Patents

Literature

35results about How to "Reduce the cost of purification treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological modifying agent for mineral substance water quality

InactiveCN101333022AViscousStrong oxidation abilityWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationChemical industrySodium Bentonite

The invention relates to a mineral water quality ecological modifying agent which is prepared by blending bentonite, alum, polyaluminium chloride and sodium dioxide in proportion; if the total amount is 1,000g, the weight proportion of each ingredient is as follows: 800-900g of bentonite, 40-80g of alum, 15-50g of polyaluminium chloride and 35-80g of sodium dioxide. The mineral water quality ecological modifying agent can be used for improving the aquaculture environment of fish ponds, balancing water ecological environment and enhancing unit fish yield per mu of fish ponds, and also can used for adsorbing blue algae, preventing the blue algae from doing harm to water, eliminating odor and protecting and improving water ecological environment; the water which derives from the treatment of chemical industry waste water, domestic sewage and the water of rivers, lakes, wells and pools can meet the national grade 1 and grade 2 water standards, and the precipitate from the water purification process can be recycled or used as feed or fertilizer, thus having low purifying treatment cost and high benefits.

Owner:唐子林

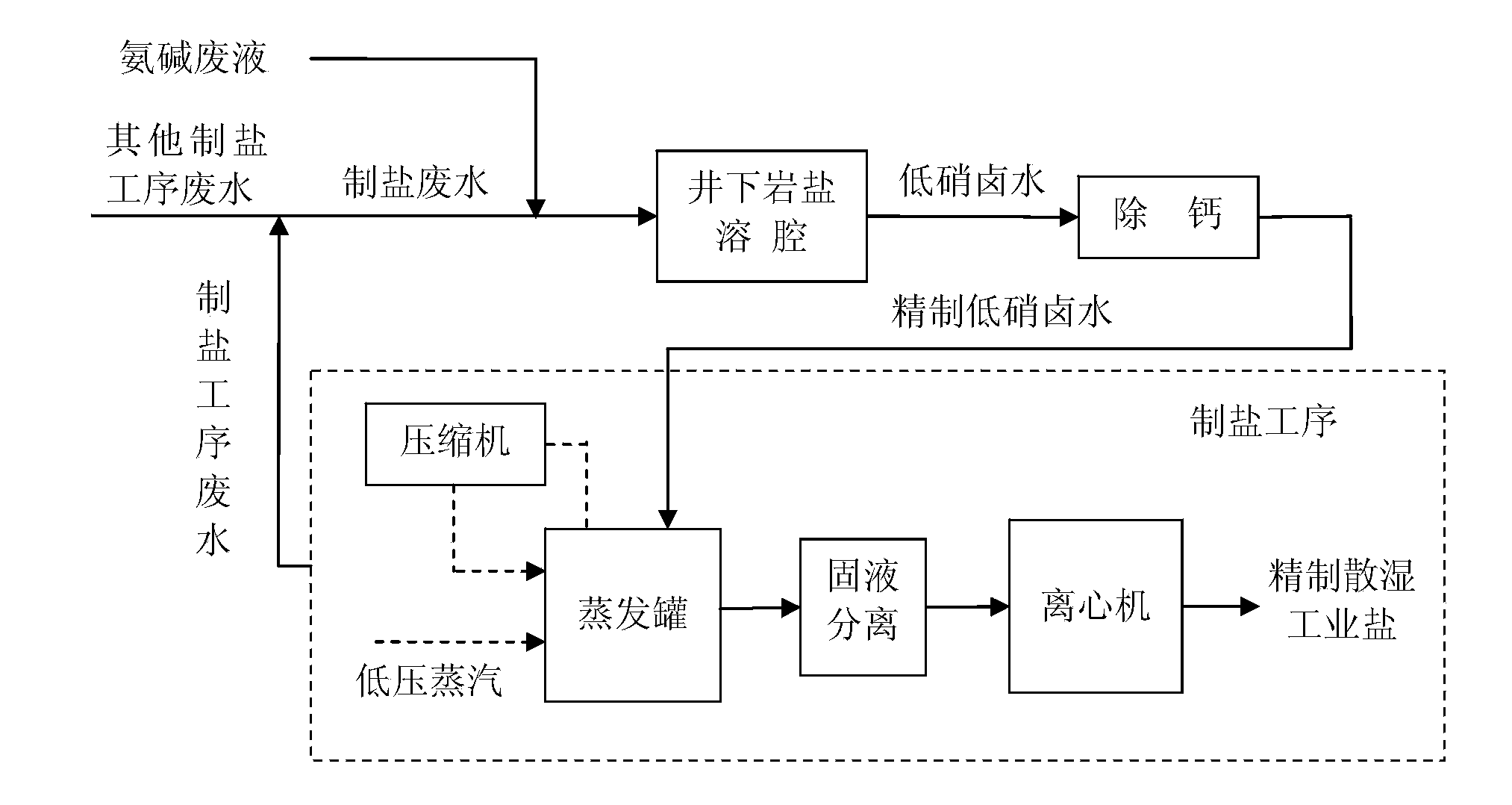

Method for producing refined moisture diffusion industrial salt based on underground recycling of waste liquid

The invention discloses a method for producing refined moisture diffusion industrial salt based on underground recycling of waste liquid. The method comprises the following steps: (1) mixing waste water of salt production with ammonia alkali waste liquid in proportion; (2) injecting the mixed waste liquid obtained in step (1) into an underground mirabilite type rock salt cavern; after sufficient reaction and natural sedimentation, extracting low-nitrate brine; (3) injecting the low-nitrate brine obtained in step (2) into a reaction barrel, injecting a sodium carbonate solution into the barrel, and adding a certain amount of sodium polyacrylate as a coagulant aid; then, stirring and standing, and removing calcium ions out of the brine to obtain refined low-nitrate brine; (4) carrying out secondary preheating on the refined low-nitrate brine obtained in the step (3), carrying out evaporation, concentration, crystallization and solid-liquid separation, and carrying out centrifugal separation on underflow salt slurry to obtain a refined moisture diffusion industrial salt product; (5) with liquid obtained by solid-liquid separation and centrifugal separation in the step (4) as the waste water of salt production, supplying the waste water into the step (1), blending the waste water with the ammonia alkali waste liquid in proportion, and injecting the mixture into the underground rock salt cavern as a brine extracting source, thus realizing the recycling of waste liquid.

Owner:江苏苏盐井神股份有限公司 +1

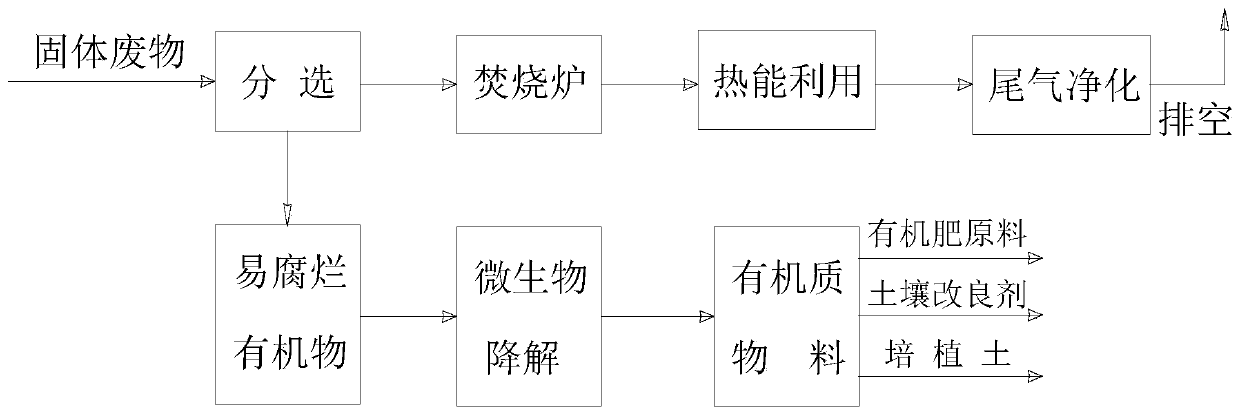

Waste incineration improved process

PendingCN109812814AFast heatingImprove efficiencyClimate change adaptationChemical industryAtmospheric pollutantsNatural gas

The invention discloses a waste incineration improved process comprising the following step 1 of performing sorting treatment to wastes, and obtaining perishable organic matters and comburents; the step 2 of putting the comburents into an incinerator for incineration power generation; and the step 3 of degrading the perishable organic matters by using aerobes, and converting the organic matters into organic materials. The problems that the heat value of materials added to a furnace is low, and combustion-supporting materials need to be added; and the operating cost is high and the overall benefit is poor are solved. According to the improved process, the overall heat value of remaining wastes after sorting can be improved greatly, and the wastes are conveyed into the furnace and burnt quickly; the combustion-supporting materials (coal, fuel, natural gas and the like) are not required; not only are energy sources saved, but also the operating cost is reduced; not only is the amount of the wastes added to the furnace reduced, but also the combustion-supporting materials are not required; the emission of waste gas is reduced greatly, and pollution to environment by atmospheric pollutants is reduced; the cost for waste gas purification and treatment is decreased; and the problems that the heat value of the materials added to the furnace is low and the combustion-supporting materials need to be added; and the operating cost is high and the overall benefit is poor are solved.

Owner:王英宾

Water purifying agent specially used for waste water treatment and preparation method of water purifying agent

ActiveCN108557943AFormulation ScienceReasonable formulaWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium BentonitePotassium fluoride

The invention discloses a water purifying agent specially used for waste water treatment. The water purifying agent is prepared from the following raw materials in parts by weight: 10-20 parts of bentonite, 15-25 parts of kaolin, 8-14 parts of modified attapulgite, 6-12 parts of aluminum hydroxide, 5-10 parts of sodium hydroxide solution, 6-11 parts of hydrochloric acid, 7-13 parts of activated coal ash, 3-7 parts of calcium carbonate, 2-5 parts of potassium alum, 3-8 parts of Chinese yam, 5-9 parts of active carbon, 0.2-0.6 part of hydrogen peroxide, 0.3-0.7 part of pore-enlarging agent, 1-2parts of dispersing agent, 1-2 parts of bactericide and a proper amount of water, wherein the activated coal ash is prepared through mixing common coal ash with potassium fluoride and then placing ina high-temperature environment to roast; the mass fraction concentration of the sodium hydroxide solution is 30%. The water purifying agent specially used for waste water treatment is scientific and reasonable in formula, good in purification performance, low in cost and good in stability, and can be used for large-scale industrial production.

