Patents

Literature

60results about How to "Meet purification requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

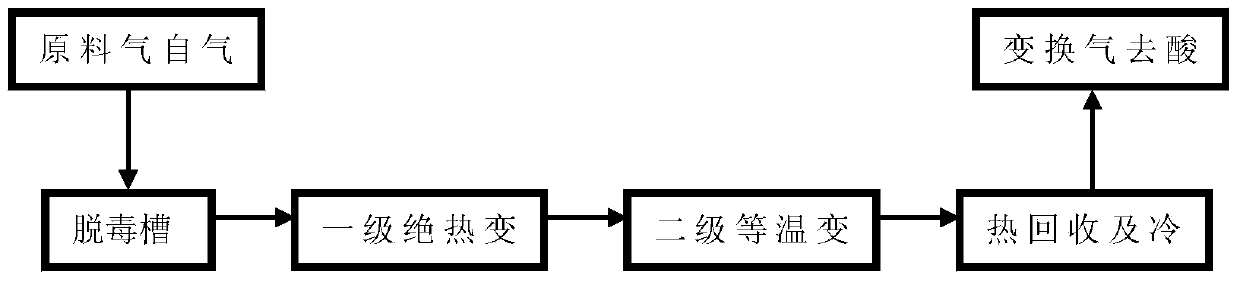

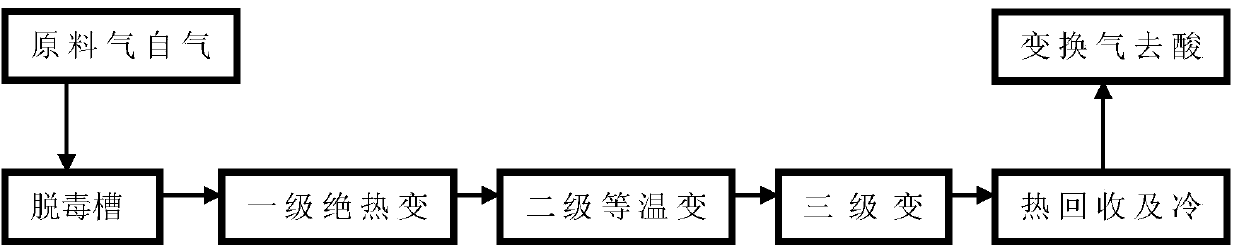

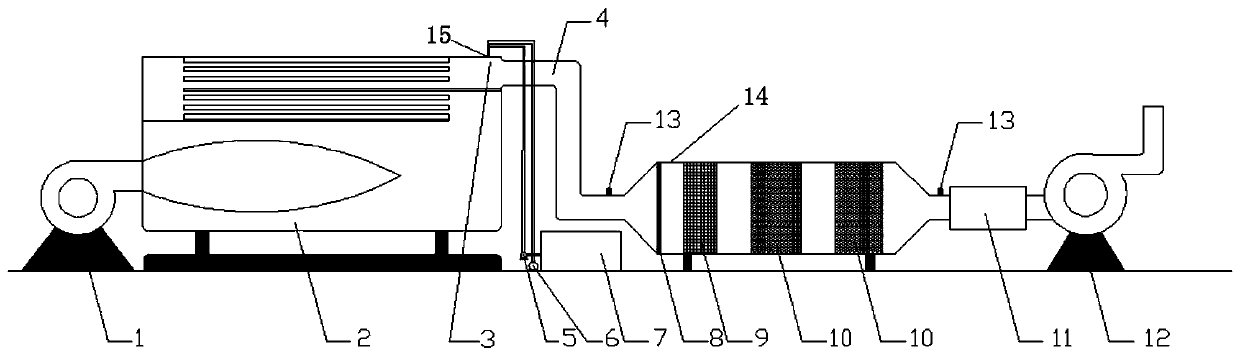

Adiabatic-isothermal shift technique for high-concentration CO raw gas

The invention provides a novel CO sulfur-tolerant shift technique which at least comprises a CO sulfur-tolerant shift production procedure composed of an adiabatic shift section and an isothermal shift section. Compared with the traditional adiabatic shift technique, the technique can simplify the shift process, reduce the equipment investment, lower the system resistance and reduce the one-time use amount of the catalyst. Compared with the direct isothermal shift technique, the isothermal reactor is arranged after the adiabatic reactor, the reaction heat generated by the primary adiabatic shift can ensure the inlet temperature of the isothermal shift reactor and avoid the problem of difficulty in self balancing of heat quantity in the direct isothermal shift technique, and thus, the technique can reasonably utilize the energy, avoid the problem of blockage since dust and other impurities in the raw gas enter the isothermal reactor, and ensure the long-period stable operation of the complete device.

Owner:青岛联信催化材料有限公司

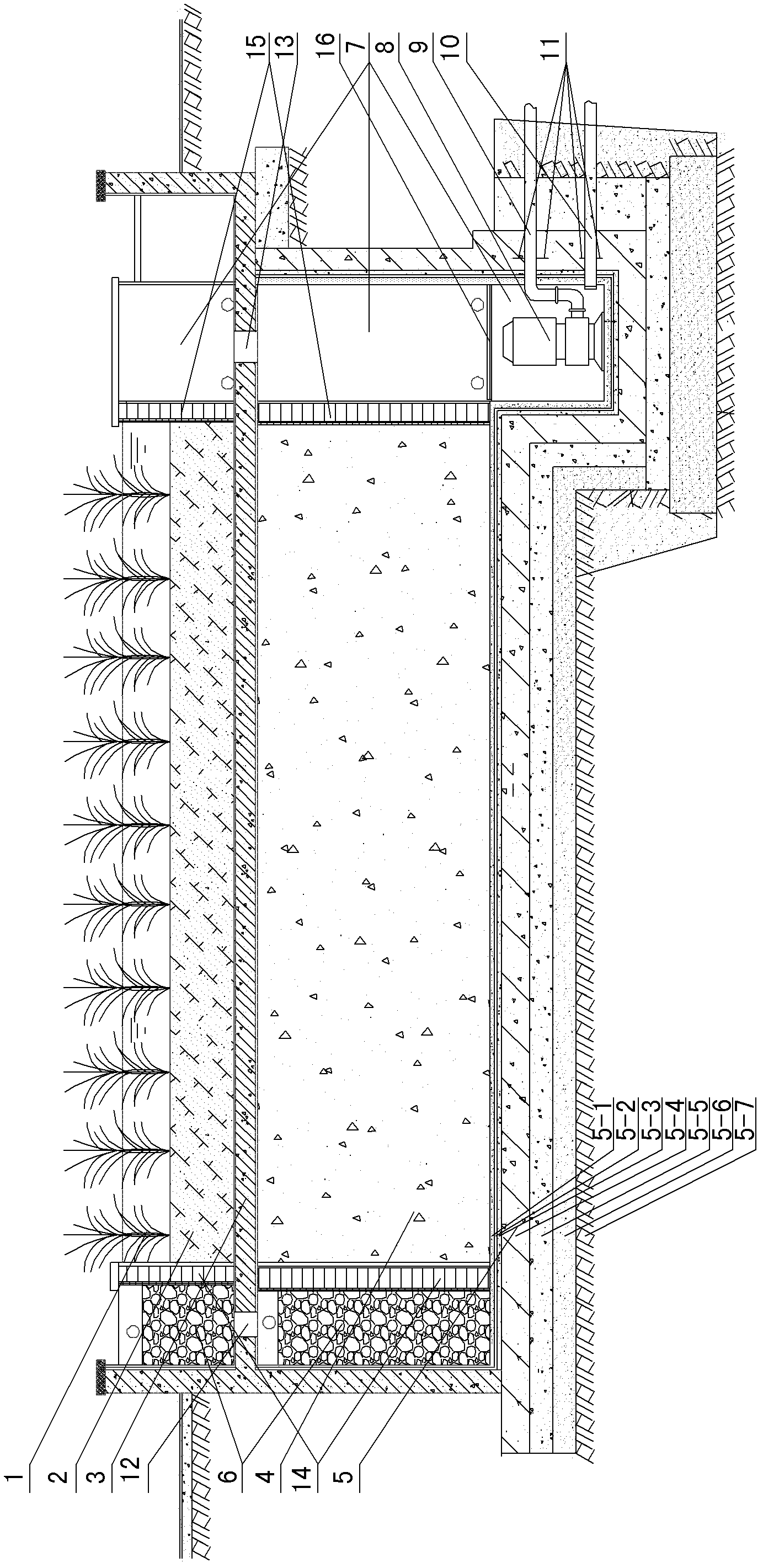

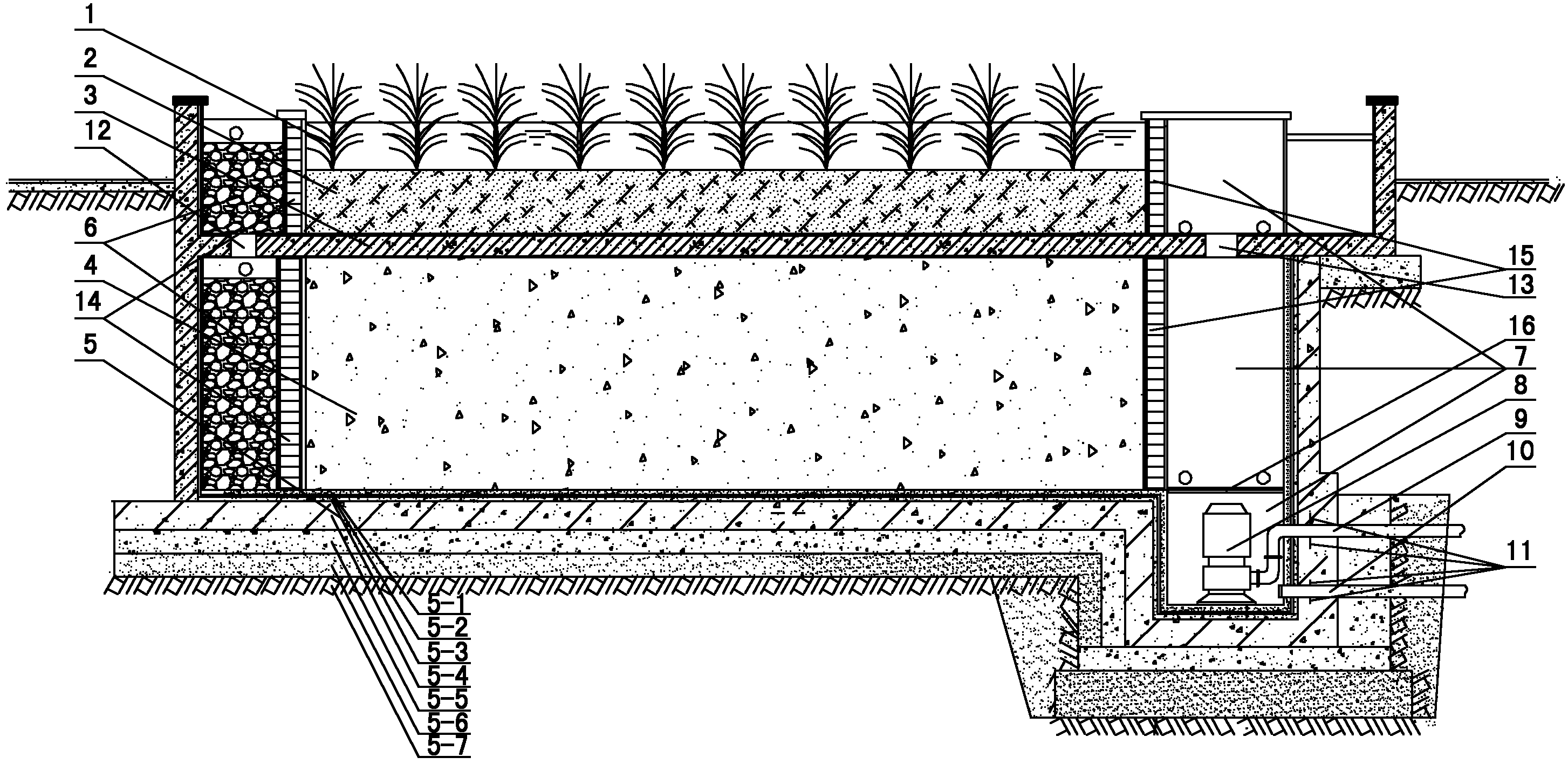

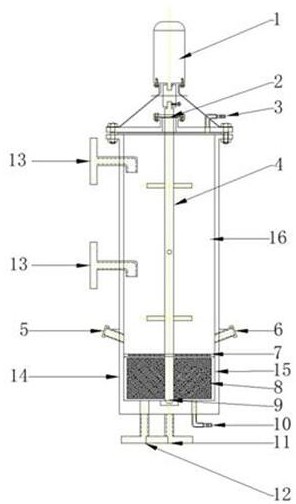

Double-layer undercurrent artificial wetland landscape pond and method thereof for recovering and treating urban roof rainwater

ActiveCN102418426AMeet purification requirementsFulfillment processing requirementsWater/sewage treatment by irradiationMultistage water/sewage treatmentConstructed wetlandEnvironmental engineering

The invention discloses a double-layer undercurrent artificial wetland landscape pond and method thereof for recovering and treating urban roof rainwater, relates to a landscape reservoir and a method thereof for recovering and treating urban rainwater, and aims to solve the problem that the rainwater recovery system cannot meet the requirements of continuously purifying and treating rainwater all the year around in northern cold-region cities. The double-layer undercurrent artificial wetland landscape pond consists of a landscape pond, upper layer horizontal undercurrent, a partition plate layer, lower layer horizontal undercurrent, a foundation layer, a water inlet regulating reservoir, a collection tank, a submersible pump, a circulating pipe, a drain pipe, a left water separation valve, a right water separation valve, a left filter wall, a right filter wall and a metal grille. The method specifically comprises the following steps of: 1, collecting rainwater; 2, coagulating and precipitating; 3, filtering; 4, performing ultraviolet sterilization; 5, injecting into the double-layer undercurrent artificial wetland landscape pond to perform deep processing; and 6, making the treated rainwater for later use. The pond and the method are mainly used for rainwater recovery and recycling and urban beautification of the northern cold-region cities.

