Patents

Literature

58results about How to "Meet separation requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

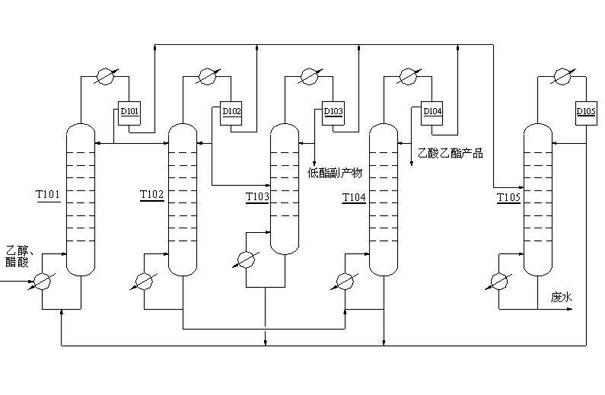

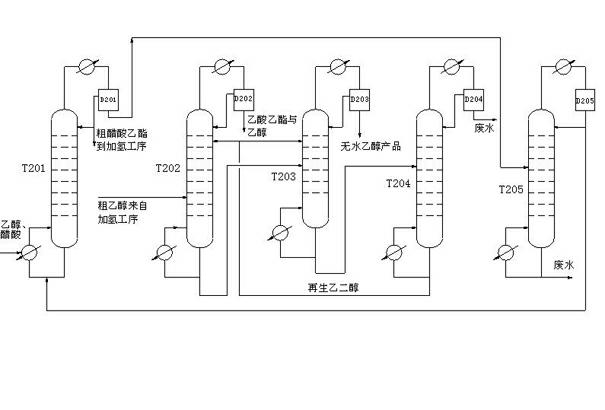

Method for simplifying rectification process for preparing ethanol through hydrogenation of acetic acid

ActiveCN102399130AMeet separation requirementsLess investmentOrganic compound preparationHydroxy compound preparationAnhydrous ethanolAcetic acid

The invention discloses a method for simplifying a rectification process for preparing ethanol through hydrogenation of acetic acid. An extractive distillation mode is adopted, and an ethanol product with higher purity can be obtained; a rectifying device can meet the separation requirement on an acetic ether product and an ethanol product; in addition, the acetic ether and the ethanol are separated by the same separation equipment; when the ethanol is produced, crude acetic ether and absolute ethanol products are obtained in the device, and when the ethanol is not produced, the device can produce the qualified acetic ether product, so that the device investment is saved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Condensing gathering separator for separating lubricating oil from refrigerant

InactiveCN102538325ACompact structureMeet separation requirementsRefrigeration componentsCooling coilEngineering

The invention provides a condensing gathering separator for separating lubricating oil from refrigerant. The condensing gathering separator comprises a cylindrical separator shell, a top cover, a bottom oil-gathering chamber, a hollow annular adsorbing filter, at least one horizontal baffle, a cooling coil, a mixer air inlet, a refrigerant outlet and a lubricating oil outlet, wherein the cylindrical separator shell is vertically placed along axial direction; the top cover and the bottom oil-gathering chamber are respectively mounted at the upper and lower ends of the shell; the hollow annular adsorbing filter is mounted at the lower end of the hollow top cover; the horizontal baffle is mounted under the adsorbing filter on an inner wall of the shell; an outer edge of the horizontal baffle exceeds the radial center of the shell; the cooling coil passes through each baffle in turn; two ends of the cooling coil respectively extend out of the shell; a cooling medium inlet is arranged at one end while a refrigerating medium outlet is arranged at the other end; the mixer air inlet is arranged on one side of the lower part of the shell; the refrigerant outlet is arranged at the top of the shell; and the lubricating oil outlet is arranged at the lower end of the bottom oil-gathering chamber. The condensing gathering separator is simple and compact in structure; various separating effects, such as impacting, condensing gathering, gravity settling, adsorbing filtering, and the like, are integrated in one separator; the refrigerant and the lubricating oil are thoroughly separated; and the higher demand on separating the lubricating oil from the refrigerant is met.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

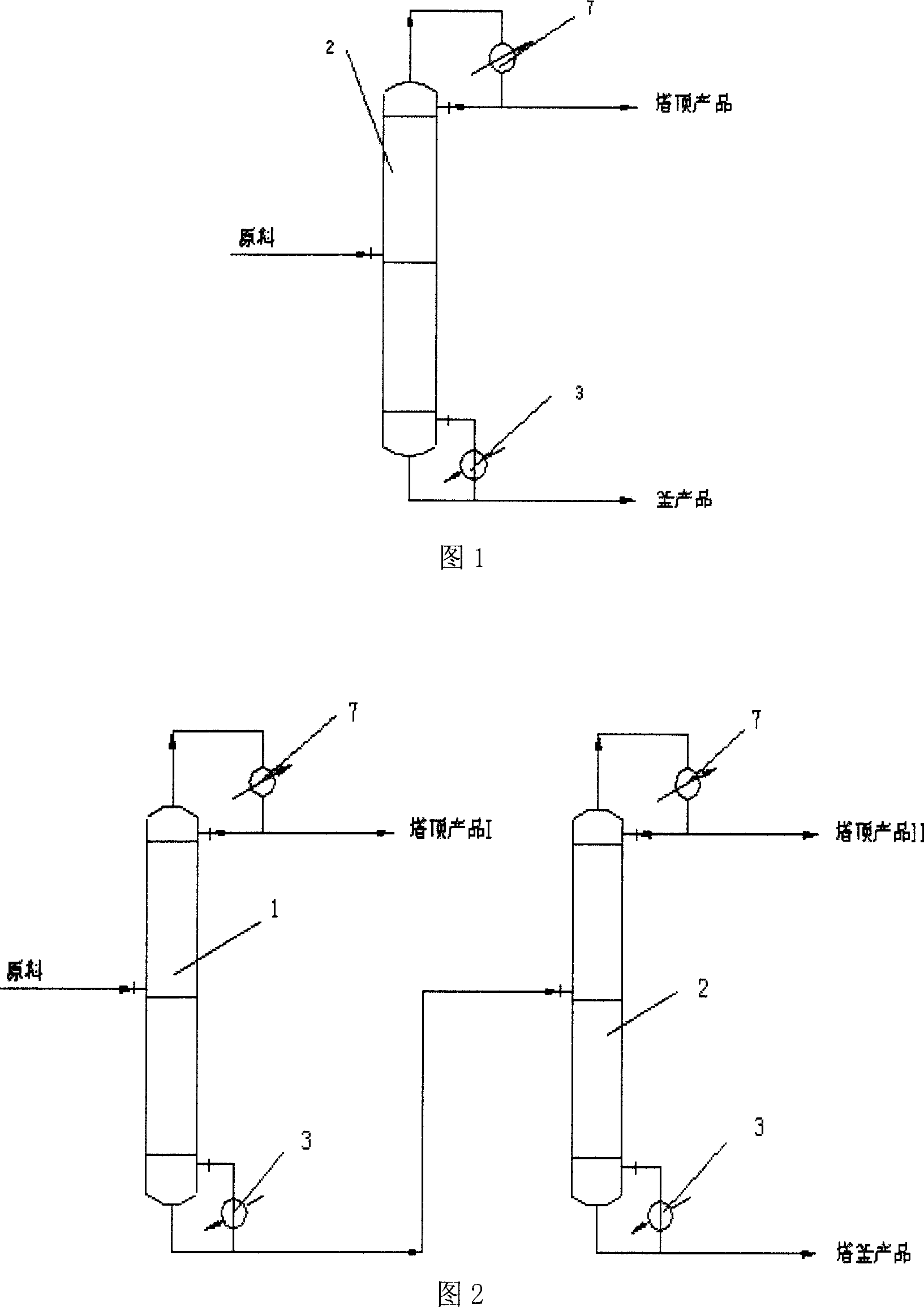

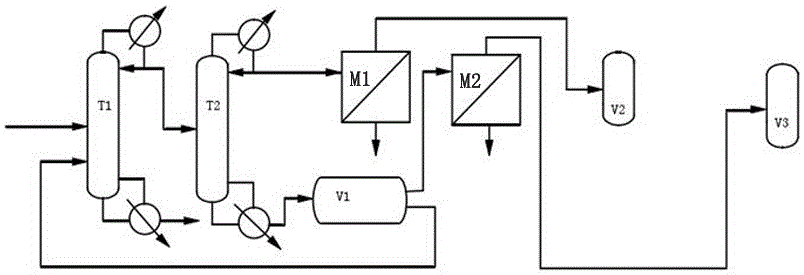

Energy saving method and equipment for rectification separation

ActiveCN101091836ATo achieve the purpose of thermal couplingThermomechanical coupling implementationFractional distillationRefluxReboiler

The invention relates to an equipment and method for saving energy conservation in selective evaporation. The equipment involves A and B rectification tower in series. The bottom of Tower A connects the reboiler. The export of Tower A connects the import of Tower B. The export of Tower A on the top connects middle reboiler, reflux accumulator, reflux pump. The bottom of Tower B connects middle reboiler. The top of Tower B connects condenser, reflux accumulator, reflux pump. The heat of condensation of Tower A is as the load of middle reboiler when connected Tower B. Part of the heat of condensation reflows to the tower and other is as the product. In Tower B, the light product boils over from the top. Some reflows to tower and other is as the product. The heat is from condenser and middle reboiler and attaches the light-load adjustment reboiler to achieve connecting in series, the mightiness coupling between condenser and middle reboiler. The design is reasonable; the effect on saving energy is obvious.

Owner:PETROCHINA CO LTD

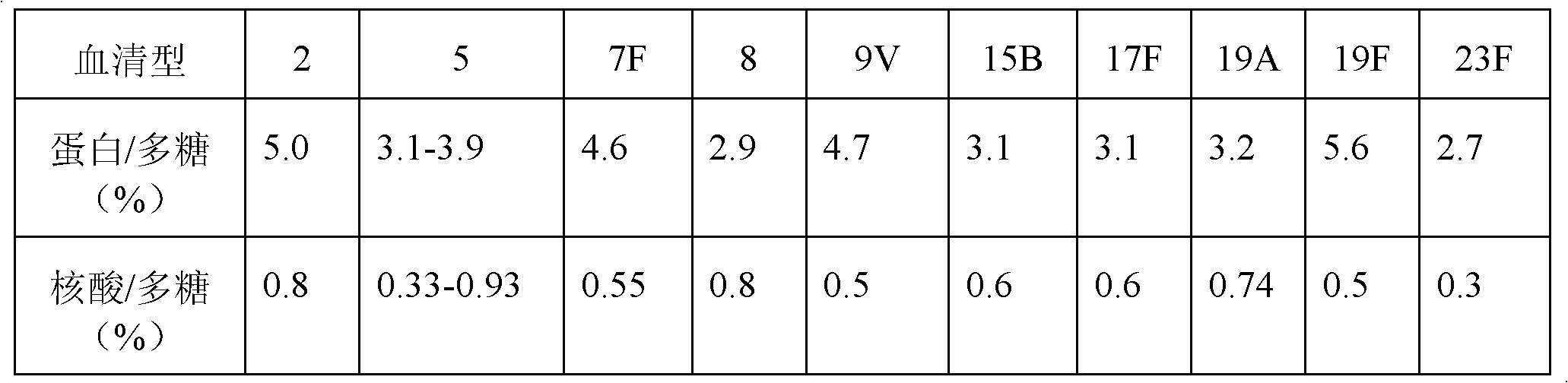

Method for rapidly purifying bacteria capsular polysaccharide

ActiveCN102660601AMeet separation requirementsMicroorganism based processesFermentationTyphoid bacillusChemistry

The invention discloses a method for rapidly purifying bacteria capsular polysaccharide, which can rapidly remove the pollutants in a specific bacteria broth, protein and nucleic acid are included, the purified capsular polysaccharide can be reserved, capsular polysaccharide-containing bacteria is included, the processes of fermentation, centrifugation and microfiltration are carried out for removing thalline and indissoluble particle substance, acid is added for adjusting the pH value of the solution for deposing the impurities, the solution is subjected to ultrafiltration concentration and filter washing to obtain a crude bacteria capsular polysaccharide solution. A basic principle of the present invention is characterized in that acid is added to regulate the pH value to a range of 3-5, the capsular polysaccharide with impurities is purified in the solution. The capsular polysaccharide can be used for purifying pneumococcus, b-type haemophilus influenza, epidemic meningococcus and typhoid bacillus.

Owner:KANVAX BIOPHARM

Xylose production and purification process

ActiveCN101824054AReduce manufacturing costReach crystallizationIon-exchange column/bed processesSugar derivativesIon exchangeEvaporation

The invention relates to a xylose production and purification process which belongs to the technical field of functional sugar production, and comprises the following steps that: (1) ion exchange is carried out to destaining solution in xylose production through an ion exchange column filled with gel-type anion exchange resin; (2) xylose solution after treatment in step (1) is beaten into a series column which comprises gel-type cation exchange resin and macroporous anion exchange resin; (3) the xylose solution after treatment in step (2) passes through a mixed bed exchange column which comprises anion and cation exchange resin; and (4) after treatment, a crystal xylose product is obtained through evaporation, concentration, centrifugation and drying procedures. The xylose production and purification process changes a traditional two-step purification into one-step purification, changes traditional step evaporation and concentration into centralized evaporation and concentration, simultaneously removes a one-step activated carbon decoloring procedure, simplifies the process, shortens the production cycle, reduces the production cost of xylose, adopts a mixed bed technology, ensures that the pH value of the exchange fluid to be 6.5 to 7.0, has lighter color after evaporation and concentration, and fully meets the requirements of xylose crystallization and separation.

Owner:鹤岗市经纬糖醇有限公司

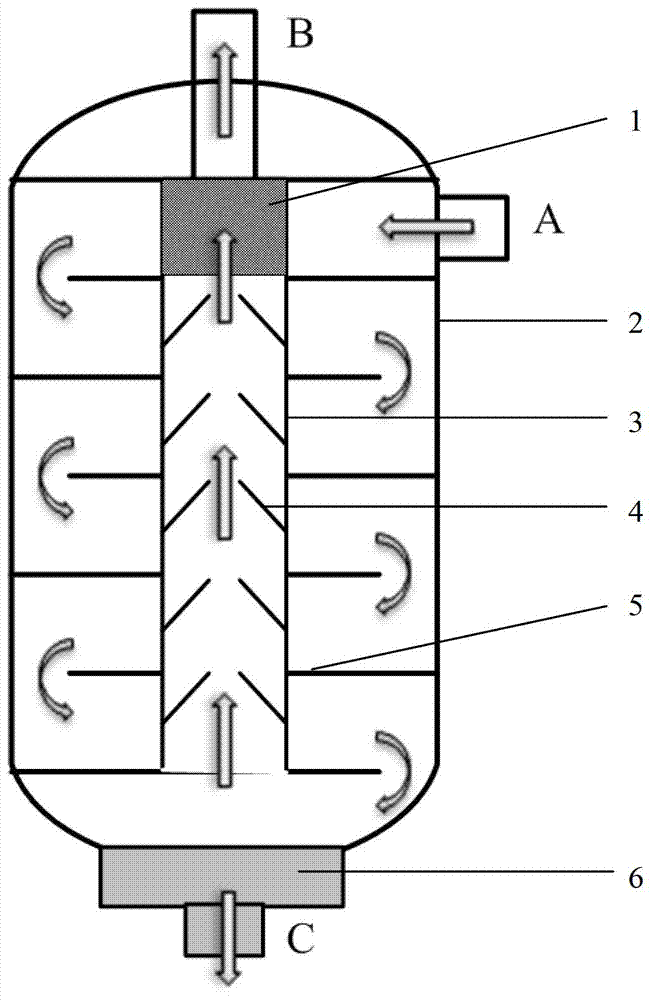

Gas-liquid separator combining centrifugal separation, baffle flow direction change and porous medium filtration

ActiveCN102764557ACompact structureMeet separation requirementsCombination devicesLiquid degasificationRefrigerantEngineering

The invention discloses a gas-liquid separator combining centrifugal separation, baffle flow direction change and porous medium filtration, which comprises an axially vertically arranged cylindrical separator housing, a top cover, a bottom oil collecting cavity, at least one horizontal baffle distributed up and down, a cylindrical absorption filter and a hollow cylindrical cavity body, wherein the top cover and the bottom oil collecting cavity are respectively arranged at the upper end and lower end of the housing; the horizontal baffle is arranged on the inner wall of the housing; the outer edge of the horizontal baffle exceeds the radial center of the housing; the cylindrical absorption filter is arranged on the lower end face of the top cover; the hollow cylindrical cavity body is arranged on the axial center of the housing; the hollow cylindrical cavity body sequentially penetrates through the horizontal baffle from bottom to top, and the upper end of the hollow cylindrical cavity body is connected with the cylindrical absorption filter; at least one cone-shaped baffle distributed up and down is arranged on the inner wall of the hollow cylindrical cavity body, and the upper end of the cone-shaped baffle is provided with an opening; one side of the upper part of the housing is provided with a mixed gas inlet; the top end of the housing is provided with a refrigerant outlet; and the lower end of the bottom oil collecting cavity is provided with a lubricating oil outlet. The gas-liquid separator has a simple and compact structure, can integrate multiple separation effects of impaction, condensation capturing, gravity settling and absorption filtration, and meets the high-efficiency separation requirement of the lubricating oil and a refrigerant.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