Owner:广州市芦苇环保科技有限责任公司

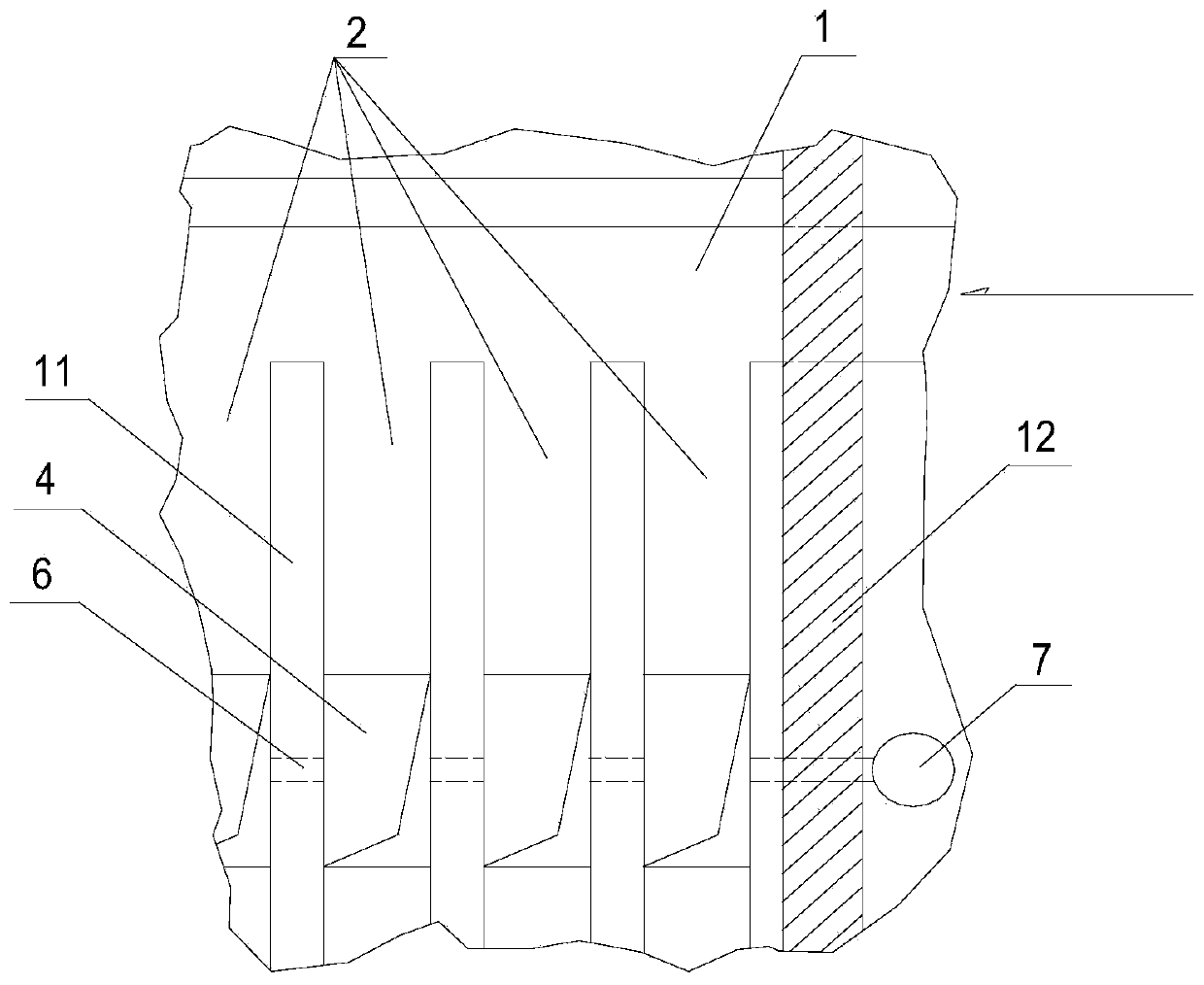

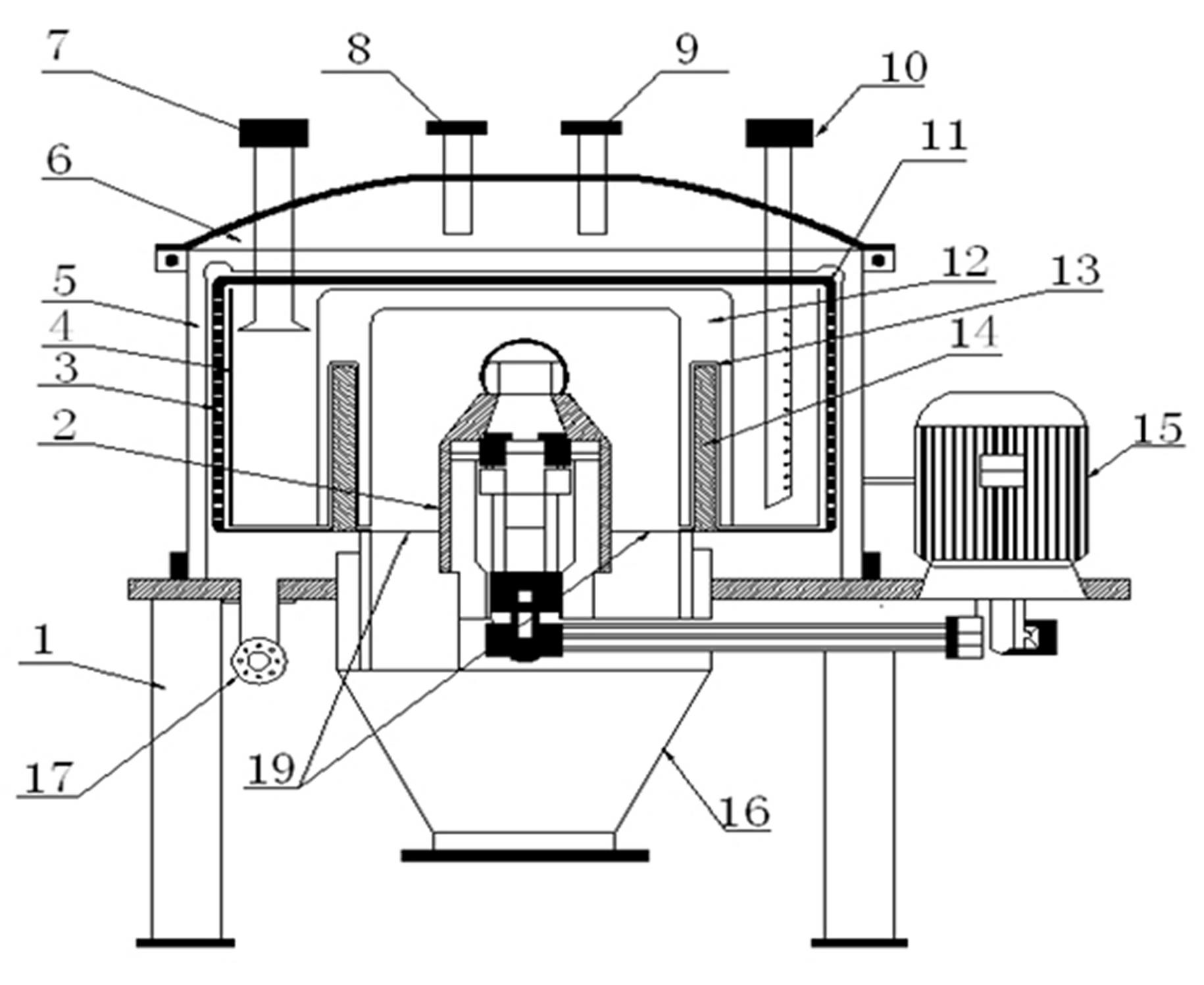

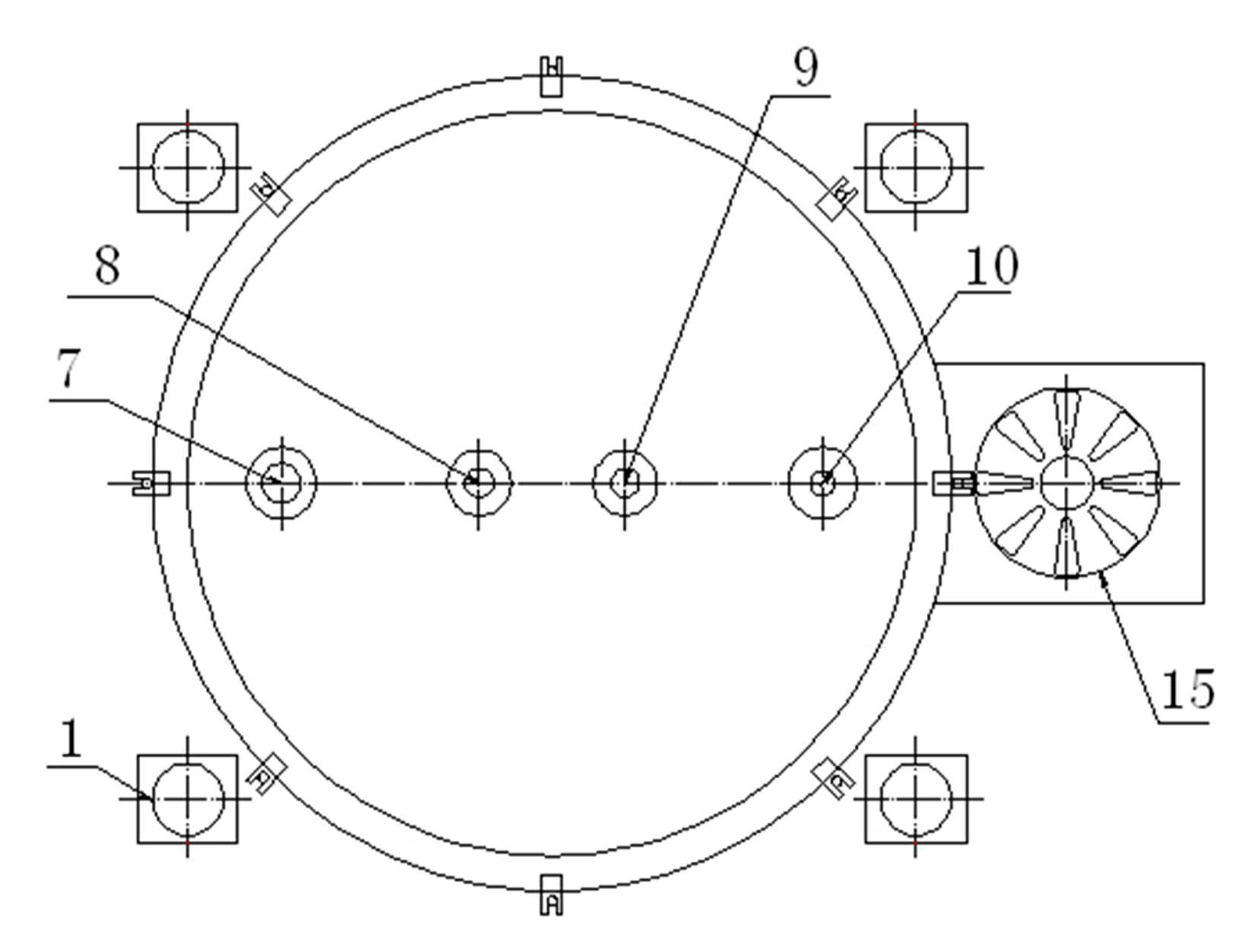

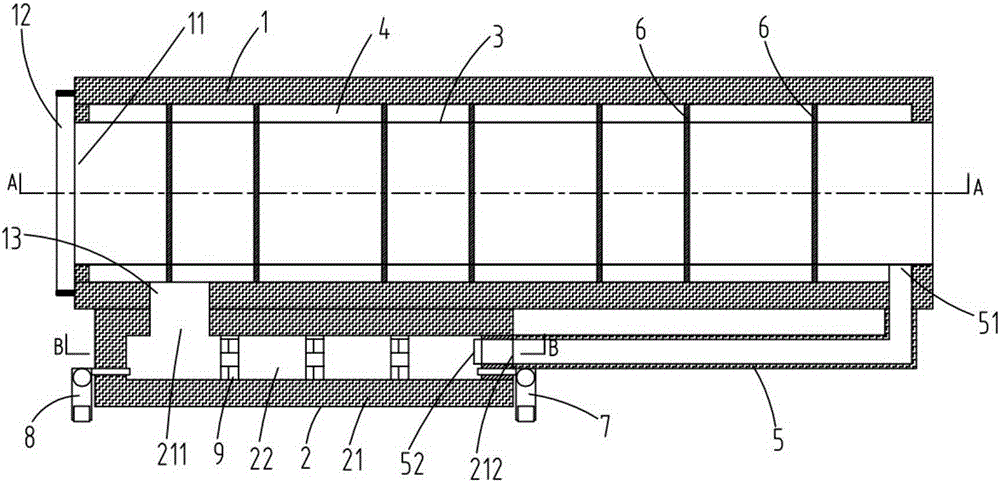

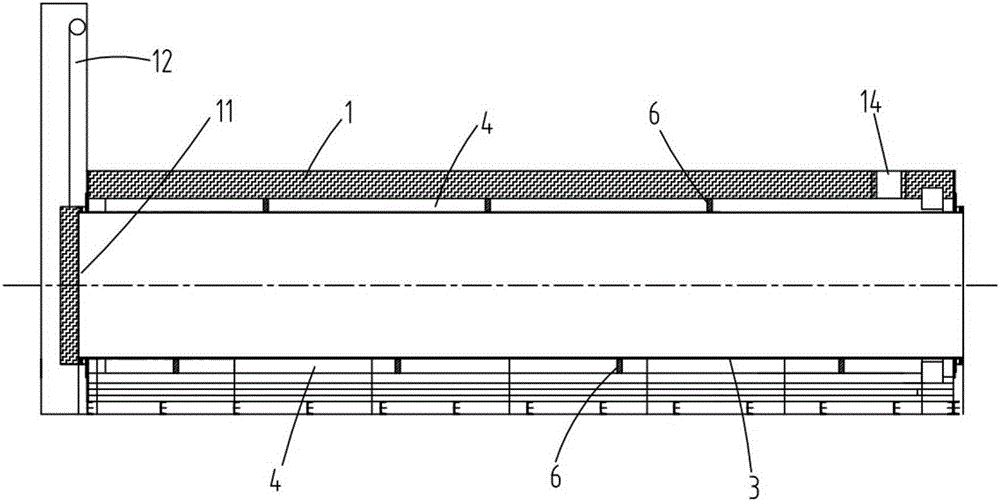

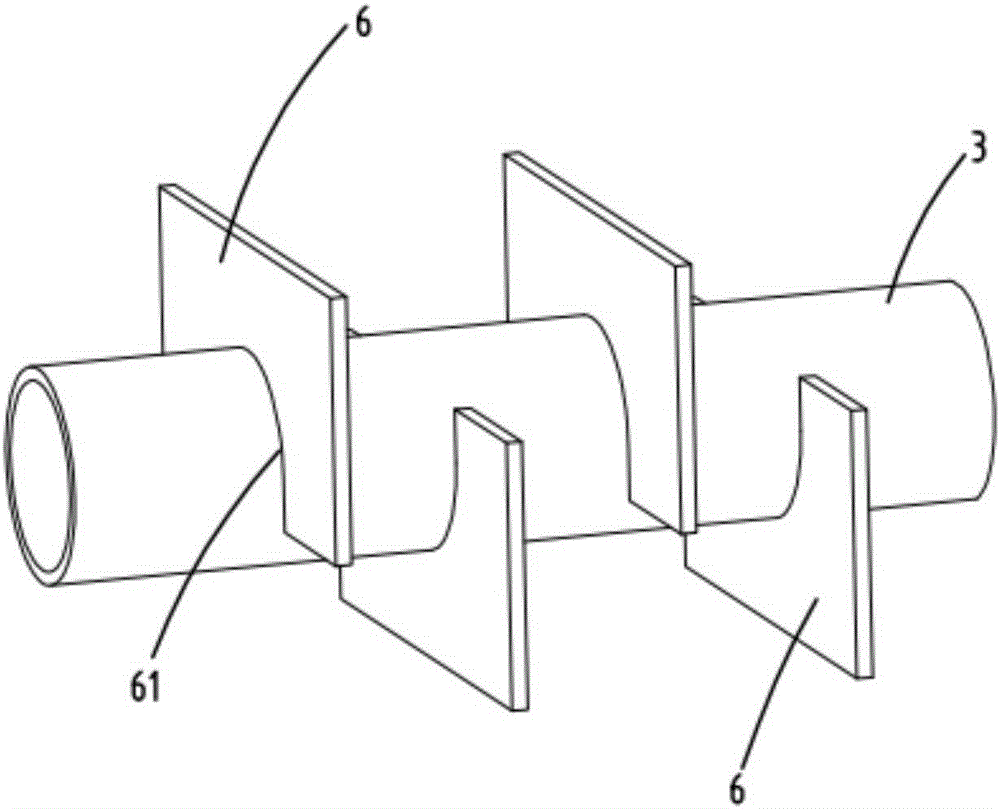

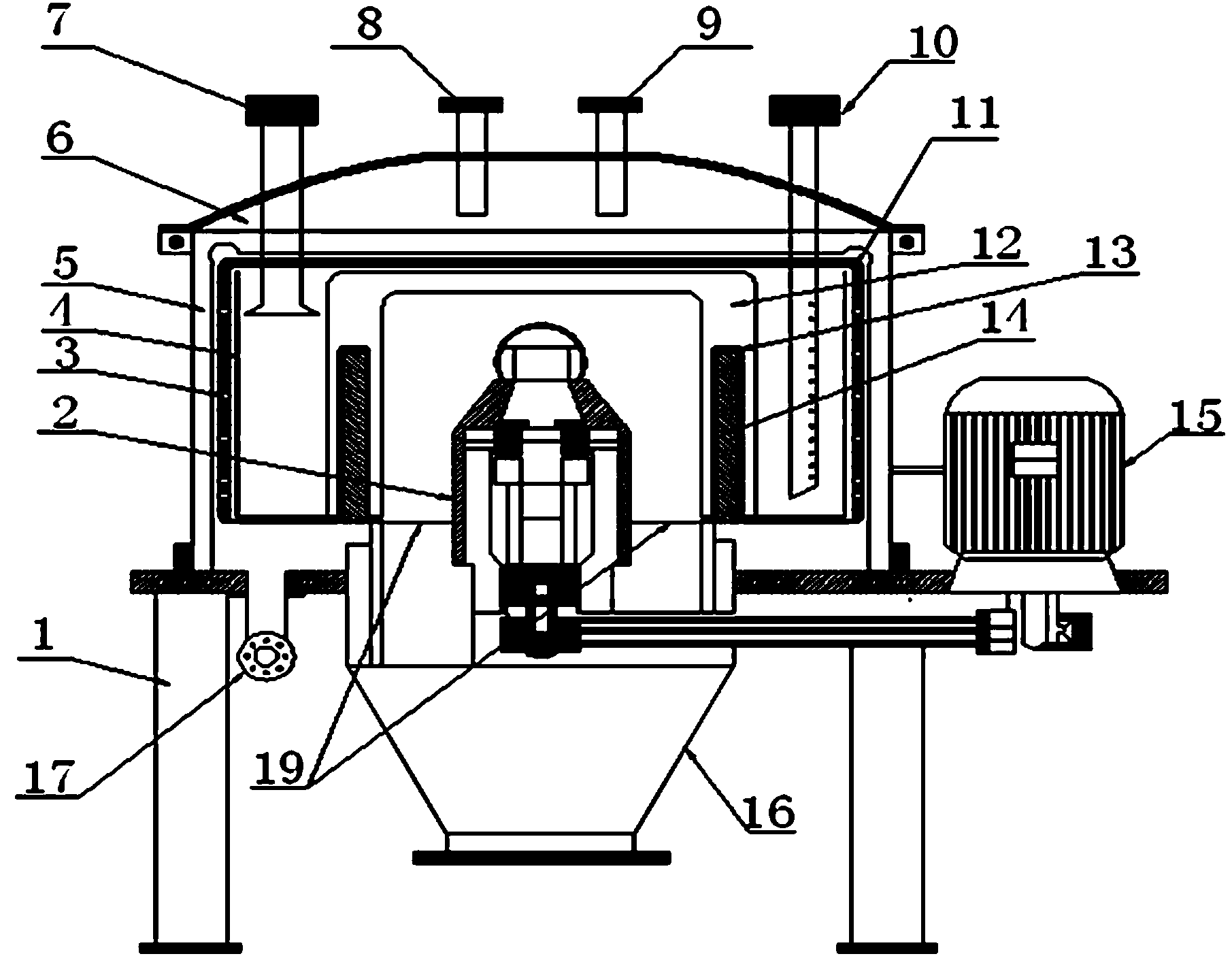

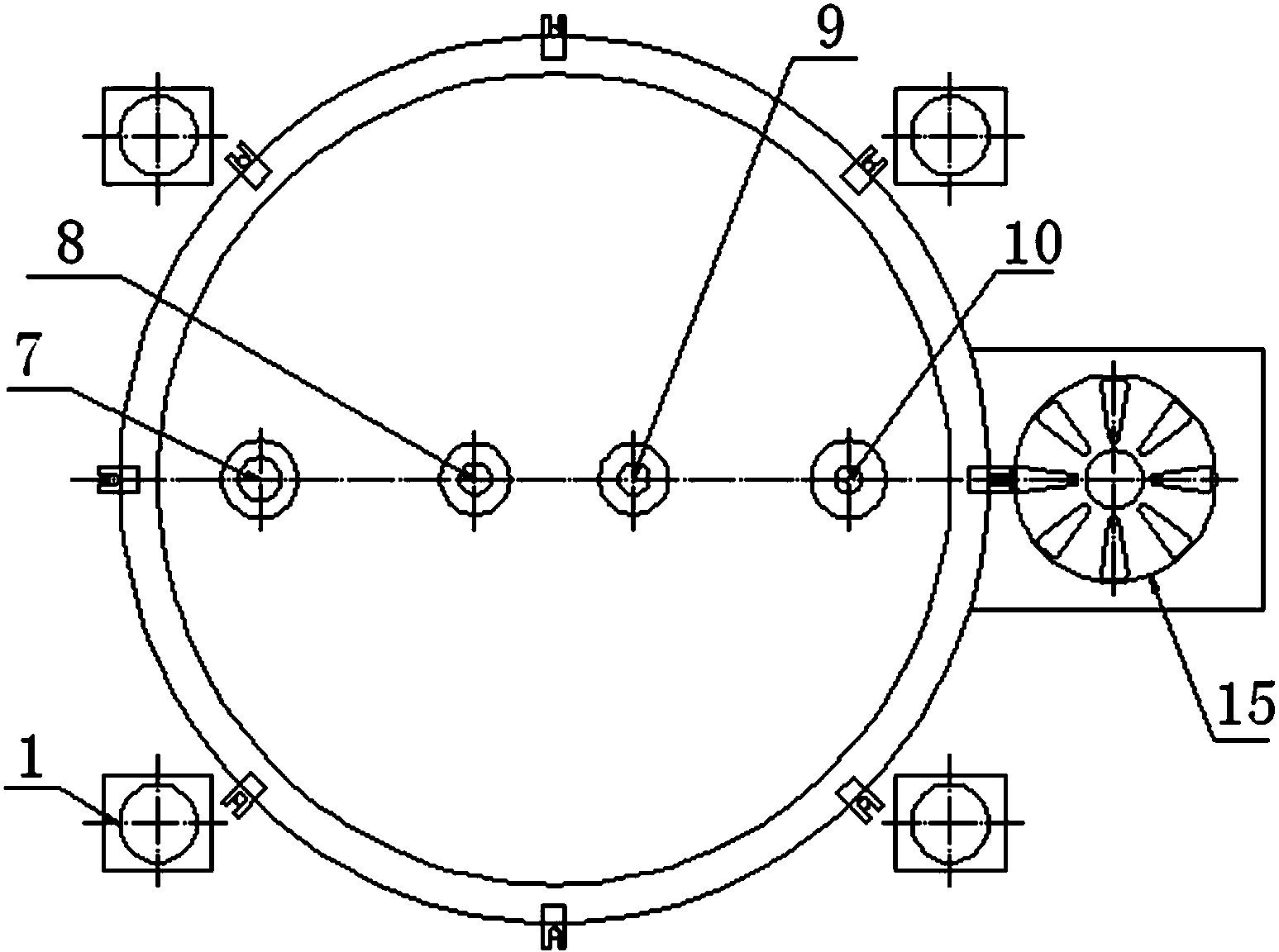

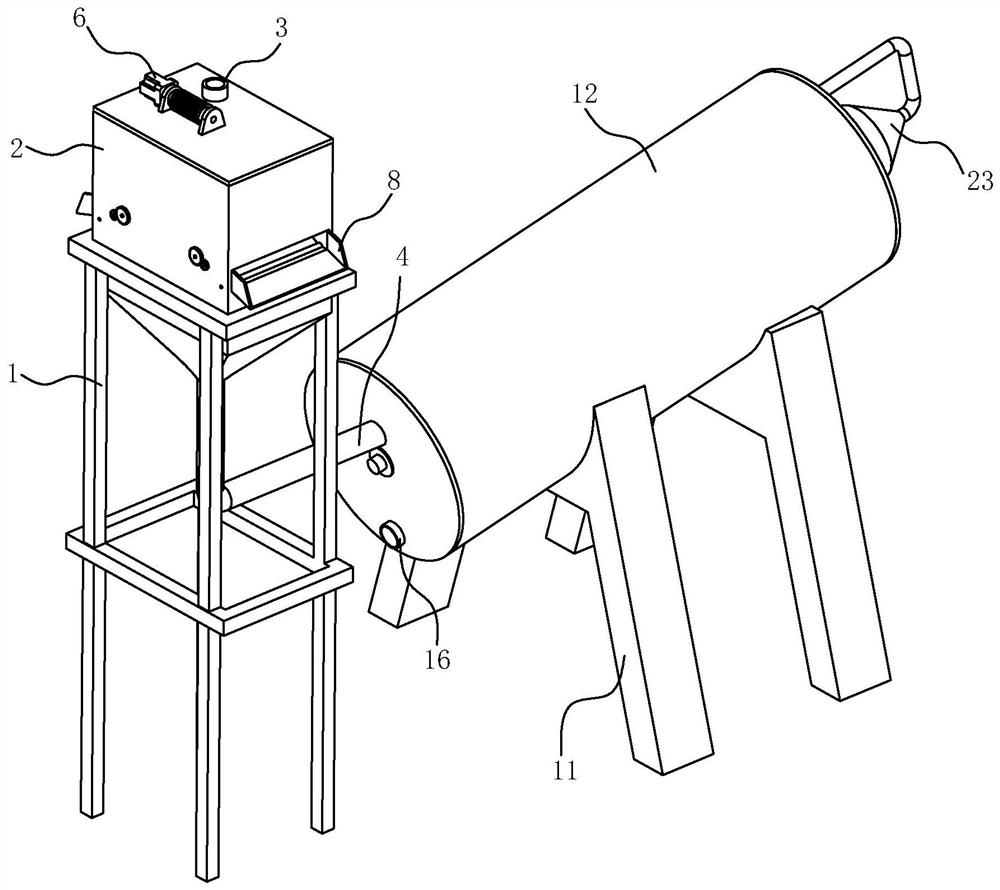

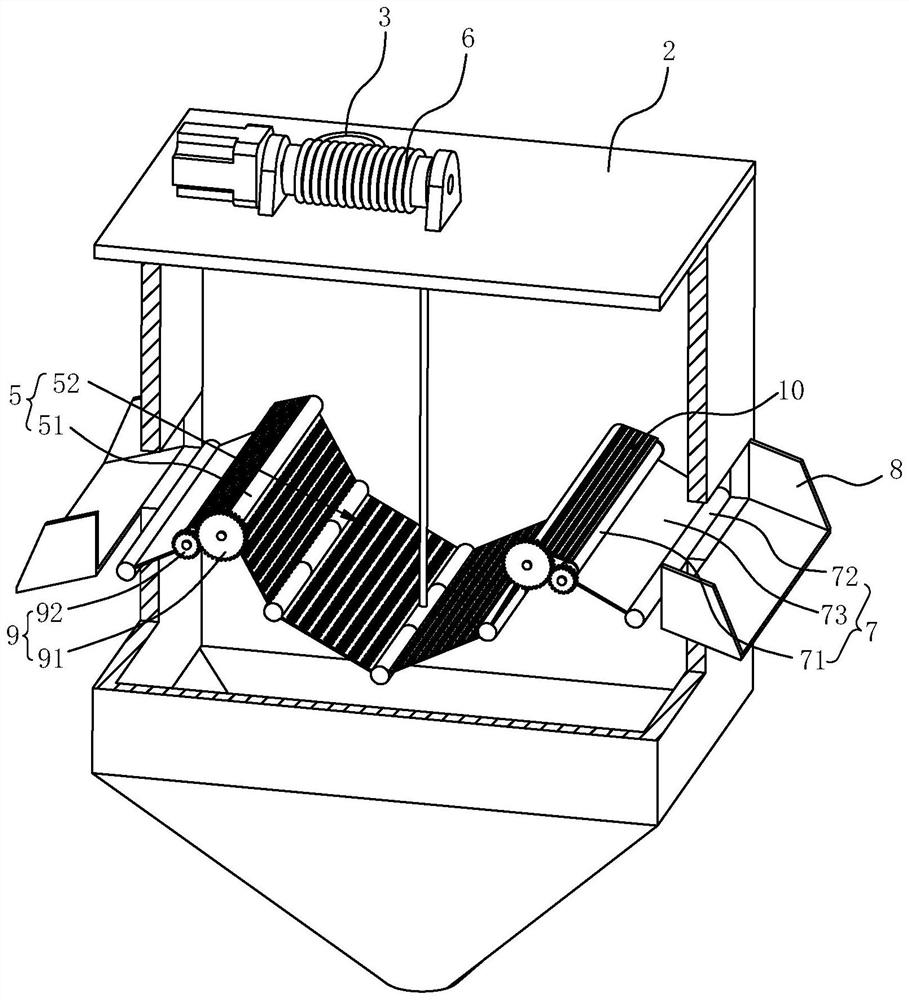

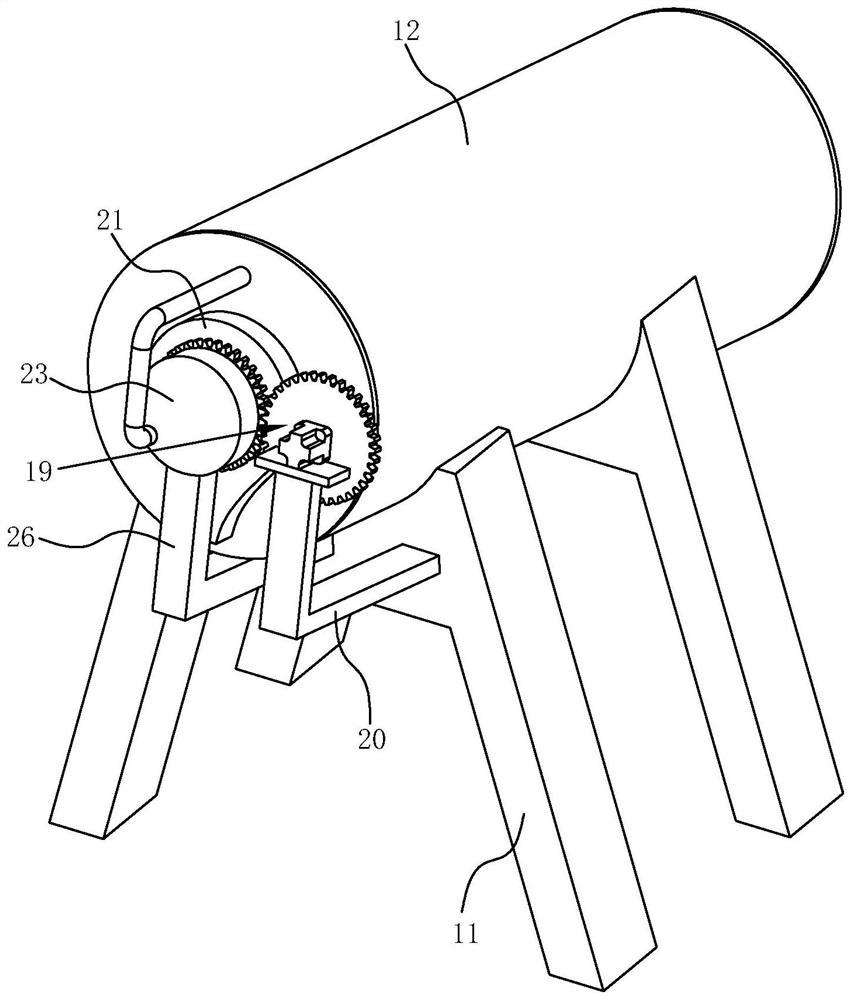

Full-automatic silver powder centrifugal filtering and washing device and silver powder washing method

ActiveCN102601353AReduce moisture contentShorten drying timeMoving filtering element filtersElectrolysisMetal

The invention relates to a full-automatic silver powder centrifugal filtering and washing device and a silver powder washing method, wherein the device comprises an engine base (1), a housing which is installed on the engine base and a cover (6) which is mounted on the top of the housing. The method provided by the invention realizes full automation for washing and filtering silver powder, improves the electrolytic silver powder washing efficiency, reduces production cost and improves metal recovery.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Flammable gas recycling thermal treatment furnace

ActiveCN105154113AEnable recyclingReduce energy consumptionSpecial form destructive distillationCombustion chamberEngineering

The invention relates to a flammable gas recycling thermal treatment furnace which comprises a furnace body, a combustion chamber provided with a combustor and an exhaust discharge pipe, wherein a furnace pipe is arranged in the furnace body, a furnace door is arranged at a feeding end, a closed annular hot air channel is formed between the inner wall of the furnace body and the outer wall of the furnace pipe, and a high-temperature glue gas inlet and a flue gas exhaust opening are formed on the furnace body; the combustion chamber comprises a housing which is internally provided with a combustion cavity, wherein an air jet hole and a gas inlet are formed on the housing, the combustion chamber is arranged out of the furnace body, the air jet hole is communicated with the high-temperature flue gas inlet on the furnace body, and the gas inlet of the exhaust gas discharge pipe is communicated with the inner side of the furnace pipe and the gas outlet of the exhaust gas discharge pipe extends into the combustion cavity through the gas inlet on the combustion chamber. According to the furnace provided by the invention, the combustion chamber and the furnace body are independently arranged, the exhaust gas discharge pipe introduces flammable gas generated in the furnace pipe into the combustion chamber to be combusted, and high-temperature flue gas generated by combustion is introduced into a hot air channel to supply energy for thermal treatment, so that energy sources are recycled, the energy consumption is reduced, and the furnace is energy-saving and environmental-friendly, easy to overhaul, simple in integral structure and low in cost.

Owner:托普工业(江苏)有限公司

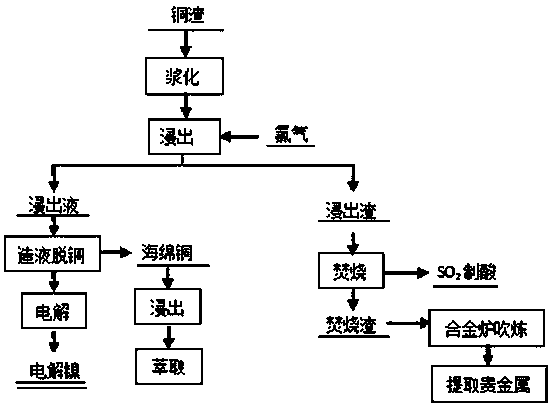

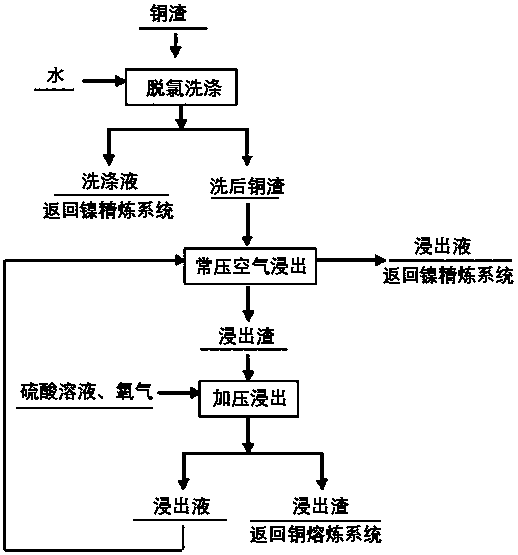

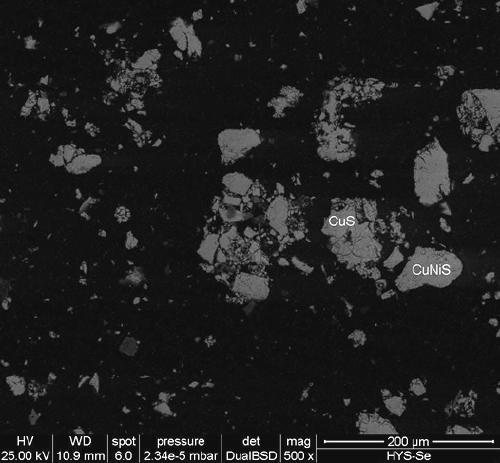

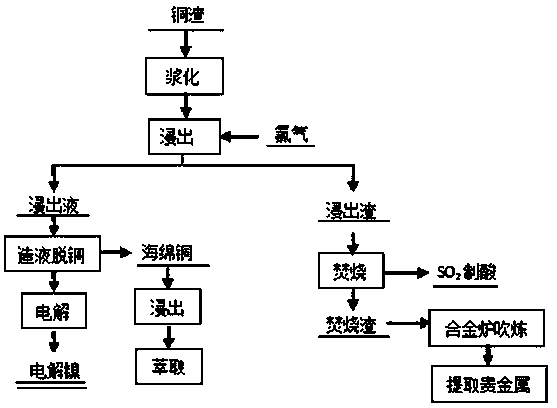

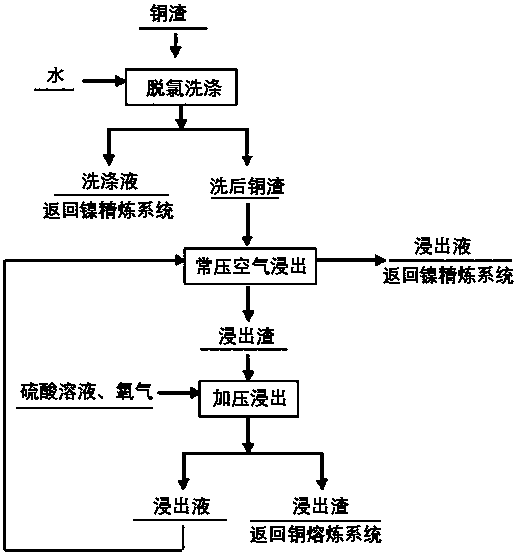

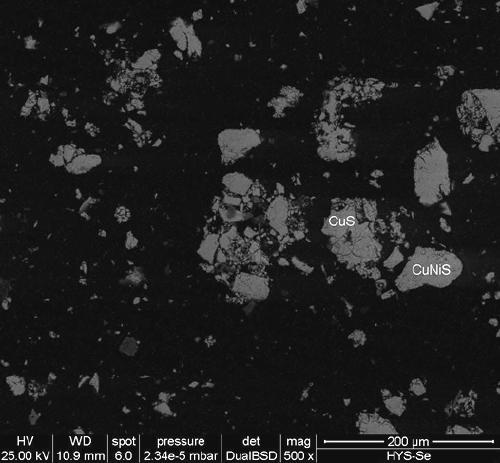

Resourceful treatment method for copper slag of nickel refining system

ActiveCN109371245AEfficient separationReduce the cost of purification treatmentProcess efficiency improvementPregnant leach solutionResource utilization