Owner:HARBIN INST OF TECH

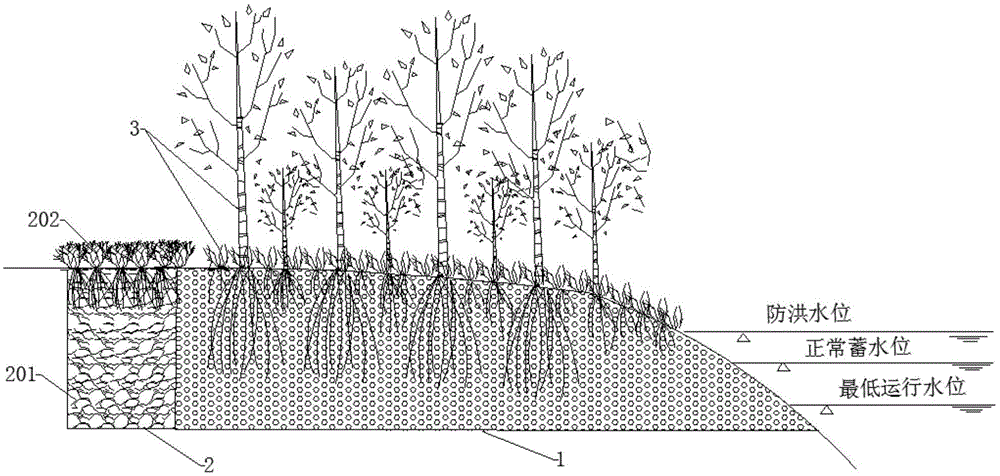

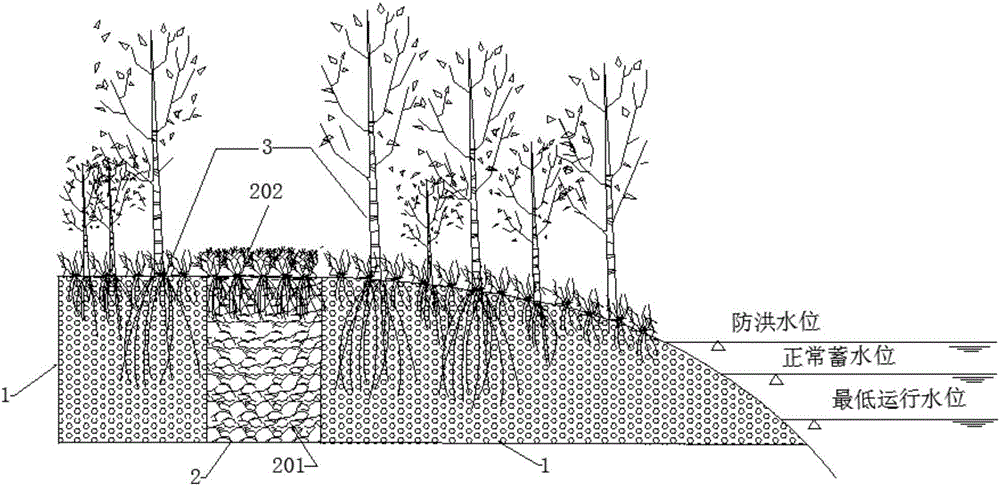

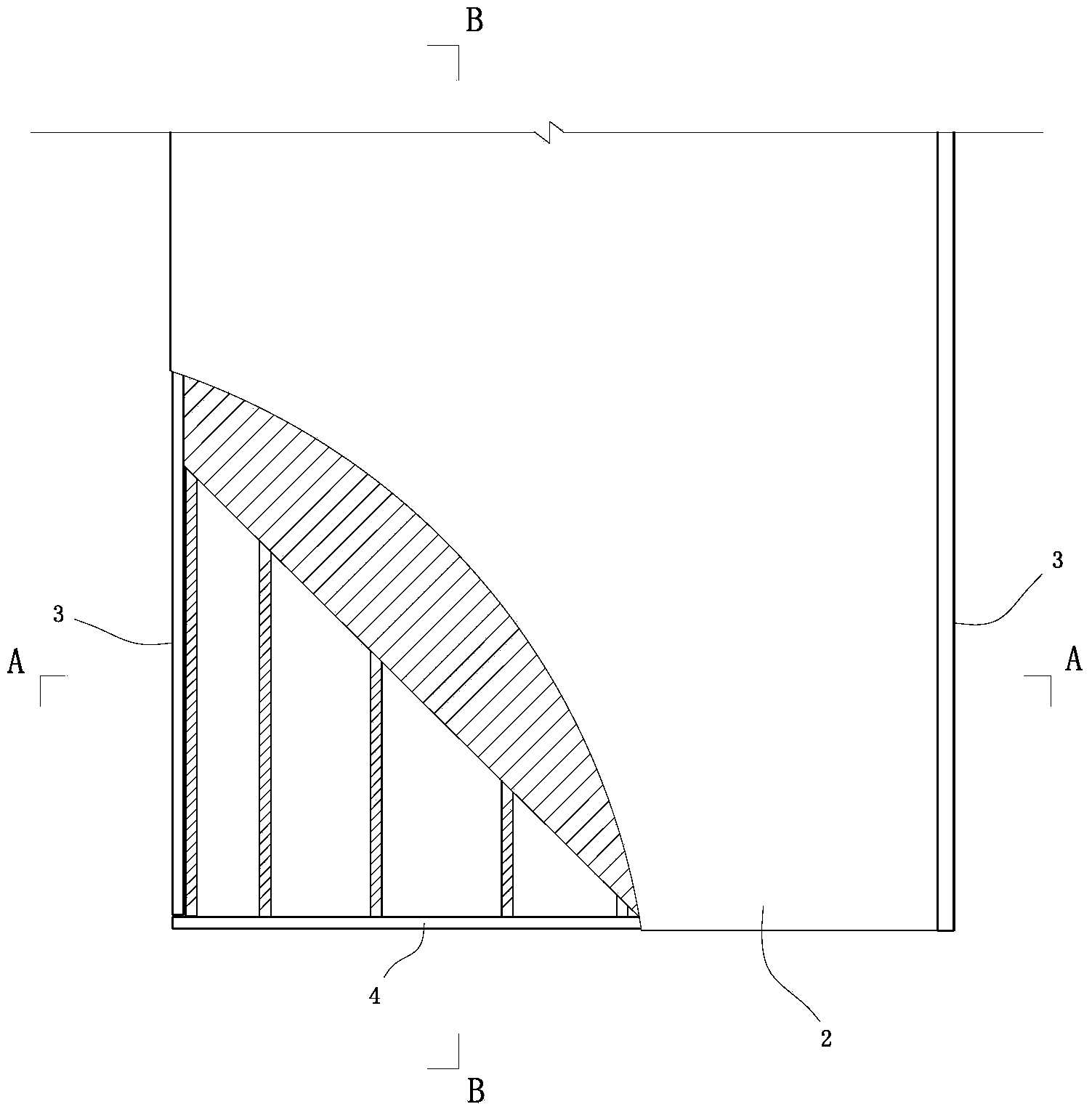

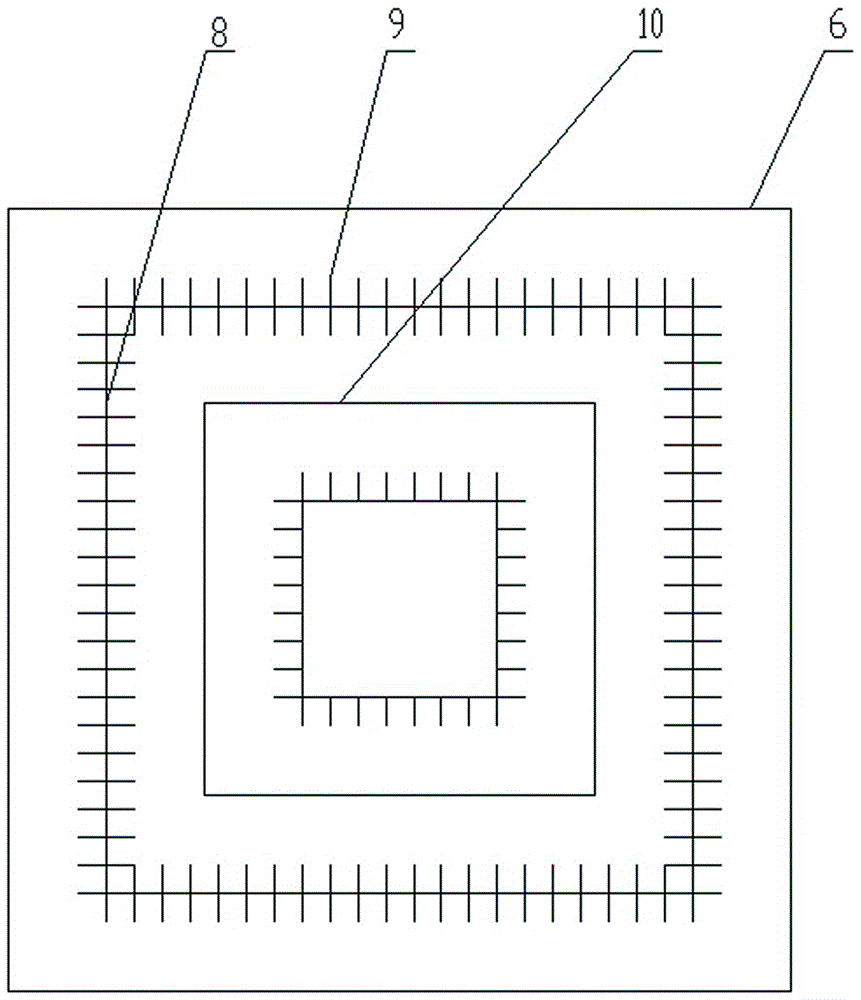

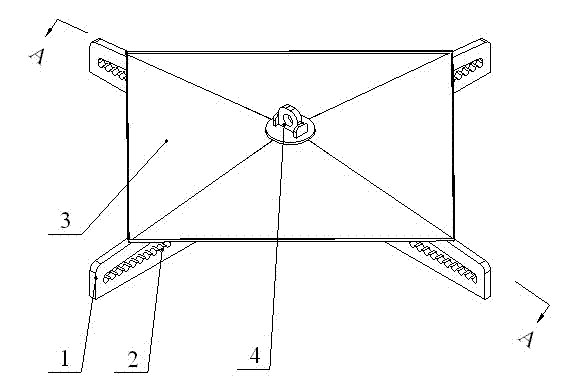

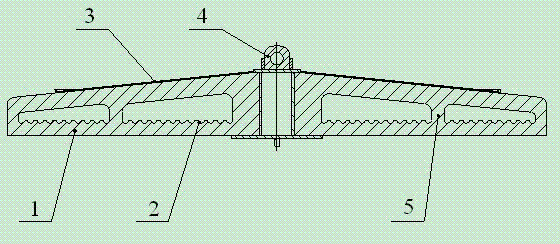

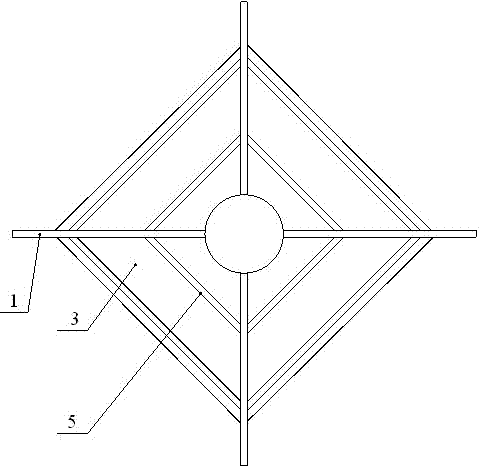

Lake buffer zone building method for non-point source pollution control

ActiveCN104452653ARealize resource utilizationLow costSustainable biological treatmentMarine site engineeringBuffer stripNitrogen