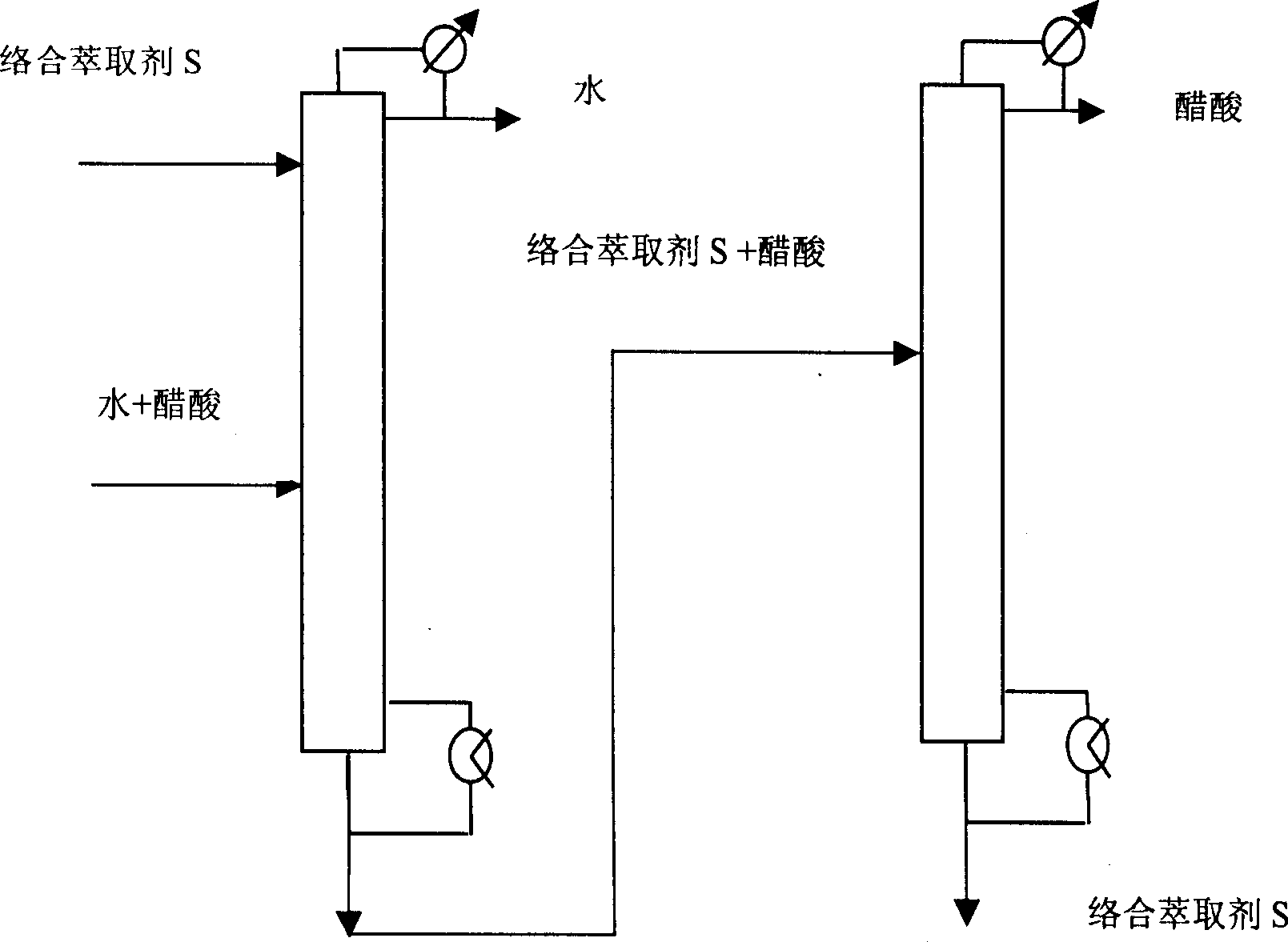

Method for separating acetic acid and water by complexation extraction and rectification

InactiveCN1405137AIncrease relative volatilityImprove energy savingCarboxylic compound separation/purificationTheoretical plateAcetic acid

THe invention provides a method for separating acetic acid and water by complexation, extraction and rectification process. Said invention utilizes the acting force between organic alkali and acetic acid, which is stronger than that of water, and greatly raises the relative volatilities of acetic acid and water so as to separate them. In the fractionating recrtifying tower with 10-50 theoretical plates it adopts tertiary amine organic alkali as complexation extracting agent, under the condition of normal pressure (or reduced pressure), its solvent ratio is 0.5-5 and refluxing ratio is 0-5, the water whose mass fraction is greater than 99.7% can be obtained from tower top, and in the solvent recovering tower with 5-40 the oretical plates, under the condition of reduced pressure and refluxing ratio of 0.5-5 the acetic acid whose mass fraction is greater than 95.0% can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

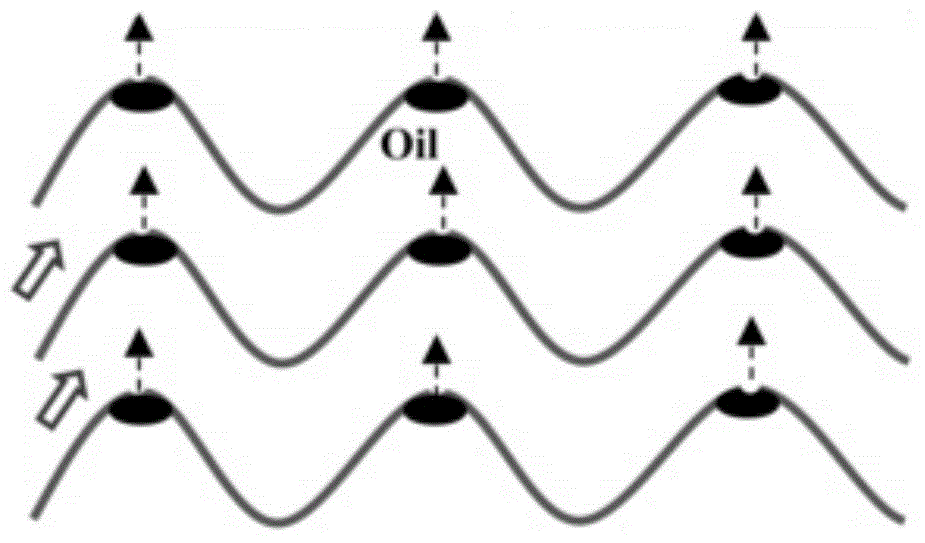

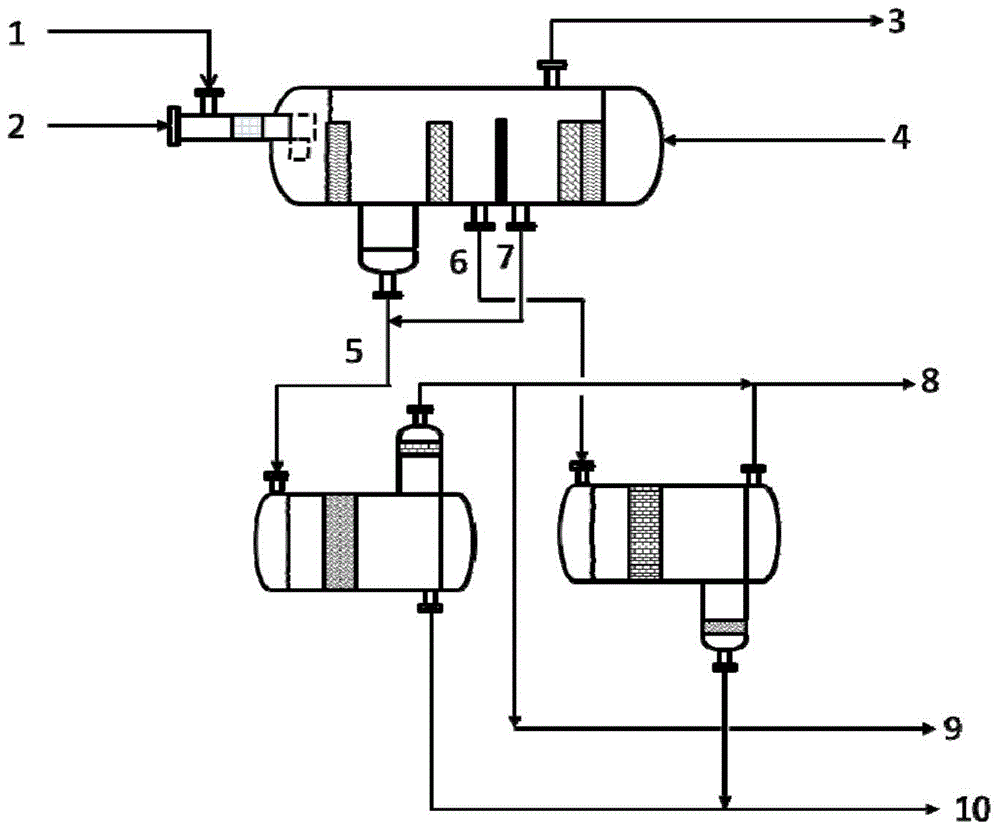

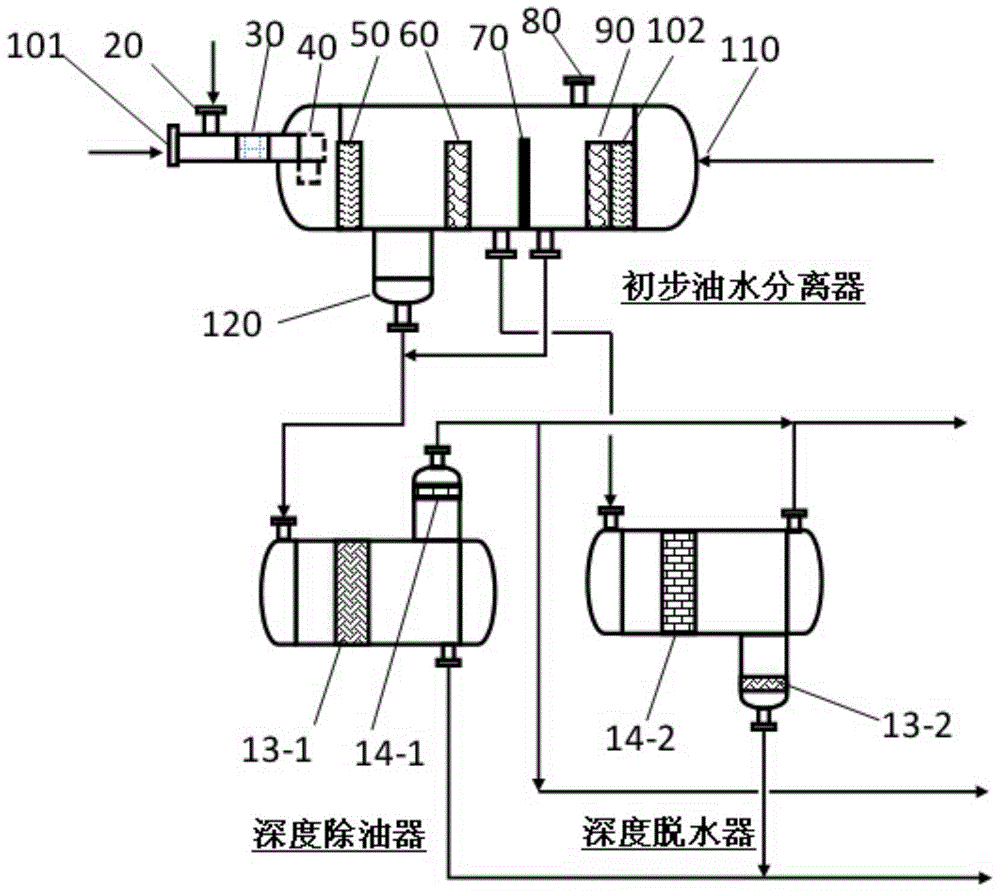

Step-by-step oil-water mixture separation method coupled with oil gas washing

ActiveCN104673367AProtection for long-term operationEfficient separationFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberWastewater

The invention relates to a step-by-step oil-water mixture separation method coupled with oil gas washing. The method comprises the following steps: first light oil containing 0.5-6 percent of synthetic water and low-pressure separator gas containing a trace amount of hydrocarbon are mixed and washed, then the light oil containing a trace amount of hydrocarbon flows into a primary oil-water separator from a left sealing head, and wastewater containing 0.05-0.5 percent of oil flows into the primary oil-water separator from a right sealing head; purified low-pressure separator gas is discharged from the top, mixed liquid is discharged into a deep dehydrater, and about 0.05-0.5 percent of water is removed from the light oil; wastewater on the left side flows into a water drum to be discharged, oil-removed wastewater on the right side is discharged nearby the right side of partition board into a deep oil remover, and about 0.03-0.6% of oil is removed from the water; by virtue of deep dehydration as well as oil removal and dehydration by a specially knitted conjugate fiber module in the oil remover, after the water content in the light oil is smaller than 0.02% and the oil content in the water is smaller than 0.01, the light oil and the water are transported outside. According to the method oil-water separation and step-by-step separation are combined, oil dehydration and wastewater oil removal can be realized rapidly and efficiently and oil is recycled to the maximum extent.

