Built-in smoke box type soot blower for horizontal type fire tube boiler

A fire-tube boiler and soot blower technology, which is applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc., can solve the problems of decreased heat transfer coefficient, difficulty in blowing soot, and labor and labor, and achieve low operating costs. , Reduce the mechanical and electrical failure rate and maintenance rate, and the effect of small one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

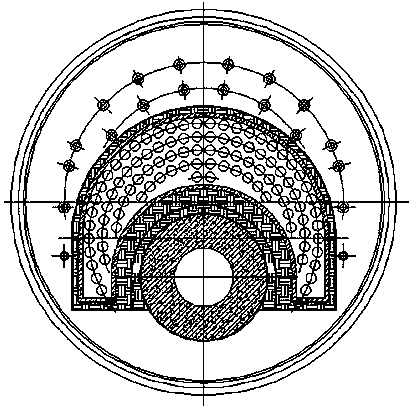

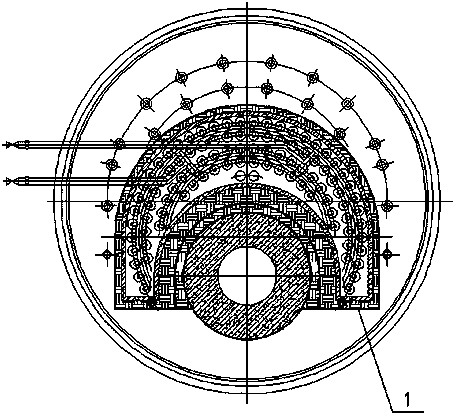

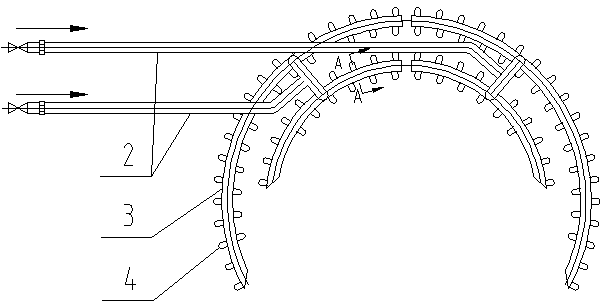

[0022] See Figure 2-4 , figure 2 It is a schematic diagram of a soot blower built into the flue box of a horizontal fire tube boiler. image 3 It is a schematic diagram of the structure of the sootblower of the present invention. Figure 4 for image 3 A-A cutaway view. by Figure 2-4 It can be seen that the horizontal fire tube boiler of the present invention has a built-in smoke box type soot blower, which is built in the front smoke box or the rear smoke box of the horizontal fire tube boiler, and is mainly composed of the main pipe 2, the branch pipe 3 and the nozzle 4. The main pipe 2 is connected to the branch pipe 3. The branch pipe 3 has multiple rows, and the multiple rows of branch pipes 3 are arranged in a ring shape. The arrangement position corresponds to the position of each exhaust pipe in the front smoke box or the rear smoke box of the horizontal fire tube boiler. A number of nozzles 4 are arranged on the branch pipe 3, and the arrangement position of each n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com