The invention discloses a lake buffer zone building method for non-point source pollution control. The method includes the following steps that a region among a farmland, a village and a lake is selected to serve as the foundation to build a buffer zone. The buffer zone comprises a vegetational zone (1) planted with indigenous plants (3). The end, away from the lake, of the vegetational zone (1) is the front end, and a reinforcement substrate zone (2) is built at the front end or the middle of the vegetational zone (1). The lake buffer zone building method for non-point source pollution control which is good in purifying effect, easy to operate and low in cost is provided for control over non-point source pollution and particularly control over nitrogen and phosphorus in the non-point source pollution.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

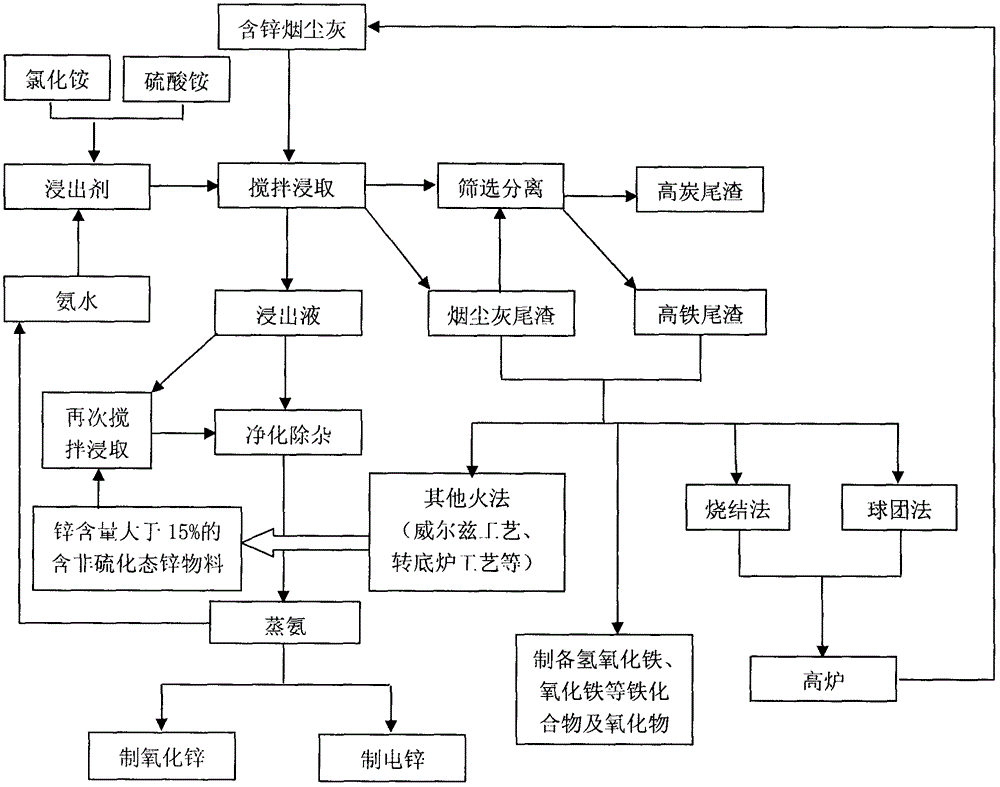

Utilizing method of zinc-containing dust ash of steel plant

InactiveCN106119556AIncrease concentrationSolve the problem of continuous enrichmentPhotography auxillary processesZinc oxides/hydroxidesEnvironmental resistanceAmmonia

The invention relates to a utilizing method for producing zinc oxide products by utilizing zinc-containing dust ash of a steel plant and recycling ferric carbon for returning to smelting. Zinc in the dust ash is leached by use of an ammonia method; materials which have the zinc content greater than 15% and contain non-vulcanized zinc are added for increasing the concentration of a zinc solution; leachate is purified, cleaned and subjected to ammonia distilling, and zinc oxide is prepared after electrolytic zinc preparation or zinc deposition; and original dust ash tailings or screened dust ash tailings are sent into a blast furnace for smelting, or a conventional pyrogenic process is adopted for recycling ferric carbon from the original dust ash tailings or the screened dust ash tailings, and collected secondary zinc oxide dust ash is used for the front end leaching, so that the zinc concentration of the leachate is increased. The utilizing method can be applicable to dust ash, with the zinc content as lower as 4% or even lower, of the steel plant; by use of a conventional method, the zinc extraction rate and the removing rate of harmful substances including alkali metal, fluorine and chlorine are both above 90%; the dust ash tailing recovery process is high in equipment adaptability, and appropriate treatment processes can be chosen according to existing equipment; and efficiency is high, the environment is protected, and comprehensive cyclic utilization of the zinc-containing dust ash is achieved.

Owner:李果

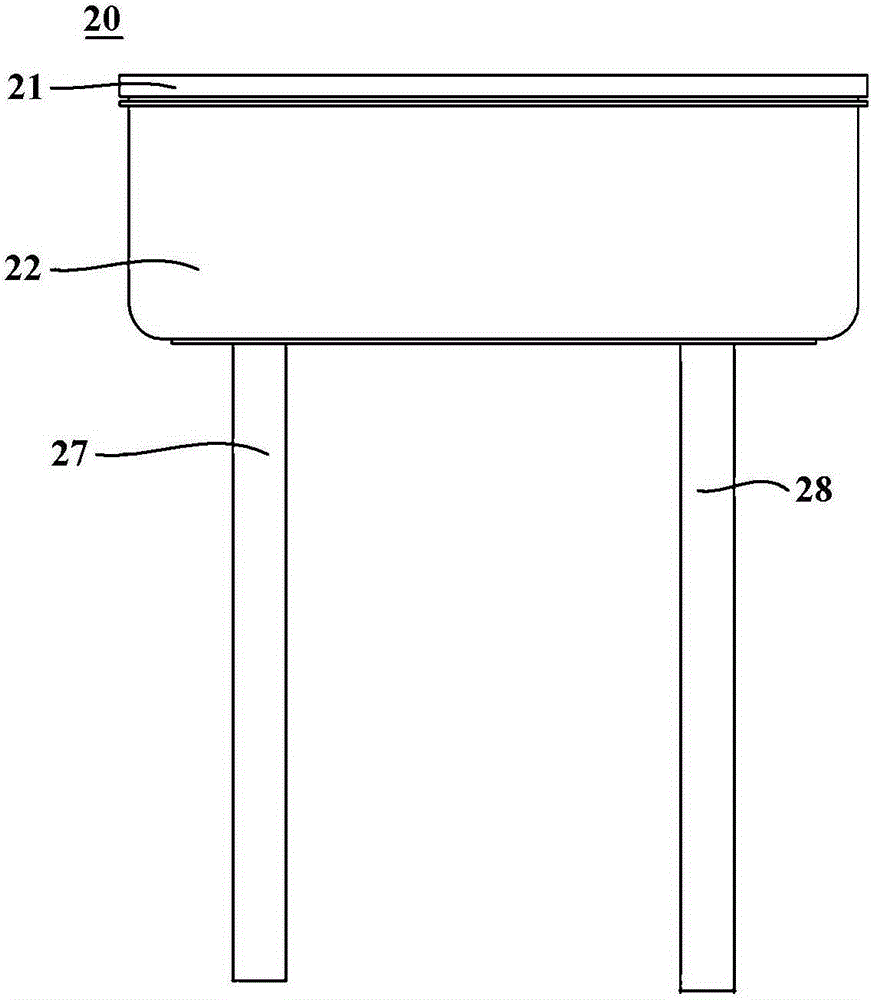

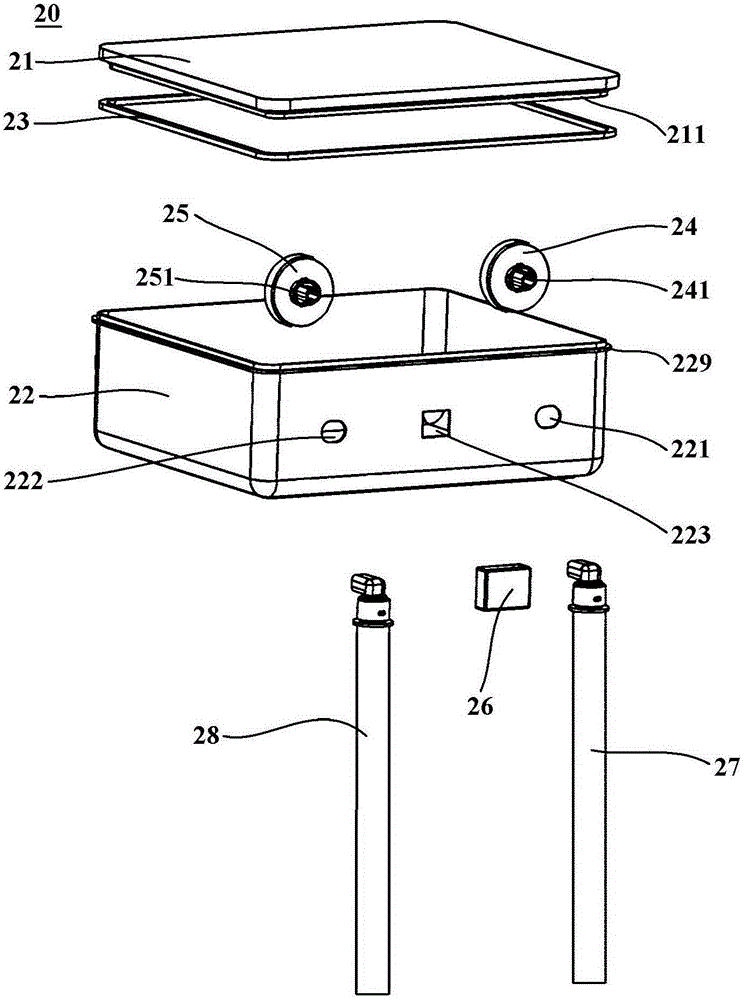

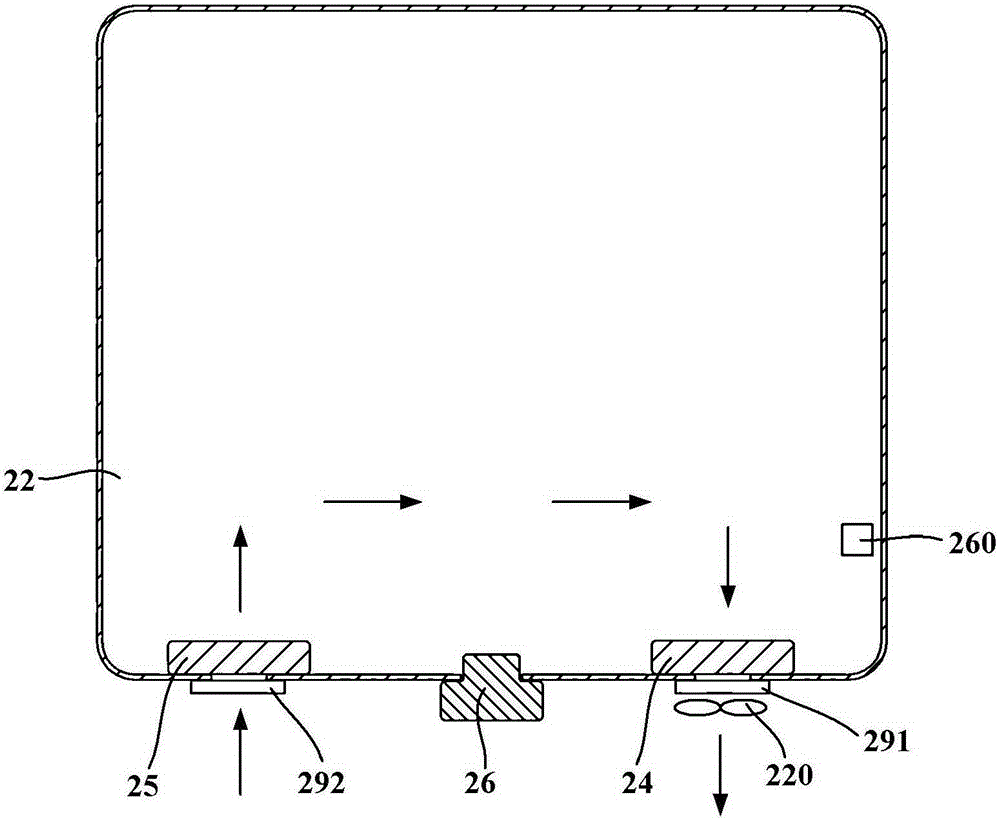

Sterile purifying fresh-keeping device, sterilization method and refrigerator

ActiveCN105167110AAvoid secondary pollutionNo pollution in the processLighting and heating apparatusFood preservationOzone generatorHigh concentration

The invention provides a sterile purifying fresh-keeping device, a sterilization method and a refrigerator. The sterile purifying fresh-keeping device comprises an antioxidative seal box, an ozone generator, a sterilizing filter and an ozone removing filter. The antioxidative seal box is provided with a pick-and-place opening and a cover body used for sealing the pick-and-place opening, and the antioxidative seal box is further provided with an air inlet and an air outlet, wherein the air inlet is formed to introduce air outside the antioxidative seal box into the antioxidative seal box, and the air outlet is formed to exhaust air in the antioxidative seal box out of the antioxidative seal box; the ozone generator is arranged to provide ozone for the antioxidative seal box so as to conduct sterilization on articles in the antioxidative seal box; the sterilizing filter is arranged on the air inlet and used for conducting sterilization on air flowing through the sterilizing filter; the ozone removing filter is arranged on the air outlet and used for removing the ozone in air flowing through the ozone removing filter. According to the sterile purifying fresh-keeping device, the sterilization method and the refrigerator, the ozone is used for conducting sterilization on the articles, the ozone can be rapidly and effectively removed by means of the ozone removing filter through an air circulating mode, and therefore sterilization can be conducted on the articles by means of the ozone with higher concentration.