The invention provides a resourceful treatment method for copper slag of a nickel refining system. The method comprises the following steps that the copper slag is washed with water, and washing liquid is merged into the nickel refining system; Cu <2+> is added to the copper slag which is cleaned for the first time, then normal-pressure air leaching is carried out after a leaching solution is subjected to slurrying, wherein the leaching solution is obtained after pressurized oxygen leaching, and the leaching solution is merged into the nickel refining system; and leaching slag is added to a sulfuric acid solution, oxygen is introduced to carry out the pressurized oxygen leaching, the leaching slag is used as copper concentrate to return to a copper smelting system, and the leaching solution is returned to be subjected to the normal-pressure air leaching. According to the method, copper, nickel and cobalt in the copper slag can be effectively separated, and the resourceful and comprehensive recycling of the nickel, the copper and the cobalt can be realized, the principle is reliable, the process is short, the resource utilization rate is high, and the industrial production is easy to realize; and the method is especially suitable for the treatment of the copper slag of the nickel refining system.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

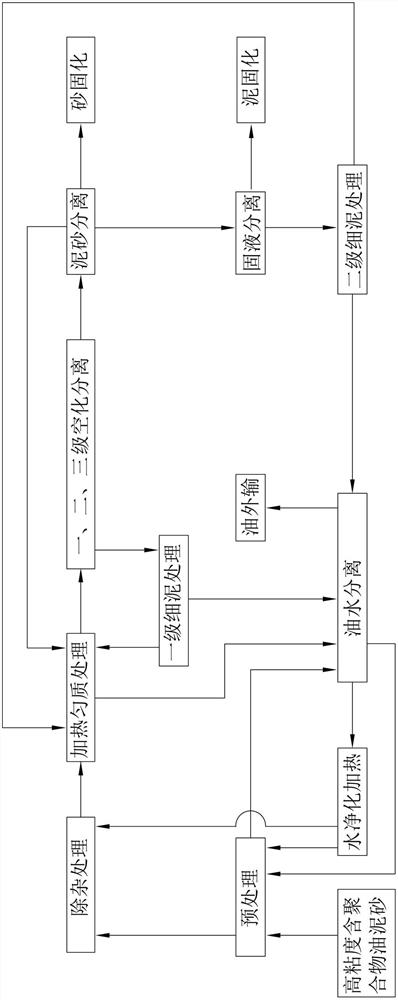

Treatment method and treatment system capable of realizing zero-emission purification of high-viscosity polymer-containing oil silt

PendingCN111807677ASolve the failure to meet the standard utilizationSolve the problem of secondary pollutionWater/sewage treatment by centrifugal separationSludge treatment by thermal conditioningPre treatmentBuilding material

The invention relates to a treatment method and a treatment system for zero-emission purification of high-viscosity polymer-containing oil silt. The treatment method comprises the following implementation steps that: heating and overflowing are conducted in a pretreatment tank; water and chemicals are added into primary and secondary impurity removal machines to remove impurities; heating, homogenizing and overflowing are conducted in a heating homogenizing tank; a slurry pump is connected in series with a first-stage cavitation oil removal separation tank, a second-stage cavitation oil removal separation tank and a third-stage cavitation oil removal separation tank to treat the oil silt; a material from an upper outlet of a fine sand cyclone separator supplies liquid to centrifuges through a centrifugal machine liquid supply buffer tank, and a lower outlet discharges clean sand through a clean sand dehydration device; a primary fine mud treatment tank is used for receiving and treating oil water overflowing around; the effluent of the first-stage centrifuge and the effluent of the second-stage centrifuge enter a second-stage fine mud treatment tank to be treated; secondary centrifugal treatment is conducted on the fine mud through a mud stirring tank, and then clean mud is discharged; an aeration system and an oil scraping machine are mounted in an oil-water separation tank; awater pump is connected with a sewage treatment tank to form closed circulation through a heating furnace, and oil is output; and a building material cured product is prepared from clean silt. According to the invention, zero-emission purification treatment is completely achieved, and the problem of secondary pollution caused by purification treatment of the high-viscosity polymer-containing oilsilt is solved.

Owner:TIANJIN TAIXING ENG TECH CO LTD

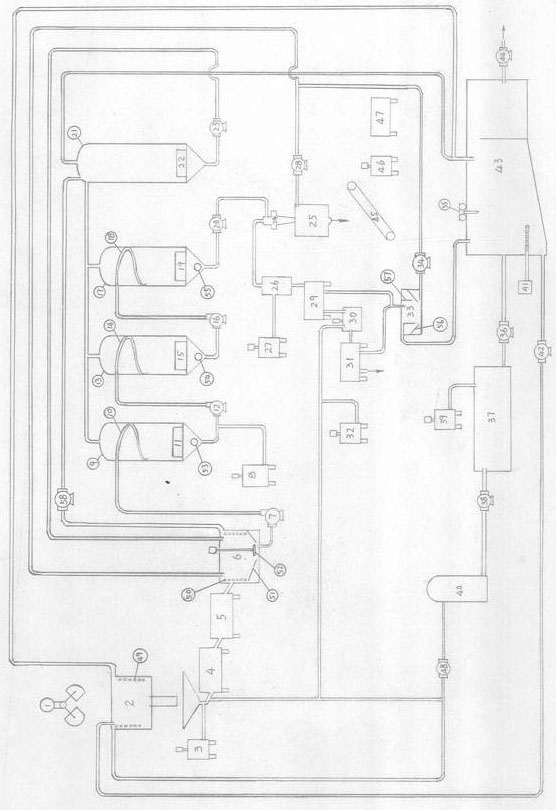

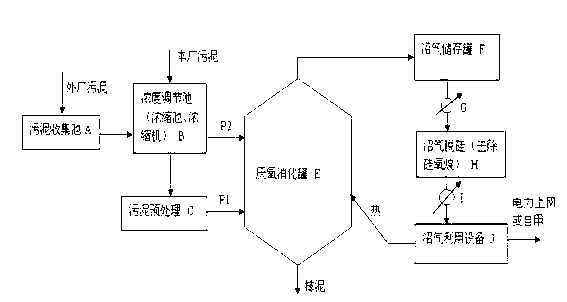

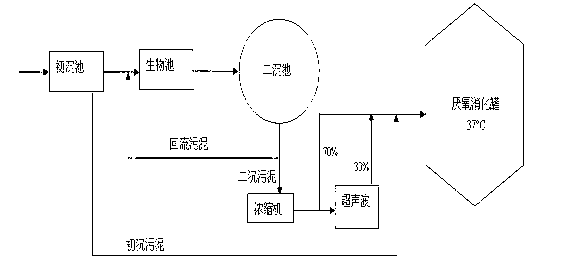

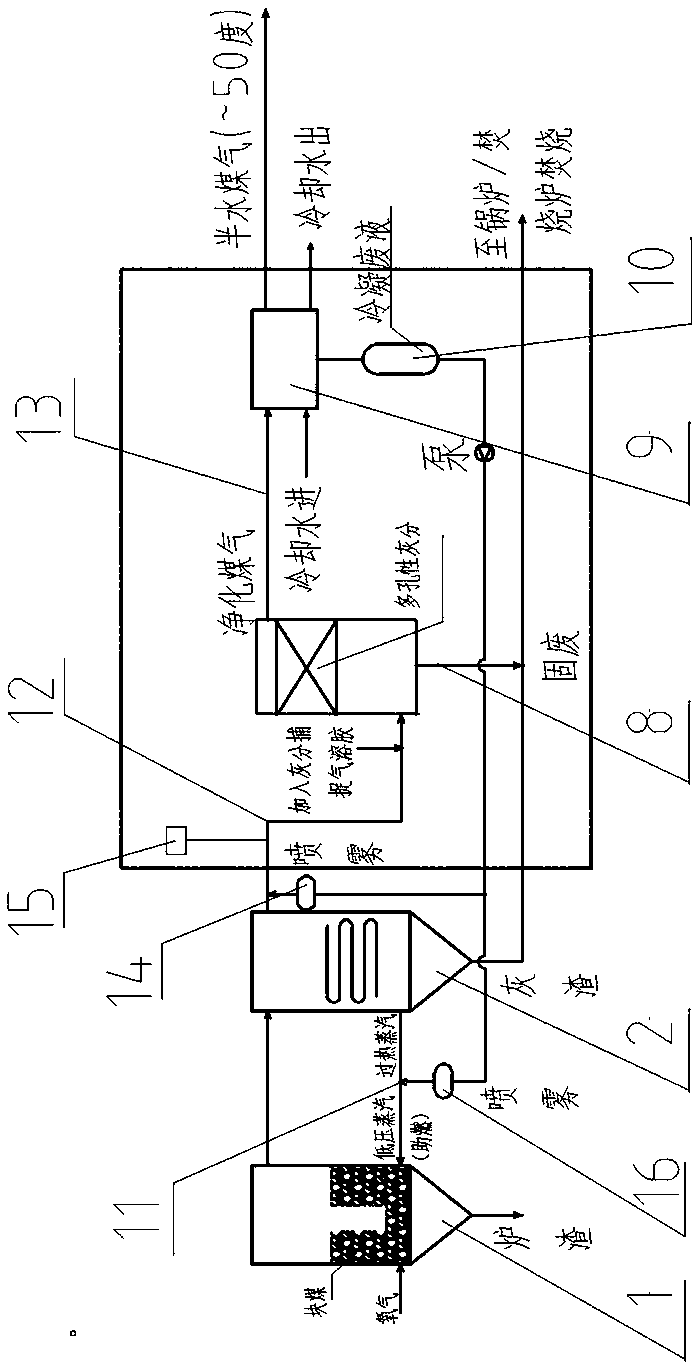

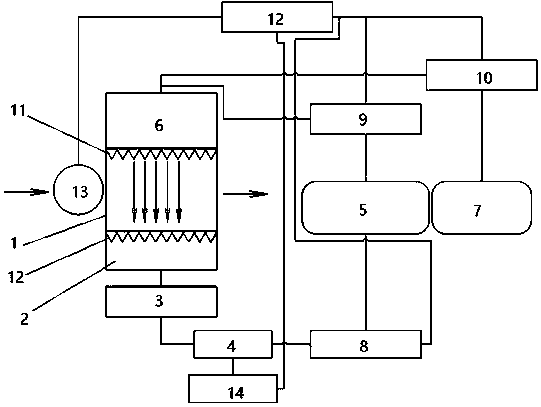

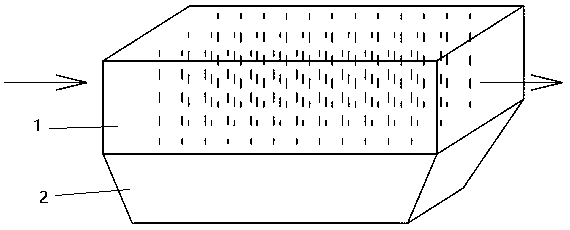

Pre-treatment method for eliminating or reducing siloxane and color material in biogas