Owner:EAST CHINA UNIV OF SCI & TECH

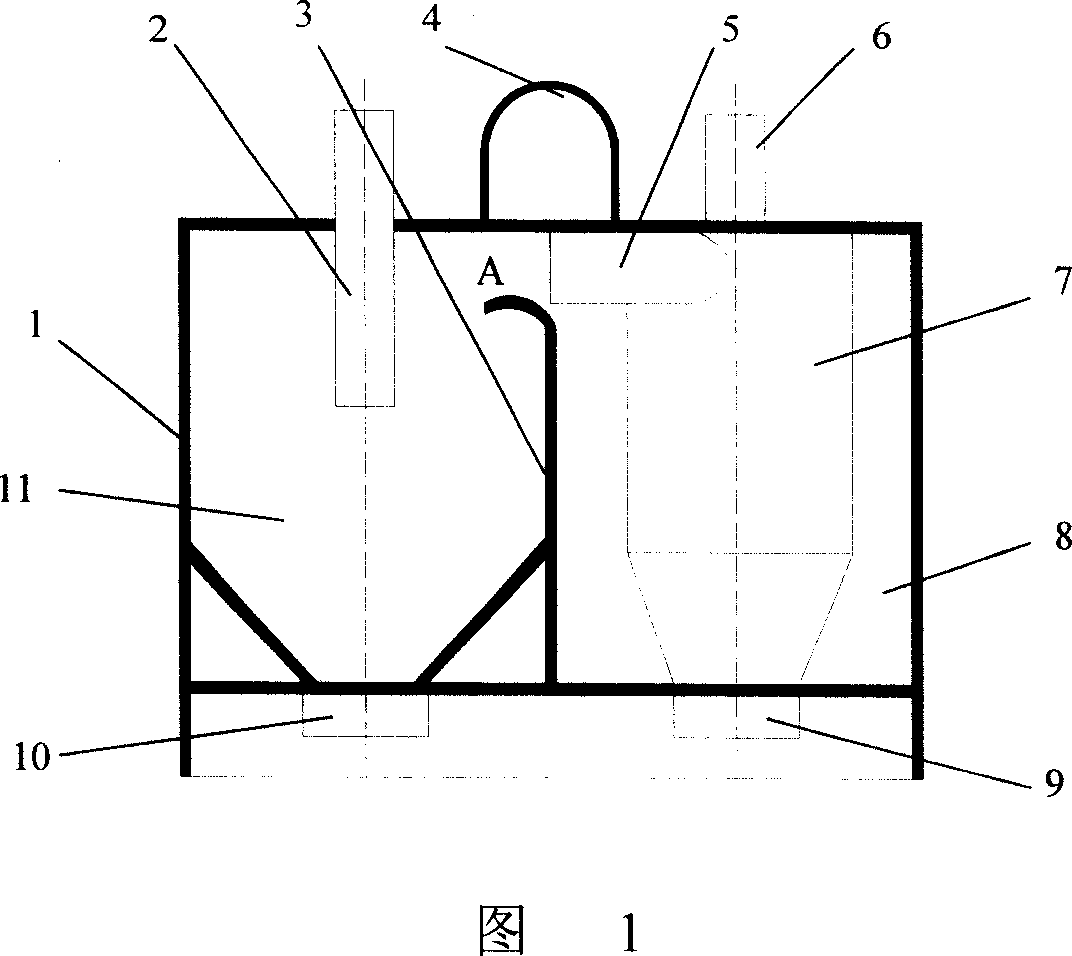

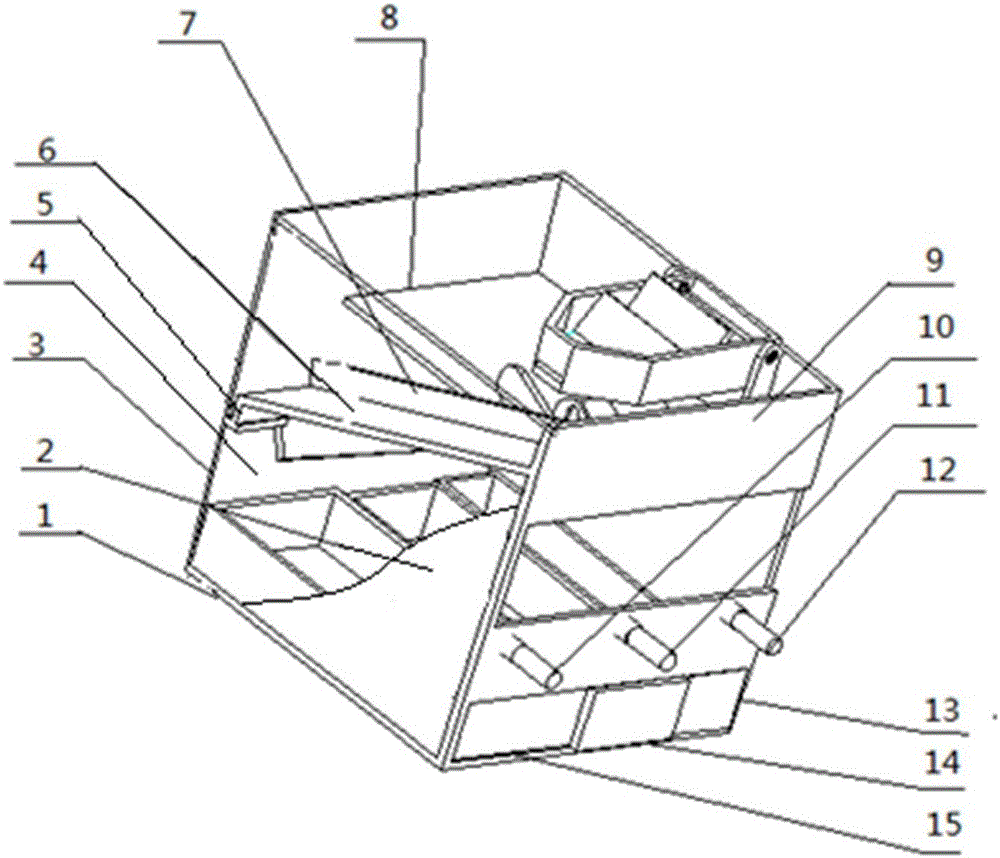

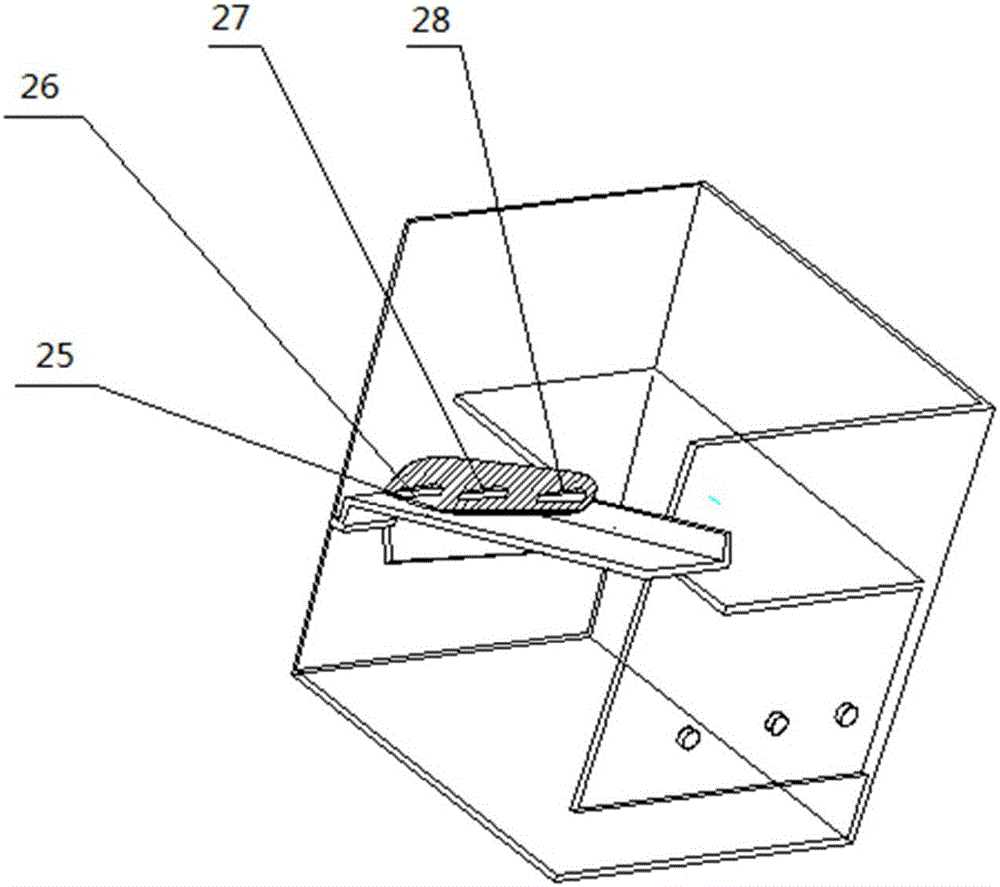

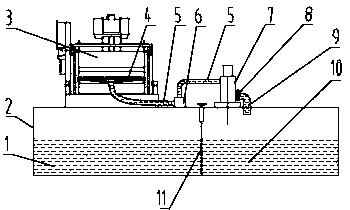

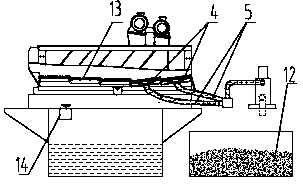

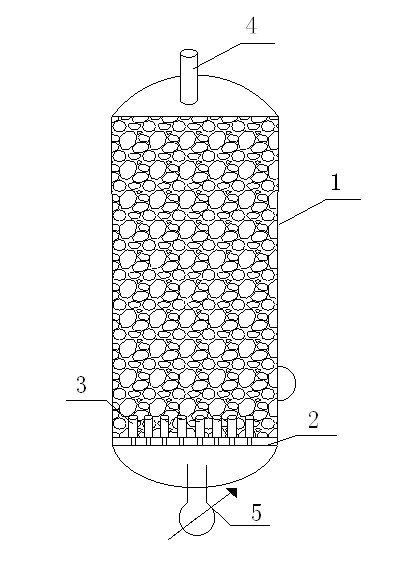

Portable sand and dust separation device and use thereof

InactiveCN101054133AMeet separation requirementsGood gas and solid phase separationPlantingDispersed particle separationEngineeringSediment

The invention discloses a portable sand-dust separation device and use thereof. The separation device includes a shell (1) with a sand inlet pipe (2) and an exhaust pipe (6), a gas-solid phase separation device is equipped in an air conveying pipe, a separator (3) is fixed in the shell (1) and separates cavity of the shell (1) into a sand sediment chamber (11) and a dust separation chamber (8), the sand inlet pipe (2) is equipped on upper of the sand sediment chamber (11), the exhaust pipe (6) is equipped on upper of the dust separation chamber (8), and a path (A) connecting the sand sediment chamber (11) and the dust separation chamber (8) is arranged between upper cover of the shell (1) and the separator (3). The device can be used for gas absorption type boring tree planter and other sand absorption works. Advantages of the portable sand-dust separation device are: structure is simple, operation is convenient, sediment of sand and removal of dust can be completed during sand absorption works, work efficiency and effect for the gas absorption type boring tree planter can be increased.

Owner:CHINA AGRI UNIV

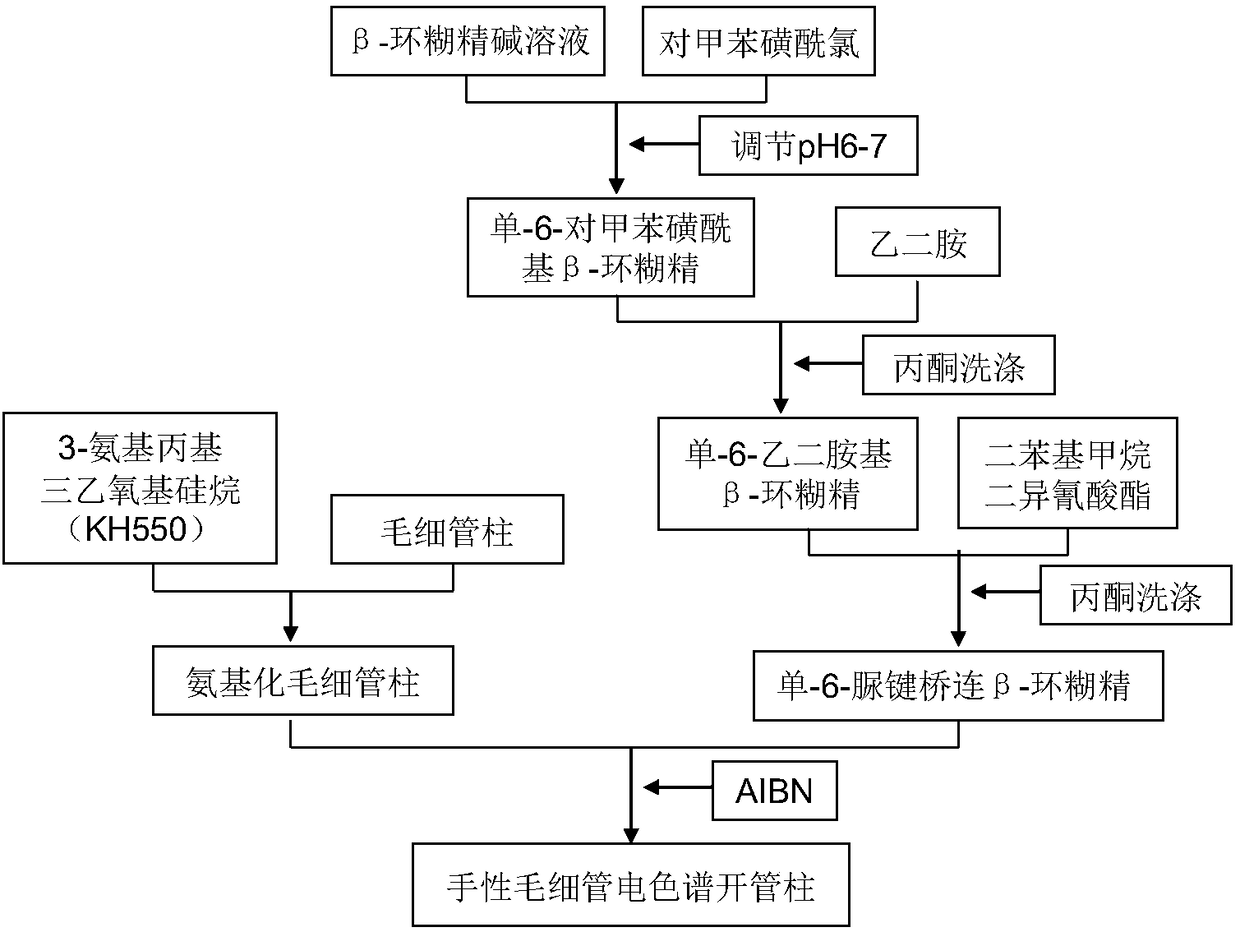

Preparation method and application of chiral bonded capillary electrochromatography open tubular column

ActiveCN108181414AHigh column efficiencyHigh separation selectivityComponent separationStationary phaseElectrochromatography

The invention discloses a preparation method and application of chiral bonded capillary electrochromatography open tubular column, which belongs to the technical field of the preparation of capillaryelectrochromatographic columns. By utilizing a special structure and molecular characteristics of beta-cyclodextrin, a derivative with an isocyanate group is designed and bonded with the inner wall ofan amination capillary tube, and a chiral capillary electrochromatogrpahy open tubular column which meets the electrochromatography separation requirement and is simple in method and good in reproducibility and stability is prepared. A stationary phase is firmly bonded onto the inner wall of the capillary tube by virtue of a chemical bond, and compared with the coated stationary phase, the mechanical strength and the stability are better.

Owner:QIQIHAR UNIVERSITY

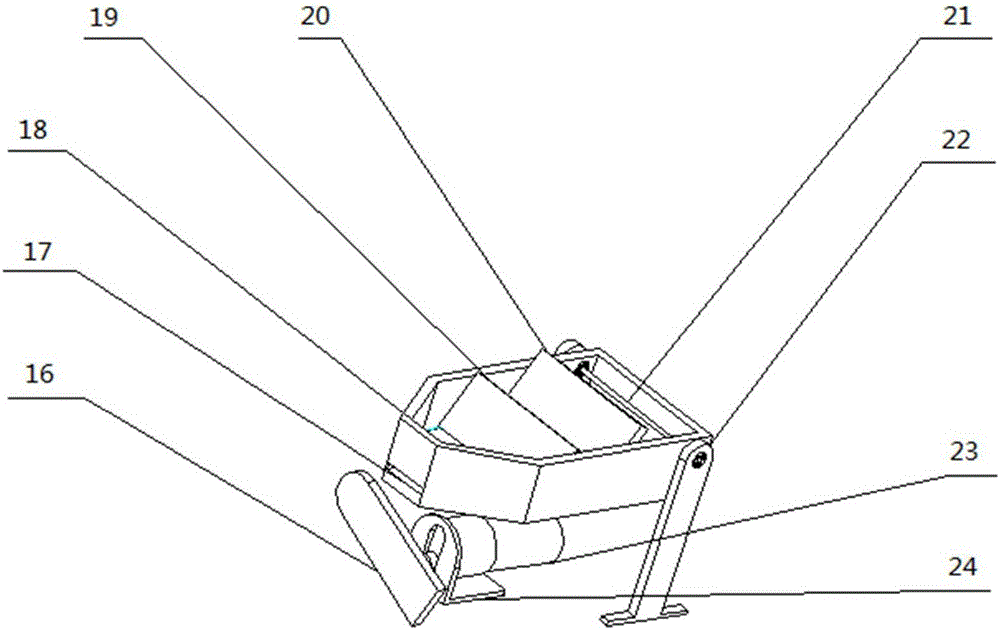

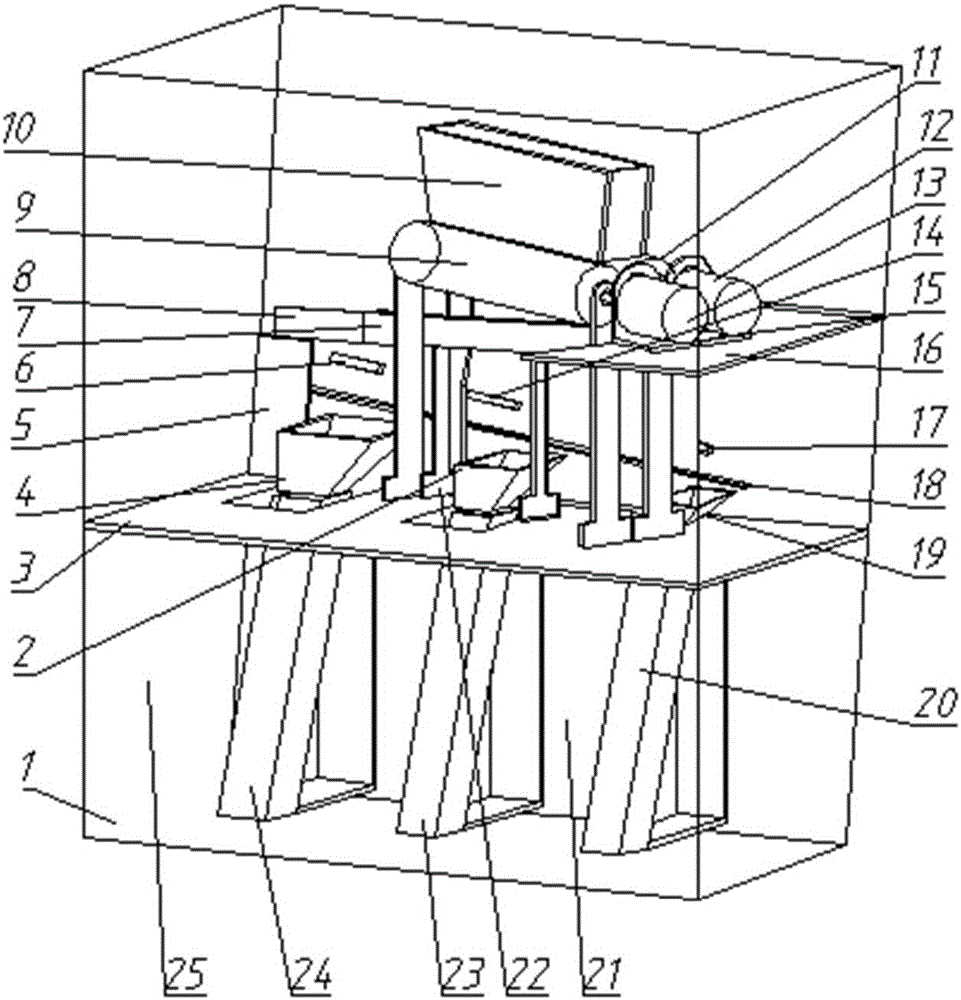

Coin sorting and counting device

The invention relates to a coin sorting and counting device which is composed of a power screening module, a coin sorting module, a counting module, and a coin storing module. In the power screening module, the diameter of a coin outlet is slightly greater than that of a one-yuan coin, screening baffles are installed on a coin shaking box, and when a DC motor is working, a cam is driven to rotate, the coin shaking box shakes, and coins are screened out. In the coin sorting module, after coins are screened from the coin shaking box, the coins fall into a coin slide under the action of gravity, slide into a T-shaped baffle via the coin slide and roll along a coin rolling track in an accelerated way, and three different wedge blocks are installed on an inclined plate to isolate one-yuan coins, five-jiao coins and one-jiao coins in sequence. The counting module is equipped with three counter probes. The coin storing module is provided with corresponding coin storing hoppers, and each coin storing hopper is used for collecting coins of a different currency value. The device can be used to screen a variety of coins, has a simple structure, and is of low cost.