Owner:HAIER SMART HOME CO LTD

Method for producing high purity nanometer zinc oxide by using steel plant dust

ActiveCN102826586AGrowth inhibitionAddressing Zinc Loading IssuesZinc oxides/hydroxidesNanotechnologyZno nanoparticlesSteaming

The invention discloses a method for producing high purity nanometer zinc oxide by using steel plant dust. The method for producing high purity nanometer zinc oxide by using steel plant dust comprises the following steps of: carrying out leaching with an ammonia-ammonium carbonate solution as the leaching agent, adding 0.3-0.5kg of sodium fluosilicate into the leaching agent per cubic meter, sequentially carrying out ammonia pre-steaming and purification and impurity removal, and finally carrying out refining treatment after purification and impurity removal. According to the method, the ammonia process is used for treating steel plant dust, the existing ammonia process is adaptively improved so that zinc in the steel plant dust can be fully recovered, and nanometer zinc oxide with the purity of more than 99.7 percent and the grain diameter of 10-60nm can be obtained by using the method; the method has the advantages of low energy consumption and high efficiency, and thoroughly solves the problem of zinc load of steel plant dust as the leaching agent can be recycled, thereby meeting the requirement of purifying the toxic components including zinc and alkali metals and realizing good production circulation as well as recovering valuable iron and carbon resources of steel plants.

Owner:SICHUAN JUHONG TECH

Method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust

The invention discloses a method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust. The method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust comprises the following steps of: carrying out leaching with an ammonia-ammonium carbonate solution as the leaching agent, adding 0.3-0.5kg of sodium fluosilicate into the leaching agent per cubic meter to obtain a leaching solution, then adding 50-60kg white lime into the leaching solution per cubic meter to carry out heating decarburization, and carrying out purification and impurity removal and then refining treatment. According to the method, the ammonia process is used for treating steel plant dust, and the existing ammonia process is adaptively improved, the leaching speed and the leaching rate of zinc in the dust are improved, and zinc oxide with the purity of more than 99.7 percent can be obtained; the method has the advantages of low energy consumption and high efficiency, and thoroughly solves the problem of zinc load of steel plant dust as the leaching agent can be recycled, thereby meeting the requirement of purifying the toxic components including zinc and alkali metals and realizing good production circulation.

Owner:SICHUAN JUHONG TECH

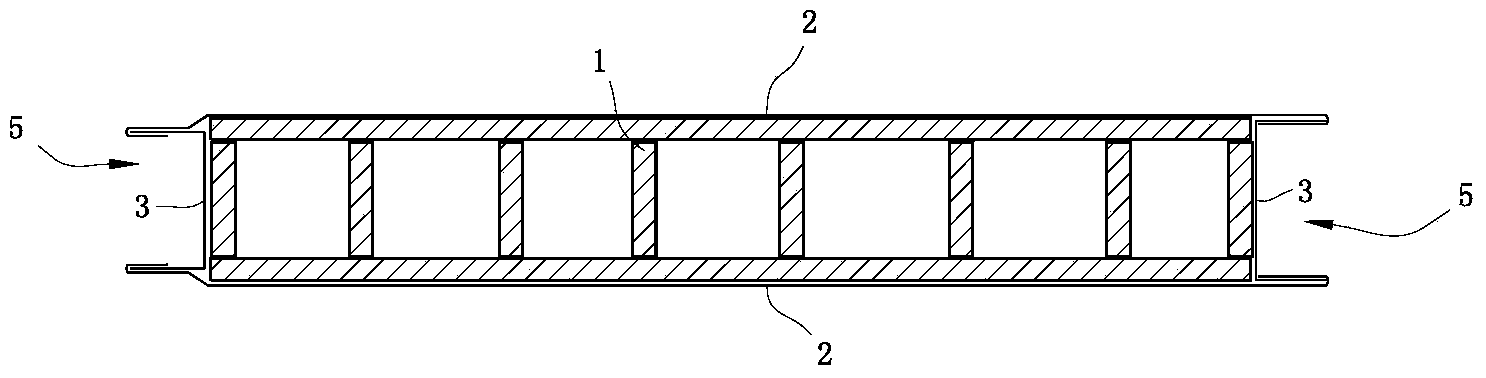

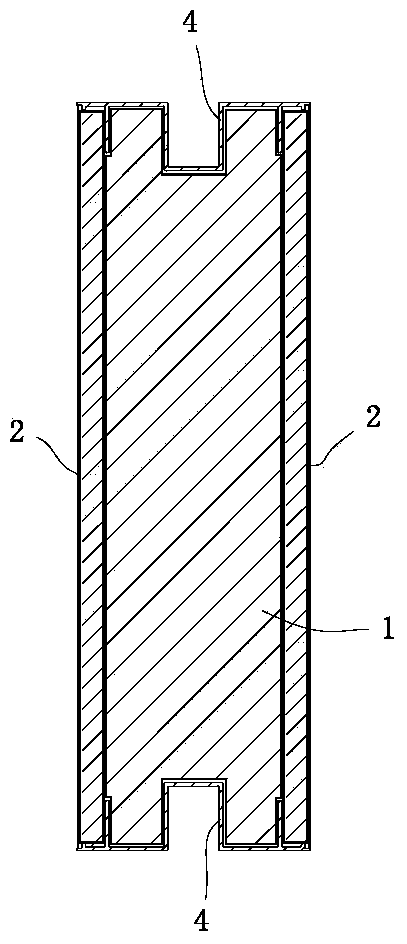

Strong-strength machine-made handmade sandwich board

InactiveCN104234354AHigh strengthGet rid of dependenceCovering/liningsSandwich boardTongue and groove

The invention discloses a strong-strength machine-made handmade sandwich board, which comprises a sandwich core material and panels covering the surfaces of the two sides of the sandwich core material, wherein side plates with U-shaped sections are arranged at the left and right side ends of the sandwich core material respectively; the longitudinal edge ends of the two panels extend and are folded to be connected with the side plates in a rolling way to form male and female tongues and grooves at the left and right ends of the sandwich core material; reinforced connecting bands are also arranged at the upper and lower side ends of the sandwich core material; groove structures or tenon structures are formed on the middle parts of the reinforced connecting bands, are connected with the sandwich core material in an embedding way, and are closely connected with the panels to strengthen the transverse strength of the board. According to the color steel sandwich board, transversely adjacent color steel sandwich boards are spliced and matched by virtue of the male and female tongues and grooves at the left and right ends of the sandwich core materials; the reinforced connecting bands are also arranged at the upper and lower ends of the sandwich core material, the strength of the board is strengthened by the reinforced connecting bands, and meanwhile, the groove structures or the tenon structures of the reinforced connecting bands can be used for connecting longitudinally adjacent color steel sandwich boards in a matched way to ensure convenient and rapid assembly positioning.

Owner:GUANGZHOU COBORN AIR CLEANING TECH CO LTD

Method for producing high purity nanometer zinc oxide by using ammonia process of steel plant dust

ActiveCN102826589AEvenly distributedEfficient leachingZinc oxides/hydroxidesNanotechnologyBiological activationZinc

The invention discloses a method for producing high purity nanometer zinc oxide by using ammonia process of steel plant dust. According to the method, white lime of 3-5 percent of the mass of steel plant dust is added for activation before leaching, then leaching is carried out with an ammonia-ammonium carbonate solution as the leaching agent, 0.3-0.5kg of sodium fluosilicate is added into the leaching agent per cubic meter, and purification and impurity removal are carried out and then refining treatment is carried out. According to the method, the ammonia process is used for treating steel plant dust, the existing ammonia process is adaptively improved, and high purity nanometer zinc oxide with larger specific surface area can be obtained; and the method has the advantages of low energy consumption and high efficiency, and thoroughly solves the problem of zinc load of steel plant dust as the leaching agent can be recycled, thereby meeting the requirement of purifying the toxic components including zinc and alkali metals and realizing good production circulation.

Owner:SICHUAN JUHONG TECH

Method for producing high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization

ActiveCN102849782AGood dispersionImprove liquidityZinc oxides/hydroxidesSolid waste disposalDecarburizationAlkali metal

The invention discloses a method for producing a high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization. The method includes that an ammonia-water-ammonium-bicarbonate solution is utilized as a leaching agent for leaching, 0.3-0.5kg of sodium fluosilicate is added into the per cubic meter of the leaching agent, and after the leaching, 50-60kg of slaked limes are added in per cubic meter of a leaching agent liquid to perform warming decarburization. According to the method, the ammonia method is applied to smoke dust ash treatment, prior ammonia methods are subjected to adaptable improvement, the leaching speed and the leaching rate of zinc in the smoke dust ash are improved, zinc oxide with a large specific surface area can be obtained, simultaneously the purity can reach above 99.7%, by means of the method, the energy consumption is low, the efficiency is high, the leaching agent can be recycled, the problem of zinc load in the steel mill blast furnace smoke dust can be thoroughly solved, the purifying requirements for harmful ingredients of zinc and alkali metal in the steel mill can be met, virtuous circle of production is achieved, valuable ferrum and carbon resources in the steel mill can be recycled, the ferrum and carbon are enriched, the energy is saved, and good economic benefits are achieved.