ActiveCN103172229AReduce the cost of purification treatmentReduce maintenance costsWaste based fuelBiological sludge treatmentPretreatment methodEngineering

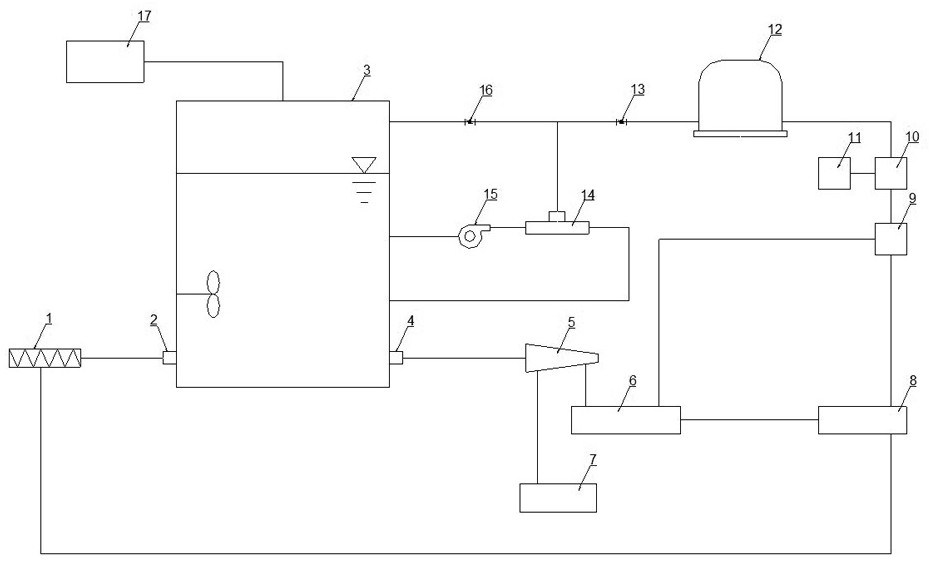

The invention relates to the technical field of sewage treatment, in particular to a pre-treatment method for eliminating or reducing siloxane and color materials in biogas. The method comprises the following steps: firstly making sludge enter into a concentration regulation pool; adjusting the concentration of the sludge; dividing the adjusted sludge into two portions, wherein one portion of the sludge directly enters into an anaerobic digestion tank and the other portion of the sludge is pre-treated firstly and then enters into the anaerobic digestion tank to perform anaerobic digestion reaction in the anaerobic digestion tank; making the produced biogas enter into a biogas storage tank, desilicating the biogas, and finally removing the siloxane in the biogas and making the biogas enter into a biogas utilization device. By adopting the technical scheme, the siloxane and color materials in the biogas are eliminated or reduced, the biogas utilization device is protected, the biogas purification treatment cost and the maintenance cost of the biogas utilization device are reduced; the intelligent analysis and control are realized, and the technical advantage and market acceptability of the sludge anaerobic digestion process technology are expanded.

Owner:国翔航天环保科技(集团)有限公司

Full-automatic silver powder centrifugal filtering and washing device and silver powder washing method

ActiveCN102601353BReduce moisture contentShorten drying timeMoving filtering element filtersElectrolysisMetal

The invention relates to a full-automatic silver powder centrifugal filtering and washing device and a silver powder washing method, wherein the device comprises an engine base (1), a housing which is installed on the engine base and a cover (6) which is mounted on the top of the housing. The method provided by the invention realizes full automation for washing and filtering silver powder, improves the electrolytic silver powder washing efficiency, reduces production cost and improves metal recovery.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

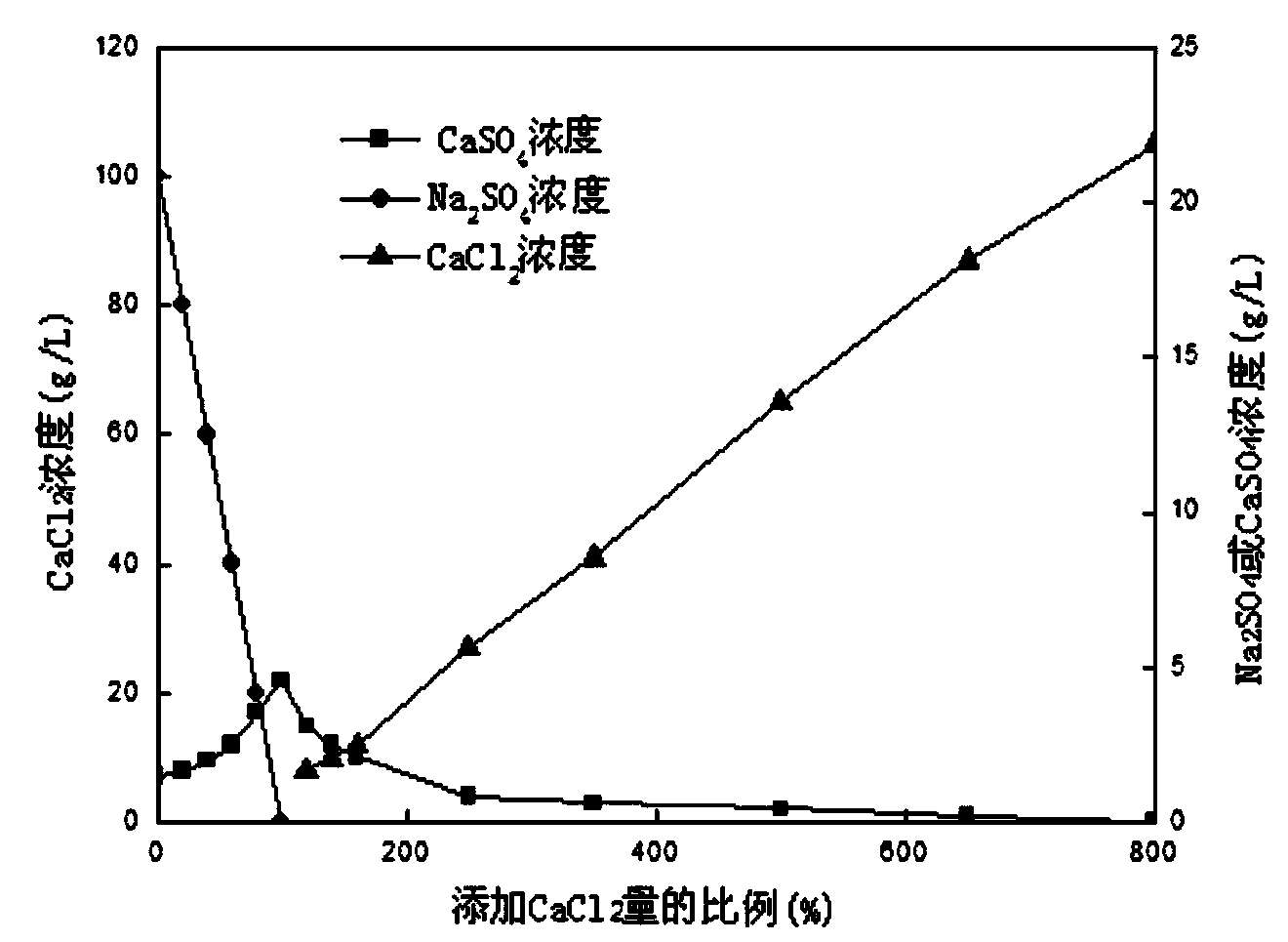

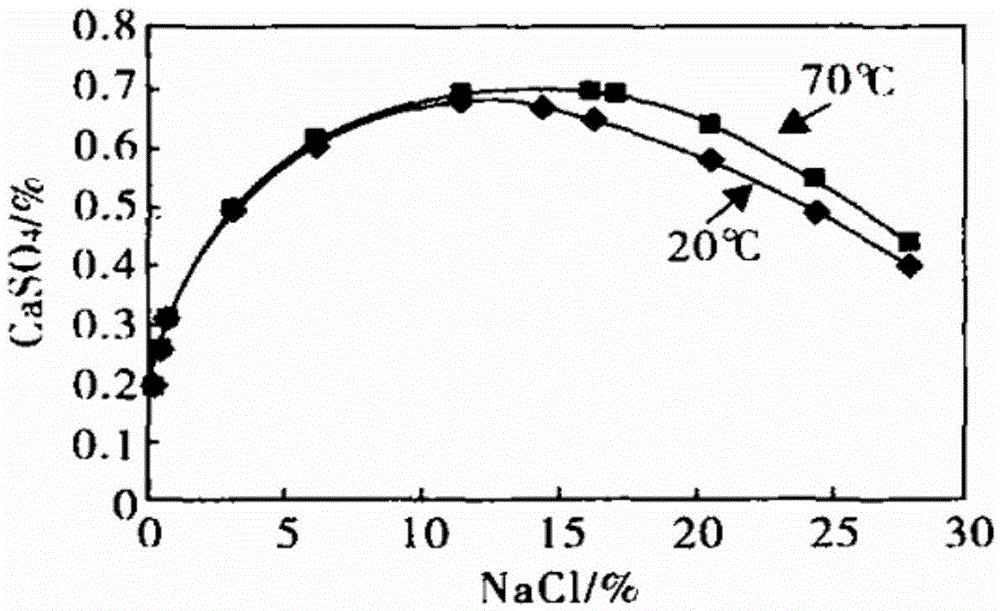

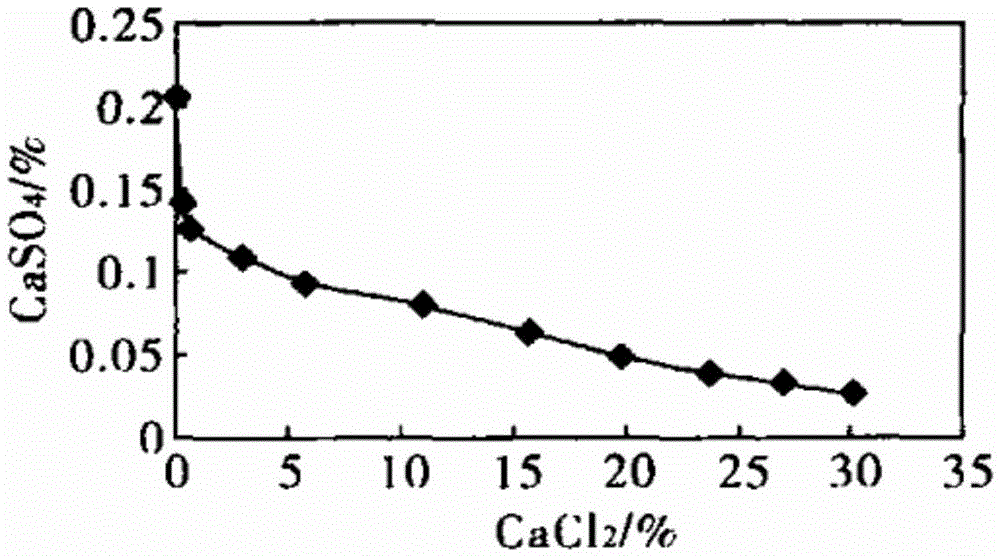

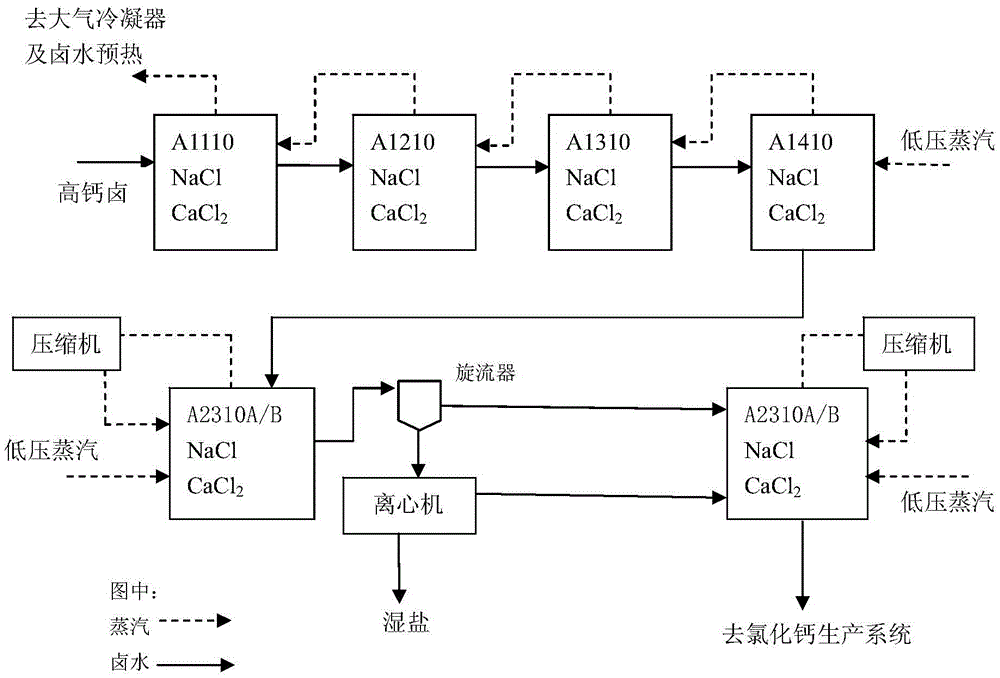

A kind of low-sulfur large-grain salt produced by sodium sulfate type salt mine and production method thereof

ActiveCN104016378BLess investmentEmission reductionCalcium/strontium/barium chloridesAlkali metal chloridesSulfate radicalsSodium sulfate

The invention relates to a low-sulfur large-grained salt produced from sodium sulfate type salt mine and a preparation method thereof. Liquid calcium from ammonia alkali factory is blended with water and injected into sodium sulfate type salt mine for underground desulfurization to form high calcium brine, and the high calcium brine as a raw material is subjected to salt calcium coproduction to produce low-sulfur large-grained salt by using an MVR (mechanical vapor recompression) evaporator with a crystal cultivation baffling cylinder and a unique production process. The product comprises not less than 99.50% of sodium chloride (dry basis), no more than 0.2% of sulfate radical, more than 70% of granularity greater than 0.4 mm, and no more than 1% of granularity less than 0.15 mm; the product does not contain any anti-caking agent, and has anti-caking period more than 4 months, so as to meet the needs of industrial production turnover.

Owner:江苏苏盐井神股份有限公司 +1

Waste heat recovery system matched with HISMELT smelting reduction ironmaking system

The invention discloses a waste heat recovery system matched with an HISMELT smelting reduction ironmaking system. The waste heat recovery system comprises a cooling flue and a flue steam pocket, the outlet end of the cooling flue is provided with a connecting flue, the outlet of the connecting flue is connected to a separator, the inlet section of the cooling flue is connected to a reacting furnace, and a cooling medium is introduced into the connecting flue to cool flue gas; a smoke outlet of the separator is connected with a steam superheater, a superheater smoke outlet of the steam superheater is connected with a fire-tube boiler, a boiler ascending tube and a boiler descending tube of the fire-tube boiler are connected to a boiler drum, the fire-tube boiler is connected with a fire-tube economizer, and a smoke exhaust barrel is arranged at the bottom of the fire-tube economizer. An economizer water outlet pipe on the fire tube economizer supplies water to the fire tube boiler drum and the flue drum, steam output by the flue drum and the fire tube boiler drum is conveyed to the steam superheater, and a superheated steam output pipe is arranged on the steam superheater. The slag-bonding phenomenon can be effectively avoided, and the heat efficiency is greatly improved.

Owner:SUZHOU HAILU HEAVY IND +1

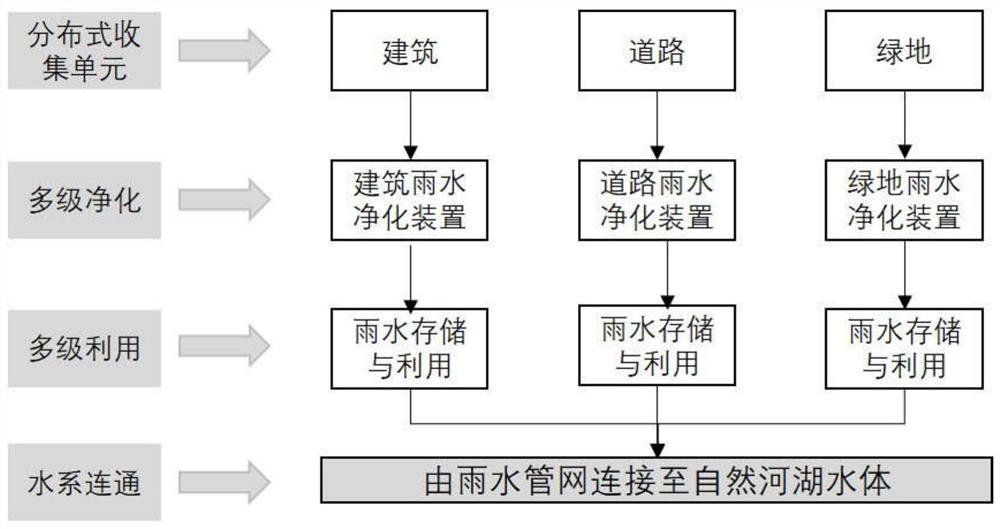

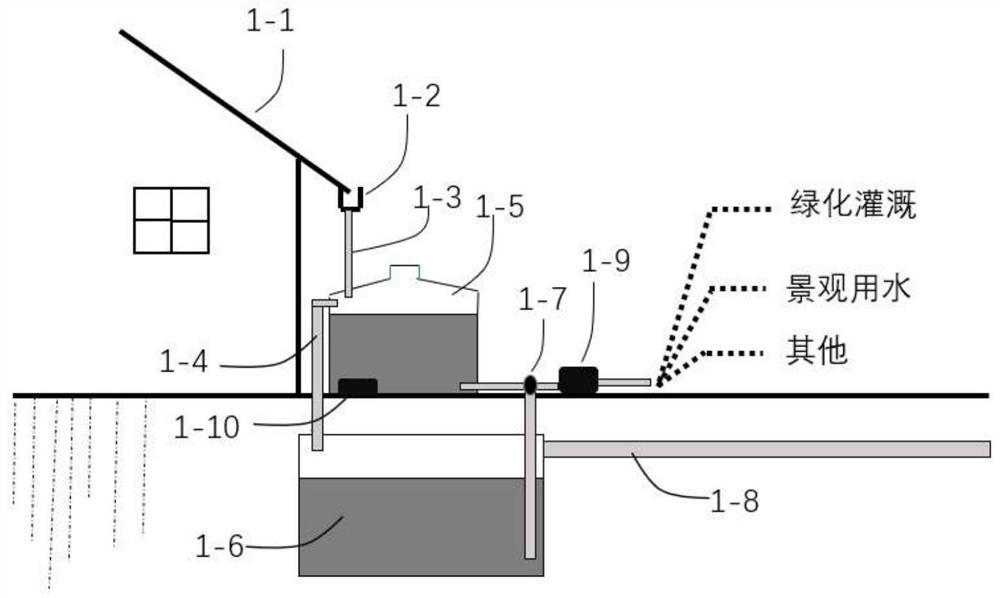

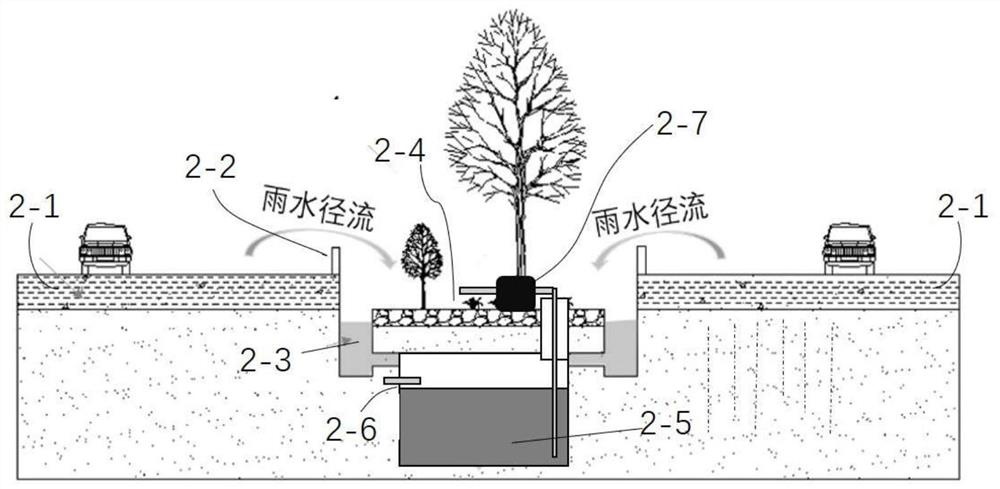

Multistage distributed type urban rainwater comprehensive utilization system and construction method therefor

InactiveCN112049185AReduce purification costsImprove flood protectionSewerage structuresGeneral water supply conservationConstructed wetlandStormwater harvesting

The invention discloses a multistage distributed type urban rainwater comprehensive utilization system and a construction method therefor. Firstly, the system divides house buildings, roads and greenbelts into a plurality of independent rainwater collection and utilization subsystems according to different underlying surface types, and each independent rainwater collection and utilization subsystem only needs to treat rainwater in the area to form a distributed type rainwater collection system, so that peak elimination from the source is realized; then excessive rainwater exceeding the storageload of each independent rainwater collection and utilization subsystem is conveyed to large regulation and storage facilities such as an artificial wetland through a pipe duct and a pump station forwater quality improvement and utilization; and finally, all the independent rainwater collection and utilization subsystems are in communication, and excessive rainwater of the distributed unit system is discharged into water bodies such as rivers and lakes for comprehensive regulation and storage. According to the system, the operation pressure caused by centralized rainfall on a rainwater pipenetwork is reduced, the rainwater zoning collection and utilization efficiency and the purification capability are improved, and the urban water environment is improved.