Owner:CHANGZHOU UNIV

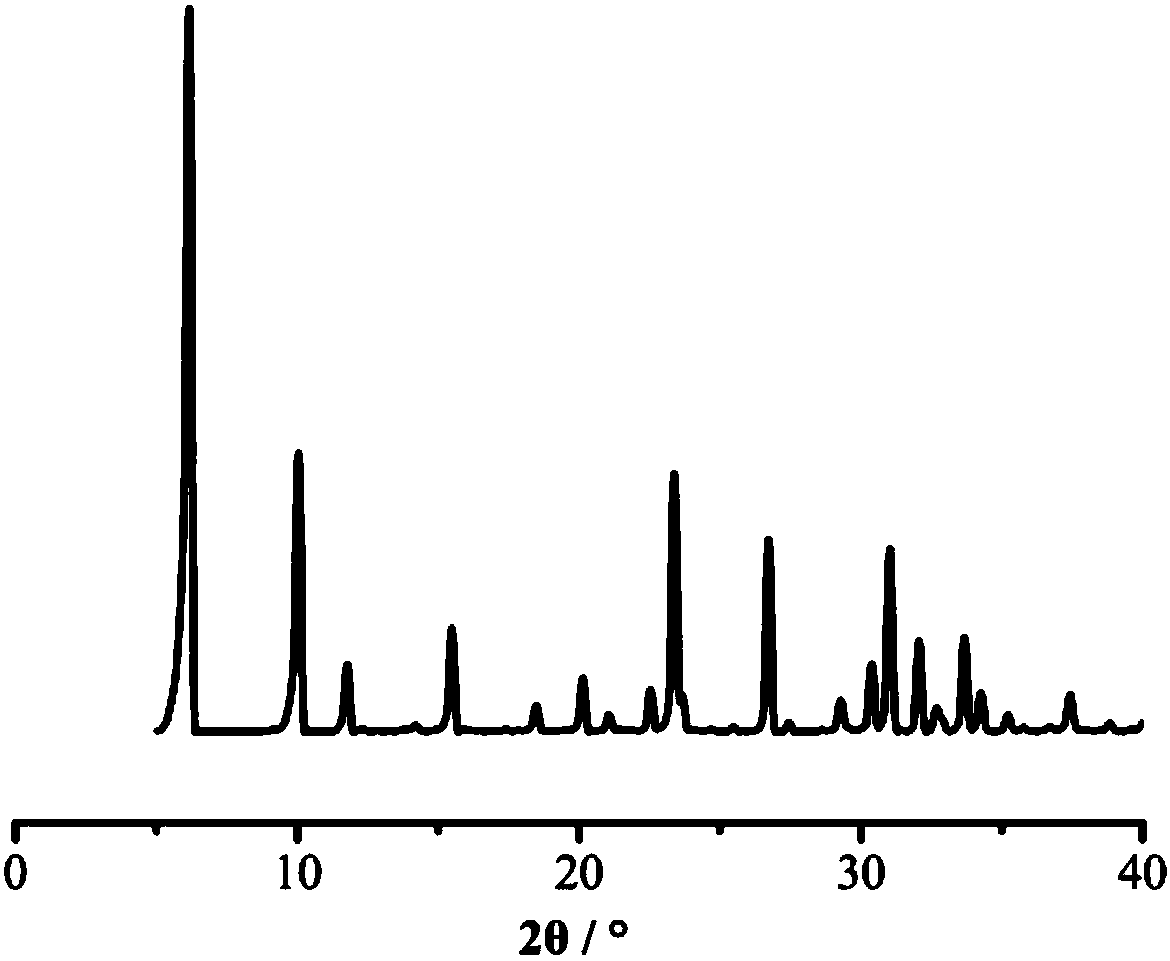

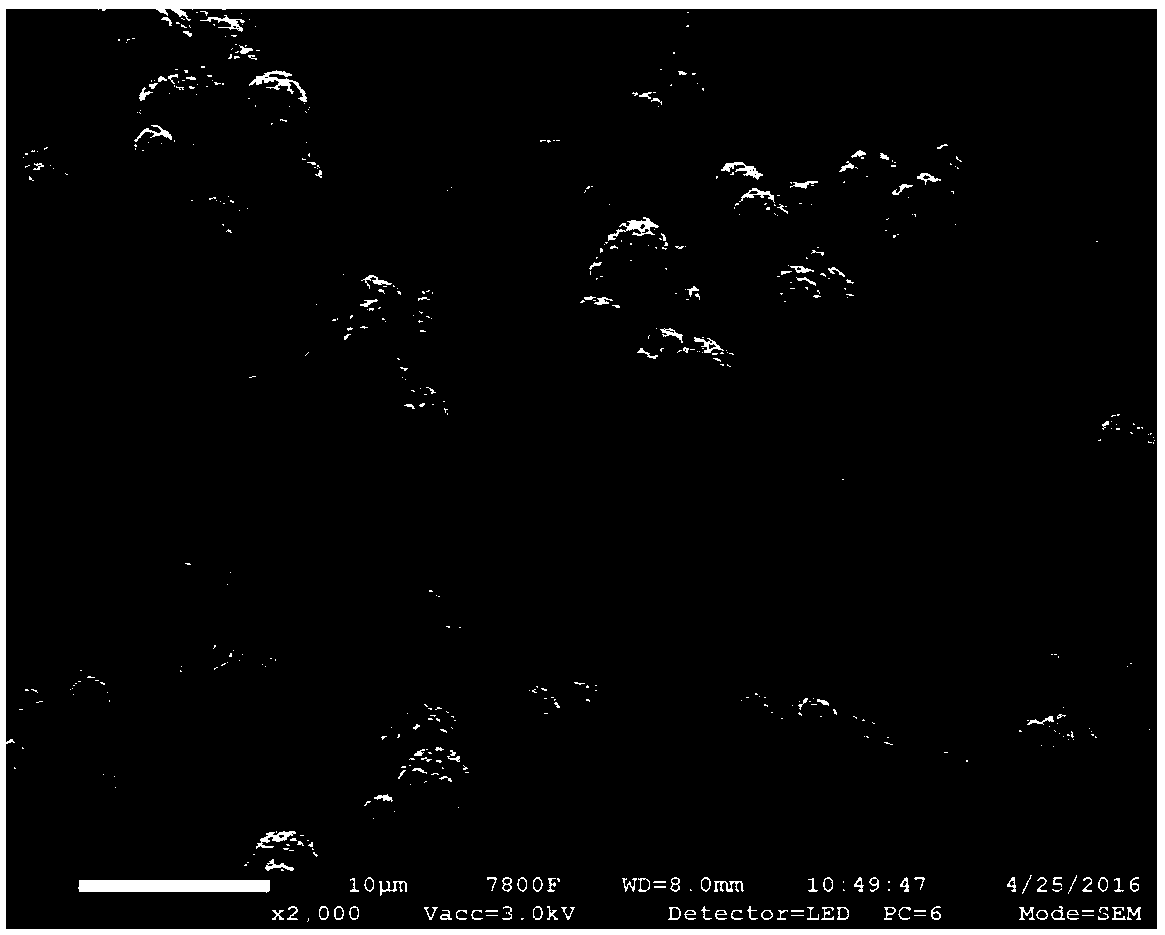

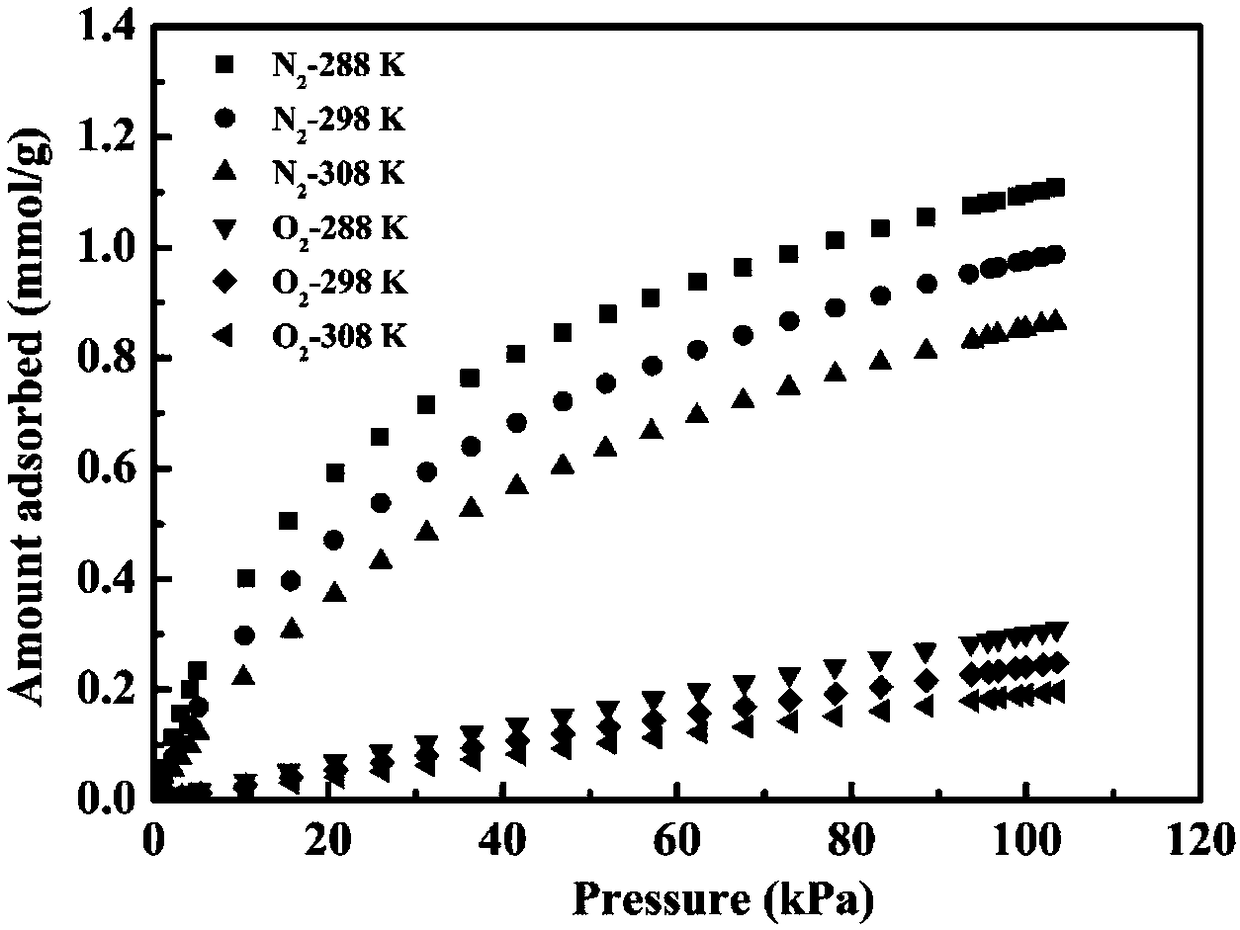

Modified X-type molecular sieve with low silica-alumina ratio, and preparation method and application thereof

ActiveCN108117090AThe synthesis method is simpleEase of industrial productionGas treatmentOther chemical processesIonIon exchange

The invention relates to a modified X-type molecular sieve with a low silica-alumina ratio, and a preparation method and application thereof, belonging to the field of preparation of molecular-sieve cellular materials. The molecular sieve is an inorganic porous material prepared by alternately assembling silicon-oxygen tetrahedrons and aluminum-oxygen tetrahedrons; an X-type molecular sieve with high purity, high crystallinity and a low silica-alumina ratio is prepared by using a normal pressure reflux stirring process; then an ion exchange modification process is employed to prepare a low-silicon X-type molecular sieve containing at least two metal ions selected from a group consisting of Fe<3+>, Ce<3+>, La<3+>, Ca<2+>, Li<+> and Ag<+>; and then surface modification is carried out to makemolecular sieve to have higher hydrophobic properties. The modified X-type molecular sieve has excellent oxygen-nitrogen-argon separation performance and is applicable to preparation of high-purity oxygen. The preparation method has the advantages of simple process flow, easiness in scaling-up, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

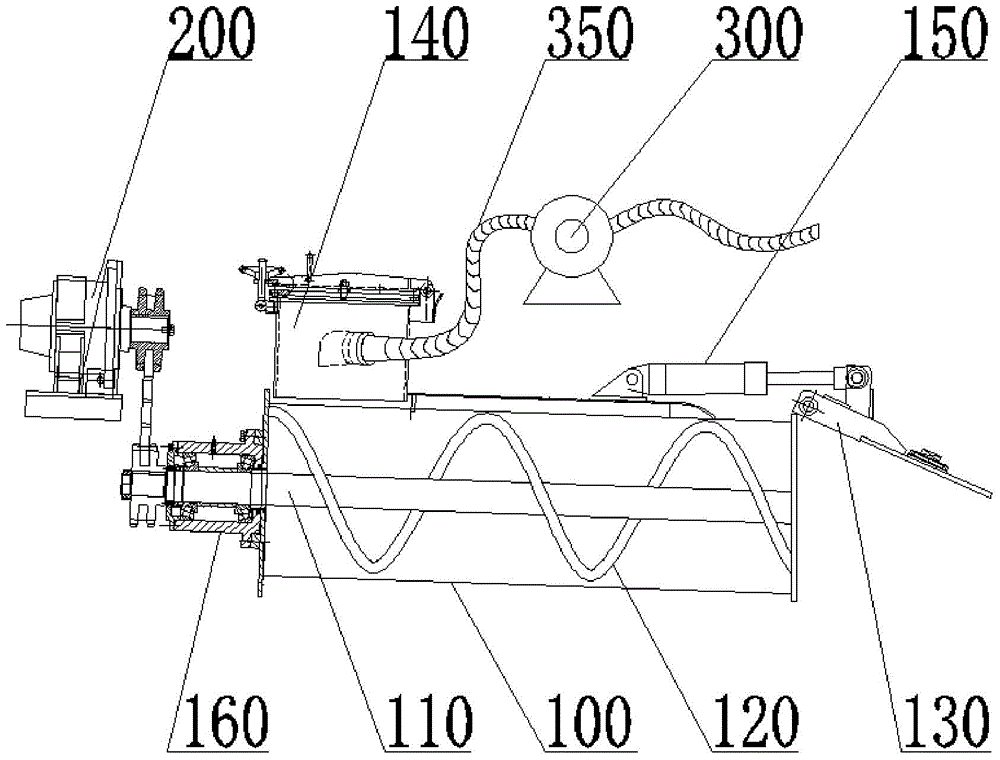

Method for refining mixed alcohol by rectification-pervaporation coupling process

ActiveCN105152860AEliminate reprocessing costsReduce pollutionOrganic compound preparationHydroxy compound separation/purificationAlcoholPhysical chemistry

The invention relates to a method for refining mixed alcohol by a rectification-pervaporation coupling process, which belongs to the technical field of separation. The method includes the following steps: aqueous mixed alcohol is sent into a dehydrating tower and rectified to be dehydrated, most of water is removed from the tower kettle, the mixture of the mixed alcohol and a small amount of water which is obtained from the tower top is sent into a rough separation tower and roughly separated, C1-C3 mixed alcohol and a small amount of water which are obtained from the top of the rough separation tower are condensed and then sent into a pervaporation device for further dehydration, the permeation side is water, and the retention side is the C1-C3 mixed alcohol; after C4-C8 mixed alcohol and a small amount of water which are obtained from the tower kettle of the rough separation tower are layered by a phase separator, the oil phase enters the pervaporation device and is separated, and the water phase returns into the dehydration tower. Compared with the prior art, the method does not need to add a third component in the process of dehydration, thus avoiding environment pollution caused by the addition of the third component and saving the retreatment cost for the third component, the process of azeotropic rectification and extractive rectification is omitted, so that energy consumption is reduced, and product quality is increased.

Owner:FUZHOU UNIV

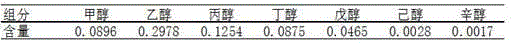

Adjustable type efficient residue-liquid separation device

InactiveCN104801088AEfficient separationEasy dischargeSludge treatment by de-watering/drying/thickeningStationary filtering element filtersSewageEngineering

The invention provides an adjustable type efficient residue-liquid separation device, and belongs to the technical field of sewage and pollutant treatment. The device comprises a separation cylinder and a rotating shaft extending into the separation cylinder, wherein a residue-liquid inlet, filter holes, a residue discharge port and a lifting cover used for covering the residue discharge port are arranged on the separation cylinder; the residue-liquid inlet is communicated with a pollution absorption device; a spiral squeezing blade and a motor are arranged on the rotating shaft; an output end of the spiral squeezing blade corresponds to the residue discharge port. The adjustable type efficient residue-liquid separation device adopts a targeted creative design according to function elements required by a strong pollution absorption and residue-liquid separation vehicle, and efficient, rapid and complete residue-liquid separation effect is achieved by adopting different separation methods according to different residue-liquid mixing kinds and states; after the device is assembled in the strong pollution absorption vehicle, various function elements of the strong pollution absorption vehicle can be displayed sufficiently.

Owner:重庆市渝中区市政管理局环卫三所

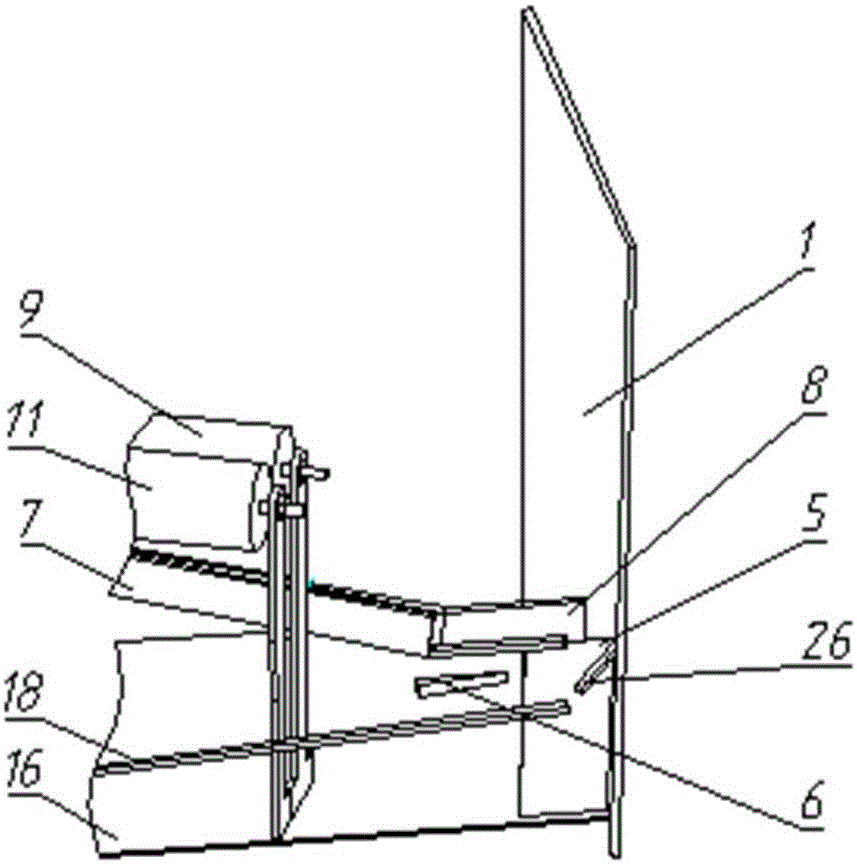

Linseed husk and kernel separation device

A linseed husk and kernel separation device comprises a feeding tube vertically arranged. The lower end of the feeding tube is open, a feeding port is formed in the upper portion of the feeding tube, a rotating shaft is vertically arranged along the axis of the feeding tube, a rotating disc is fixed under a lower end opening of the feeding tube on the rotating shaft, and a discharging gap is formed between the rotating disc and the lower end opening of the feeding tube. An outer tube is embedded in the outer portion of the feeding tube, a husk outlet channel is formed in a gap between the feeding tube and the outer tube, a husk outlet is formed in the upper portion of the husk outlet channel to be connected with an exhaust fan, a protruding portion is arranged on the lower portion of the outer tube, and the lower end of the protruding portion is shrunk to form a discharging port. The protruding portion is located under the lower end opening of the feeding tube, and the upper surface of the rotating disc is a conical face. The taper of the upper surface of the rotating disc is 10-40 degrees, and an upward blower can be arranged at the position of the discharging port. The linseed husk and kernel separation device is high in efficiency, simple in structure and capable of conducting separation of husks and kernels of linseeds and meeting the separation requirement.