Owner:SICHUAN JUHONG TECH

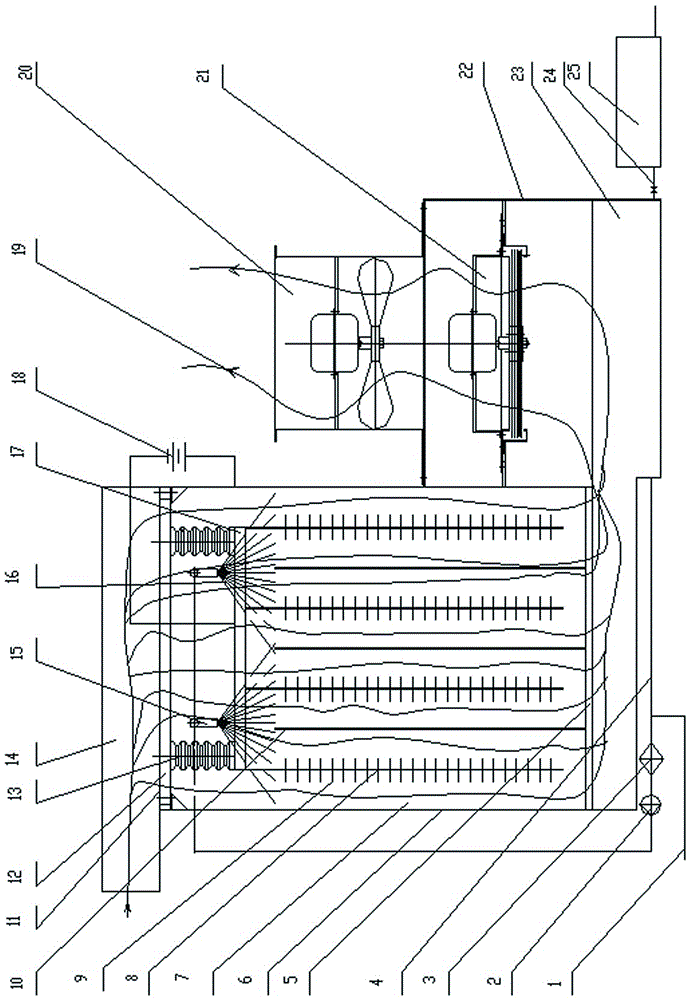

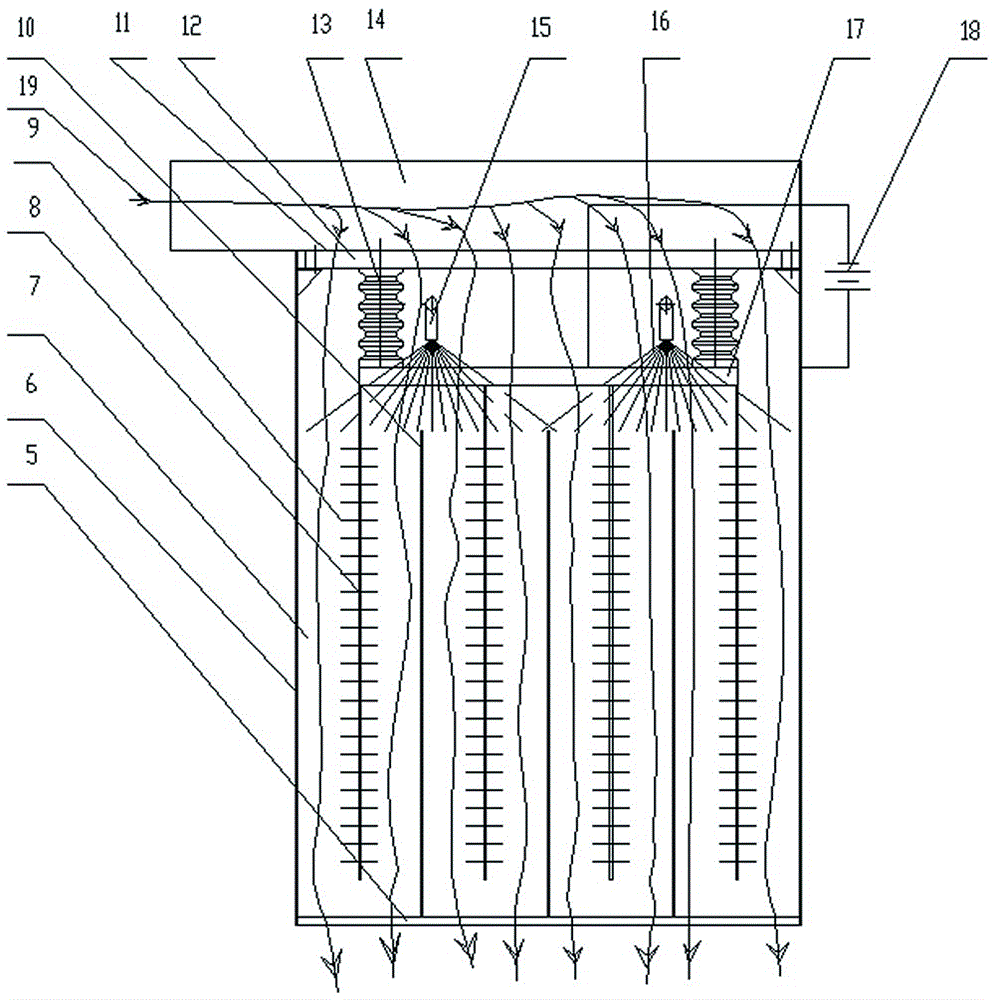

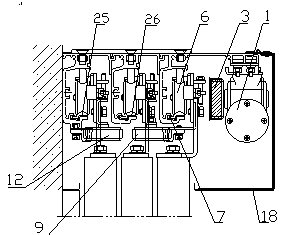

Compound water mist electric field type purifier

InactiveCN106422630AImprove purification efficiencyReduce secondary pollutionCombination devicesGas treatmentFire hazardElectric field

The invention relates to a smoke purifying device, in particular to a compound water mist electric field type purifier capable of generating a water mist electric field. The compound water mist electric field type purifier comprises a purifier shell, a hanging bracket is arranged at the top of the purifier shell, water mist generators and connectors made of insulation materials are arranged below the hanging bracket, a discharge electrode fixing frame is connected to the lower ends of the connectors made of the insulation materials, high-voltage electrostatic power supply leads are connected to the discharge electrode fixing frame, discharge electrodes distributed with needles are connected to the lower portions of the high-voltage electrostatic power supply leads, dust collecting electrodes combined with the discharge electrodes are connected to a dust collecting electrode support arranged on the lower portion of the purifier shell, the dust collecting electrodes and the discharge electrodes are arranged at intervals, and a smoke passage is formed between each of the dust collecting electrode and the adjacent discharge electrode. The compound water mist electric field type purifier has the advantages of simple structure, low production cost, small occupied area, high purification efficiency, capability of removing solid, liquid and gaseous pollutants in smoke, low resistance, low energy consumption, no condensate aggregation, avoidance of cleaning, low maintenance and operation cost, long service life and no fire hazard.

Owner:李焱

Method for producing high-purity zinc oxide through fume ash in steel works

ActiveCN102849781AAddressing Zinc Loading IssuesMeet purification requirementsZinc oxides/hydroxidesSolid waste disposalSolventSodium silicate

The invention discloses a method for producing high-purity zinc oxide through fume ash in steel works. Ammonia-ammonium bicarbonate liquid is used as leaching solvent to perform leaching; 0.3 to 0.5 kg of sodium fluosilicate is added in each cubic meter of the leaching solvent; before an impurity removal step, leaching liquid subjected to leaching is heated to 95 to 105 DEG C to be subjected to ammonia pre-steaming; and by applying ammonia process to the treatment of the fume ash in the steel works and performing adaptive improvement on the existing ammonia process, zinc in the fume ash in the steel works can be rapidly leached completely as far as possible, the zinc in the fume ash in the steel works can be sufficiently recycled, and the purity of zinc oxide obtained can reach more than 99.7 percent. The method has the advantages that the energy consumption is low; the efficiency is high; the leaching solvent is circularly utilized; the problem of zinc load in the fume ash in the steel works is thoroughly solved; not only the requirement of purification of noxious constituent zinc and alkali metal by the steel works is satisfied, and the virtuous cycle of production is achieved, but also valued iron and coal resources in the steel works are recovered, and iron and coal are enriched; and not only energy is saved, but also good economic benefit is created.

Owner:SICHUAN JUHONG TECH

Method for producing high-purity zinc oxide by steel plant smoke ash ammonia method

The invention discloses a method for producing high-purity zinc oxide by a steel plant smoke ash ammonia method, comprising the following steps of: adding slaked lime of which the weight is 3-5% of the weight of steel plant smoke ash before leaching for activating in a stirring way, leaching the steel plant smoke ash which is activated in a stirring way by taking ammonia water-carbon ammonium liquid as leaching agent, and adding 0.3-0.5kg of sodium fluosilicate into each cubic meter. An ammonia method is applicable to the treatment of smoke ash, and the existing ammonia method is adaptively improved, so that the zinc leaching speed and leaching rate in the smoke ash can be improved. The treatment method disclosed by the invention is low in energy consumption, and high in efficiency, thoroughly solves the problem of the zinc load of the steel plant blast furnace smoke since leaching agent is recycled, meets the purification requirement of the steel plant to the harmful ingredients such as the zinc and the alkali metal, reaches the virtuous circle of the production, and not only saves the energy resources but also creates the good economic benefit.

Owner:SICHUAN JUHONG TECH

Preparation method of ultra-high molecular weight polyethylene composite microporous membrane

The invention relates to a preparation method of an ultra-high molecular weight polyethylene composite microporous membrane. The preparation method comprises the following steps: (1) carrying out desizing treatment on base cloth which is high-temperature-resistant cloth, then drying, and performing pretreatment with pretreating agents; (2) weighing ultra-high molecular weight polyethylene, diluents and antioxidants in parts by weight, melting and mixing by a double-screw extruder, performing hot-pressing combination on the mixture and the base cloth to obtain a composite jelly membrane by a continuous extrusion process or a gap type mold-pressing process; and (3) removing the diluents in the composite jelly membrane by extraction agents, drying and shaping to obtain the composite microporous membrane. According to the preparation method, the ultra-high molecular weight polyethylene enters the inside of the cloth sufficiently to form a penetrating network, the combined membrane has good penetrating property, high water flux and high mechanical property improved greatly, and the prepared microporous membrane can be used for production of foods, medicines, and ultrapure water, and can meet the requirements of separation, purification, concentration and purification.

Owner:DONGHUA UNIV

Transformer coil lifting beam

InactiveCN102765657AAvoid partial dischargeBarrier contactLoad-engaging elementsForeign matterTransformer

The invention discloses a transformer coil lifting beam, and particularly relates to a lifting mechanism for demoulding of a transformer. The transformer coil hanging beam comprises at least three mutually connected radial lifting arms, wherein a group of suspension positioning mechanisms are arranged on each lifting arm in the length direction and a lifting hook is arranged above each lifting arm. The lifting arms of the lifting beam have a certain adjustable range and can be used for the demoulding of transformer coils with different outer diameters, so that the commonality of the lifting beam is enhanced and the cost is reduced. Moreover, the structure of a top cover can meet the purification requirement, so that fallen metal chips or other foreign matters due to wear in running can be effectively prevented from being in contact with the coils and are convenient for users to clean regularly, and local discharge of the transformer due to the foreign matters is avoided at the same time.

Owner:SHANDONG POWER EQUIP

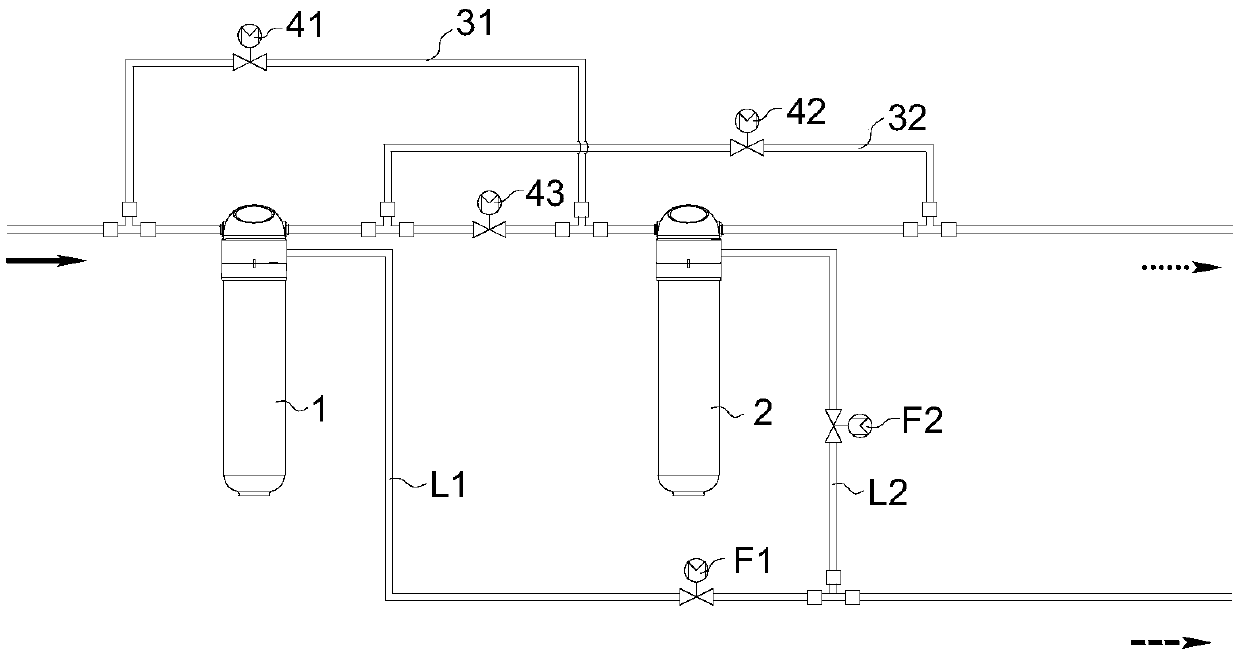

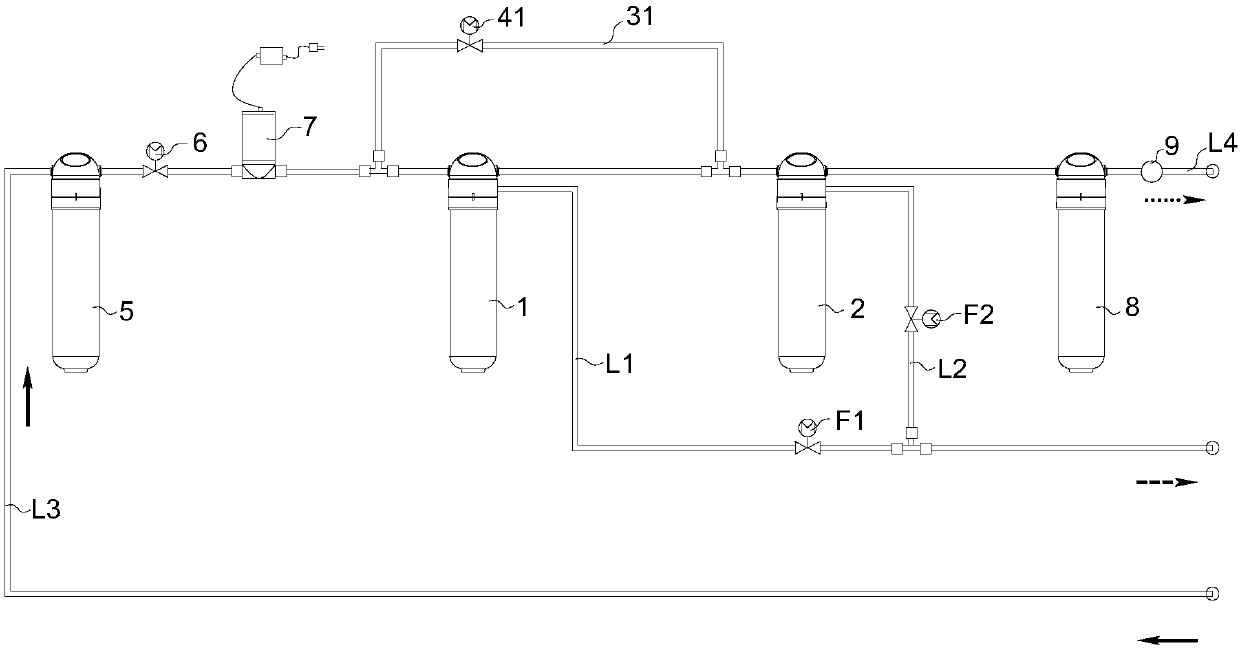

Temperature swing adsorption gas purification device

InactiveCN102489112AMeet purification requirementsReduce dosageDispersed particle separationProcess engineeringTower

The invention discloses a temperature swing adsorption gas purification device, and aims to solve the problems that regeneration gas required by the conventional temperature swing adsorption separation device is needed to be input from outside and high in consumption, and the device is high in operating cost. The device comprises a feed port, at least three adsorbers, coolers, heaters and a discharge port, wherein the feed port, the adsorbers and the discharge port are connected through pipelines; the coolers, the heaters and the adsorbers are connected through pipelines; adsorption towers are connected through pipelines; and valves are arranged on the pipelines. A small amount of regeneration gas is required, energy consumption is low, the device is flexibly operated, energy can be effectively saved, and production cost is reduced.