Owner:NANCHANG INST OF TECH

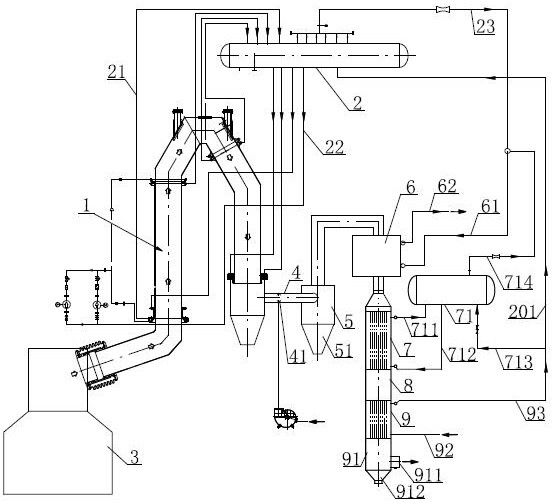

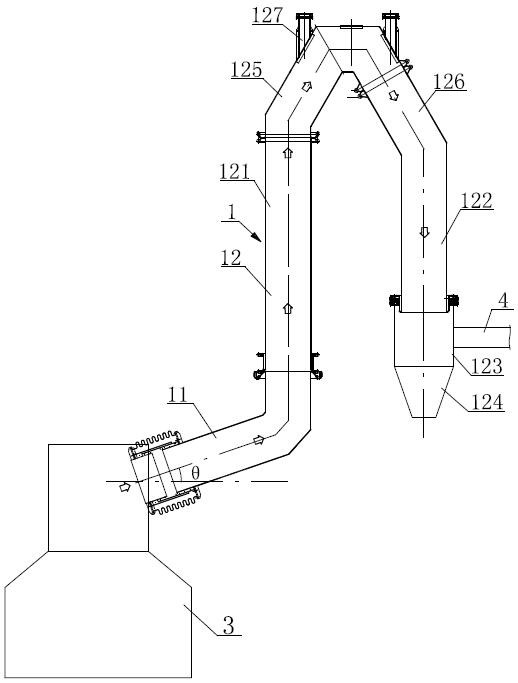

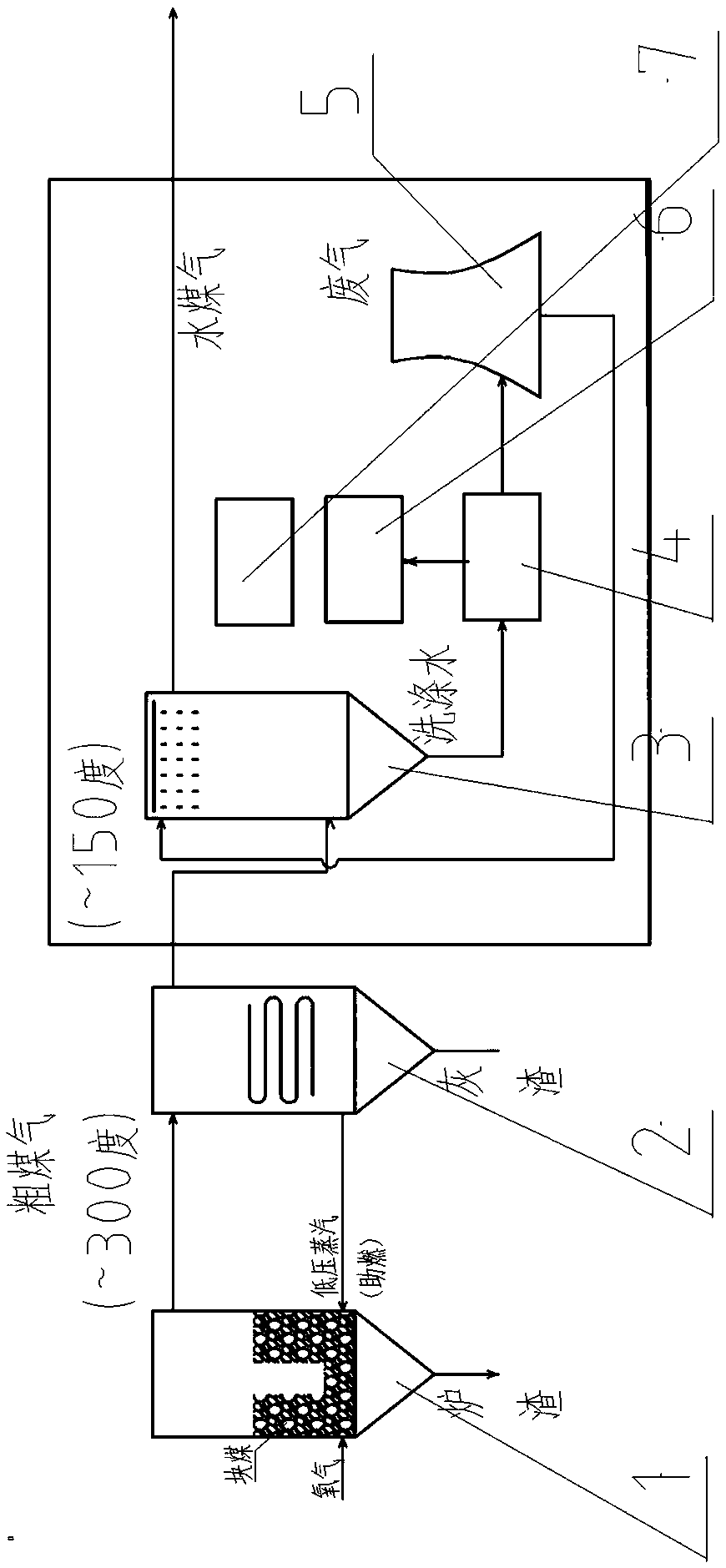

Three-waste processing method and system in coal-to-gas technology of fixed bed

InactiveCN108384584AReduce construction costsReduce use costGas purification by non-gaseous materials condensationIncinerator apparatusCoal chemical industrySystem building

The invention discloses a three-waste processing method in a coal-to-gas technology of a fixed bed. A traditional gas-water separation device is replaced with a gas-solid separation device, and therefore a cooling tower and a waste water processing pool huge in occupied area in a traditional process are omitted, the construction cost of a system is reduced, the use cost of a large amount of waterresources and the purification processing cost of waste water are saved, and therefore the use and maintenance cost of the system is reduced; extremely high economy is realized compared with the traditional process, the production cost of a coal chemical industry enterprise is greatly reduced, people are more willing to use the system, and extremely good market prospects are realized.

Owner:上海境业环保能源科技股份有限公司

Construction method of composite horizontal subsurface wetland

InactiveCN103896405AAbility to prevent eutrophicationRealize ecological treatment technologySustainable biological treatmentBiological water/sewage treatmentSlagGranularity

The invention discloses a construction method of a composite horizontal subsurface wetland. The construction method comprises the following steps of primarily clearing a river bed, mixing marble pebbles and iron-ore slag in mass ratio of 1000: (1-3) to obtain a stone material, and paving the stone material on the cleared river bed to form a riverway; selecting reed or cattail of 1 to 3 years old, cutting stem leaves on the upper part of the reed or cattail, and planting perennial roots of the reed or cattail onto the paved stone material; and paving the toxic-free rubber particles with the granularity of 2cm to 4cm on the surface of the riverway with the reed or cattail, and finally inserting ventilation pipes into the surface of the riverway which is paved with the toxic-free rubber particles to complete the construction of the composite horizontal subsurface wetland.

Owner:SHANGHAI INST OF TECH

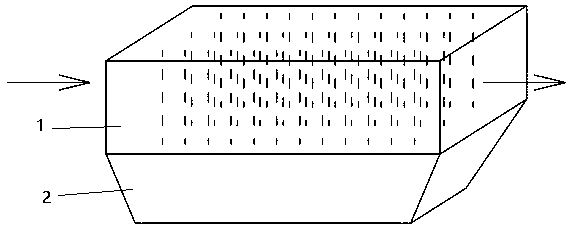

Purification device for exhaust particulate matter of internal combustion engine

ActiveCN108533364BMeet purification requirementsEasy to getExhaust apparatusSilencing apparatusParticulatesWastewater

The invention discloses a method for purifying internal combustion engine exhaust particles. The method comprises the following steps: S1, enabling internal combustion engine exhaust to unidirectionally flow through a particle collection channel, wherein the particle collection channel is a hollow cavity; S2, pressurizing water in a water tank to form a pressure water column and injecting the water column into the particle collection channel, wherein an injection of the pressure water column is orthogonal to a flow direction of the internal combustion engine exhaust; S3, collecting wastewaterobtained after contacting the pressure water column and the internal combustion engine exhaust, determining light transmittance of the wastewater and feeding the wastewater into the water tank; renewing the water in the water tank when the light transmittance is less than a set value, and returning to the S2, otherwise directly returning to the S2. The invention further discloses a device for purifying the internal combustion engine exhaust particles. According to the method disclosed by the invention, the internal combustion engine exhaust can be continuously purified, and the exhaust particles are adsorbed. Moreover, the purification device does not need to be subjected to high-cost regeneration treatment, and the device is low in using cost, low in energy consumption, clean and environmental-friendly.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Copper slag resource treatment method in nickel refining system

ActiveCN109371245BEfficient separationReduce the cost of purification treatmentProcess efficiency improvementPregnant leach solutionCobalt

The invention provides a resourceful treatment method for copper slag of a nickel refining system. The method comprises the following steps that the copper slag is washed with water, and washing liquid is merged into the nickel refining system; Cu <2+> is added to the copper slag which is cleaned for the first time, then normal-pressure air leaching is carried out after a leaching solution is subjected to slurrying, wherein the leaching solution is obtained after pressurized oxygen leaching, and the leaching solution is merged into the nickel refining system; and leaching slag is added to a sulfuric acid solution, oxygen is introduced to carry out the pressurized oxygen leaching, the leaching slag is used as copper concentrate to return to a copper smelting system, and the leaching solution is returned to be subjected to the normal-pressure air leaching. According to the method, copper, nickel and cobalt in the copper slag can be effectively separated, and the resourceful and comprehensive recycling of the nickel, the copper and the cobalt can be realized, the principle is reliable, the process is short, the resource utilization rate is high, and the industrial production is easy to realize; and the method is especially suitable for the treatment of the copper slag of the nickel refining system.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

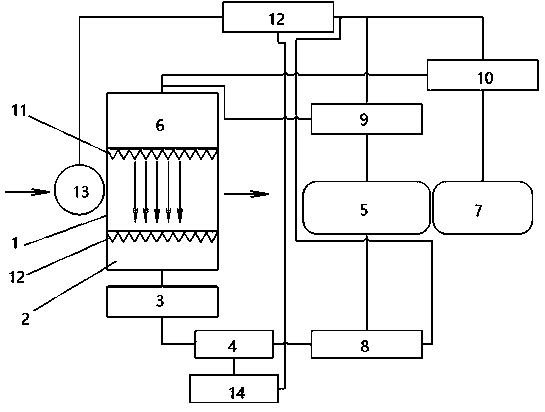

a gas combustion chamber

ActiveCN105020701BBurn fullyChange flow pathCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

The invention relates to a gas combustor which comprises a housing. A combustion chamber is formed inside the housing. The housing is square and is provided with an air nozzle and a fuel gas inlet which are communicated with the combustion chamber. A first burner and a second burner are arranged on the left and right sides of the housing respectively. The first burner is arranged on the same side with the fuel gas inlet and is located below the fuel gas inlet. At least one air retaining wall for separating the first burner from the second burner is arranged in the combustion chamber, and the air retaining walls are lower than the combustion chamber. A high temperature fuel gas flue is reserved between the ends of the air retaining walls and the inner walls of the housing. Two-stage combustion is adopted, so that it is guaranteed that fuel gas burns sufficiently. Due to cooperation of the two burners and the air retaining walls, the flowing path of fuel gas in the combustion chamber is changed so as to prolong the residence time of fuel gas in the combustion chamber; the contact time of fuel gas and flame nozzles of the two burners is prolonged, so that the combustion ratio is high, and the cost for later purification treatment is reduced. The gas combustor is simple in overall structure and environmentally friendly, and saves energy.

Owner:嘉善凝溪建设有限公司

A kind of purification treatment device for recycling sewage

ActiveCN113577899BImplement filteringImprove filtration efficiencyFiltration circuitsStationary filtering element filtersFiltrationSewage

The invention discloses a purification treatment device for recycling sewage, which comprises a filter and a deslimer, the water outlet of the filter is connected with the water inlet of the deslimer, the filter comprises a filter box and a filter set in the filter box The filter assembly and the receiving assembly for receiving garbage; the filter assembly includes two horizontally oppositely arranged first rotating rods and a filter plate arranged between the two first rotating rods, the first rotating rod is rotatably connected with the filter box, and the filter The plate is hinged sequentially by multiple screen plates, the distance between the two first rotating rods is less than the length of the filter plate after flattening, the top of the filter box is provided with a driving piece for lifting the filter plate; the receiving component is provided with two sets of , two sets of receiving components are respectively located on both sides of the filter plate. The application has the effect of realizing continuous filtration of sewage to improve the filtration efficiency of sewage and preventing the mesh holes on the filter plate from being blocked by suspended matter such as algae.

Owner:广东粤壮市政建设有限公司

A special water purifying agent for wastewater treatment and its preparation method

ActiveCN108557943BFormulation ScienceReasonable formulaWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPotassium fluorideAluminium hydroxide

