Ground high-low pressure mixed gas-liquid separation system based on multi-reservoir commingling production gas field

A high-low pressure, mixed gas technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of equipment waste, increased engineering cost, idleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

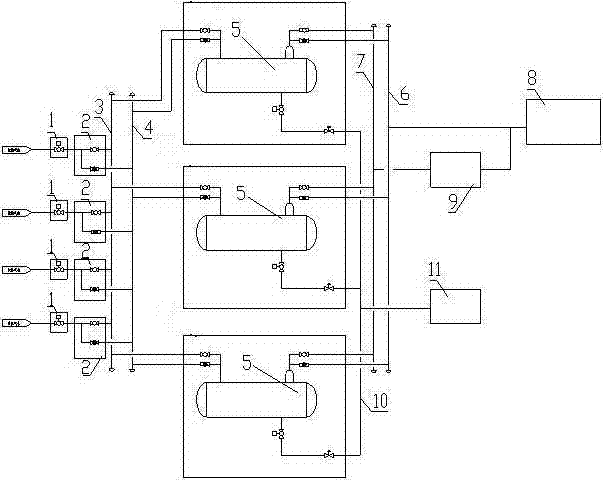

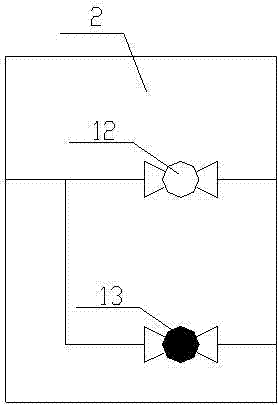

[0019] This embodiment provides a ground high-low pressure mixed gas-liquid separation system based on a multi-reservoir co-production gas field, which includes an air inlet pipeline and a gas-liquid separator 5, and an inlet cut-off valve 11 is arranged on the inlet pipeline, and the The outlet end of the entry cut-off valve 11 is connected with a high-low pressure flow switching valve group 2, and the high-low pressure flow switching valve group 2 is composed of a high-pressure flow control valve 12 and a low-pressure flow control valve connected in parallel with the exit end of the entry cut-off valve 11. 13 composition;

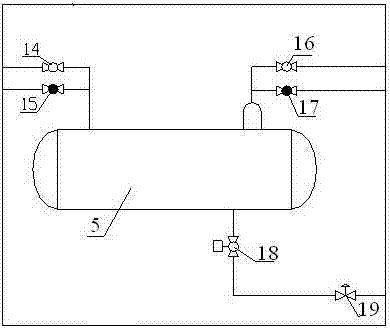

[0020] The high-pressure process control valve 12 communicates with the inlet end of the gas-liquid separator 5 through the high-pressure gas collecting pipe 3 before separation, and the high-pressure gas collecting pipe 3 before separation is provided with a separator inlet high-pressure flow control valve 14, and the gas-liquid separation The gas phase ...

Embodiment 2

[0027] On the basis of Embodiment 1, a flow meter 8 is connected to the outlet end of the high-pressure gas manifold 6 after separation; a natural gas compressor 9 is connected to the outlet end of the low-pressure gas manifold 7 after separation, and the outlet end of the natural gas compressor 9 communicates with the flow meter 8 .

[0028] In this embodiment, the flow meter 8 can meet the flow measurement requirements of natural gas. After separation, the natural gas compressor 9 connected to the outlet end of the low-pressure gas manifold 7 can increase the low-pressure natural gas to a high-pressure level, and connect to the flow meter 8 for flow measurement after pressurization.

Embodiment 3

[0030] This embodiment provides a figure 1 In the shown ground high-pressure and low-pressure mixed gas-liquid separation system based on the multi-reservoir co-production gas field, multiple sets of the mixed gas-liquid separation system are arranged side by side in this embodiment to meet different requirements at the same time.

[0031] Such as figure 1 As shown, the inbound natural gas first enters the inbound shut-off valve 11 through the intake pipeline, and the inbound shut-off valve 11 communicates with the inlet port of the high-low pressure process switching valve group 2, and the high-pressure process control valve 12 at the outlet end of the high-low pressure process switching valve group 2 and The low-pressure process control valve 13 communicates with the high-pressure gas manifold 3 before separation and the low-pressure gas manifold 4 before separation, respectively, and the high-pressure gas manifold 3 before separation and the low-pressure gas manifold 4 befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com