Owner:SICHUAN TIANYI SCI & TECH

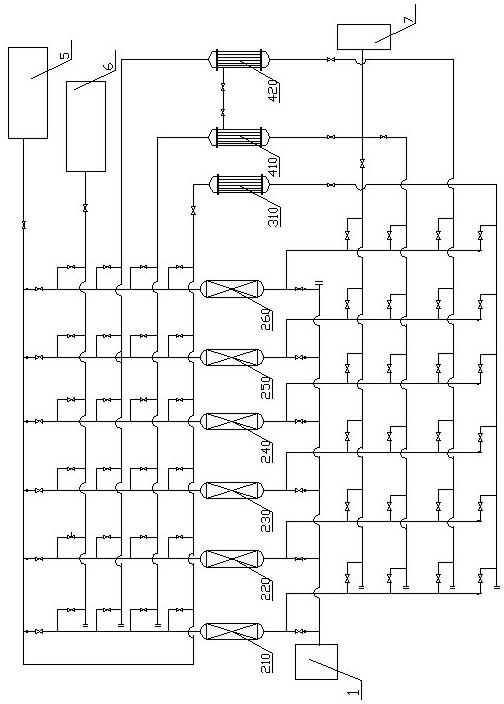

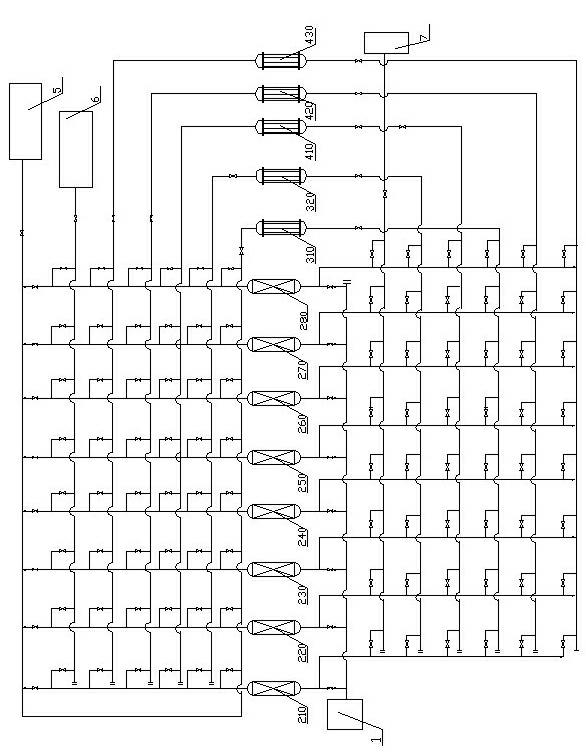

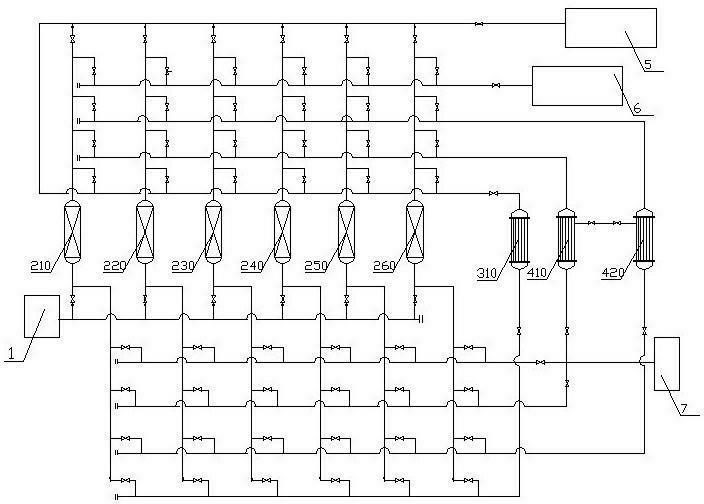

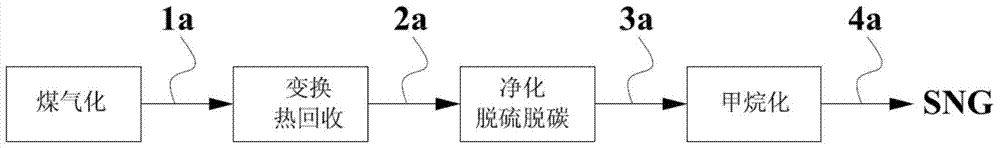

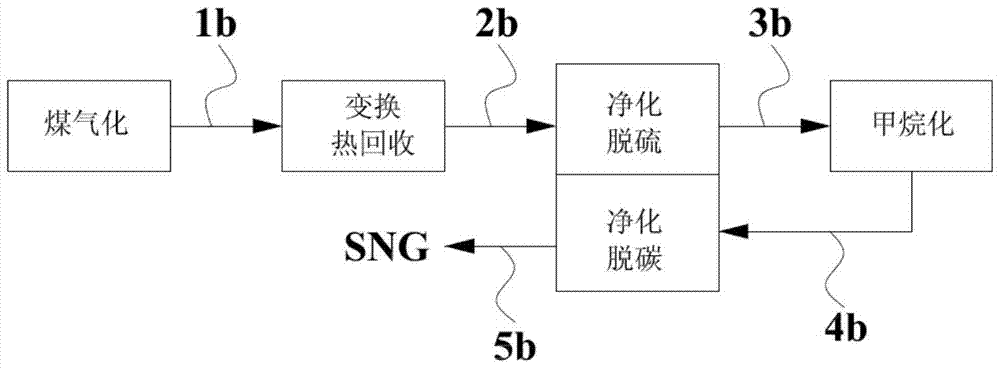

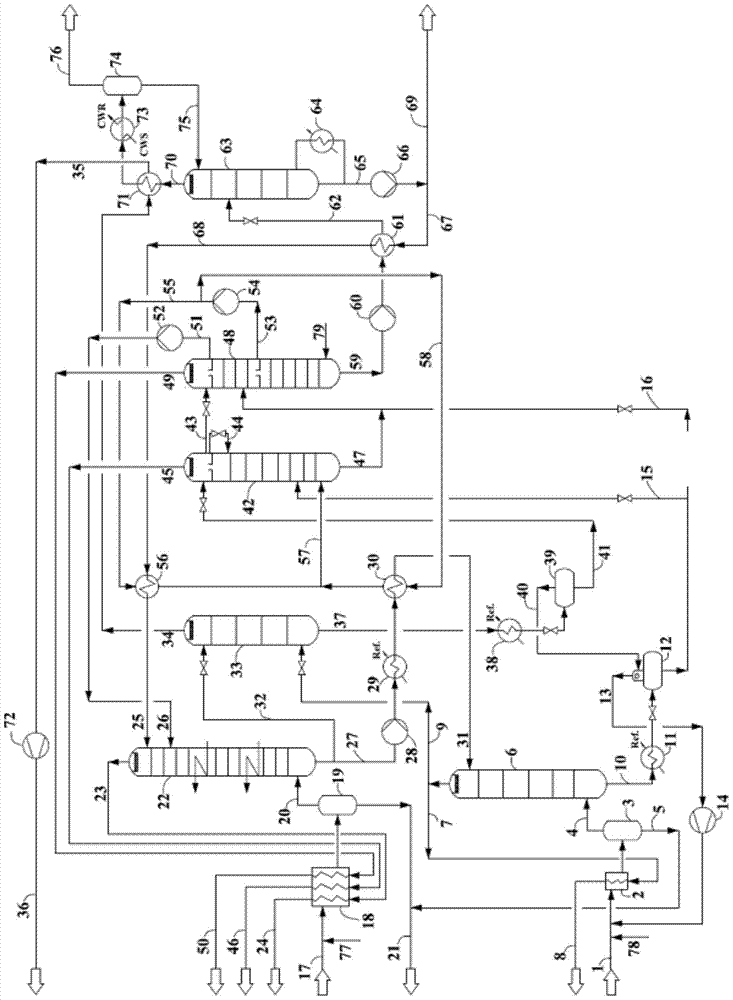

Gas purification method applied to coal-based synthetic natural gas device

ActiveCN107011950ABurn out preventionAvoid damageGaseous fuelsCombustible gas purificationPurification methodsMethanation

The invention relates to a gas purification method applied to a coal-based synthetic natural gas device. The coal-based synthetic natural gas device comprises a coal gasifier, a transformation heat recycling device, a purification device and a methanation reactor, wherein the purification device comprises a purification and desulfurization system and a purification and decarbonization system. The gas purification method is characterized by simultaneously desulfurizing transformation gas from an upstream device and decarbonizing crude methane product gas from a downstream methanation reactor, namely desulfurizing the transformation gas obtained by transformation of the transformation heat recycling device via the purification and desulfurization system and subsequently introducing the transformation gas into the methanation reactor to prepare the crude methane product gas, and removing CO2 in the transformation gas via the purification and decarbonization system to obtain the SNG (Synthetic Natural Gas) product. Compared with the prior art, the purification requirements of two raw material gases can be simultaneously met; the purification effect is excellent; meanwhile, the absorbent can be recycled, so that the cost is reduced.

Owner:WISON ENG

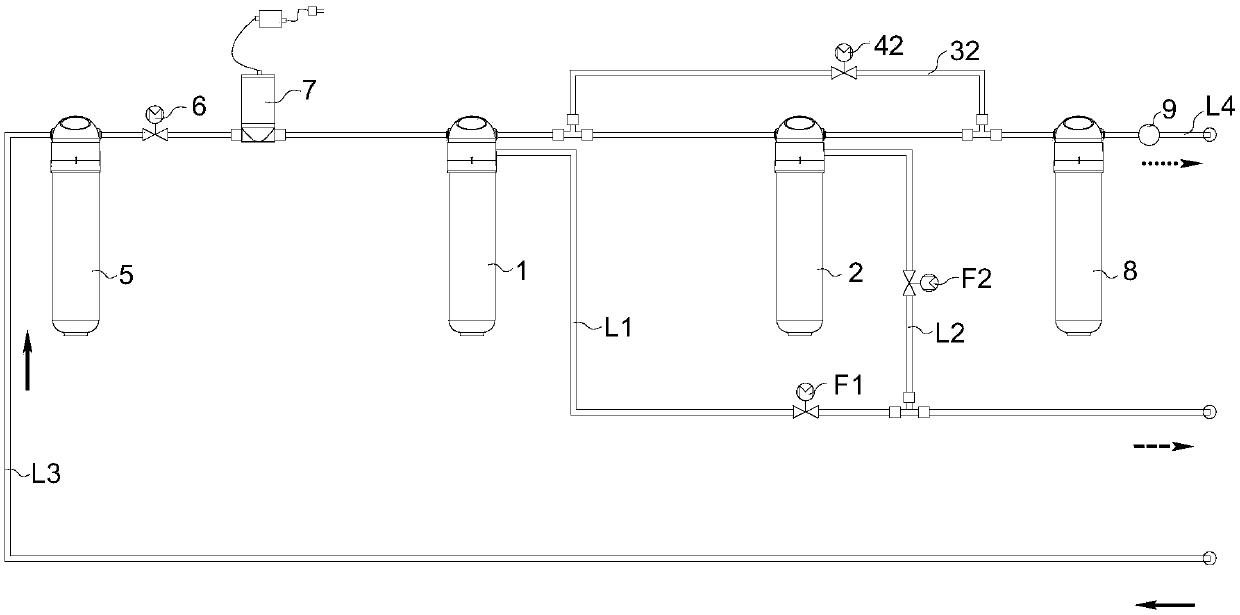

Water purification system and water purification equipment

PendingCN110845030AEnsure water qualityMaximum water outputTreatment involving filtrationMultistage water/sewage treatmentProcess engineeringEnvironmental engineering

The invention relates to the field of water purification, and discloses a water purification system and water purification equipment. The water purification system comprises a main pipeline, which issequentially connected with a first filtering core and a second filtering core, the first filtering core and the second filtering core are connected in series, the main pipeline is also connected witha switching pipeline, a switching valve is arranged on the switching pipeline, and with the switching pipeline, water in the main pipeline is switched between a first working mode and a second working mode through the opening and the closing of the switching valve, wherein the first working mode is that the water is sequentially filtered by the first filtering core and the second filtering core,and the second working mode is that the water is only filtered by one of the first filtering core and the second filtering core. According to the invention, with the water purification system and thewater purification equipment, the water yield can be maximized on the premise of ensuring of the water quality, and the user requirements can be well met.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