Owner:广州市芦苇环保科技有限责任公司

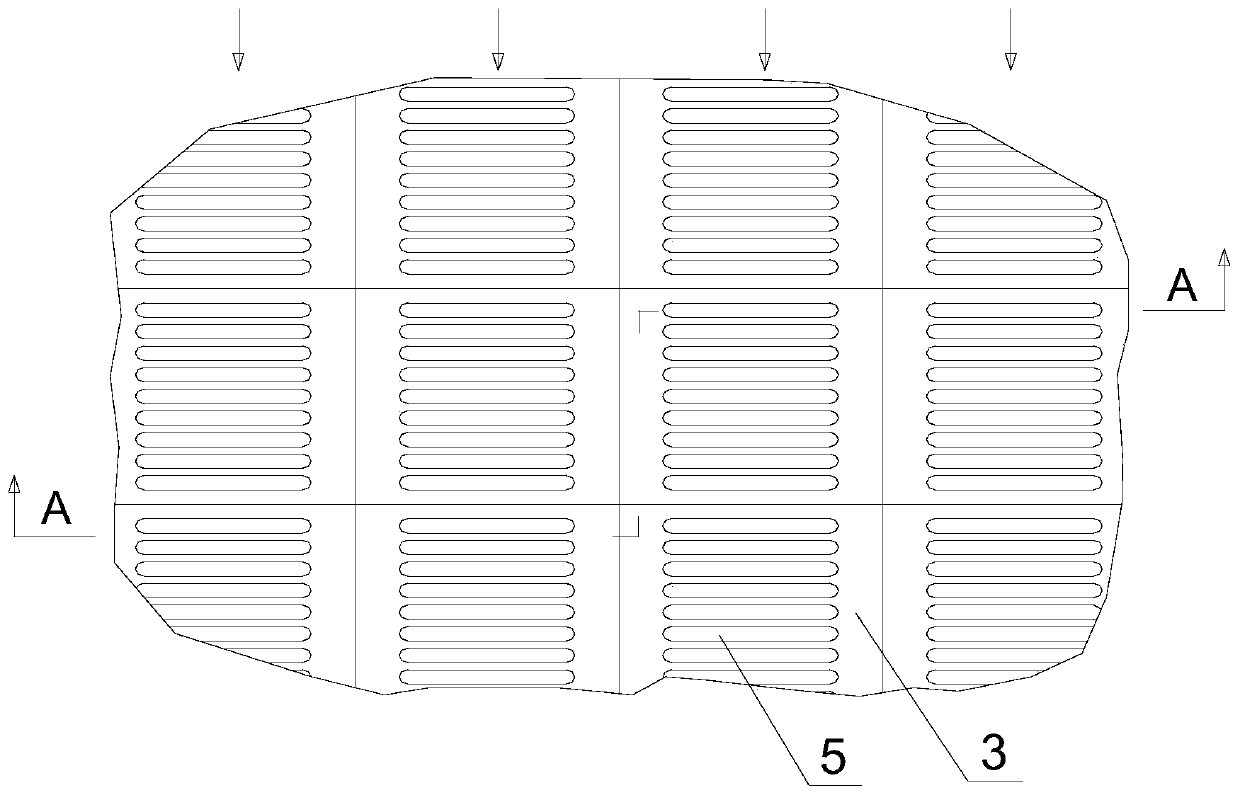

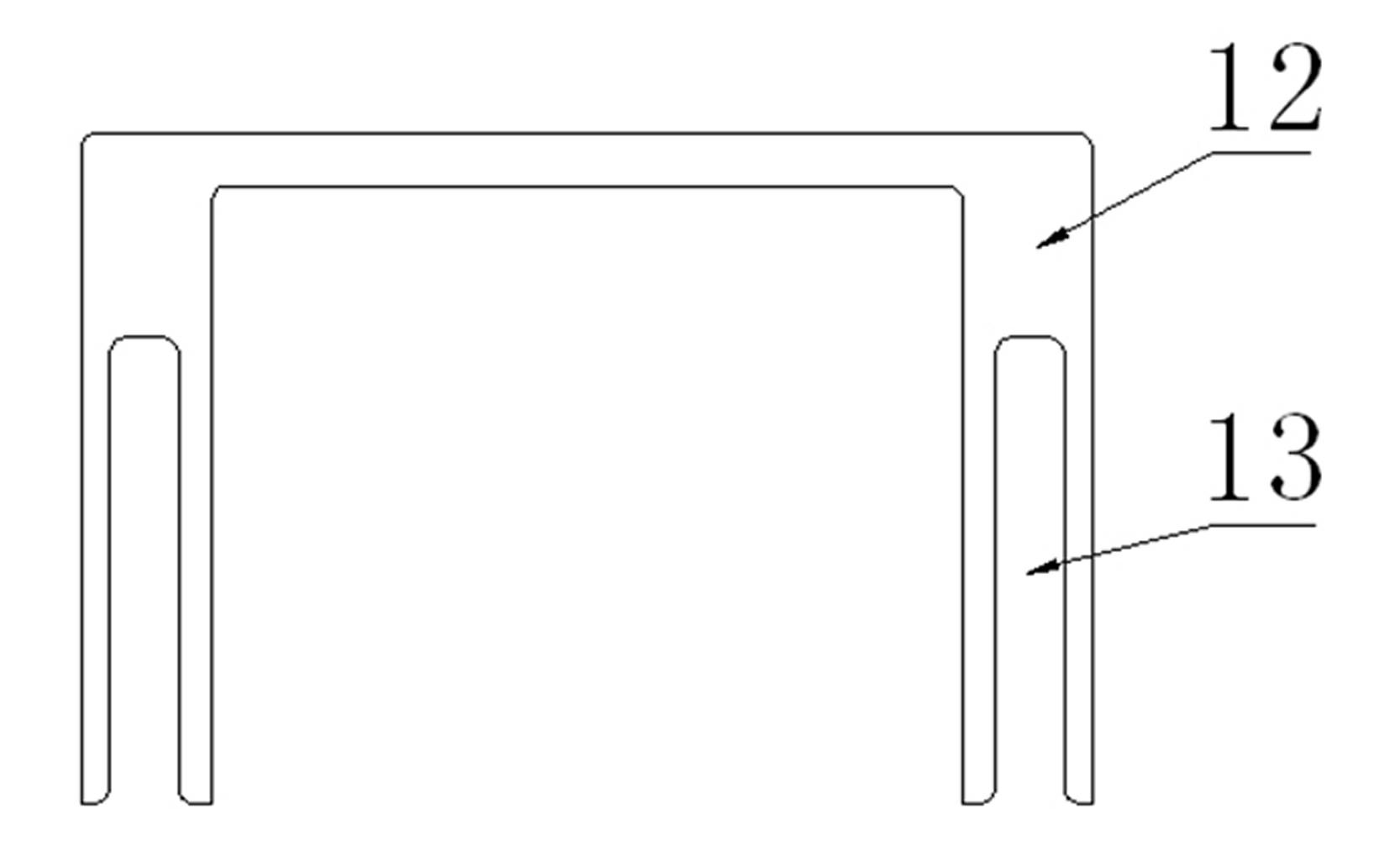

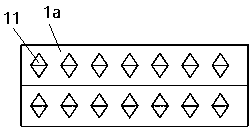

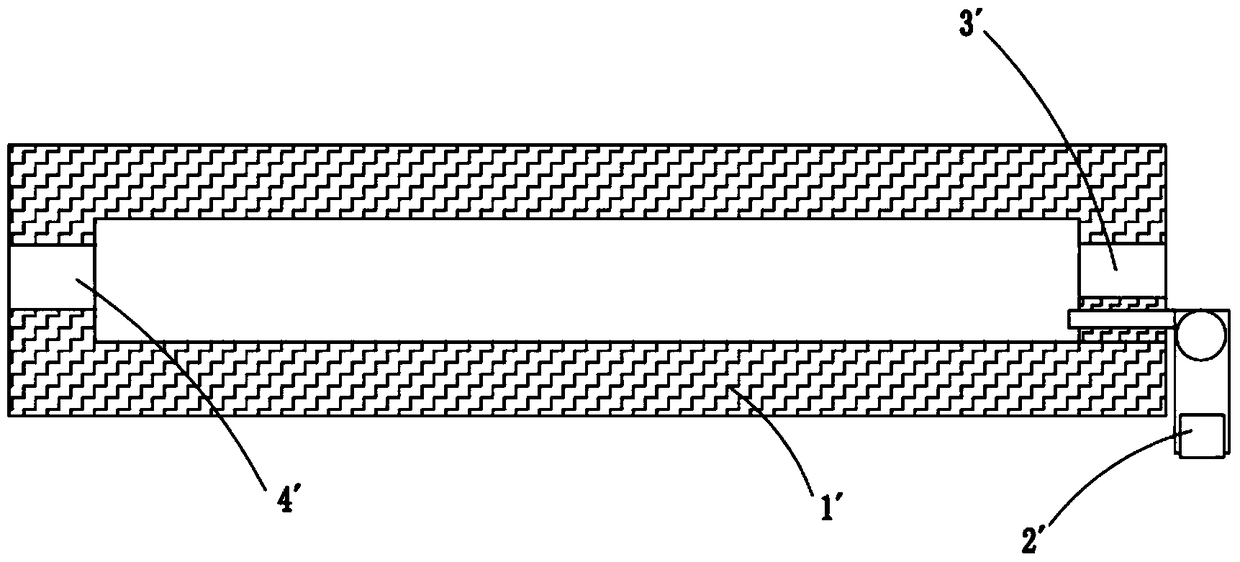

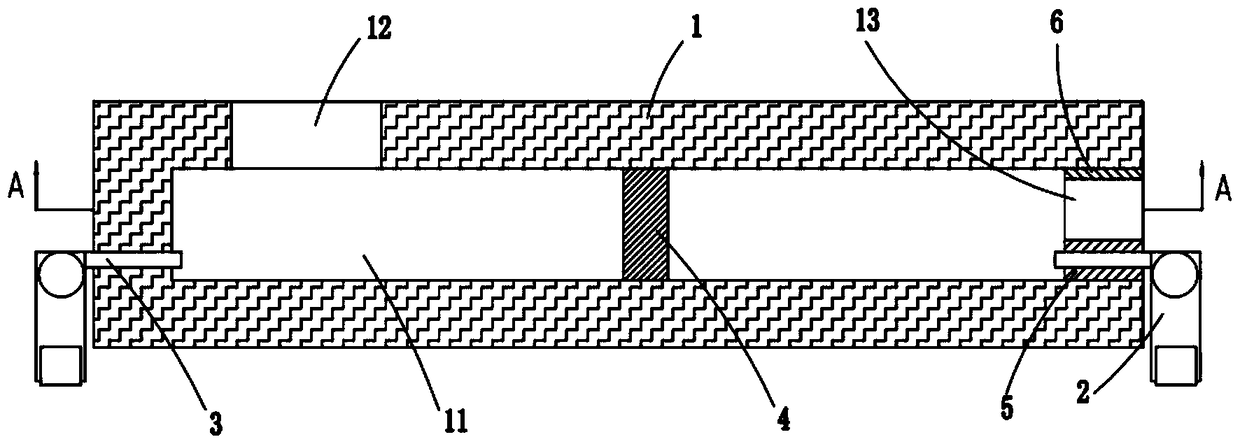

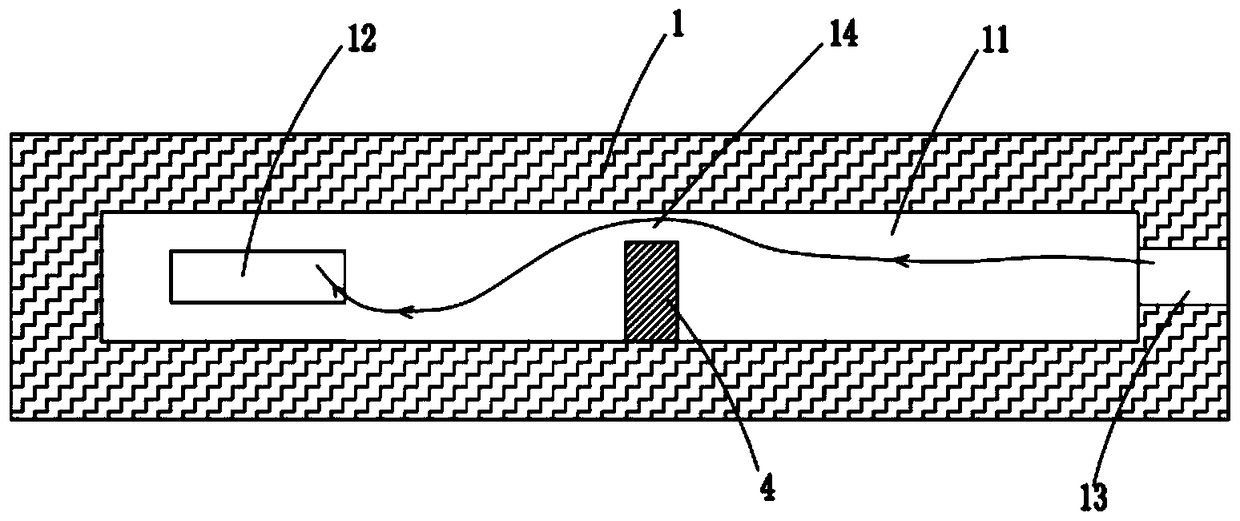

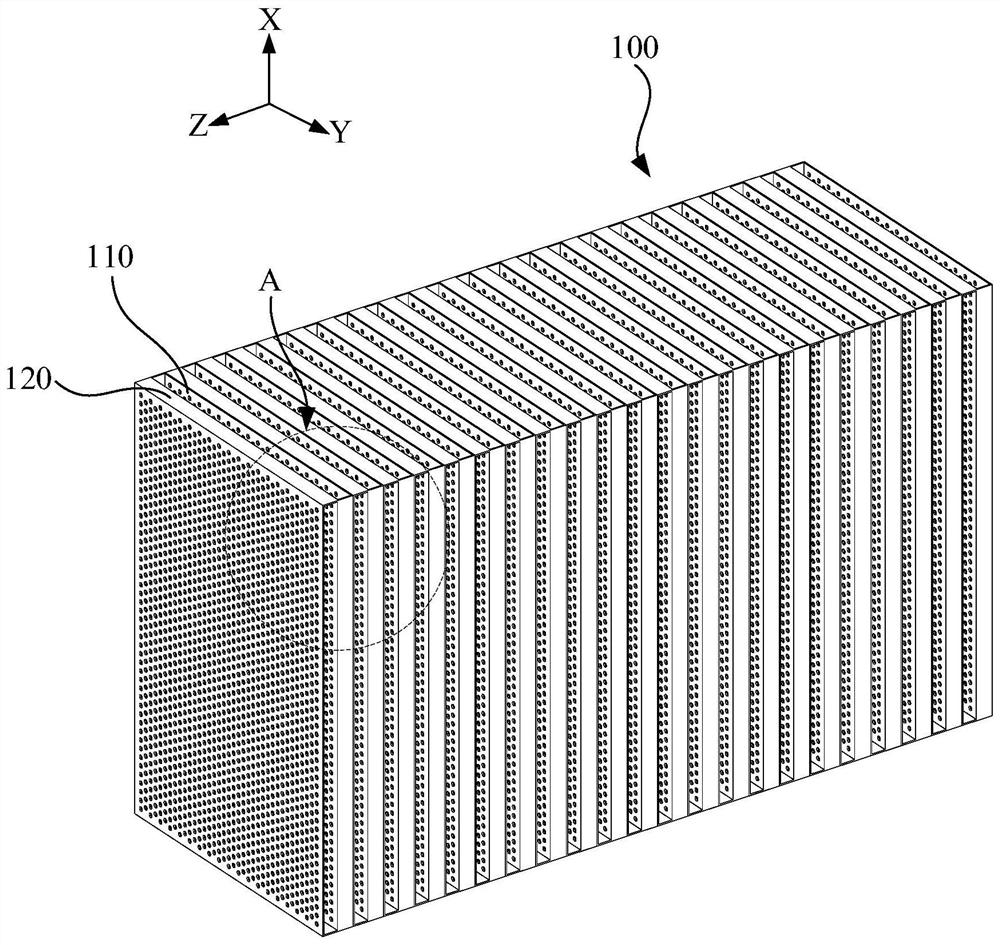

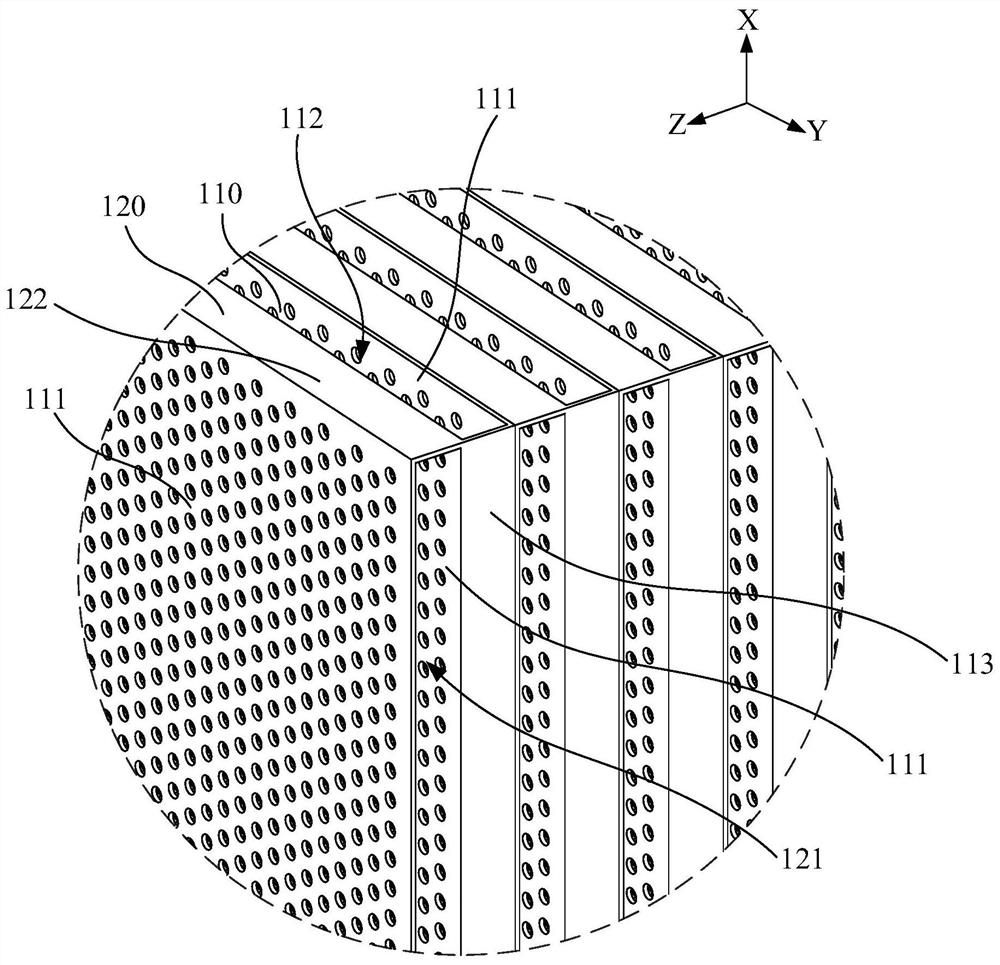

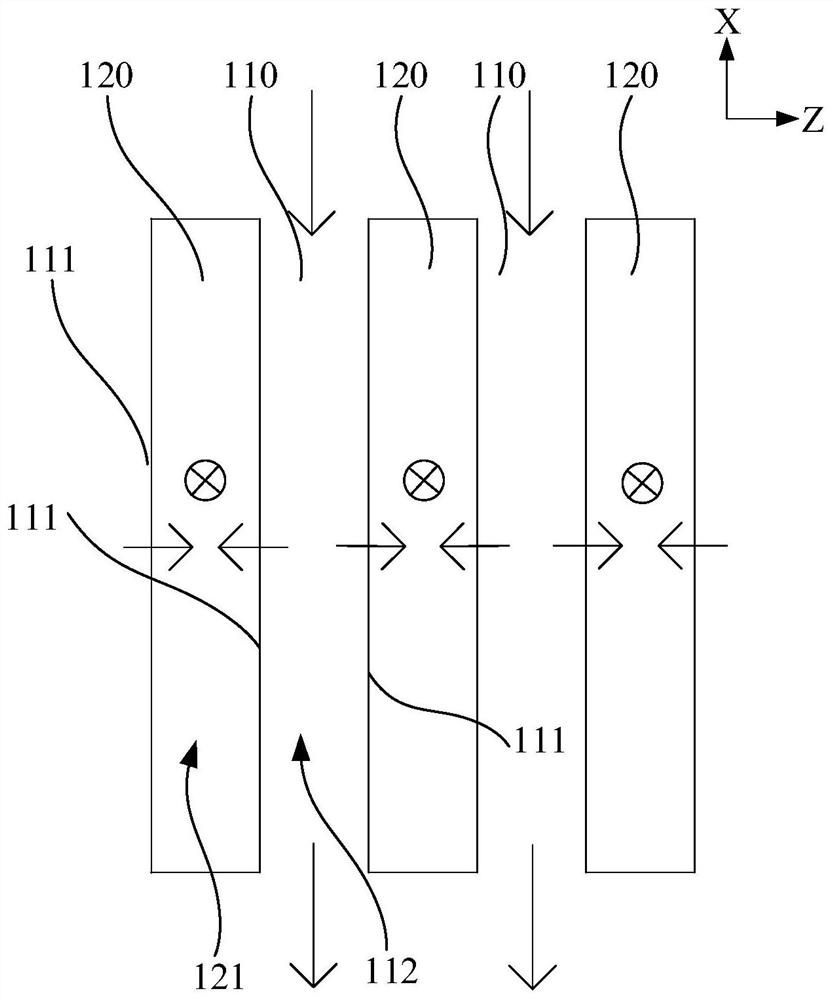

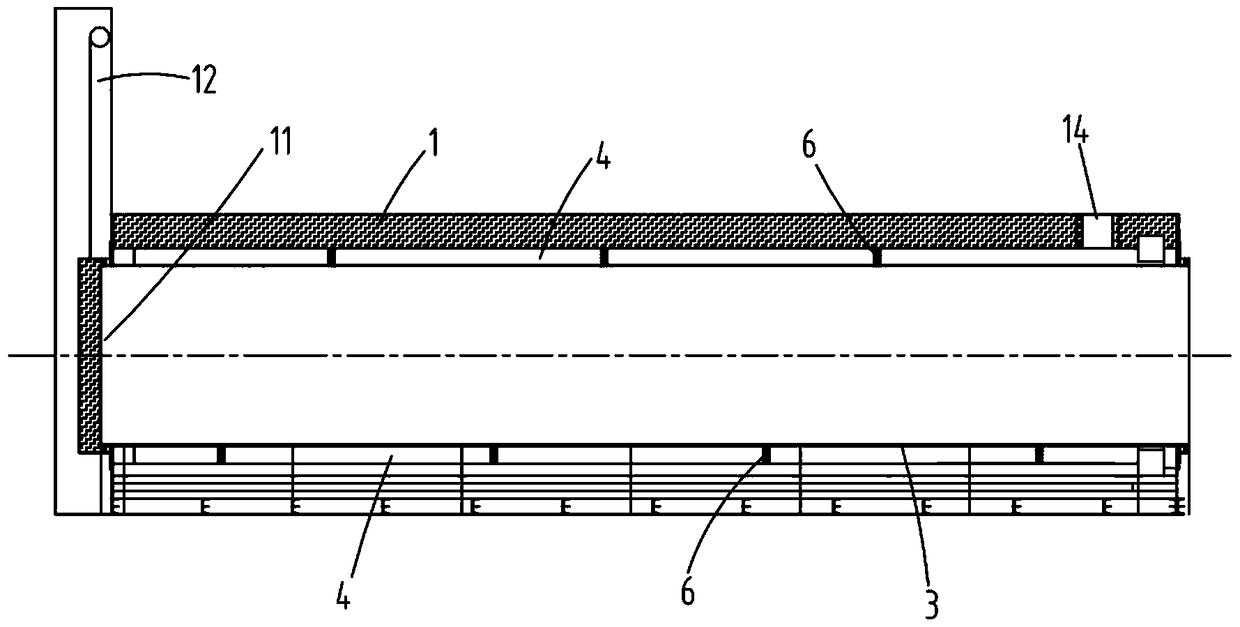

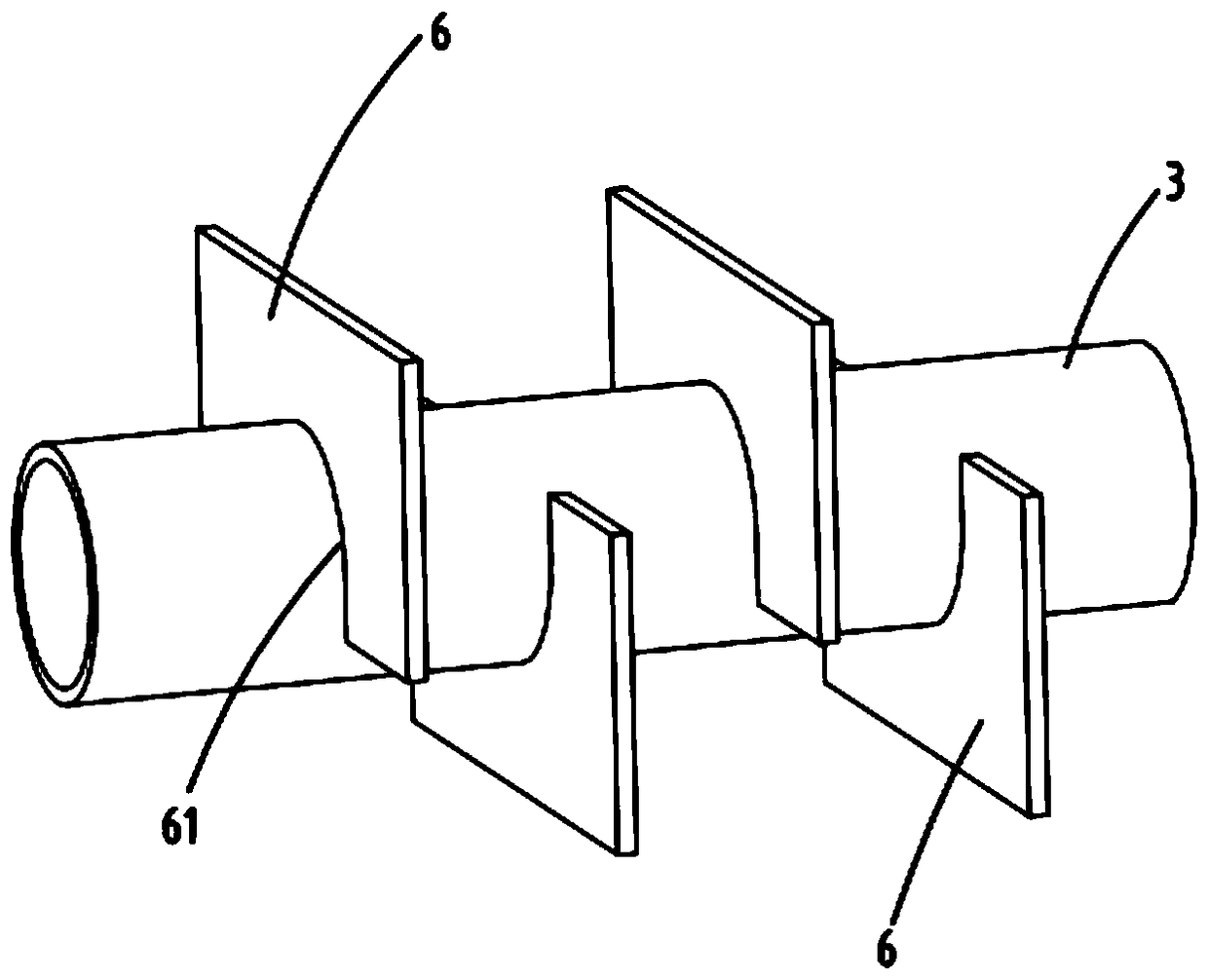

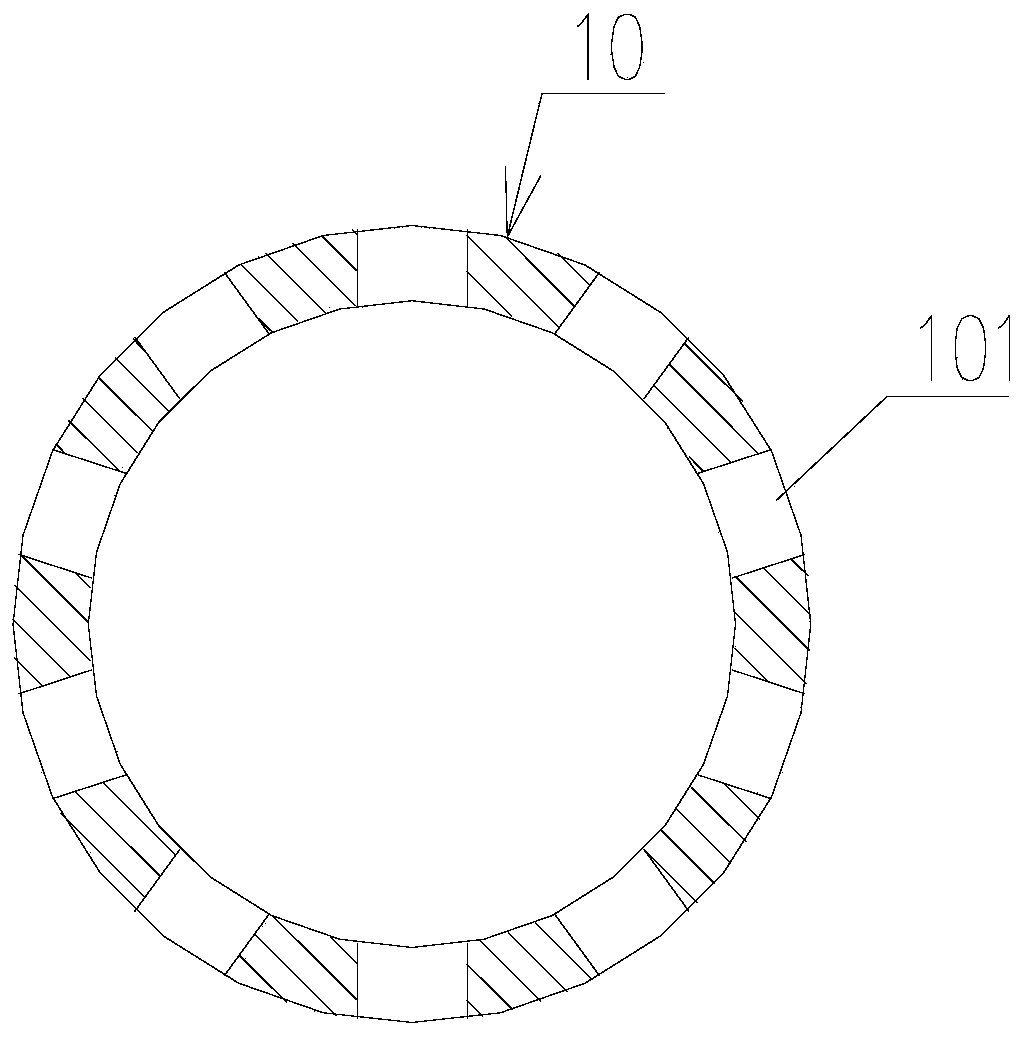

Filtering mechanism and filter

PendingCN111617538ASimple structureReduce the cost of purification treatmentStationary filtering element filtersWater flowSewage

The invention relates to a filtering mechanism and a filter. The filtering mechanism comprises a first filtering assembly and a second filtering assembly, the first filtering assembly comprises two layers of filtering screens which are oppositely arranged, and a first flow channel is formed between the two layers of filtering screens of the first filtering assembly; the second filtering assembly comprises two layers of filter screens which are oppositely arranged, a second flow channel is arranged between the two layers of filtering screens of the second filtering assembly, and one layer of filtering screen of the second filtering assembly is arranged close to one layer of filtering screen of the first filtering assembly so that the second flow channel is arranged close to the first flow channel; sewage raw water can flow in the first direction to pass through the first flow channel to obtain concentrated water; through the pressure difference formed between the sewage raw water and the concentrated water, clear water obtained after the sewage raw water is filtered by the filtering screens, close to each other, of the first filter assembly and the second filter assembly enters thesecond flow channel, and the clear water flows in the second direction perpendicular to the first direction to penetrate through the second flow channel.

Owner:SHENZHEN UNIVERSILICON ENVIRONMENTAL SCI & TECH CO LTD

Domestic garbage burning processing method

ActiveCN101285579BReduce the cost of purification treatmentReduce generationIncinerator apparatusSolid removalAtmospheric airExhaust fumes

The invention discloses a method for incineration treatment of domestic waste, relating to a method for processing waste, which solves the problem of high purification treatment cost for smoke gas which is generated after incineration in the prior art. The method for incineration treatment of domestic waste comprises the following steps of: 1. incinerating; 2. deacidifying and dust-removing exhaust fume of the incinerating; 3. feeding smoke gas which undergoes the dust removal into a vertical kiln for secondary incineration; 4. post processing the smoke gas after the secondary incineration, and discharging into air. The method for incineration treatment of domestic waste also comprises the step of burning sufficiently unburnt organic pollution pollutant in the vertical kiln at a temperature of between 1400 and 1700 DEG C and further purifying the pollutant in the smoke gas by using humid green pellets in the middle section and the upper section of the cement vertical kiln. The domesticwaste is processed by the method, the index of exhausted gas is better than Standard for Pollution Control on the Municipal Solid Waste Incineration in China (GB18485-2001), at the same time, the purification treatment cost for the smoke gas is reduced greatly.

