Method for producing refined moisture diffusion industrial salt based on underground recycling of waste liquid

A technology for industrial salt and waste liquid, applied in the direction of alkali metal chloride, etc., can solve the problem of restricting the use of mixed condensate water, and achieve the effect of significant water saving, saving purification treatment cost, and speeding up the dissolution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

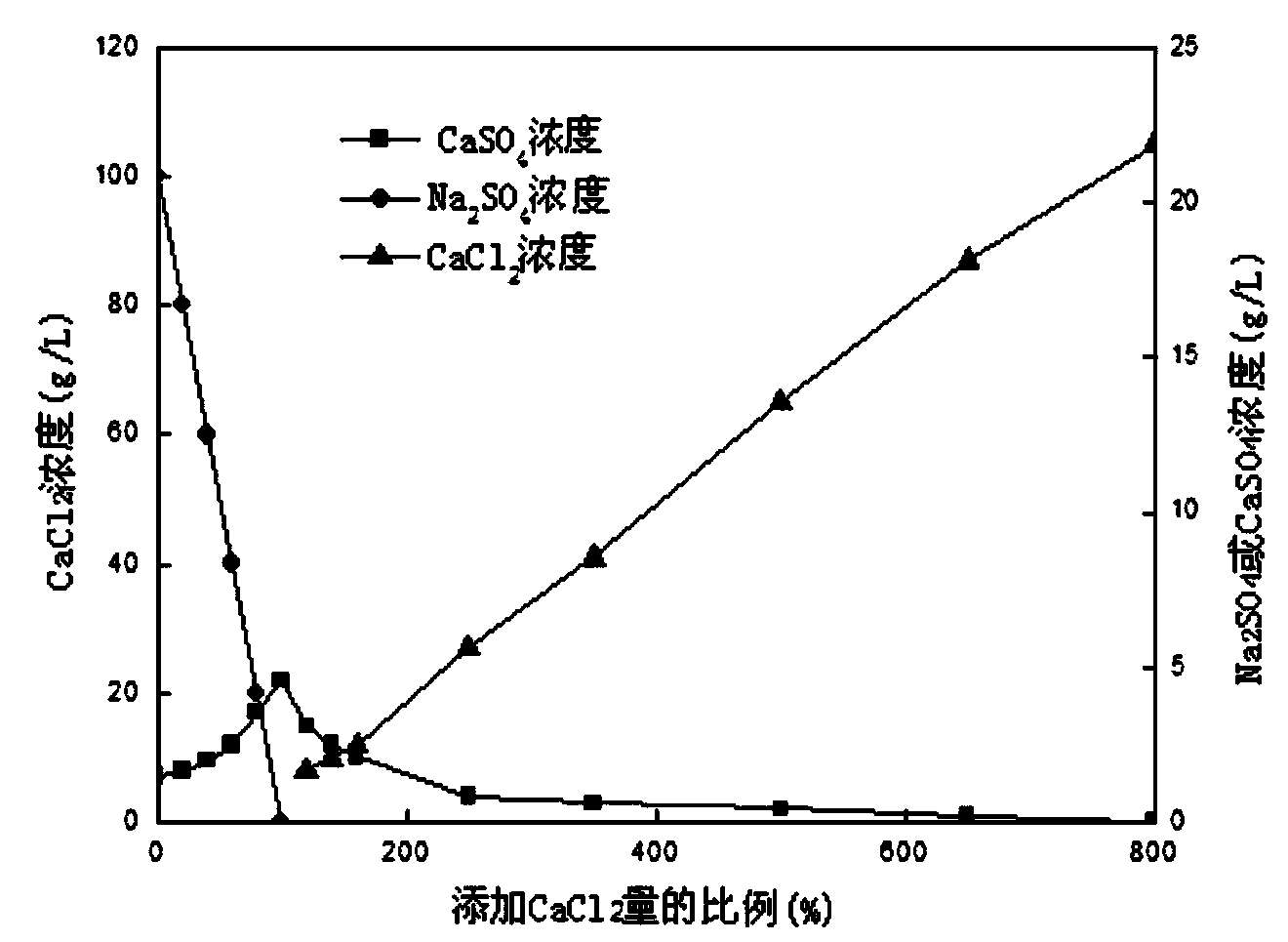

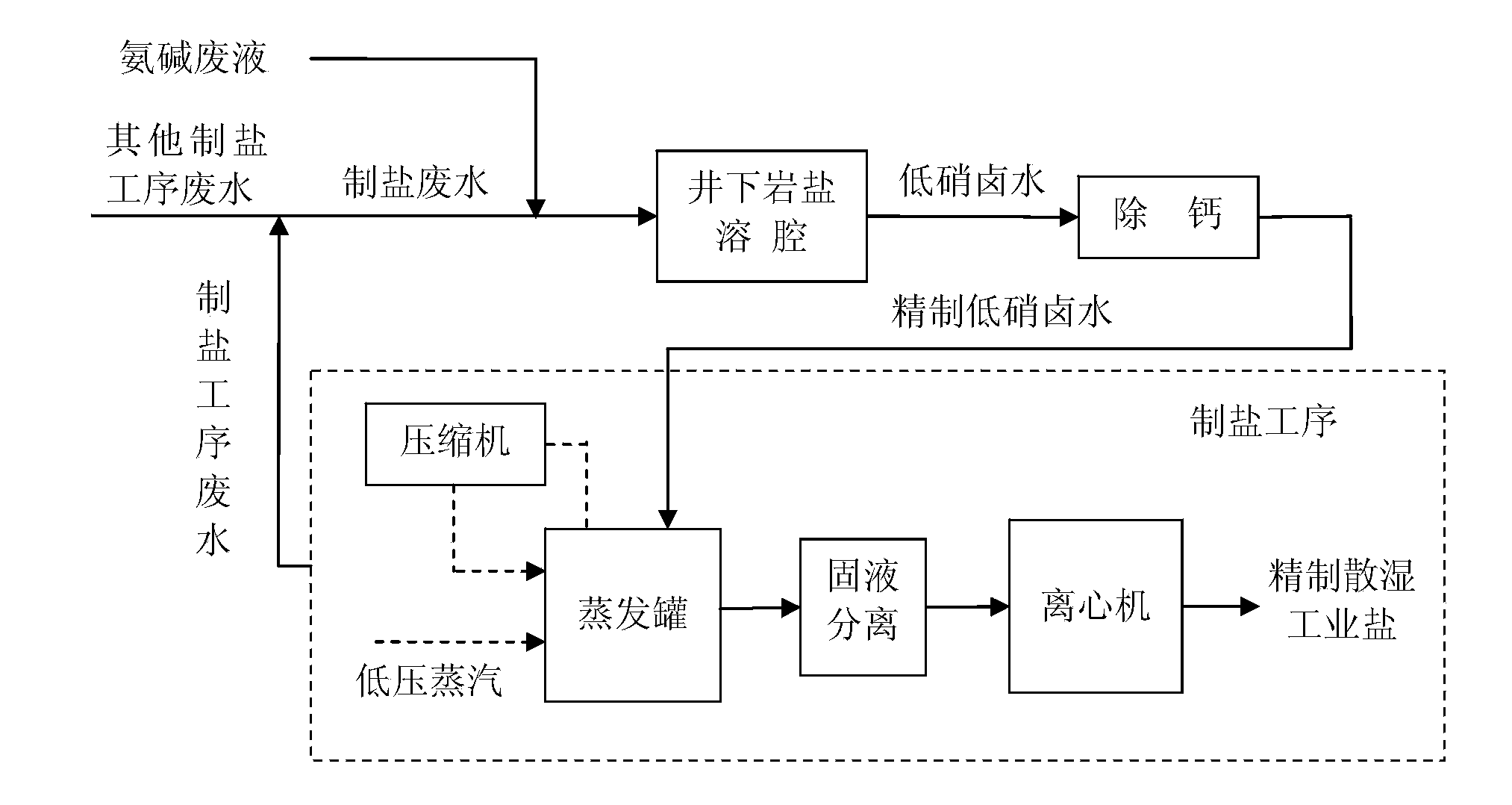

[0039] 1. CaCl 2 Ammonia-alkali waste liquid with a content of 111g / l is added to salt-making wastewater at a temperature of 60°C, and the blending ratio is controlled to be 1:14, that is, 1 part of ammonia-soda waste liquid is mixed with 14 parts of salt-making wastewater (the pH value of the mixture is about After 12), it is injected into the downhole rock salt solution cavity, and the rock salt is dissolved downhole, and the sulfate and magnesium ions in the original brine are simultaneously removed. 2 SO 4 Content about 10g / l, CaSO 4 Low-nitrate brine with a content of 2.5-2.7g / l.

[0040] 2. Add soda ash to the mined low-nitrate brine, stir to make the soda ash react with calcium sulfate in the low-nitrate brine until the calcium ion content in the brine is detected to be lower than 20mg / l, then add 3g / m 3 The sodium polyacrylate of brine (add in the form of sodium polyacrylate solution of 0.3wt% concentration. The number-average molecular weight of sodium polyacrylate...

Embodiment 2

