuum distillation unit is 240wt / a. The vacuum distillation process includes a vacuum flash tower, a vacuum furnace, and a vacuum distillation tower. The vacuum distillation tower is structured packing and is operated by a wet process. The steam blowing volume at the bottom of the tower is 1-3wt% of the tower feed, the operating pressure at the top of the tower is 1-20kPa, and the pressure drop of the whole tower is 1-10kPa.

[0030] Atmospheric residue oil from the bottom of the atmospheric distillation tower is preheated successively through the convection section of the atmospheric furnace and the convection section of th...

Embodiment 2

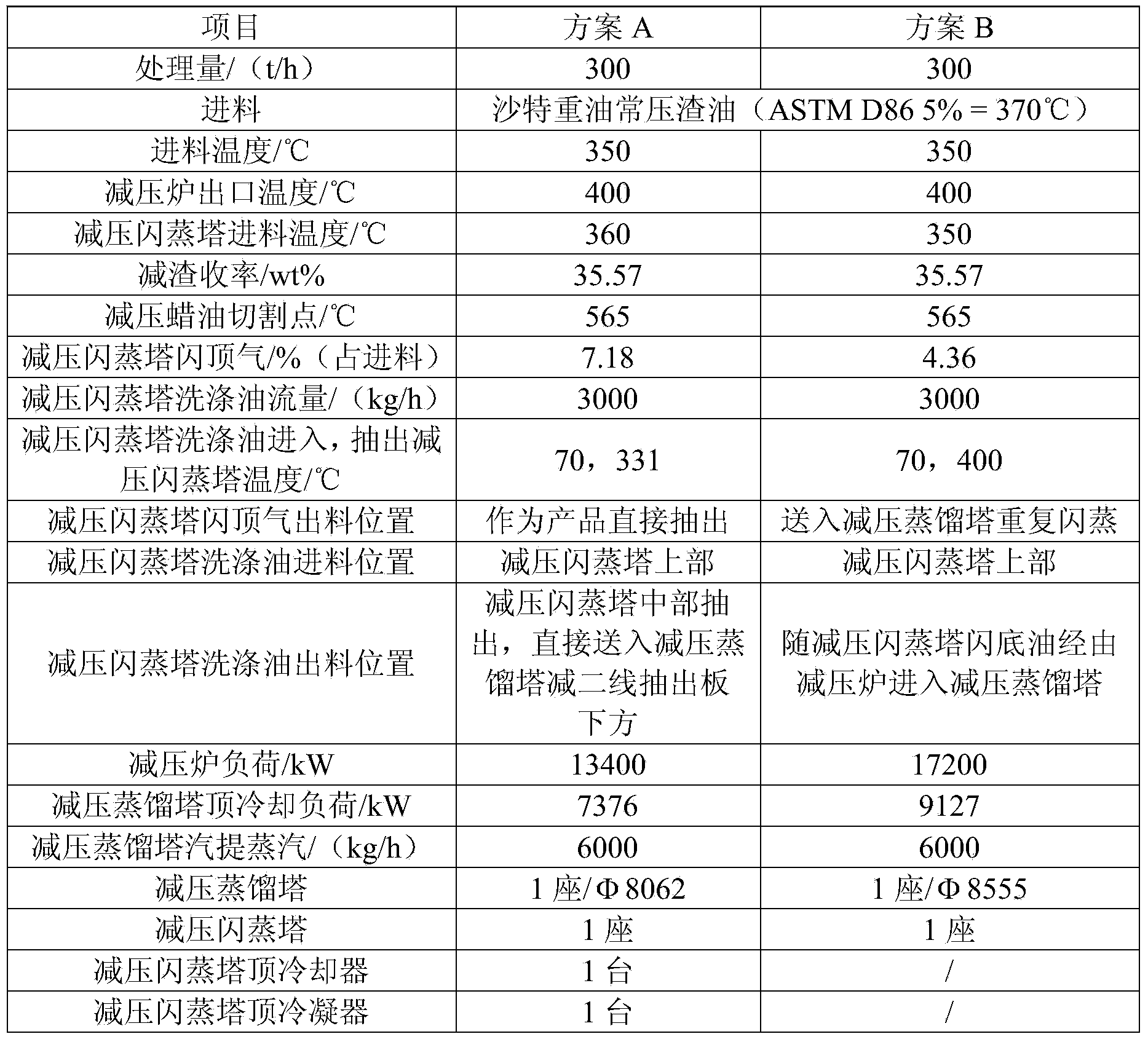

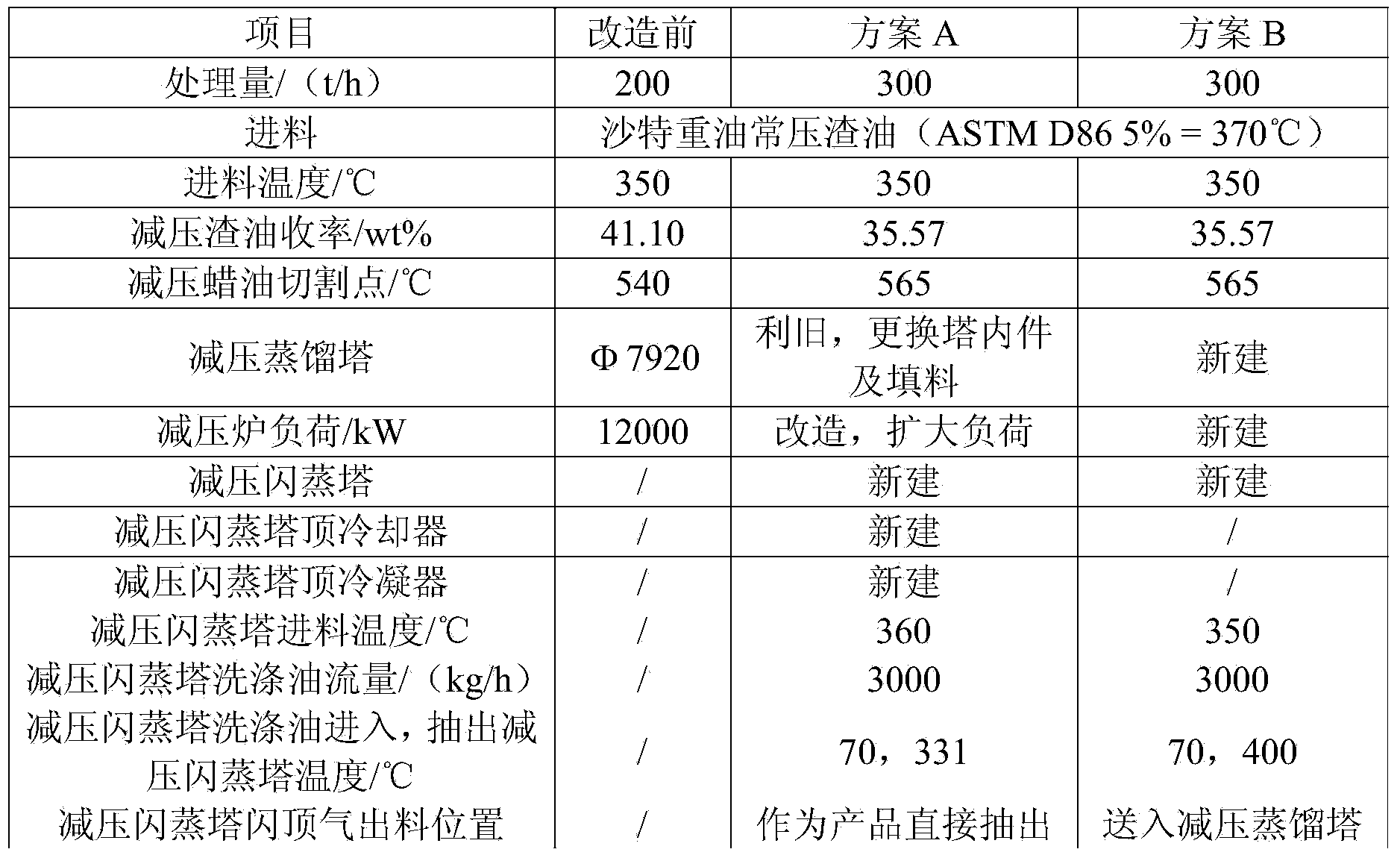

[0036] The scheme of the present invention is used for the capacity expansion transformation of a certain crude oil atmospheric and vacuum distillation unit. The flow process before the transformation is a conventional "two furnaces and three towers" flow process. After the transformation, the pretreatment and atmospheric pressure parts are the same as the conventional flow process, and the vacuum distillation part The process flow is attached figure 1 As shown, the main equipment includes a vacuum flash tower, a vacuum furnace, and a vacuum distillation tower. The vacuum distillation tower is a structured packing tower, the operating pressure at the top of the tower is 2.6kPa, and the pressure drop across the tower is 1.4kPa.

[0037] Atmospheric residue oil from the bottom of the atmospheric distillation tower is preheated through the convection section of the atmospheric furnace and the convection section of the vacuum furnace successively at a feed rate of 300t / h. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com