Owner:湖南哈工机器人研究院有限公司

Method and device for purifying internal combustion engine exhaust particles

ActiveCN108533364AMeet purification requirementsEasy to getExhaust apparatusSilencing apparatusParticulatesTransmittance

The invention discloses a method for purifying internal combustion engine exhaust particles. The method comprises the following steps: S1, enabling internal combustion engine exhaust to unidirectionally flow through a particle collection channel, wherein the particle collection channel is a hollow cavity; S2, pressurizing water in a water tank to form a pressure water column and injecting the water column into the particle collection channel, wherein an injection of the pressure water column is orthogonal to a flow direction of the internal combustion engine exhaust; S3, collecting wastewaterobtained after contacting the pressure water column and the internal combustion engine exhaust, determining light transmittance of the wastewater and feeding the wastewater into the water tank; renewing the water in the water tank when the light transmittance is less than a set value, and returning to the S2, otherwise directly returning to the S2. The invention further discloses a device for purifying the internal combustion engine exhaust particles. According to the method disclosed by the invention, the internal combustion engine exhaust can be continuously purified, and the exhaust particles are adsorbed. Moreover, the purification device does not need to be subjected to high-cost regeneration treatment, and the device is low in using cost, low in energy consumption, clean and environmental-friendly.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

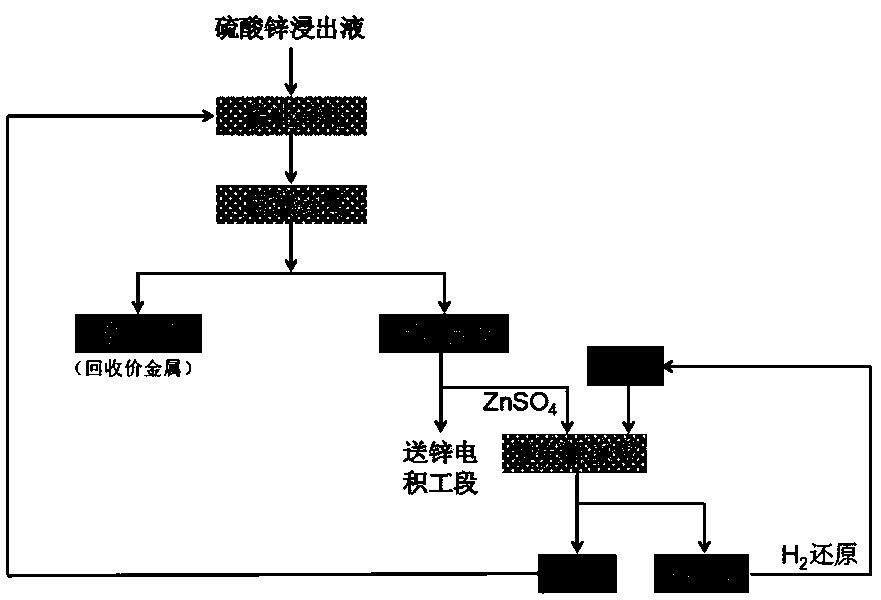

A process for deep purification and impurity removal of wet zinc leaching solution

ActiveCN111254283BReduce manufacturing costReduce generationProcess efficiency improvementSulfate zincPregnant leach solution

The invention discloses a process for deep purification and impurity removal of wet zinc leaching liquid. The process uses zinc sulfide solution to carry out deep purification and removal of impurities on wet zinc leaching liquid, wherein the zinc sulfide solution is purified and contains zinc sulfate Houli and barium sulfide are prepared as raw materials through metathesis reaction, and barium sulfide is prepared from barium sulfate through reduction reaction. In the process of the present invention, the zinc leaching solution to be purified is treated with the zinc sulfide solution as an impurity removal agent, and the sulfide ion released from the zinc sulfide reacts with heavy metal ions such as Cu, Cd, and As in the zinc leaching solution to precipitate in the form of precipitation. Purification and removal of impurities in zinc liquid has the advantages of low processing cost, environmental protection, low zinc loss rate, and good purification effect. It can realize deep purification and removal of impurities in wet zinc leaching liquid. A new impurity removal process for thoroughly purifying wet zinc leaching solution has high use value and good application prospects.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