Owner:神池县中科胡麻开发有限公司

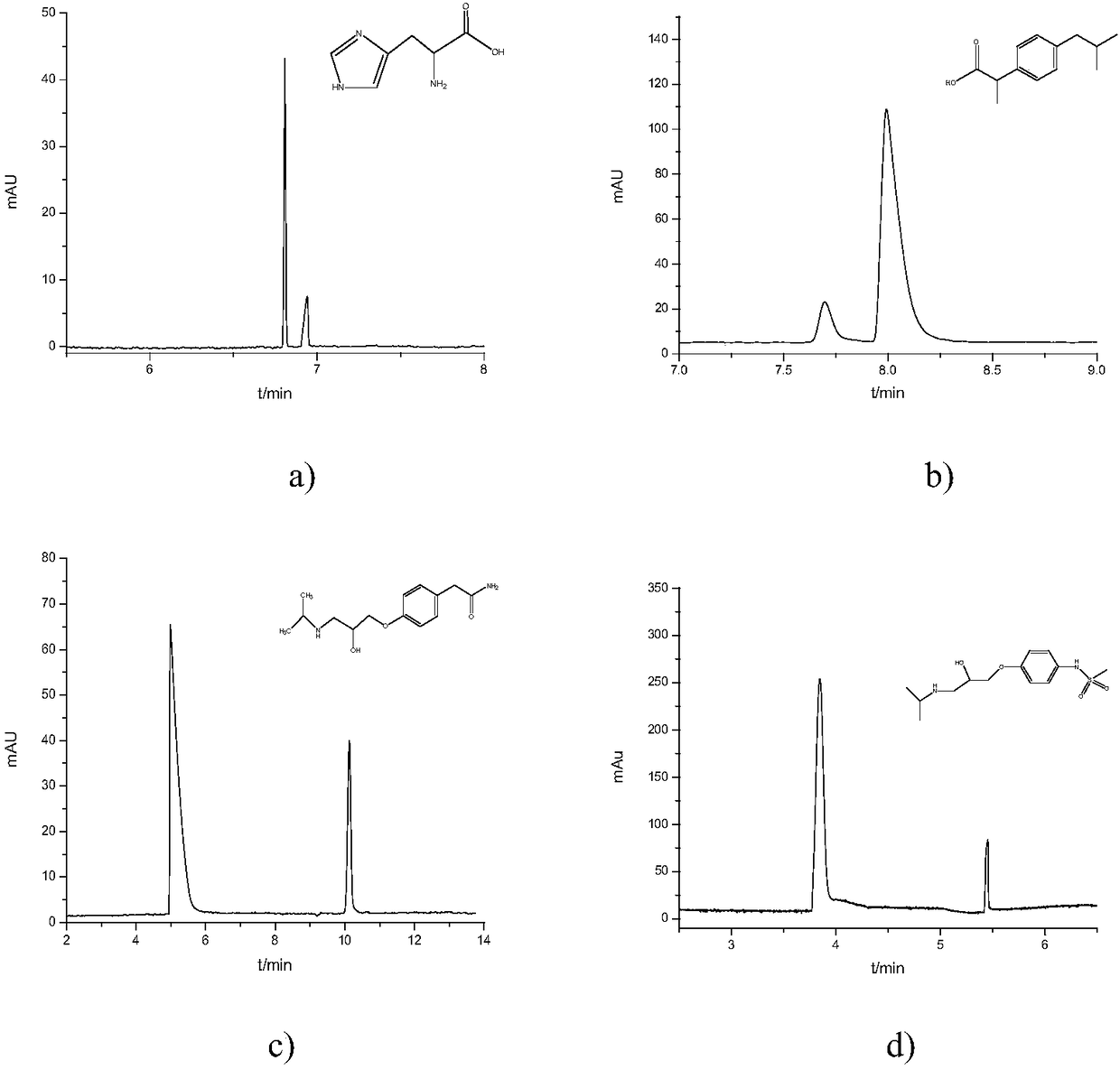

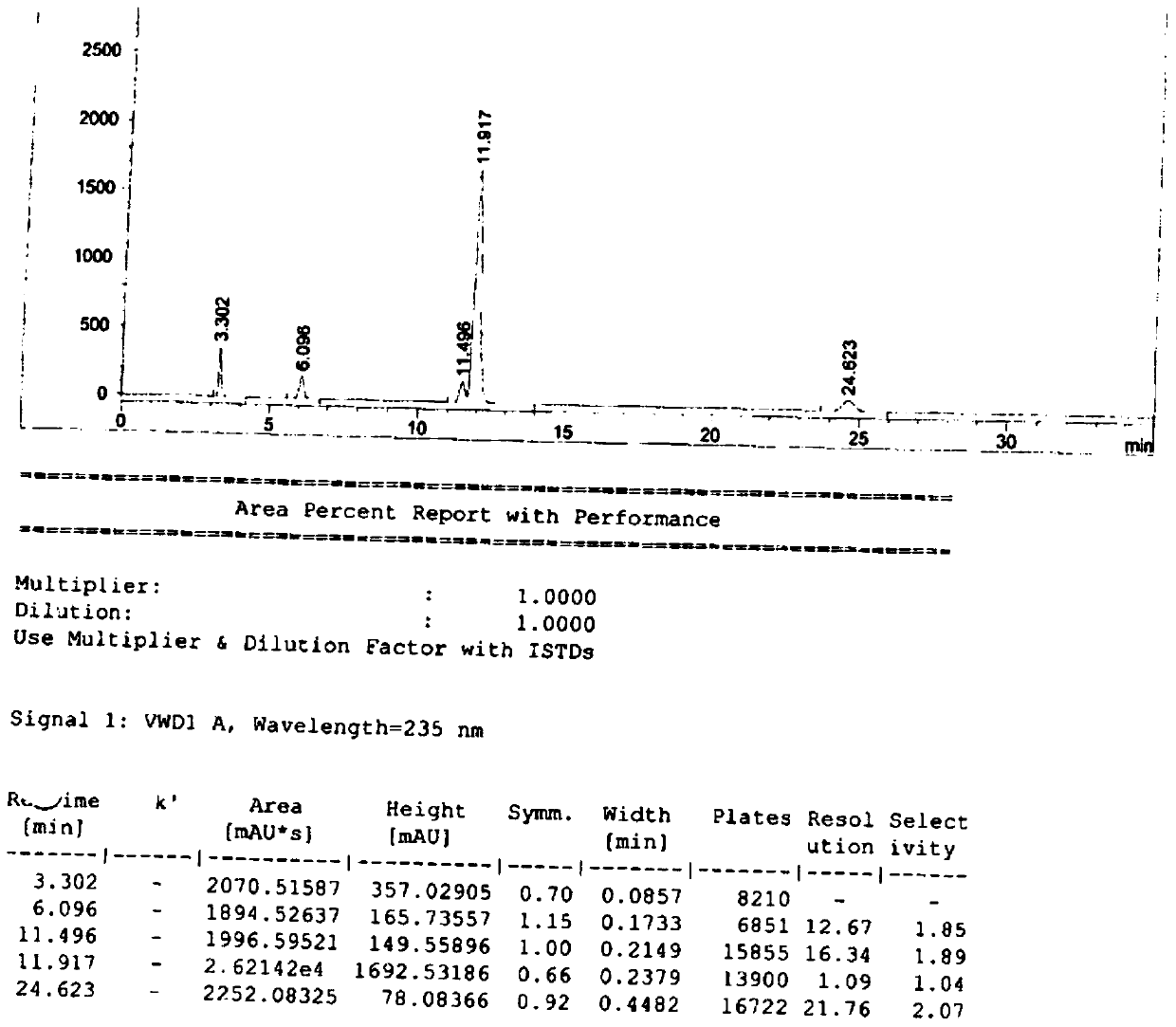

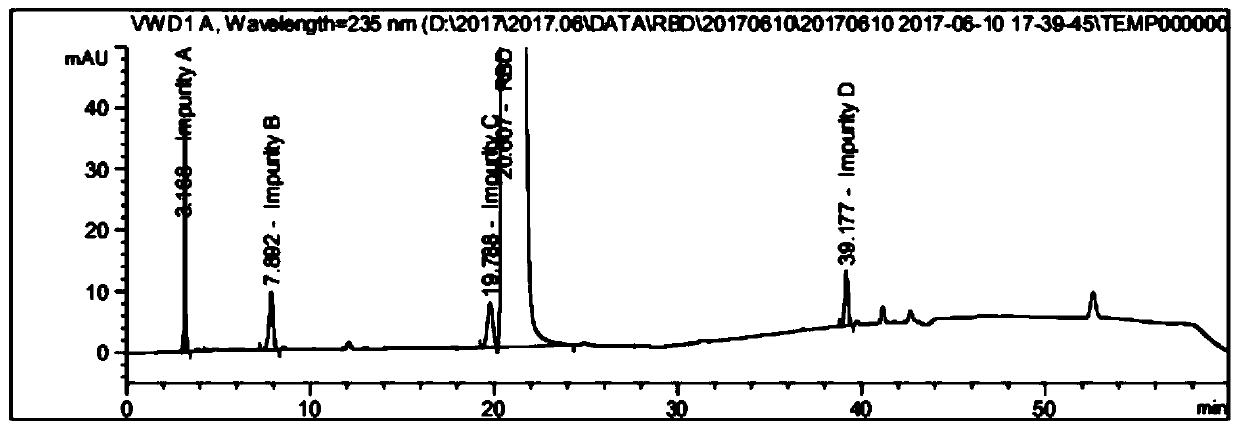

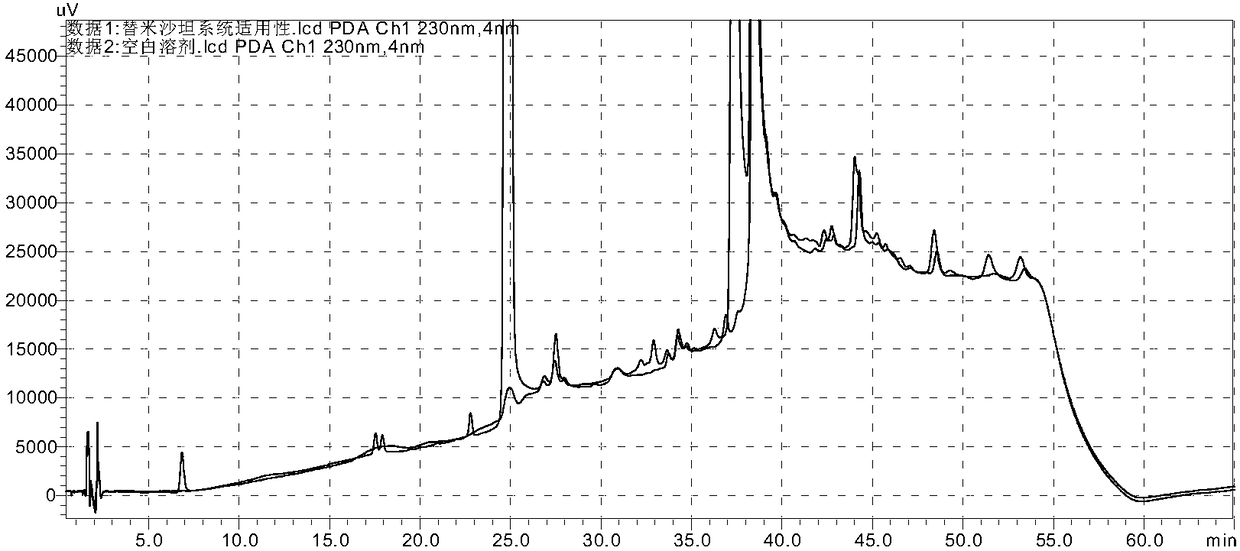

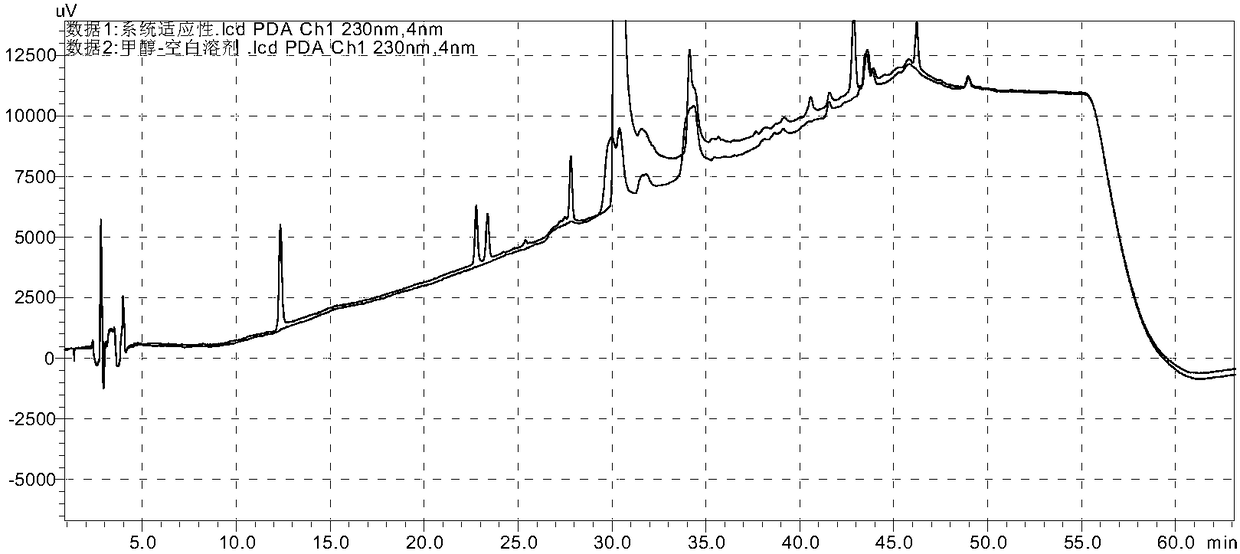

Analysis method for determining rebamipide related substances by using HPLC

ActiveCN111595985AEfficient separationMeet separation requirementsComponent separationSilanesGradient elution

The invention relates to the technical field of analytical chemistry, and discloses an analysis method for determining rebamipide related substances by using HPLC. According to the analysis method, octadecylsilane chemically bonded silica is used as a reversed phase chromatographic column of a filler, a buffer salt solution is used as a mobile phase A, the buffer salt solution, methanol and tetrahydrofuran are used as a mobile phase B, gradient elution is carried out on a rebamipide sample solution, and HPLC analysis is carried out. The analysis method provided by the invention can effectivelyseparate rebamipide and related substances thereof, so that impurity peaks and rebamipide peaks are not overlapped, the peak shape is good, the separation requirement is met, and the method is suitable for controlling related substances and researching impurities.

Owner:苏州正济药业有限公司

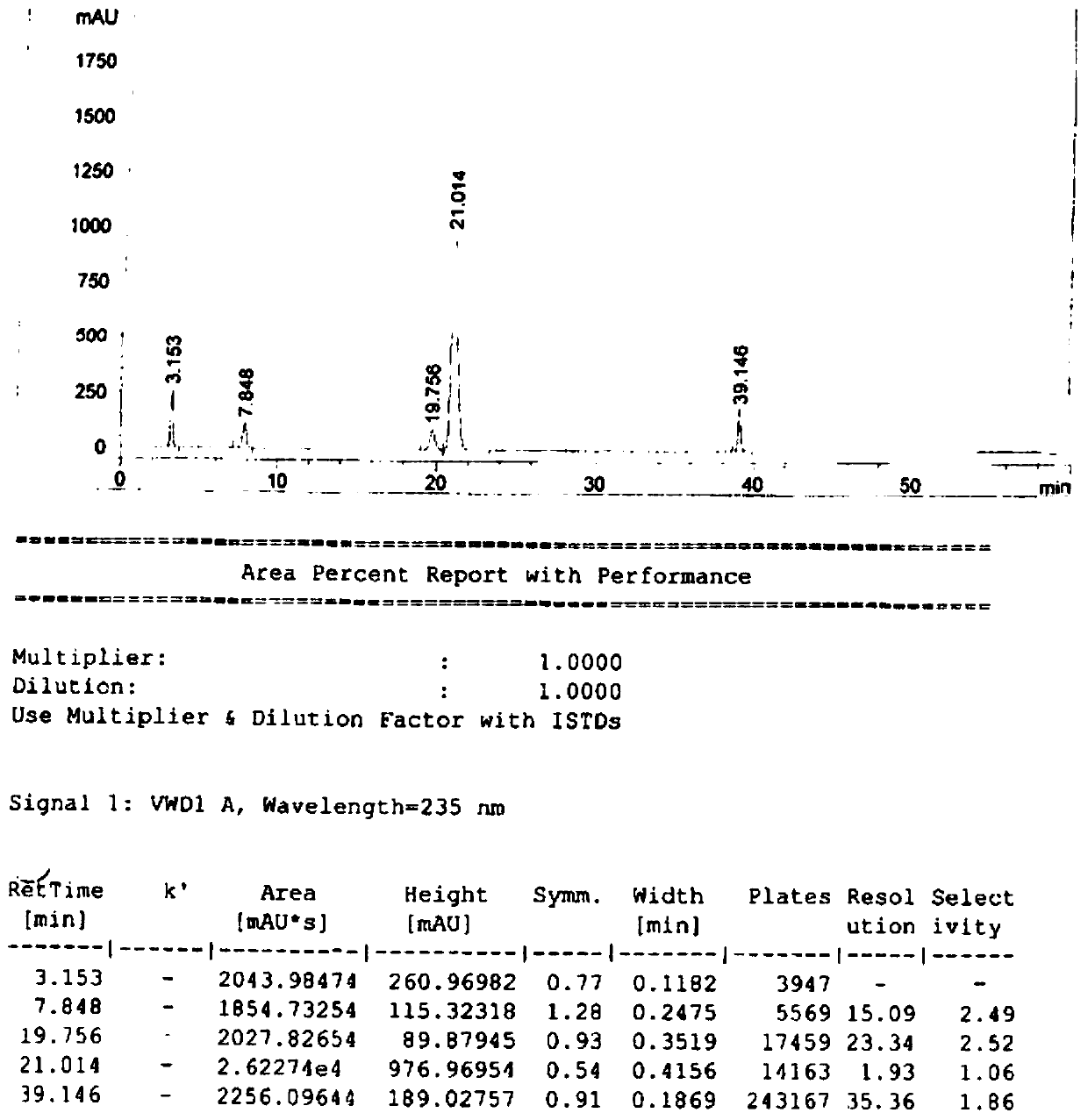

Impurity separation and detection method for telmisartan

The invention relates to an impurity separation and detection method for telmisartan. The method comprises the following steps: 1, dissolving a raw medicament of the telmisartan or a preparation of the telmisartan into a methanol solution to obtain a test sample solution; 2, injecting the test sample solution into a high performance liquid chromatograph to obtain a chromatogram; 3, calculating thecontent of the telmisartan and impurities thereof according to a peak area of the chromatogram, wherein high performance liquid chromatographic conditions are as follows: a chromatographic column isODS-2C18, the flow velocity is 1.0ml / min, the column temperature is 40 DEG C, the wavelength is 230nm, and the sample size is 10 mu l. A gradient elution table is as follows (shown in the specification).

Owner:南京迈迪信泽医药科技开发有限公司

Solid-liquid separation and vibrating liquid-removing drying integrated device

PendingCN111485836AMeet separation requirementsMeet purification requirementsDrying machines with non-progressive movementsFlushingWell drillingSmall footprint

The invention provides a solid-liquid separation and vibrating liquid-removing drying integrated device, and the device comprises a liquid phase collection storehouse, a drilling fluid circulating pot, a vibrating screen, a sucking disc, a liquid inlet pipe, a tee joint, a vacuum pump, a control valve, a liquid outlet pipe, a clapboard, a drilling cuttings collection storehouse, a screen cloth anda gate valve. Mechanical vibration and vacuum adsorption principles are used for the device, thus, solid phase moisture content of a solid-liquid mixture returned up from a shaft bottom is reduced after the solid-liquid mixture is subjected to solid-liquid separation and liquid-removing drying by the vibrating screen, thus, the solid-liquid mixture meets rock debris transportation requirements, pollution to environment caused by waste generated in a drilling process is reduced effectively, and the recycled drilling fluid is collected for cycle use in the drilling fluid circulating pot. The device has the advantages of being simple in structure, needing low energy consumption, being convenient to use, being mounted quickly, having high equipment reliability, needing low manufacturing costand occupying small area; moisture content of the treated drilling cuttings is not more than 60%, and the drilling cuttings meet drilling cuttings transportation reequipments; and the device is used for a drilling fluid solid phase control and no-landing integrated treatment system, and simplifies system constitution.

