Solid-liquid separation and vibrating liquid-removing drying integrated device

A solid-liquid separation and deliquoring technology, which is applied in drying solid materials, filtration separation, separation methods, etc., can solve the problems of a large ungrounded processing system, unattainable moisture content, and drilling cuttings pulling requirements, etc., and achieves low manufacturing costs. , The effect of low moisture content of drilling cuttings and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

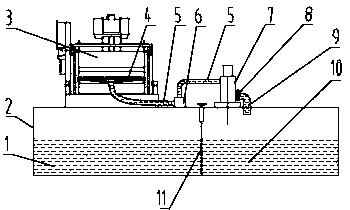

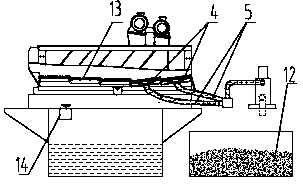

[0020] See figure 1 , figure 2 An integrated device for solid-liquid separation and vibration de-liquid drying, comprising a liquid-phase collection bin 1, a drilling fluid circulation tank 2, a vibrating screen 3, a suction cup 4, a liquid inlet pipe 5, a tee 6, a vacuum pump 7, a control valve 8. The liquid outlet pipe 9, the liquid phase collection bin 10, the partition 11, the drill cuttings collection bin 12, the screen 13, and the flapper valve 14.

[0021] The vibrating screen 3 adopts a two-stage plate screen 13 installed on the surface of the drilling fluid circulation tank 2. The bottom of the first stage screen 13 is directly connected to the drilling fluid circulation tank 2, and the second stage screen 13 is close to the slag discharge port. A suction cup 4 is installed below, and the suction cup 4 and the screen 13 are installed in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com