Waste heat recovery system matched with HISMELT smelting reduction ironmaking system

A waste heat recovery system and system technology, applied in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve the problems of reduced heat transfer effect of waste heat boilers, serious safety hazards, slagging of heat exchange tubes, etc., to save purification treatment costs , prolong the service life and improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and preferred embodiments.

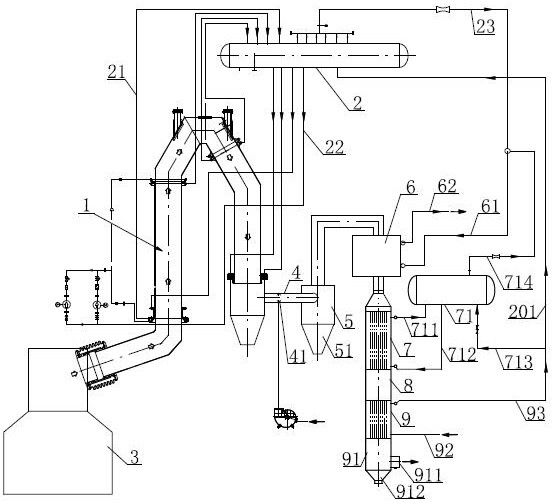

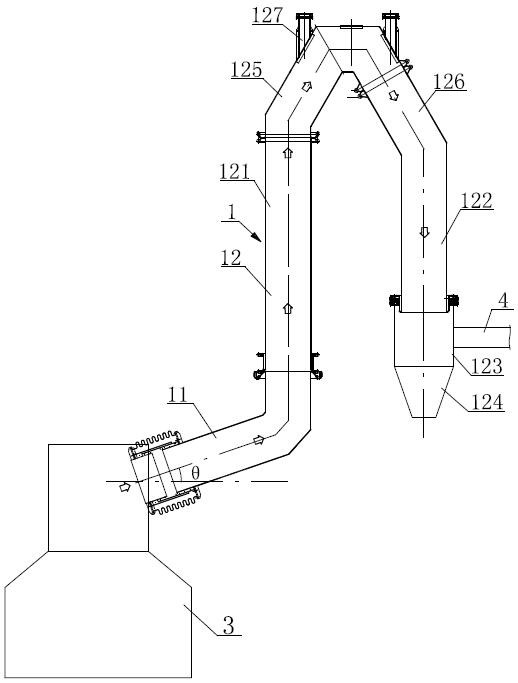

[0019] like figure 1 , figure 2 As shown in the figure, the waste heat recovery system matched with the HISMELT smelting reduction ironmaking system includes: the cooling flue 1 of the membrane water wall structure, the flue water wall riser 21 of the membrane water wall of the cooling flue 1, and the flue water cooling The wall downpipe 22 is connected to the flue drum 2 . The cooling flue 1 includes the cooling flue 11 in the inlet section, the cooling flue 11 in the inlet section is connected with the reaction furnace 3, the cooling flue 11 in the inlet section is gradually inclined upward from the reaction furnace 3, and the cooling flue 11 in the inlet section is arranged in a horizontal direction. The angle θ is greater than or equal to 45 degrees and less than or equal to 60 degrees. The molten slag in the high-temperature fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com