Owner:中石化石油工程技术服务有限公司 +3

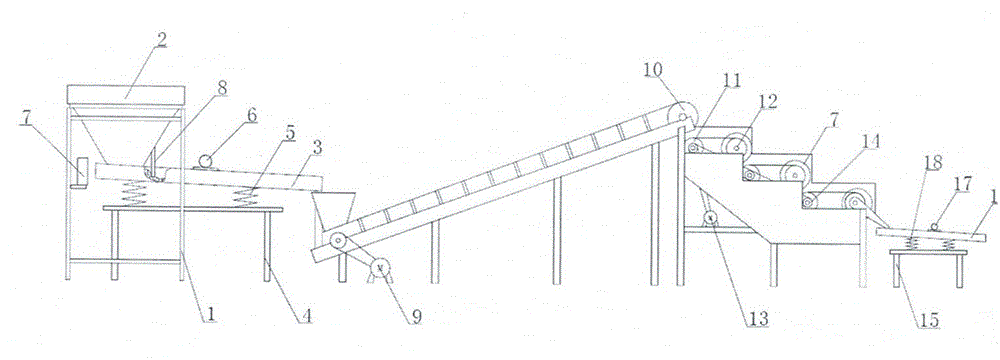

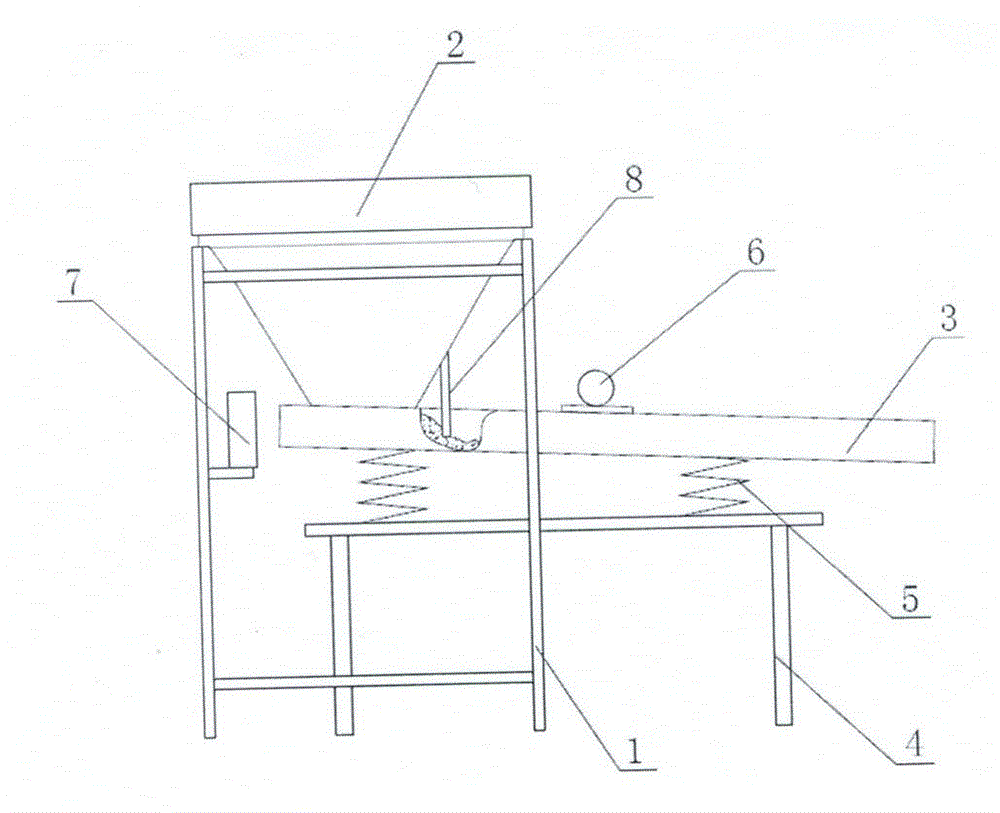

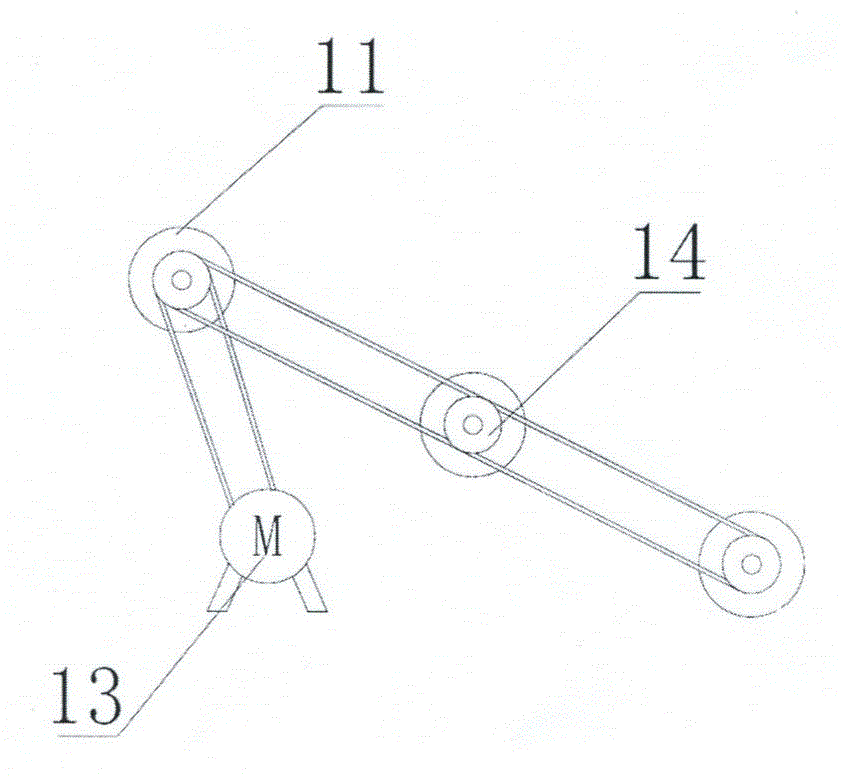

Iron scrap and aluminum scrap separating and conveying device

The invention provides an iron scrap and aluminum scrap separating and conveying device. Through two different separation processes, namely vibrating separation and multistage separation, the problem that separation modes are different due to different sizes of particles of iron scraps and aluminum scraps is solved, the iron scraps and the aluminum scraps can be separated more thoroughly, the separation quality is improved, and the purity of separated iron scraps and the purity of separated aluminum scraps are improved; the iron scrap and aluminum scrap separating and conveying device is simple in overall structure, reasonable in design, convenient to operate, high in adaptability and capable of meeting the requirements for separation of most kinds of iron scraps and aluminum scraps.

Owner:沁阳市第一造纸机械有限公司

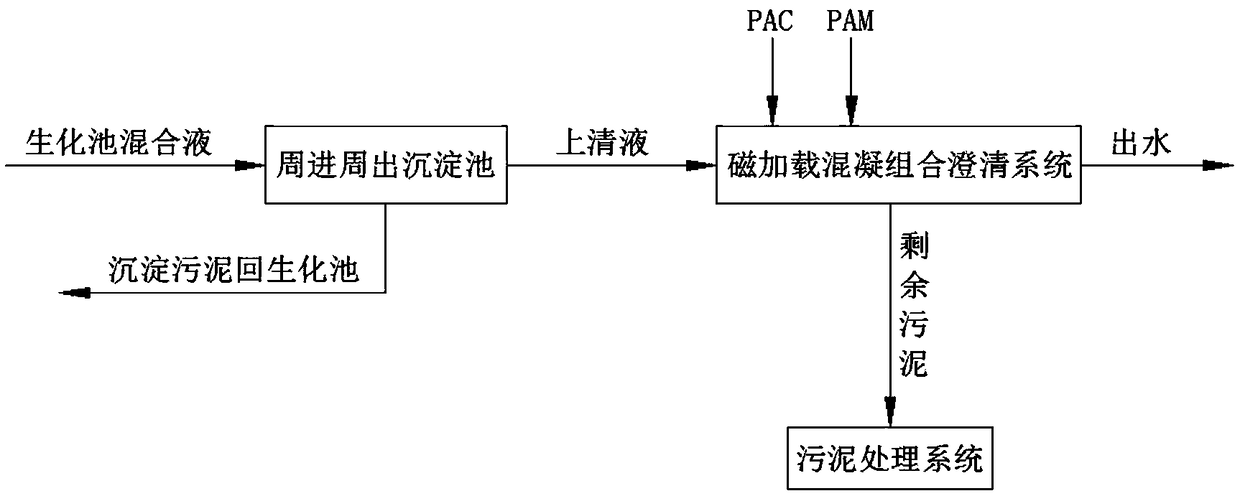

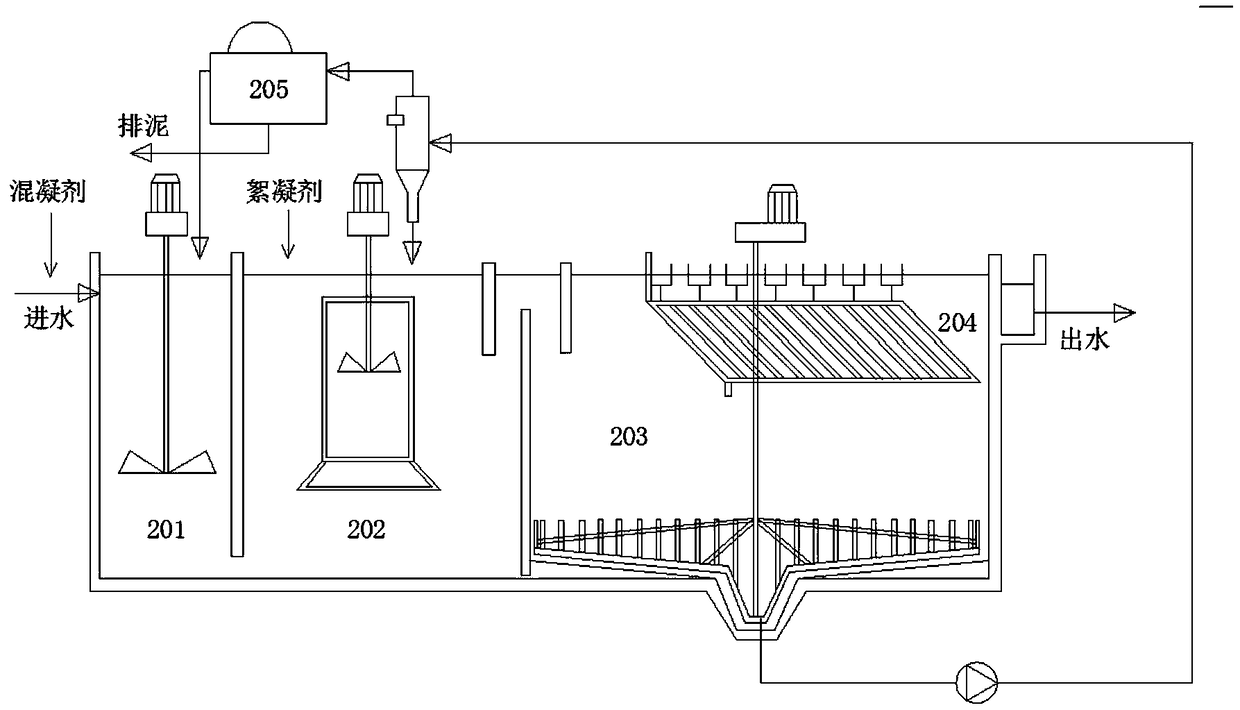

Multi-effect combined mud-water separation system

PendingCN108996805AMeet separation requirementsSmall footprintMultistage water/sewage treatmentTreatment involving sedimentationSludgeMulti effect

The invention discloses a multi-effect combined mud-water separation system. The system comprises a sedimentation tank with circumferential feeding and circumferential discharging functions and a magnetic loading coagulation combined clarification system. The sedimentation tank with circumferential feeding and circumferential discharging functions is connected to the magnetic loading coagulation combined clarification system through a pipe. The sedimentation tank is an auxiliary flowing-type sedimentation tank realizing circumferential feeding and discharging of water, is used for sludge-waterpre-precipitation separation of a sludge mixed liquid, can realize sludge-water separation of a mixed liquid in a biochemical pool and has a circular structure. The supernatant discharged from the sedimentation tank is fed into the magnetic loading coagulation combined clarification system, and the sludge is returned to the biochemical pool to maintain the sludge concentration in the biochemicalpool. The multi-effect combined mud-water separation system further reduces the covering area of the sedimentation tank by increasing the design surface hydraulic load of the sedimentation tank. SS inthe product water is further removed through the magnetic loading coagulation combined clarification system so that the sludge-water separation requirements are satisfied and the covering area of thesedimentation tank is reduced. The system has a high integrated degree so that the covering area is greatly reduced.

