Prefabricated ceramsite foamed concrete sandwich thermal insulation external wall panel

A technology of foamed concrete and thermal insulation exterior walls, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of non-environmental protection, slow construction, poor earthquake resistance and typhoon strength, etc., and achieve coal saving, convenient pipe penetration, and excellent moisture-proof performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

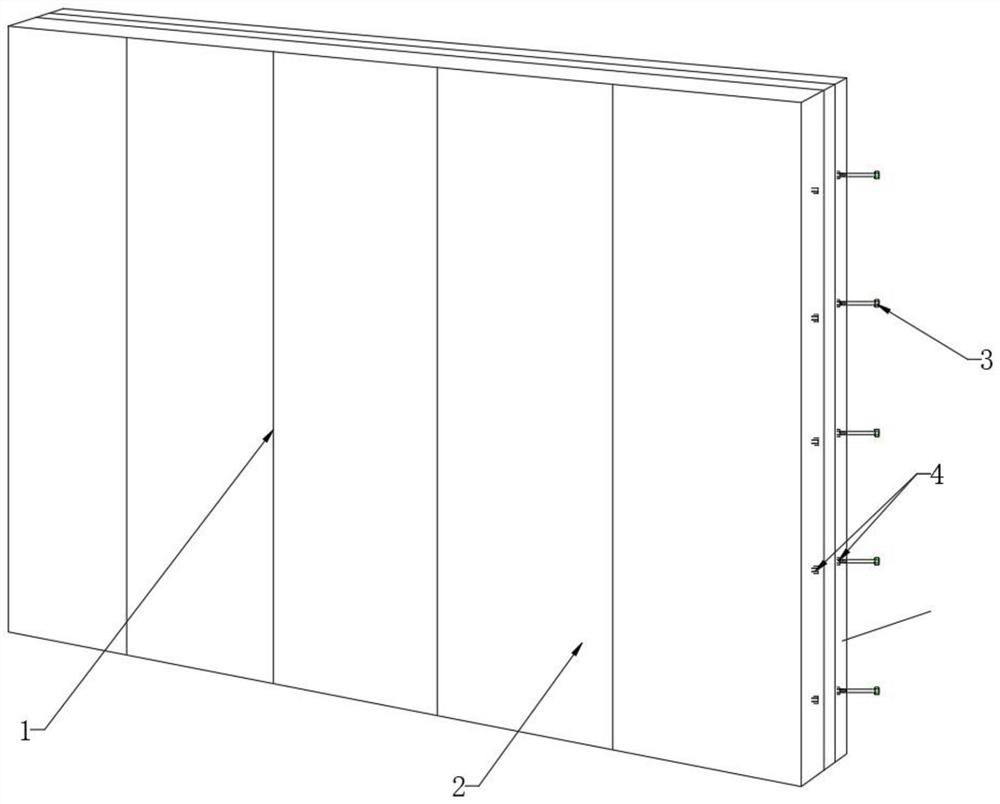

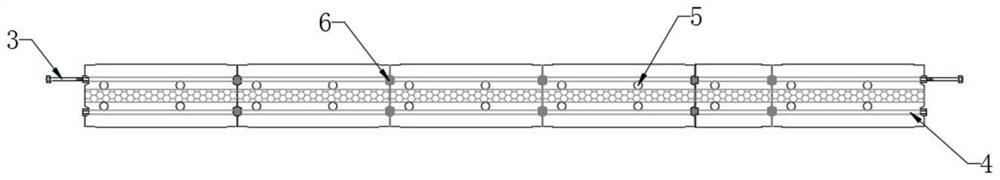

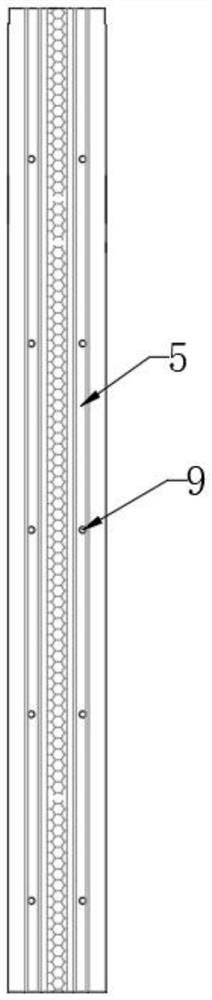

[0035] Example: such as Figure 1-15As shown, the present invention provides a prefabricated ceramsite foamed concrete sandwich insulation exterior wall panel, which includes several layers of rectangularly distributed peripheral walls 1, and the peripheral wall 1 includes several longitudinally arranged unit panels 2 , the vertical surface of the unit panel 2 is longitudinally provided with several reserved pipeline holes 5, and each wall panel vertically reserves two reserved pipeline holes 5, which not only ensures the characteristics of the solid wall panel, but also facilitates the passage of water and electricity pipelines , in line with the requirements for the separation of pipelines in prefabricated buildings, a number of horizontally distributed steel bars 7 are installed horizontally on the inner vertical surface of the unit plate 2, and a number of longitudinally stressed steel bars 8 are installed longitudinally on the inner vertical surface of the unit plate 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com