[0043] 1. CaCl 2 Ammonia-alkali waste liquid with a content of 120g / L is added to salt-making wastewater at a temperature of 60°C, and the blending ratio is controlled to be 1:14, that is, 1 part of ammonia-alkali waste liquid is mixed with 14 parts of salt-making wastewater (the pH of the mixture is about After 11.5), it is injected into the downhole rock salt solution cavity to dissolve the rock salt downhole and remove the sulfate and magnesium ions in the original brine at the same time. After 3 to 5 days of settlement, the NaCl content is 300~312g / l, and the NaCl content is 300~312g / l. 2 SO 4 Content about 8g / L, CaSO 4 Low-nitrate brine with a content of 2.6-2.8g / L.

[0044] 2. Add soda ash to the mined low-nitrate brine, stir to make the soda ash react with calcium sulfate in the low-nitrate brine until the calcium ion content in the brine is detected to be lower than 20mg / l, then add 2g / m 3 The sodium polyacrylate of brine (add in the form of sodium polyacrylate solu...

Embodiment 3

[0047] 1. CaCl 2 Ammonia-alkali waste liquid with a content of 111g / l is added to salt-making wastewater at a temperature of 60°C, and the blending ratio is controlled to be 1:11, that is, 1 part of ammonia-alkali waste liquid is mixed with 11 parts of salt-making wastewater (the pH value of the mixture is about After 11.5), it is injected into the downhole rock salt solution cavity to dissolve the rock salt downhole and remove the sulfate and magnesium ions in the original brine at the same time. After 3 to 5 days of settlement, the NaCl content is 302 to 314g / L, and the NaCl content is 302 to 314g / L. 2 SO 4 Content about 7g / L, CaSO 4 Low-nitrate brine with a content of 2.7-2.9g / L.

[0048] 2. Add soda ash to the mined low-nitrate brine, stir to make the soda ash react with calcium sulfate in the low-nitrate brine until the calcium ion content in the brine is detected to be lower than 20mg / L, then add 3g / m 3 The sodium polyacrylate of brine (add in the form of sodium polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com