Owner:利得环境科技(北京)有限公司

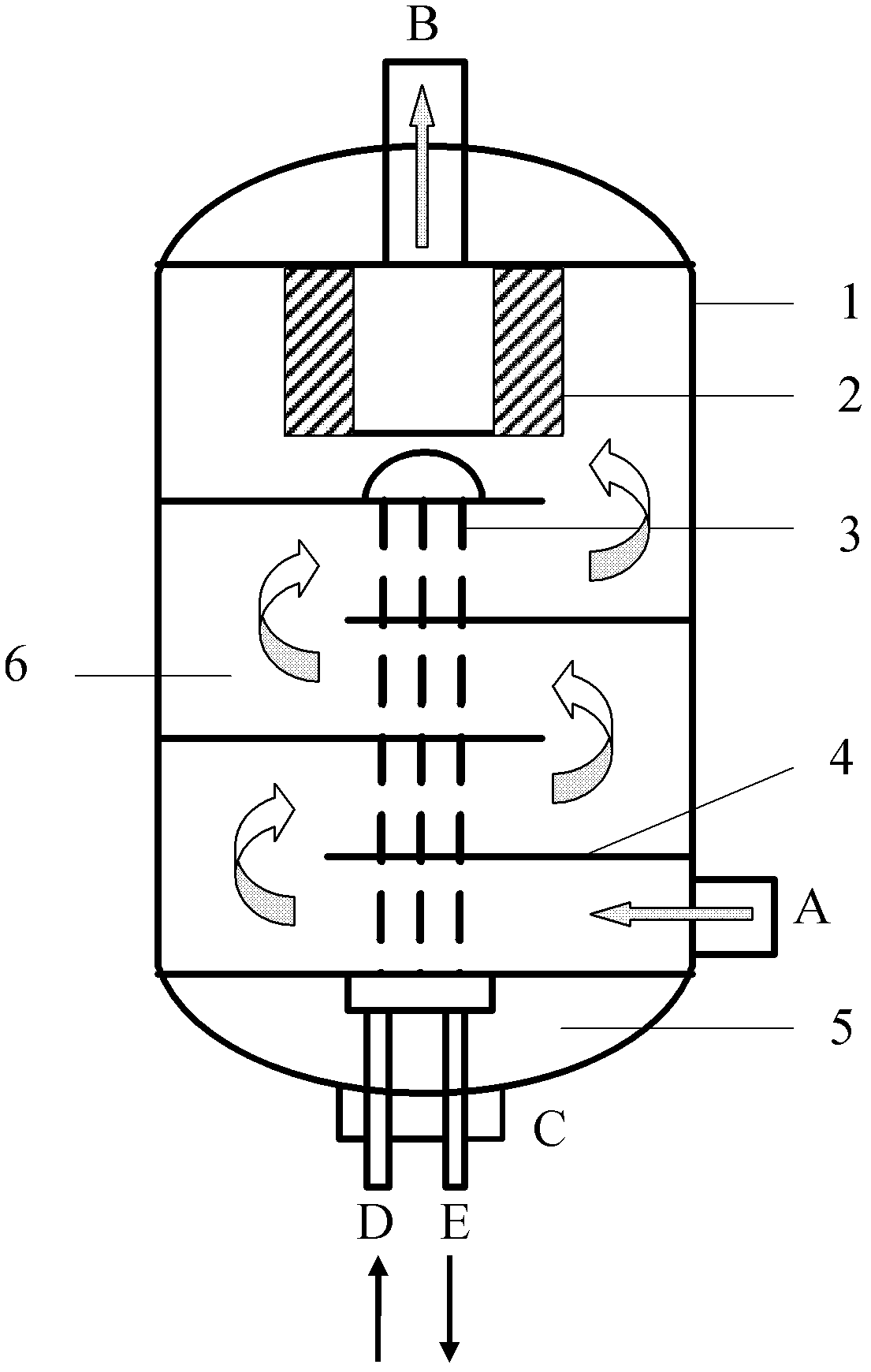

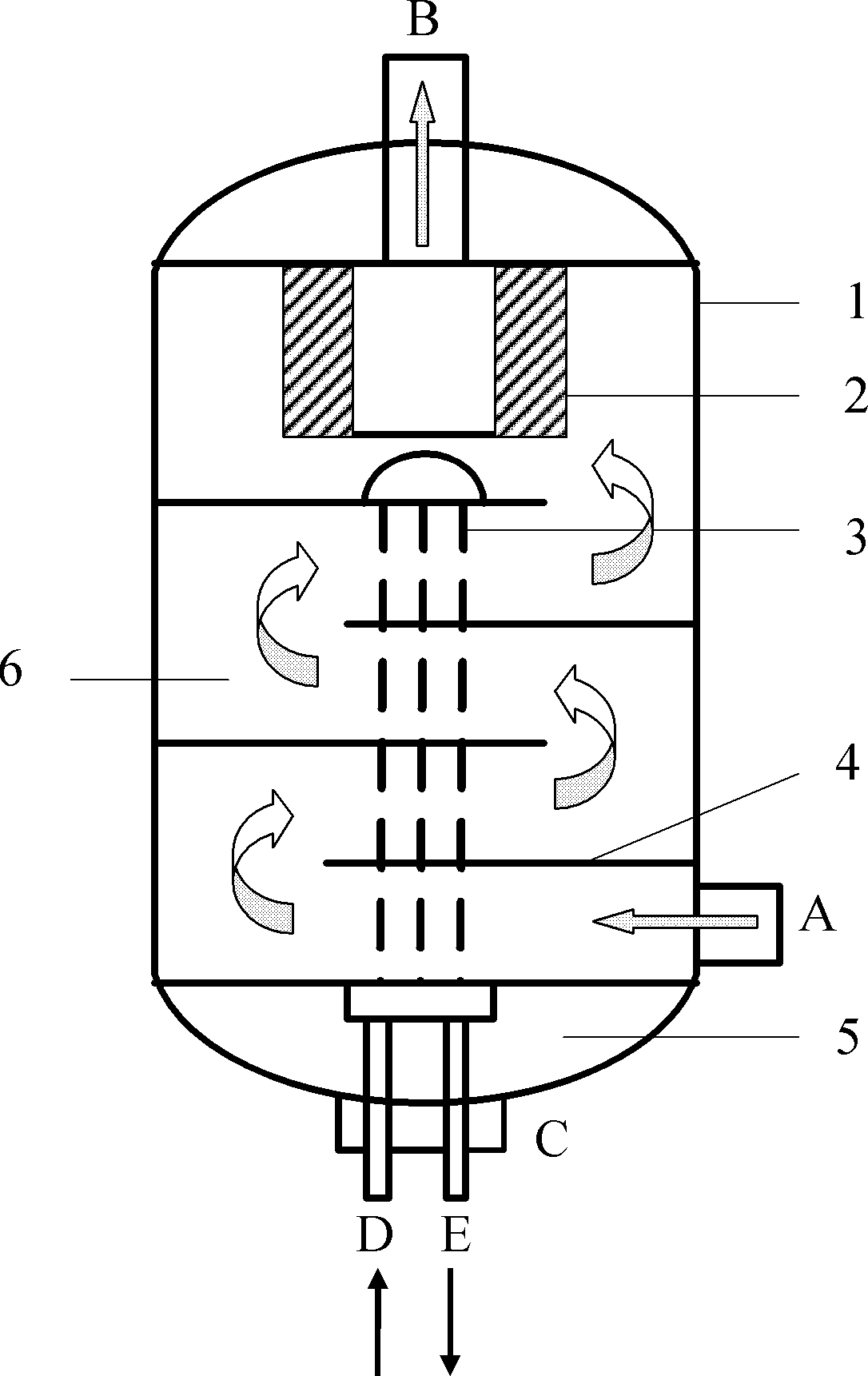

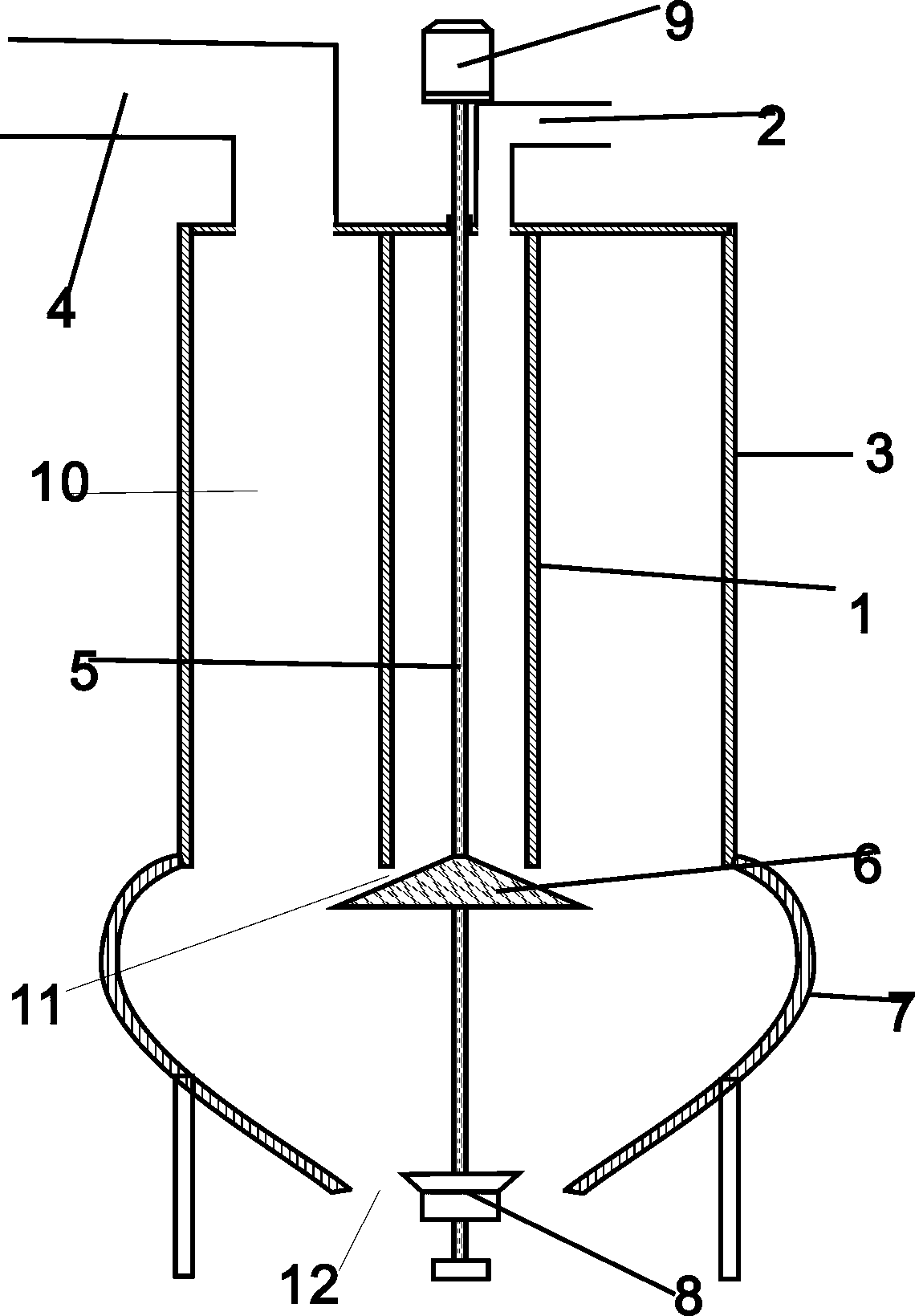

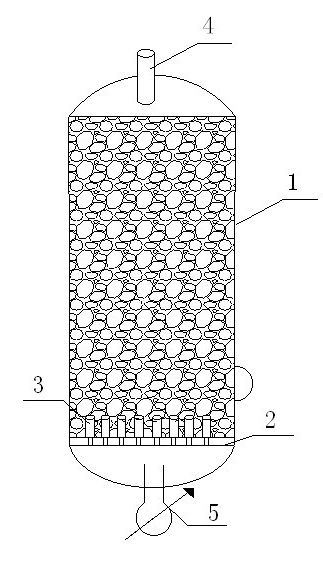

Chemical reactor

InactiveCN101954262AEasy to processMeet separation requirementsOrganic chemistryOrganic compound preparationPtru catalystChemical reactor

The invention discloses a chemical reactor, comprising a reactor tank body for loading reactants and a catalyst, wherein the upper part of the reactor tank body is provided with a feed pipe, the lower part thereof is provided with a discharge pipe; a catalyst / reactant separator is arranged at the lower part of the inner cavity of the reactor tank body and is composed of a mounting plate; the mounting plate is provided with mounting holes alternatively, and water caps are arranged in the mounting holes and comprise screwed pipes matched with the mounting holes; and filter vats are arranged on the upper parts of the screwed pipes, and the surface of the filter vat is of a meshed structure of which the clearance is smaller than the diameter of the catalyst. Only by processing the mounting holes with large diameter on the mounting plate, steel plates with larger thickness can be used as the mounting plates so as to satisfy the requirement of high bearing capacity and facilitating processing of the mounting plate; and the meshed structure on the surface of the water cap can completely satisfy the separation requirement of the catalyst and the reactants, thus taking the bearing capability and filtering effect into account simultaneously, and conforming to the special requirements for the reactor.

Owner:JIANGSU LINGFEI CHEM

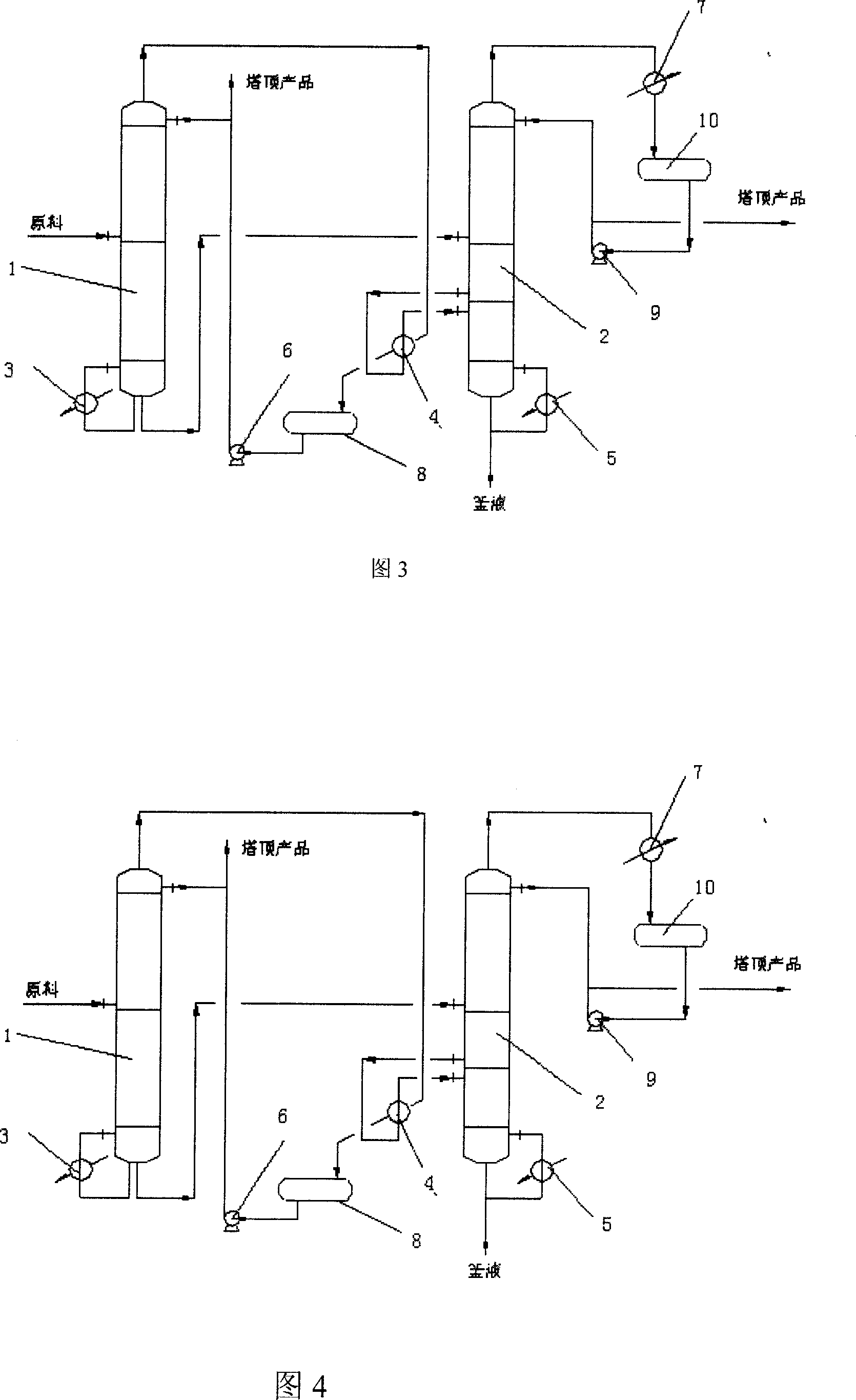

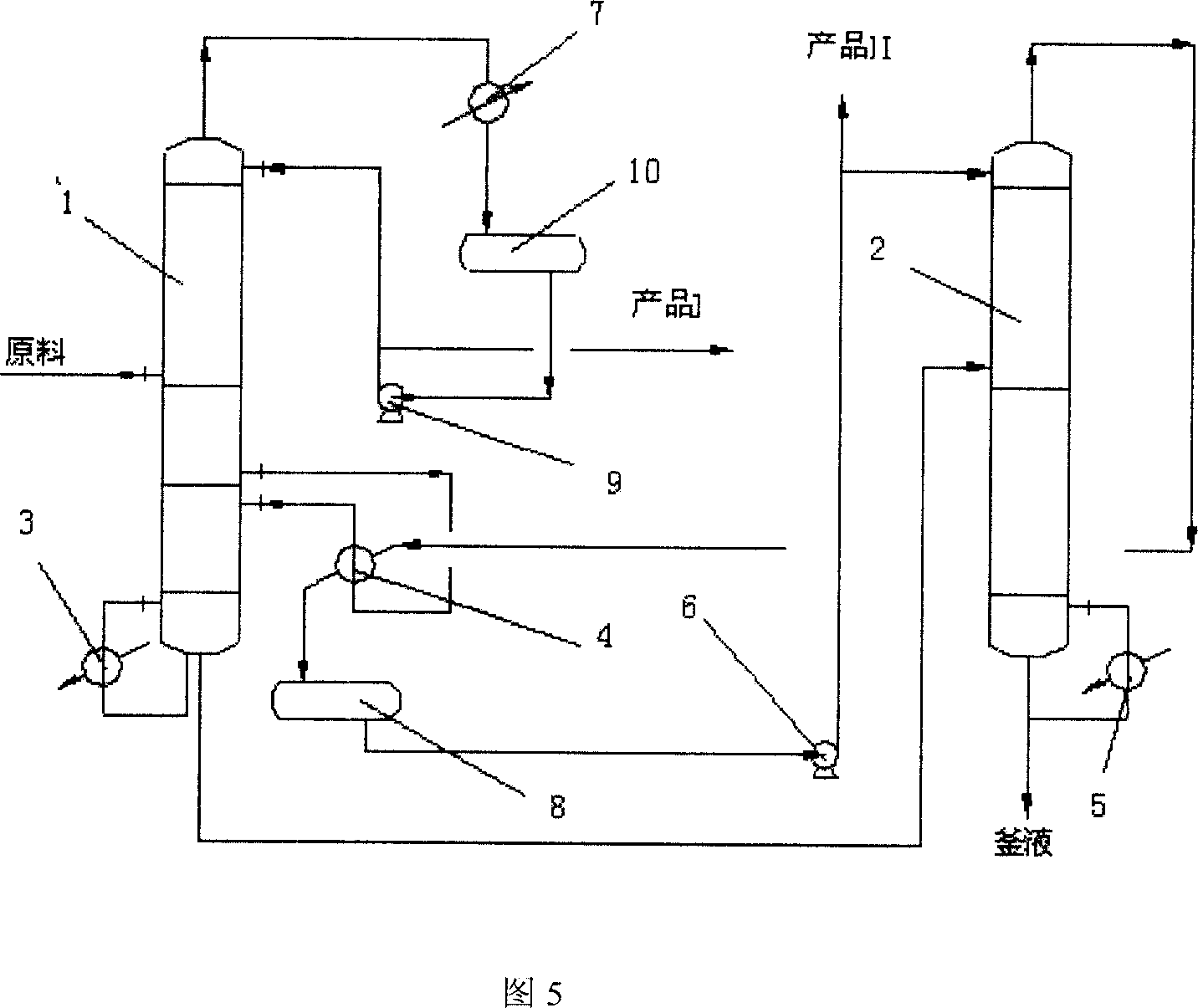

Method for preparing ultrahigh-purity gas through low temperature separation, and low temperature separation system

ActiveCN107648976ALow purity requirementMeet separation requirementsDispersed particle separationLiquid productReflux

The invention discloses a method for preparing an ultrahigh-purity gas through low temperature separation, and a low temperature separation system. The method comprises the following steps: a target product raw gas is introduced into a first heavy-fraction removal tower, a gas discharged from the tower top of the first heavy-fraction removal tower goes through a tower top condenser, one part of the obtained condensed liquid returns to the first heavy-fraction removal tower from the tower top as a reflux liquid, the remaining condensed liquid is introduced to a second heavy-fraction removal tower as an extracted material, and heavy component impurities are discharged from the tower bottom of the first heavy-fraction removal tower; a gas discharged from the tower top of the second heavy-fraction removal tower goes through a condenser, the obtained condensed liquid returns to the second heavy-fraction removal tower from the tower top as a reflux liquid, uncondensed light component impurities are discharged, and heavy component impurities are discharged from the tower bottom; and a material extracted from the middle part of the second heavy-fraction removal tower is introduced to a light-fraction removal tower, a gas discharged from the tower top of the light-fraction removal tower goes through a condenser, the condensed liquid returns to the light-fraction removal tower from the tower top as a reflux liquid, uncondensed light component impurities are discharged, heavy component impurities are discharged from the tower bottom, and a liquid product is extracted from the middle part of the light-fraction removal tower. The method and the system have the characteristics of simple device, high device efficiency, wide range of the prepared product, and low requirement of the purity of the raw gas.