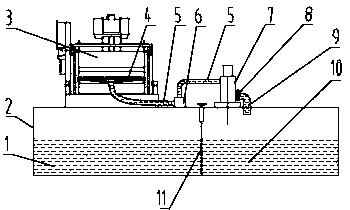

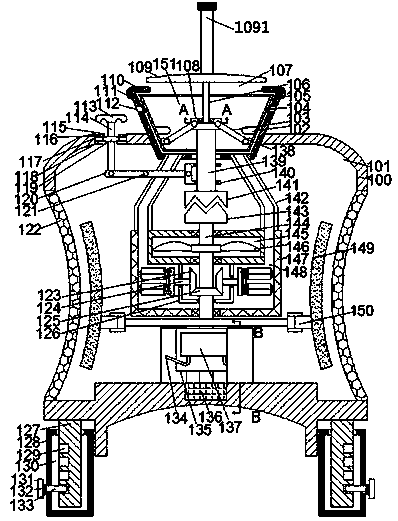

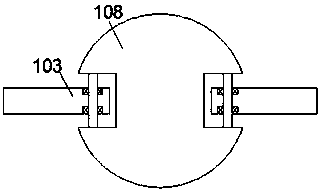

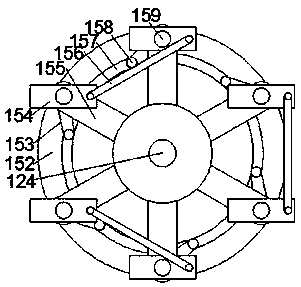

Solid-liquid separation and vibrating liquid-removing drying integrated device

PendingCN111485836AMeet separation requirementsMeet purification requirementsDrying machines with non-progressive movementsFlushingWell drillingSmall footprint

The invention provides a solid-liquid separation and vibrating liquid-removing drying integrated device, and the device comprises a liquid phase collection storehouse, a drilling fluid circulating pot, a vibrating screen, a sucking disc, a liquid inlet pipe, a tee joint, a vacuum pump, a control valve, a liquid outlet pipe, a clapboard, a drilling cuttings collection storehouse, a screen cloth anda gate valve. Mechanical vibration and vacuum adsorption principles are used for the device, thus, solid phase moisture content of a solid-liquid mixture returned up from a shaft bottom is reduced after the solid-liquid mixture is subjected to solid-liquid separation and liquid-removing drying by the vibrating screen, thus, the solid-liquid mixture meets rock debris transportation requirements, pollution to environment caused by waste generated in a drilling process is reduced effectively, and the recycled drilling fluid is collected for cycle use in the drilling fluid circulating pot. The device has the advantages of being simple in structure, needing low energy consumption, being convenient to use, being mounted quickly, having high equipment reliability, needing low manufacturing costand occupying small area; moisture content of the treated drilling cuttings is not more than 60%, and the drilling cuttings meet drilling cuttings transportation reequipments; and the device is used for a drilling fluid solid phase control and no-landing integrated treatment system, and simplifies system constitution.

Owner:中石化石油工程技术服务有限公司 +3

Method for producing feed grade zinc oxide through sodium chloride-ammonia combined leaching

ActiveCN108275714ALower decomposition temperatureGood dispersionZinc oxides/hydroxidesImpurityCalcination

The invention discloses a method for producing feed grade zinc oxide through sodium chloride-ammonia combined leaching. The method comprises the following steps: leaching smoke dust of a steel mill, purification and dust removal, distilling ammonia and depositing zinc and drying and calcining, wherein when the smoke dust of the steel mill is leached, ammonium hydroxide, ammonium bicarbonate and sodium chloride are taken as leaching agents. The method has the advantages a sodium chloride solution is added to leaching liquid, the zinc leaching speed and leaching rate in the smoke dust are improved, the fact that the leaching rate of impurities, such as iron, is extremely low can be further guaranteed, the zinc depositing speed during ammonia seperation is further accelerated, the chemical components and structure of a product are changed, a solution can be completely used for performing circulation ammonia absorption leaching utilization after ammonia separating and zinc depositing, andthe cost is saved; an adopted technology changes the phase components of a product intermediate, low calcination temperature can be adopted, a feed zinc oxide product with the content of high bulk density being capable of reaching greater than 99.0 percent, and the method has excellent economic benefit.

Owner:SICHUAN JUHONG TECH

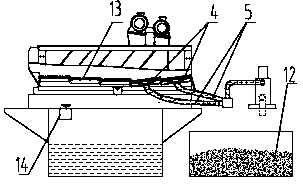

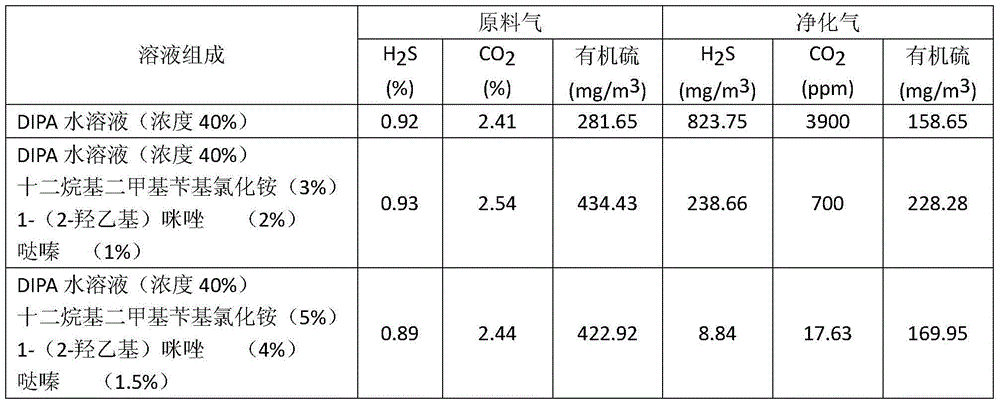

Compound active additive and applications thereof

ActiveCN104624024AImprove corrosion resistanceImproves anti-foaming propertiesGaseous fuelsDispersed particle separationCarbon dioxide contentChemical stability

The invention relates to a compound active additive and applications thereof. The compound active additive is a mixture composed of 50 to 75% of quaternary ammonium salt (A), 15 to 30% of imidazole (B), and 10 to 20% of azine (C). The provided compound active additive is used to deeply remove acidic components from acidic natural gas containing carbon dioxide and organic sulfur. The active additive is compounded with an alcohol-amine solvent before using, the addition amount of the additive is 1 to 10% of the solvent weight, the pH of the mixture is 11 to 12 at a temperature of 25 DEG C, and the final kinematic viscosity is 20 to 30 m2 / s. The active additive can deeply remove hydrogen sulfide, carbon dioxide, and organic sulfur. The hydrogen sulfide content is less than 3 mg / m3, the carbon dioxide content is less than 50 mg / m3, and the organic sulfur content is less than 50 mg / m3 after application of the active additive. At the same time, the anticorrosive and antifoaming properties of alcohol-amine solvent are improved, and the thermal stability and chemical stability of the alcohol-amine solvent are not affected.

Owner:PETROCHINA CO LTD

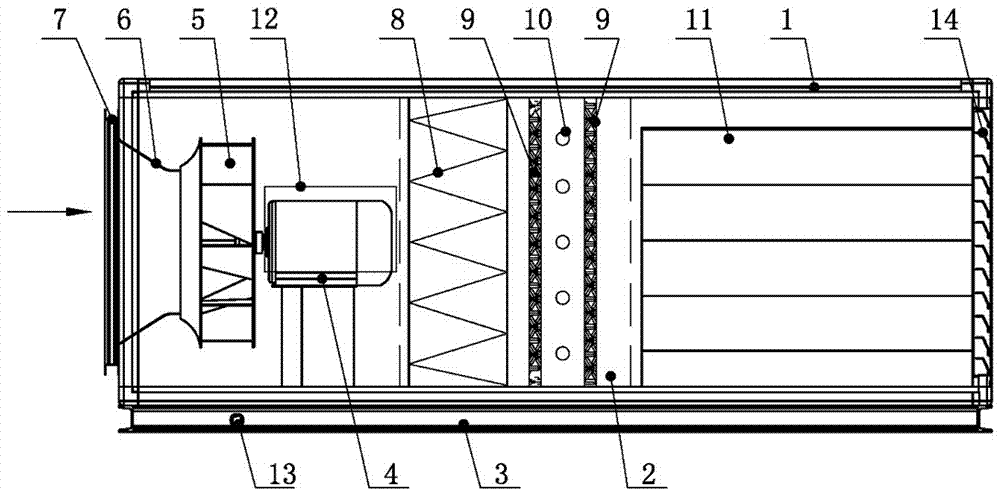

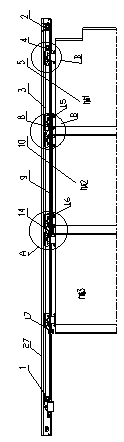

Low-noise cooking fume purification fan

PendingCN107990385AReduce noiseSmall pressure lossDomestic stoves or rangesLighting and heating apparatusLow noiseImpeller

The invention provides a low-noise cooking fume purification fan, and belongs to the technical field of waste gas treatment machines. The low-noise cooking fume purification fan solves the problems that an existing purification fan is low in purification efficiency and high in noise. The low-noise cooking fume purification fan comprises a box body, a panel and a base. The panel is mounted on the box body to form a fan shell. The base is fixedly connected to the bottom of the box body to achieve a supporting function. The interior of the box body can be sequentially divided into a fan segment,a purification segment and a noise reduction segment. A motor, an impeller and a fan cover are mounted at the position, located on the fan segment, in the box body. The impeller is mounted on a motortransmission shaft and is connected with the fan cover to form an air inlet. The purification segment is arranged at the position, located behind the motor, in the box body. A filter, photocatalyst carrier nets and ultraviolet lamps are sequentially mounted on the purification segment. The the two layers of photocatalyst carrier nets are arranged, and the ultraviolet lamps are located between thetwo photocatalyst carrier nets. The noise reduction segment is arranged at the rear end of the box body, noise reduction cotton is arranged on the panel in an attached manner, multiple noise reductionbarrels are exhibited in the box body, and therefore the effect of noise reduction is achieved. The low-noise cooking fume purification fan has the advantages of being low in noise and high in purification efficiency.

Owner:ZHEJIANG XINGYI VENTILATOR ELECTRICAL APPLIANCE

Extensible type protective door

InactiveCN103541638ATo achieve synchronous operationBig spaceRadiation protectionPower-operated mechanismOperating theatresStructural engineering

The invention discloses an extensible type protective door. The extensible type protective door comprises the protective door, a door beam, slide rails, a lower rail, a power mechanism and the like and is characterized in that the protective door is provided with two or more door leaves; the slide rails which are arranged on the door beam are corresponding to the door leaves; the number of the slide rails is more than two; the extensible type protective door is also provided with moving devices for the door leaves; a protective cover is arranged on the upper portion of the last door leaf. The extensible type protective door has the advantages of achieving synchronous operation of the three leaves due to the fact that three identical automatic door beams are organically combined together; leaving large room (more than 3500) for a device moving area when the protective door is completely opened due to the fact that the three door leaves are completely superposed; effectively satisfying an operating room requirement for cleansing when the protective door is completely closed due to the fact that reliable leakproofness of the protective door can completely isolate two adjacent space; effectively blocking harmful radiation of an X-ray radiated from a CT (Computed Tomography) to adjacent areas.