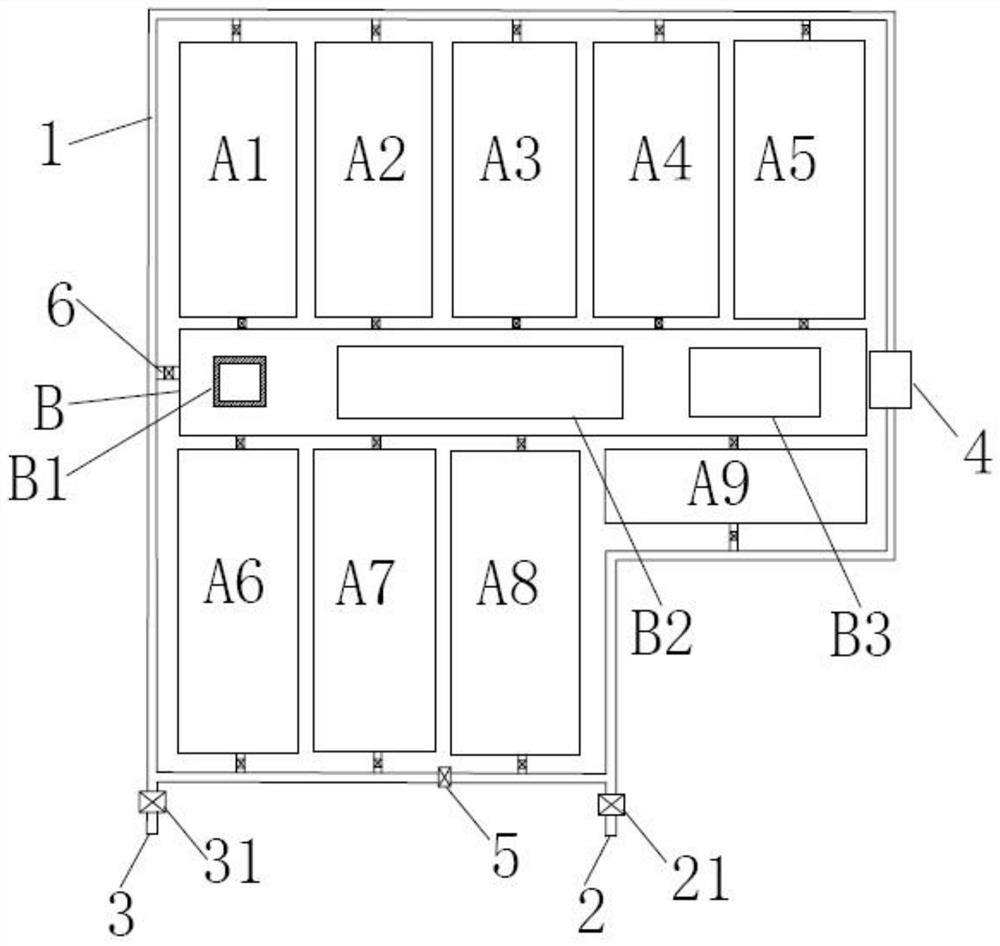

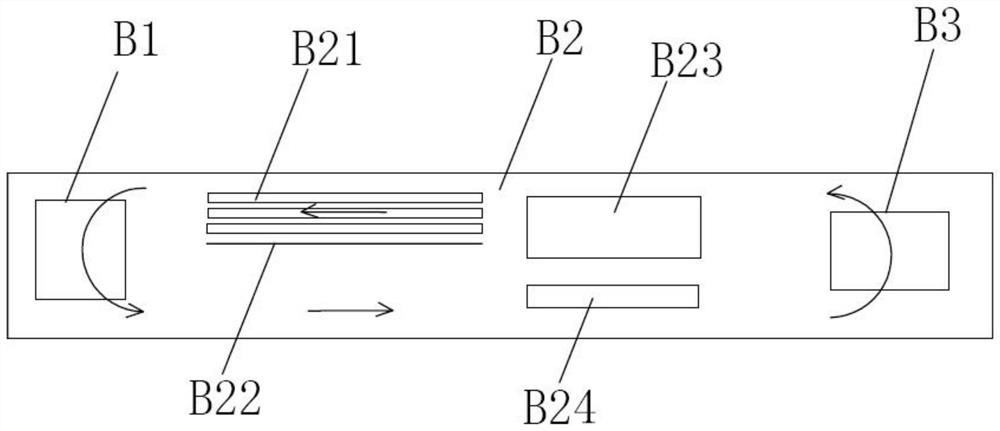

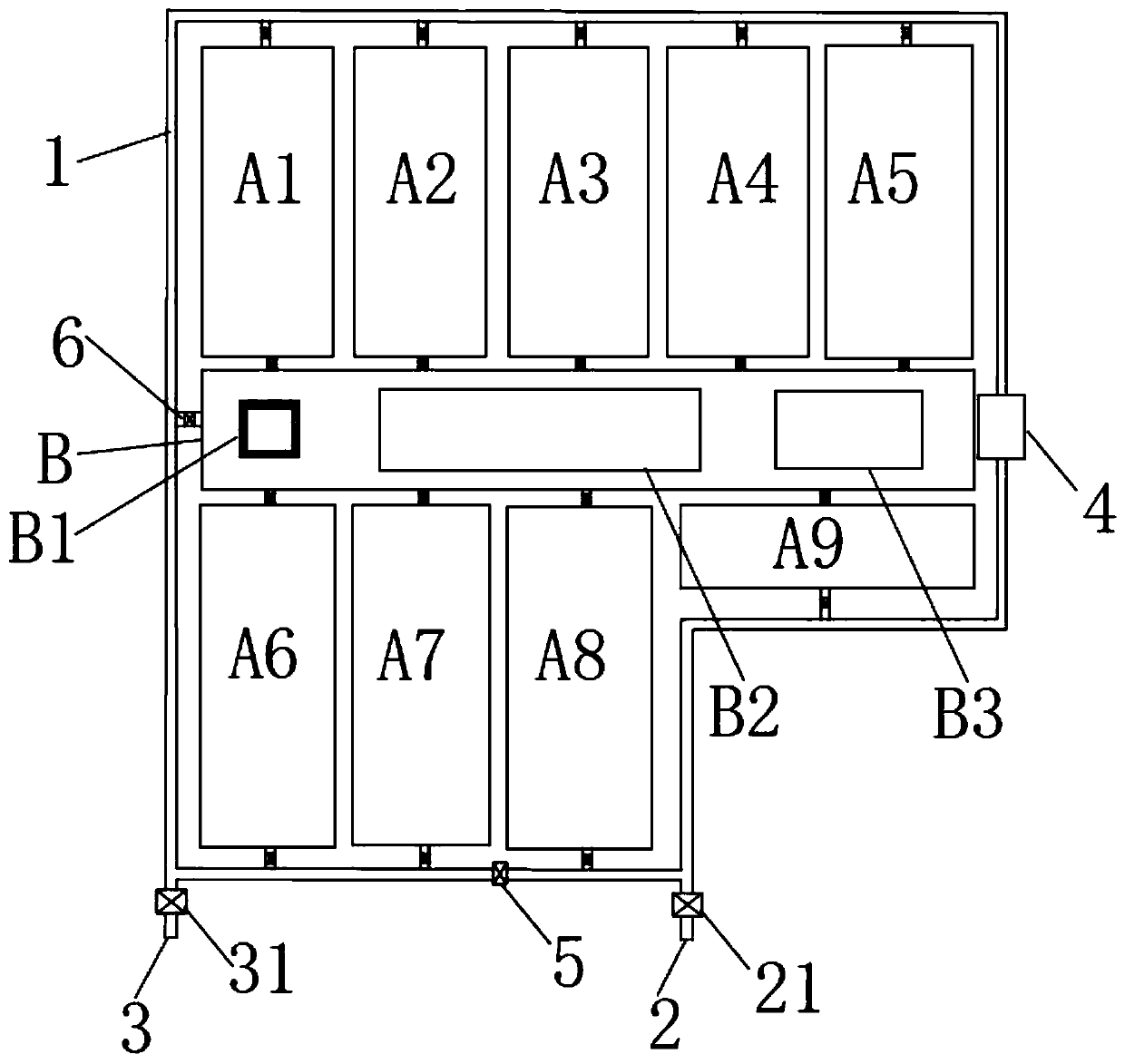

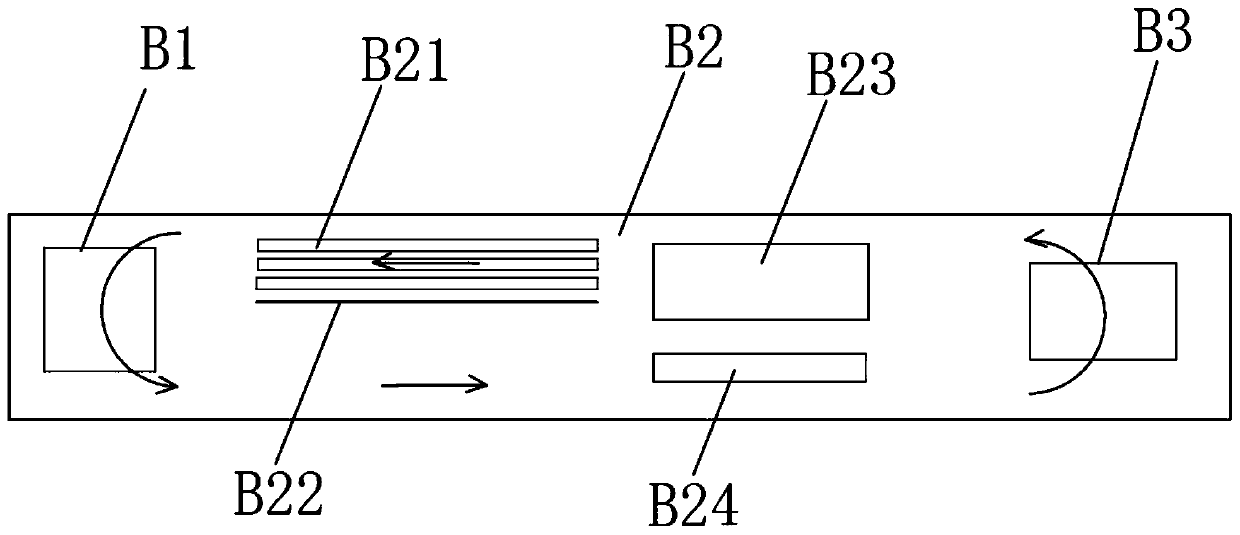

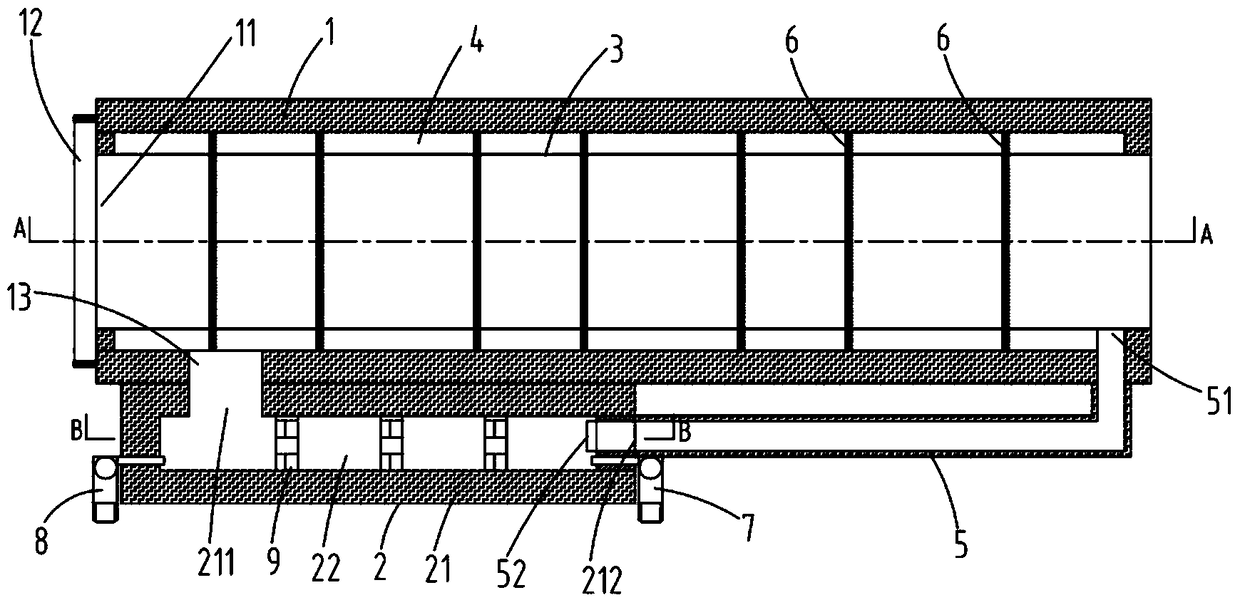

A method for constructing a pond culture circulating water system

ActiveCN110896911BEven purification cycleTo achieve a comprehensive purification effectWaste water treatment from animal husbandryPisciculture and aquariaFisheryEngineering

The invention proposes a construction method of a pond culture circulating water system, including the construction of the culture system and the circulation of water: the culture system includes a purification pond and several cultivation ponds, the purification pond is located in the middle of the cultivation system, and several cultivation ponds are distributed in the purification On the opposite sides of the pool, there are water purification equipment, the first purification area and the second purification area in the purification pool in sequence from left to right; there is a return water storage tank outside the breeding system, and a circulating water pipeline is set on the outer circumference of the breeding system , the circulating water pipeline is provided with a sluice, a water inlet and a water outlet, the water inlet and the water outlet are respectively arranged on both sides of the sluice, the water inlet is provided with a water inlet valve, and the water outlet is provided with a water outlet valve. The circulating water pipeline and the purification tank are connected, and the outlet branch pipe and the water inlet branch pipe on the same culture pond are arranged at the bottom of the culture pond oppositely; the purification pond is connected with the circulation water pipeline through a drain pipe, and a control valve is arranged on the drain pipe. The invention has high efficiency, less investment, low energy consumption, good applicability and high operability.

Owner:TIANJIN AGRICULTURE COLLEGE

Efficient treatment system and treatment method for organic waste anaerobic digestion

PendingCN112680327AReduce contentHas adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringEnvironmental engineering

The invention discloses an efficient treatment system and treatment method for organic waste anaerobic digestion. A discharge port of an anaerobic reactor is connected with a feed port of a pyrolysis reactor, a biochar discharge port of the pyrolysis reactor is connected with an inlet of a mixer, an outlet of the mixer is connected with a feed port of the anaerobic reactor, a gas outlet of the pyrolysis reactor is connected with a gas holder inlet, a gas holder outlet is connected with one end of a second one-way valve, the other end of the second one-way valve is connected with one end of a first one-way valve and a gas inlet of a gas aspirator, the other end of the first one-way valve communicates with the liquid level upper side of the anaerobic reactor, one end of a circulating pump is connected below the liquid level of the anaerobic reactor, the other end of the circulating pump is connected with a liquid inlet of the gas aspirator, and an outlet of the gas aspirator is connected with the anaerobic reactor. The efficient treatment system and treatment method can effectively improve the anaerobic fermentation efficiency, increase the biogas yield and reduce the sulfur content of biogas.

Owner:CHINA TIANYING +1

Method for constructing pond culture circulating water system

ActiveCN110896911AEven purification cycleTo achieve a comprehensive purification effectWaste water treatment from animal husbandryPisciculture and aquariaEnvironmental engineeringDrainage tubes

The present invention provides a method for constructing a pond culture circulating water system. The method comprises the following steps of constructing a culture system and circulating water. A culture system comprises a purification pond and a plurality of culture ponds, the purification pond is positioned in middle of the culture system, the plurality of the culture ponds are distributed on two opposite sides of the purification pond, and a water purification device, a first purification area and a second purification area are sequentially arranged in the purification pond from left to right; a backflow reservoir is arranged outside the culture system, circulating water pipelines are arranged on an outer periphery of the culture system in a surrounding mode, a water gate, a water inlet and a water outlet are arranged on the circulating water pipelines, the water inlet and the water outlet are respectively arranged on two sides of the water gate, a water inlet valve is arranged onthe water inlet, a water outlet valve is arranged on the water outlet, each culture pond communicates with the circulating water pipeline and the purification pond, and a water outlet branch pipe anda water inlet branch pipe on the same culture pond are oppositely arranged at a bottom part of each culture pond; and the purification pond communicates with the circulating water pipeline through a water drainage pipe, and a control valve is arranged on the water drainage pipe. The method is high in efficiency, low in investment, low in energy consumption, good in applicability and high in operability.

Owner:TIANJIN AGRICULTURE COLLEGE

A combustible gas recycling heat treatment furnace

ActiveCN105154113BEnable recyclingReduce energy consumptionSpecial form destructive distillationCombustion chamberEngineering

The invention relates to a flammable gas recycling thermal treatment furnace which comprises a furnace body, a combustion chamber provided with a combustor and an exhaust discharge pipe, wherein a furnace pipe is arranged in the furnace body, a furnace door is arranged at a feeding end, a closed annular hot air channel is formed between the inner wall of the furnace body and the outer wall of the furnace pipe, and a high-temperature glue gas inlet and a flue gas exhaust opening are formed on the furnace body; the combustion chamber comprises a housing which is internally provided with a combustion cavity, wherein an air jet hole and a gas inlet are formed on the housing, the combustion chamber is arranged out of the furnace body, the air jet hole is communicated with the high-temperature flue gas inlet on the furnace body, and the gas inlet of the exhaust gas discharge pipe is communicated with the inner side of the furnace pipe and the gas outlet of the exhaust gas discharge pipe extends into the combustion cavity through the gas inlet on the combustion chamber. According to the furnace provided by the invention, the combustion chamber and the furnace body are independently arranged, the exhaust gas discharge pipe introduces flammable gas generated in the furnace pipe into the combustion chamber to be combusted, and high-temperature flue gas generated by combustion is introduced into a hot air channel to supply energy for thermal treatment, so that energy sources are recycled, the energy consumption is reduced, and the furnace is energy-saving and environmental-friendly, easy to overhaul, simple in integral structure and low in cost.

Owner:托普工业(江苏)有限公司

Method for treating high-arsenious solution with low cost

ActiveCN101613150BReduce the amount addedEasy to operateArsenic compoundsWater/sewage treatment by oxidationSlagHydrometallurgy

Owner:YUNNAN WUXIN IND

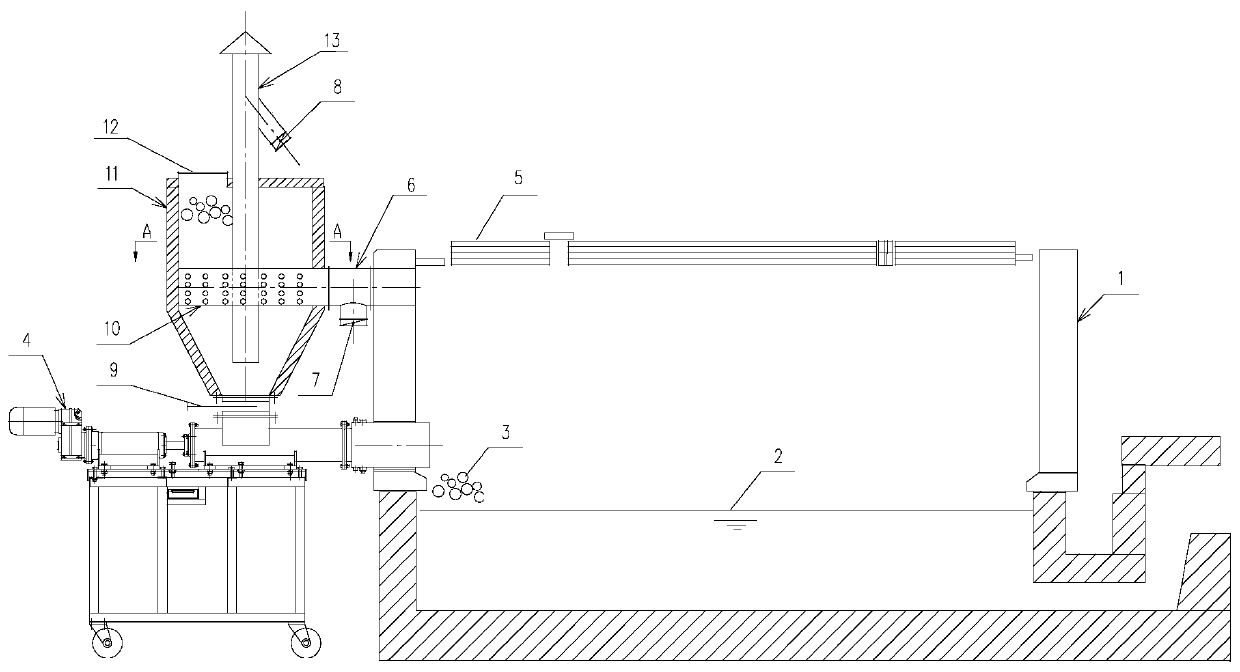

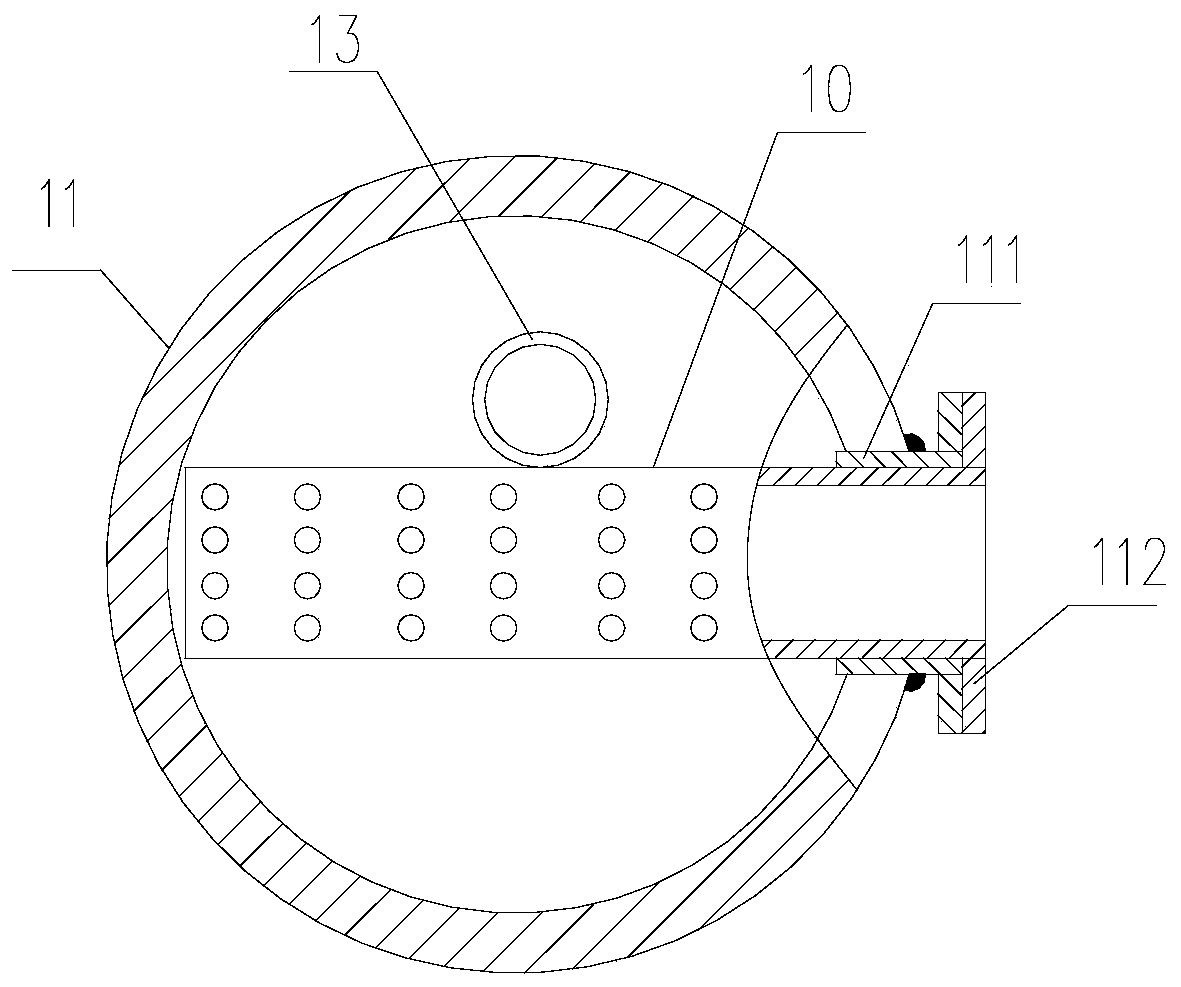

Preheating systems for bulk raw materials for rock wool, basalt fiber or glass production

ActiveCN110183096BRaise the initial temperatureReduce energy consumptionCharging furnaceBasalt fiberMechanical engineering

The invention discloses a preheating system for a blocky raw material for production of rock wool, basalt fibers or glass. The preheating system comprises a kiln, a material cabin and a feeding machine, wherein the material cabin is internally provided with a hot air distributor and an exhaust chimney; the upper end of the exhaust chimney extends outside the material cabin; an exhaust hole is formed in the upper end; the lower end of the exhaust chimney extends into the bottom of the material cabin; an air inlet is formed in the bottom; the hot air distributor is arranged in the middle of thematerial cabin and is communicated with a high-temperature exhaust chimney at the arch top of the kiln; a raw material inlet is formed in the top of the material cabin; a raw material outlet is formedin the bottom of the material cabin; the raw material outlet is communicated with the inlet of the feeding machine through a discharge valve; and the outlet of the feeding machine is communicated with the inlet of the kiln. By adopting the preheating system, a high-temperature flue gas of the kiln is recycled, the blocky raw material is preheated by using waste heat of the high-temperature flue gas, the primary temperature of the blocky raw material fed into the kiln is increased, and energy consumption of the kiln can be thus greatly reduced.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com