Owner:JINAN DAHUA YITE ENVIRONMENTAL PROTECTION ENG

Method for removing heavy metal ions in high-salinity water by using hydrogen sulfide

ActiveCN111892148AMeet purification requirementsMeet the purification production requirementsWater contaminantsChemical industrySaline waterPhysical chemistry

The invention discloses a method for removing heavy metal ions in high-salinity water by using hydrogen sulfide. The method comprises reaction equipment and a reaction process. The reaction equipmentcomprises a reaction kettle body, a stirring paddle penetrating through the kettle body is installed in the reaction kettle body, and the stirring paddle is composed of a flat blade paddle and a porous flat blade type turbine paddle. A porous sieve plate is arranged in the reaction kettle to divide the interior of the reaction kettle into a reaction area and a curing area; the reaction kettle bodyis provided with a liquid inlet and an air inlet; the liquid outlet is formed in the reaction kettle body corresponding to the curing area; an exhaust port is formed in the top of the reaction kettlebody. The high-salt solution and the hydrogen sulfide gas are violently stirred by a turbine of a stirring paddle in a bottom reaction area of the reactor, are in close contact with each other and fully react; and after the reaction is finished, the two phases enter the curing area for deep reaction and gas-liquid separation, separated unreacted gas enters a tail gas absorption system through anexhaust port, and liquid overflows out of the kettle through a liquid outlet. Heavy metal ions in the reacted high-salt aqueous solution can be reduced to 0.0005 g / L or below, and the purification requirement of the high-salt aqueous solution is met.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

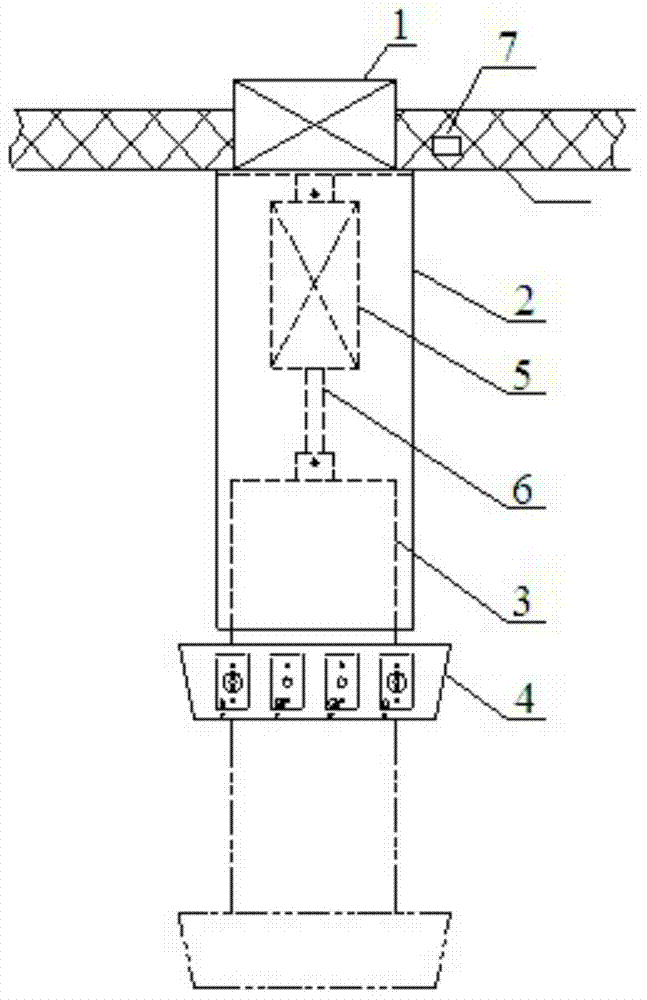

Lifting type medical crane

InactiveCN104739507AMeet purification requirementsSave spaceDiagnosticsSurgeryNetwork communicationEngineering

The invention relates to a lifting type medical crane. The lifting type medical crane comprises a mounting frame, an outer barrel, an inner barrel, a terminal box, a lifting device and a lifting push rod. the mounting frame is fixed on a slab or beam of a building, the outer barrel is fixed on the mounting frame, the inner barrel is mounted in the inner barrel, the lifting device is mounted at the top of the outer barrel, the lifting push rod is connected with the bottom of the lifting device and the top of the inner barrel, and the terminal box is fixed at the bottom of the inner barrel. The terminal box is lifted by the lifting device via the lifting push rod. Medical terminals are mounted on the terminal box and provide corresponding functions such as a power source interface, a protecting grounding interface, a medical gas terminal, a network communication port, disinfection, a lamp, a film viewer, a shadowless lamp and call control, indoor temperature and humidity can be controlled, intelligent control of an operating room is realized, and the lifting type medical crane is convenient to operate, small in occupation space, simple to maintain and accordant with medical purification standard.

Owner:JIANGSU XINHUAHENG PRECISION MACHINERY GRP CO LTD

Flexible polyurethane conductive material and preparation method thereof

The invention belongs to the technical field of material synthesis, and particularly relates to a flexible polyurethane conductive material and a preparation method thereof. The material is prepared from the following raw materials: 64 to 73% of polyurethane monomer, 10 to 18% of isocyanate, 3 to 5% of coated graphite powder, 2 to 3% of ordered mesoporous carbon, 1 to 2% of single-walled carbon nanotubes, 1 to 2% of dodecyl dimethyl ammonium oxide, 3 to 5% of polyethylene glycol p-toluenesulfonate, 1.5 to 3.5% of 2-mercaptoethanol and 0.5 to 1% of pigment filler. The flexible polyurethane conductive material prepared by the invention has the advantages that the addition amount of the conductive filler is small; the prepared material is good in flexibility, adjustable in elongation at breakwithin the range of 20-300%, capable of meeting various flexibility requirements, diverse in color, attractive and elegant, capable of being matched with various color surfaces, capable of meeting purification requirements, wide in application range and capable of being used in places such as clean rooms and clean rooms.

Owner:济南捷盛建材新技术有限公司

Method for advancedly removing molybdenum from manganese sulfate solution

The invention discloses a method for advancedly removing molybdenum from a manganese sulfate solution. The method for advancedly removing the molybdenum from the manganese sulfate solution is carriedout according to the following steps of after a pH value of the manganese sulfate solution is adjusted, adding a molybdenum removal agent into the solution, and conducting stirring and filtering to obtain filter liquor, namely a purified manganese sulfate solution; and therefore, the requirement of purifying the manganese sulfate solution can be met, and in the molybdenum removal process, the solution does not need to be heated. The method for advancedly removing the molybdenum from the manganese sulfate solution has the advantages that the procedures are simple, the cost is low, the efficiency is high, no pollution is generated, the defects of existing methods are overcome, and the requirements of the molybdenum content of manganese sulfate for producing a high-purity manganese-bearing material are met.

Owner:GUIZHOU UNIV +1

Method for producing high purity nanometer zinc oxide by using ammonia process of steel plant dust

ActiveCN102826589BEvenly distributedEfficient leachingZinc oxides/hydroxidesNanotechnologyBiological activationZinc

The invention discloses a method for producing high purity nanometer zinc oxide by using ammonia process of steel plant dust. According to the method, white lime of 3-5 percent of the mass of steel plant dust is added for activation before leaching, then leaching is carried out with an ammonia-ammonium carbonate solution as the leaching agent, 0.3-0.5kg of sodium fluosilicate is added into the leaching agent per cubic meter, and purification and impurity removal are carried out and then refining treatment is carried out. According to the method, the ammonia process is used for treating steel plant dust, the existing ammonia process is adaptively improved, and high purity nanometer zinc oxide with larger specific surface area can be obtained; and the method has the advantages of low energy consumption and high efficiency, and thoroughly solves the problem of zinc load of steel plant dust as the leaching agent can be recycled, thereby meeting the requirement of purifying the toxic components including zinc and alkali metals and realizing good production circulation.

Owner:SICHUAN JUHONG TECH

LED lamp for filtering formaldehyde

ActiveCN110173630ASimple structureEasy to operateGas treatmentDispersed particle filtrationInstrumentationLED lamp

The invention discloses an LED lamp for filtering formaldehyde. The LED lamp comprises an apparatus shell, extending leg devices are arranged on the outer side of the bottom of the apparatus shell ina left-right symmetric mode, the apparatus shell is internally provided with an suction chamber, physical filter net rings are slidably connected to the inner wall of the periphery of the suction chamber in a matched mode, a spraying direction switch device extending out of the outer end surface of a machine body is fixedly connected to the top end of the suction chamber, wherein the spraying direction switch device is internally provided with a driven shaft extending into the suction chamber, a pulling blocking device located at the left end of the spraying direction switch device is arrangedon the inner wall of the top end of the suction chamber and controls the driven shaft, when the air outlet direction is needed to be changed, the pulling blocking device is needed to be pulled by a user, and the suction chamber is internally provided with an air suction power box located at the lower end of the spraying direction switch device. The LED lamp for filtering the formaldehyde is simple in structure, convenient to operate, the air outlet direction and height of air after the air is purified according to the requirements, and meanwhile the professional ability of the equipment is improved through the triple filter mode.

Owner:石冬初

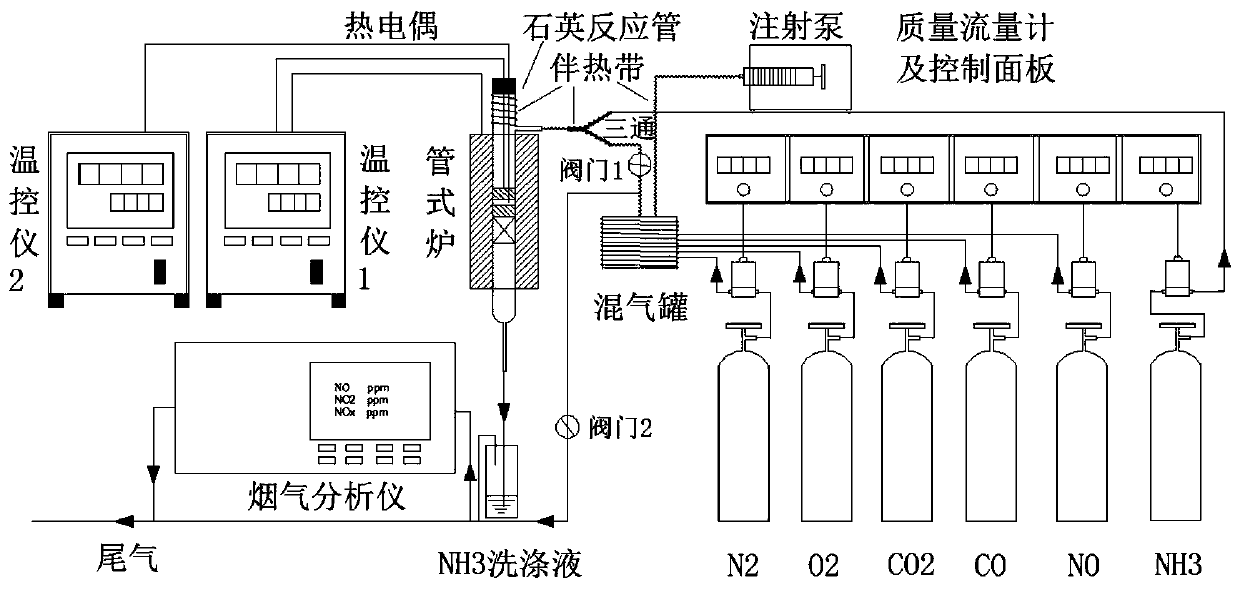

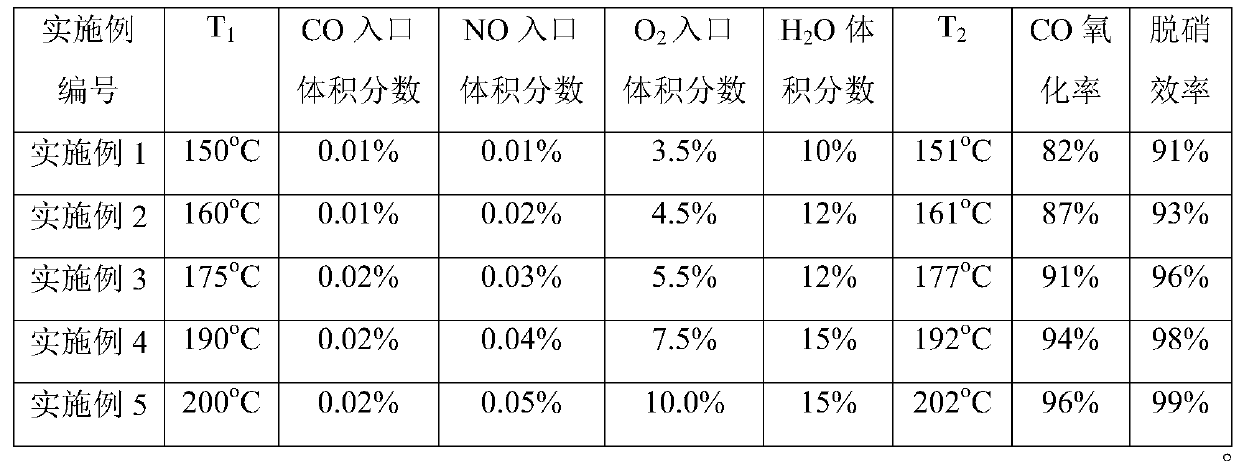

Integrated purification method and device for CO and NOx removal of gas boiler

PendingCN109999631AImprove denitrification efficiencyExtended service lifeGas treatmentDispersed particle separationPurification methodsFlue gas

The invention discloses an integrated purification method and device for CO and NOx removal of a gas boiler, and belongs to the field of treatment of gaseous pollutants. A return flue of the gas boiler is connected with a gas inlet of a catalytic reaction device through a boiler flue gas outlet, and a gas outlet of the catalytic reaction device is connected with a fan through a waste heat recoverysystem; a urea solution injection device (15) is arranged in the return flue, and the urea solution injection device is connected with a urea storage tank through a metering device and a control device; a guide plate, a CO oxidant layer and a denitration catalyst layer which are all vertical to a shaft are arranged in the catalytic reaction device sequentially to form a multi-stage reactor. The injection point of a denitration reductant is located in the return flue of the gas boiler within 300-500 DEG C, urea decomposition is facilitated, and decomposition product NH3 is uniformly mixed in arear flue section, CO and NOx are simultaneously removed by a CO oxidant and a denitration catalyst, denitration efficiency of the catalyst is improved, service life of the catalyst is prolonged, andclean and energy-saving emission is finally realized.

Owner:BEIJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com