Owner:衢州杭氧气体有限公司 +2

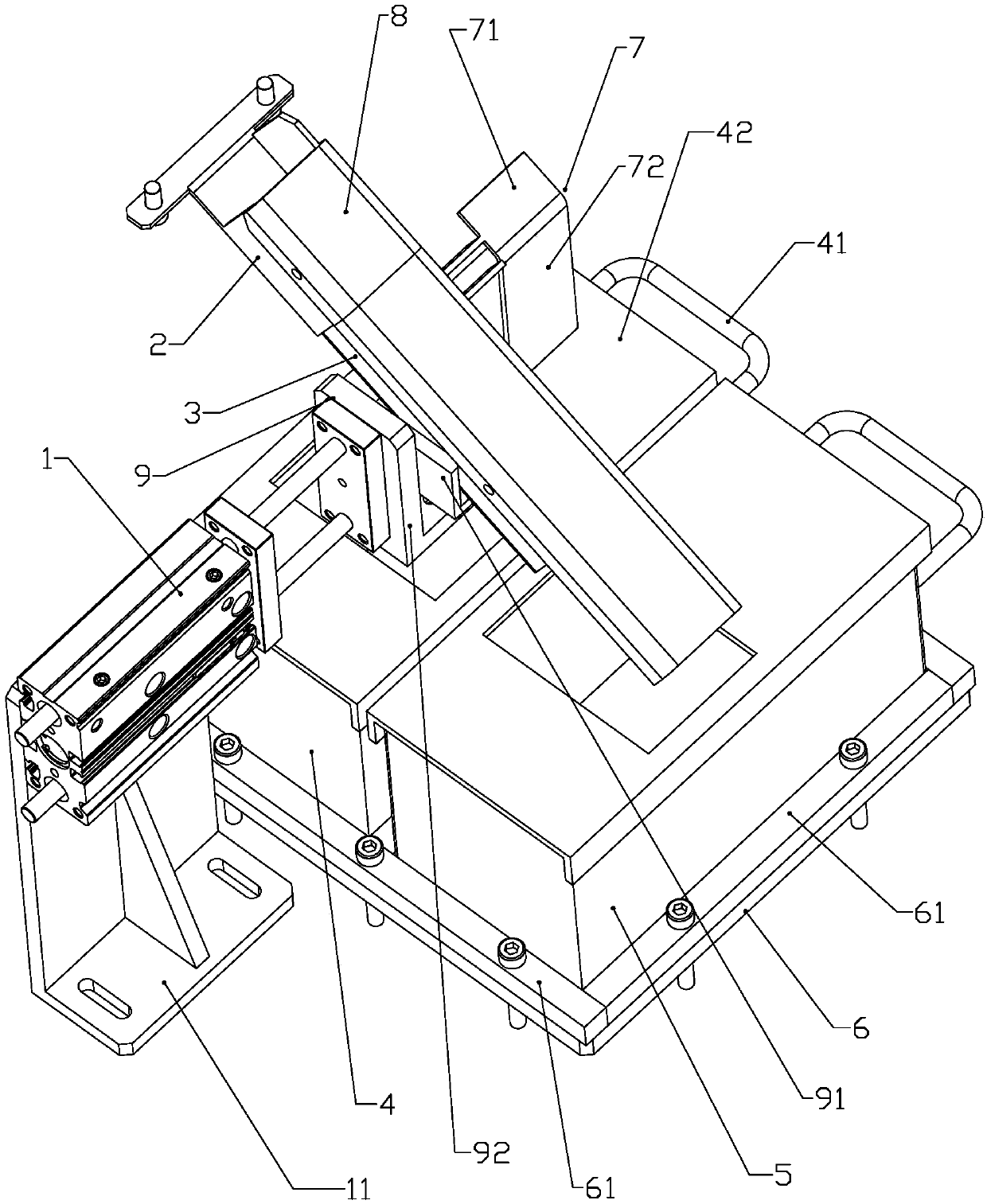

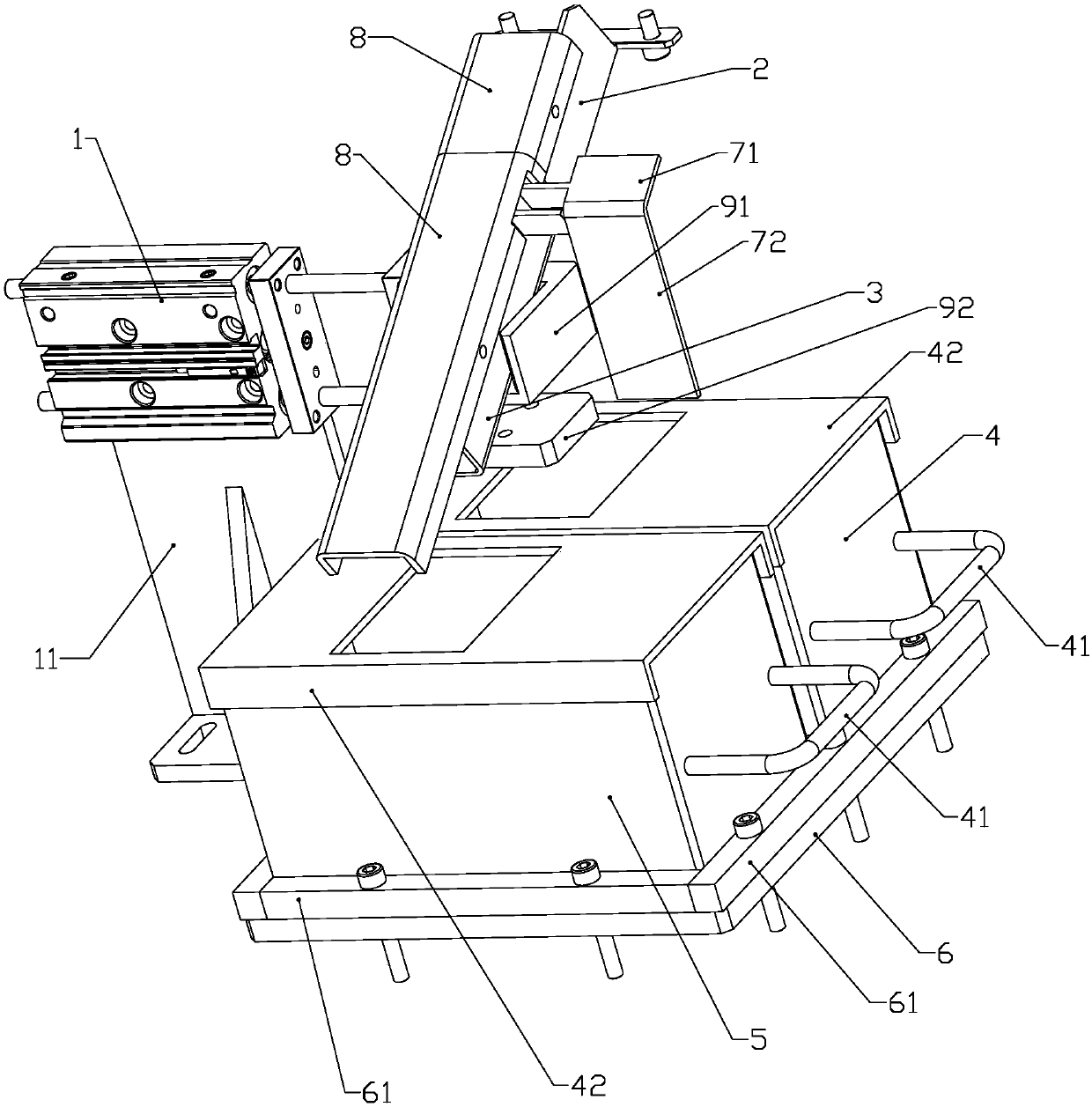

Visual detection automatic material separating unit for product size

PendingCN107803352ASeparation meetsMeet separation requirementsSortingVisual inspectionProduct characteristics

The invention discloses a visual detection automatic material separating unit for a product size and belongs to material separating devices. The visual detection automatic sorting unit structurally comprises a sorting cylinder, a first material separating path, a second material separating path, a qualified product material box, an unqualified product material box and a material separating support. The qualified product material box and the unqualified product material box are arranged on the upper part of the material separating support respectively and are arranged left and right, the firstmaterial separating path is arranged on the upper part of the qualified product material box, the second material separating path is arranged on the right side of the first material separating path, the lower part of the first material separating path is jointed with the top of the second material separating path, a material separating cylinder is arranged on the front part of the material separating support, a cylinder rod of the material separating cylinder is connected to the second material separating path, a material path baffle is arranged on the back side of the second material separating path, and the material path baffle is arranged on upper part of the qualified product material box. The visual detection automatic sorting unit for a product size has the characteristics of capability of realizing automatic discharging of products and totally replacing manual work for material separating, reduction of labor intensity of manual work and obviously improved product test efficiency.

Owner:山东爱通代代良智能科技有限公司

High-efficiency particle size separation and sampling device for artificial radioactive aerosol and natural radioactive aerosol

PendingCN109870329AReduce pipe wall lossMeet the needs of fractional sampling measurementWithdrawing sample devicesSpray nozzleGas chamber

The invention relates to a high-efficiency particle size separation and sampling device for artificial radioactive aerosol and natural radioactive aerosol. The device comprises a collection gas chamber, a separation gas chamber, a gas chamber bottom plate, a gas chamber partition plate, an adjusting gasket, a nozzle, a collection nozzle, a collection tube and a baffle plate, wherein the whole collection gas chamber used for collecting small-diameter particles is of an annular structure with openings at two ends; the upper end surface of the collection gas chamber is fixedly connected to the lower end of the separation gas chamber through the gas chamber partition plate; the lower end surface of the collection n gas chamber is fixedly connected to the gas chamber bottom plate through the adjusting gasket; the nozzle used for being connected to an external atmosphere collection pipeline penetrates through the middle of the upper end of the separation gas chamber and is fixedly connectedto the separation gas chamber through a bolt; and the collection nozzle used for separating the particles penetrates through a position, corresponding to the nozzle, of the middle of the gas chamber partition plate. According to the device, the requirements for classified sampling measurement of the radioactive aerosol in different particle size ranges can be met, and the device has the advantagesof high separation efficiency and small particle tube wall loss and can be used as grading measurement of the aerosol within the different particle size ranges such as PM0.5, PM1.0, PM2.5, PM10 and the like of the atmospheric environment.

Owner:中国人民解放军军事科学院国防工程研究院工程防护研究所

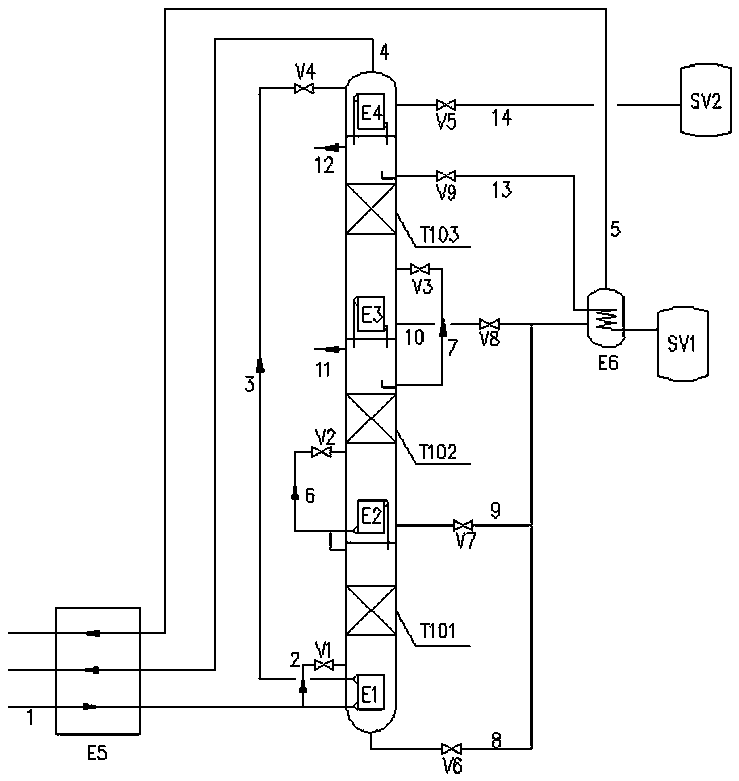

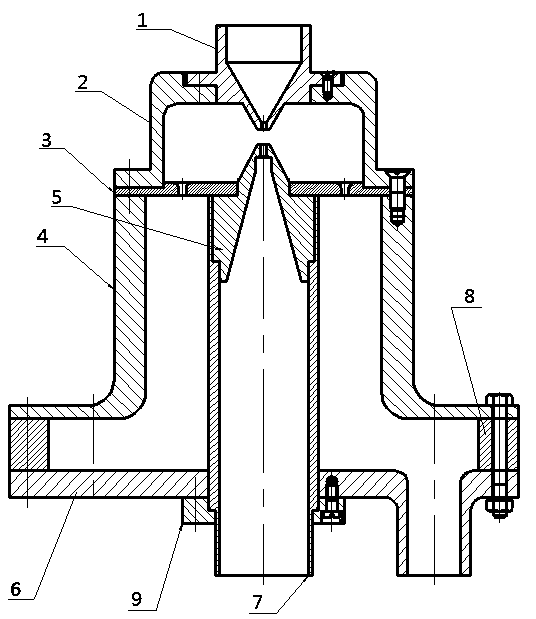

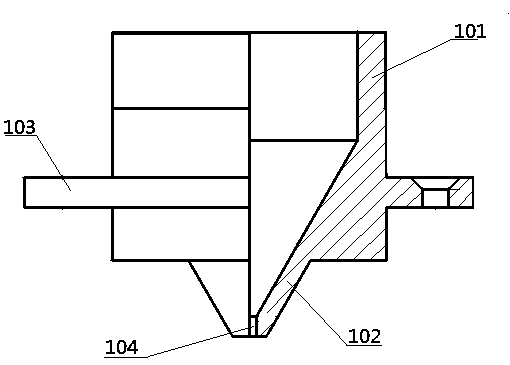

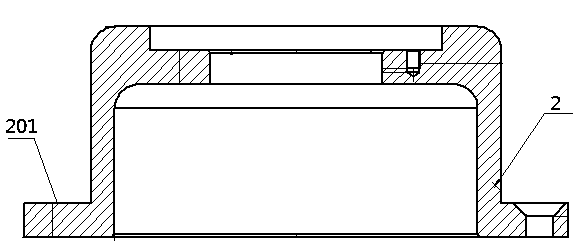

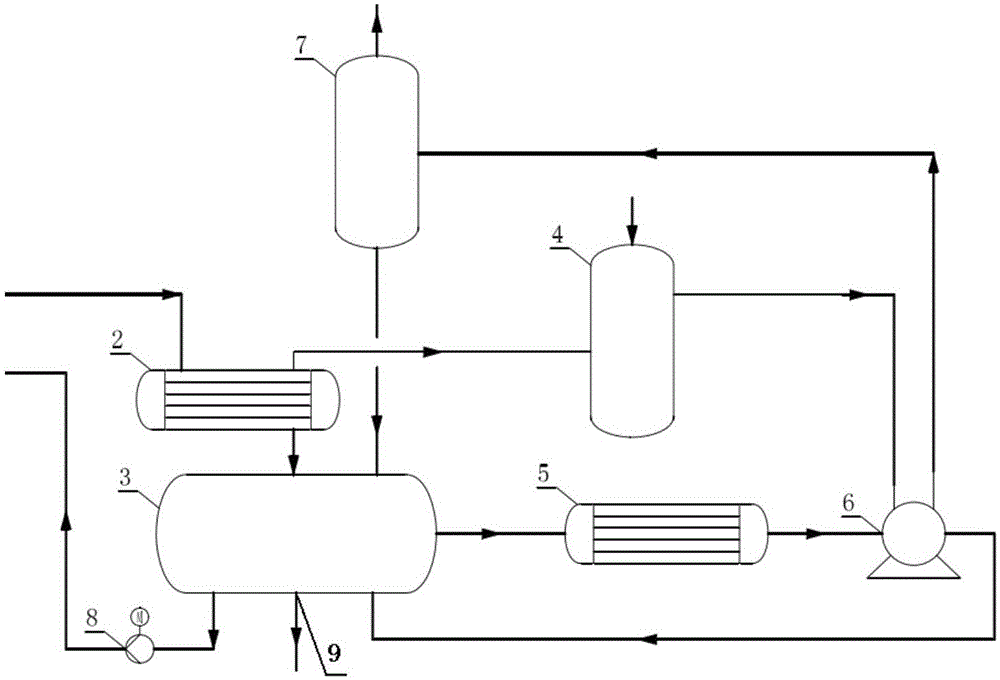

Ammonia gas absorption device for tert-butyl alcohol reduced pressure recovery tower and ammonia gas absorption method

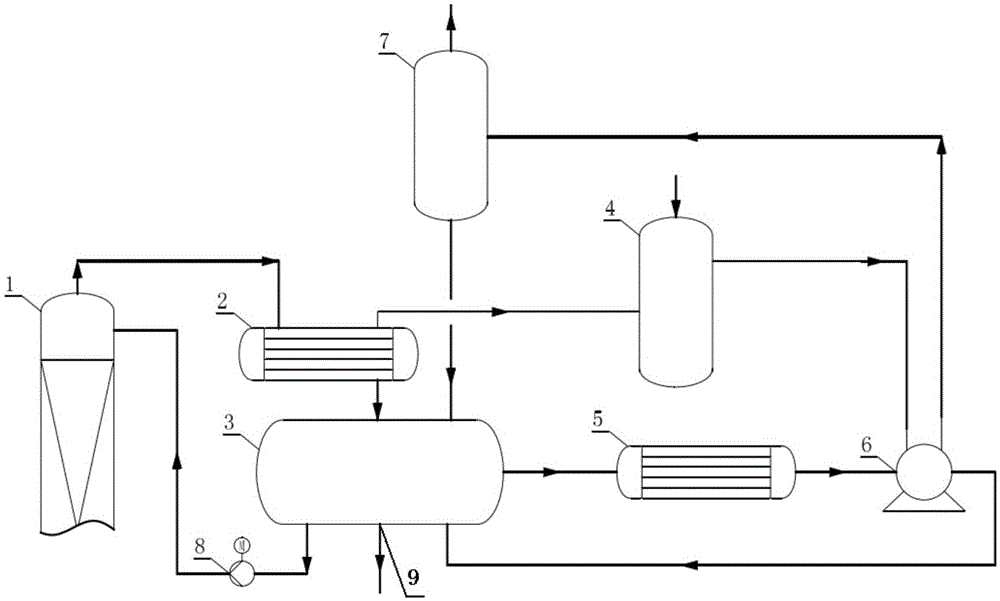

ActiveCN104998519ALow investment costHigh recovery rateChemical industryDispersed particle separationVapor–liquid separatorAutomatic control

The invention discloses an ammonia gas absorption device for a tert-butyl alcohol reduced pressure recovery tower and an ammonia gas absorption method. The device comprises a primary cooler 2, a storage tank 3, a vacuum buffer tank 4, a deep cooling device 5, a vacuum pump 6, a gas-liquid separator 7 and a reflux pump 8. A pipe connected to the top of a tert-butyl alcohol reduced pressure tower is orderly connected to the primary cooler, the storage tank and the reflux pump and then is connected to a tert-butyl alcohol reduced pressure tower return pipe. A noncondensable gas outlet of the primary cooler is orderly connected to the vacuum buffer tank, the vacuum pump and the gas-liquid separator by pipes and then is connected to the storage tank by a pipe. The storage tank is orderly connected to the deep cooler and the vacuum pump by pipes and then is connected to the storage tank by a pipe. The bottom of the storage tank is provided with a tower top finished product collection hole of the tert-butyl alcohol reduced pressure tower. An overflow plate is arranged in the storage tank or a liquid level automatic control valve is arranged at the finished product collection hole. The ammonia gas absorption device realizes recovery of a noncondensable tert-butyl alcohol vapor phase from a tert-butyl alcohol reduced pressure tower, absorbs ammonia gas in the system, satisfies rectifying tower separation requirements, improves a product yield and realizes stable caprolactam ammoximation.

Owner:TIANJIN TIANDI CHUANGZHI TECH DEV

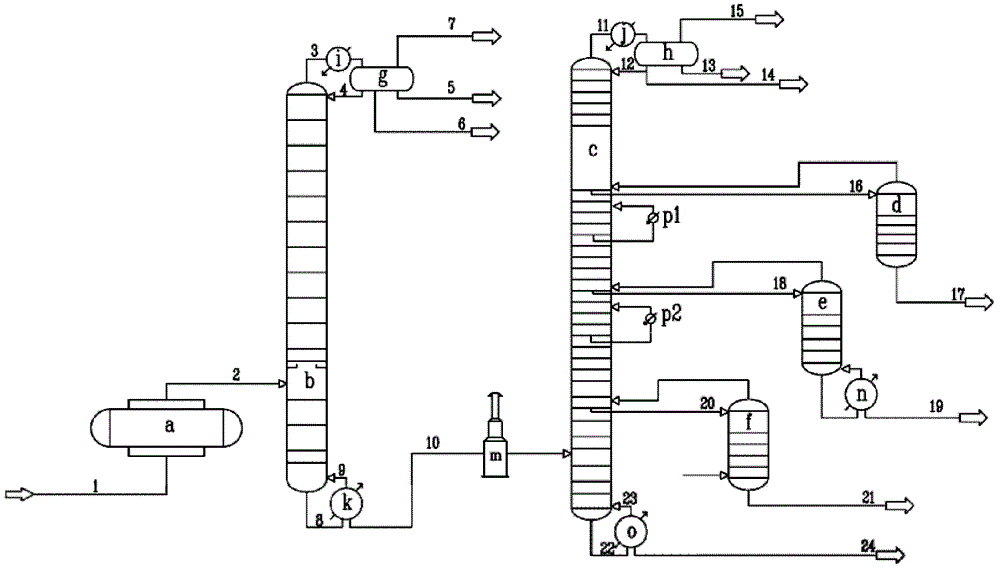

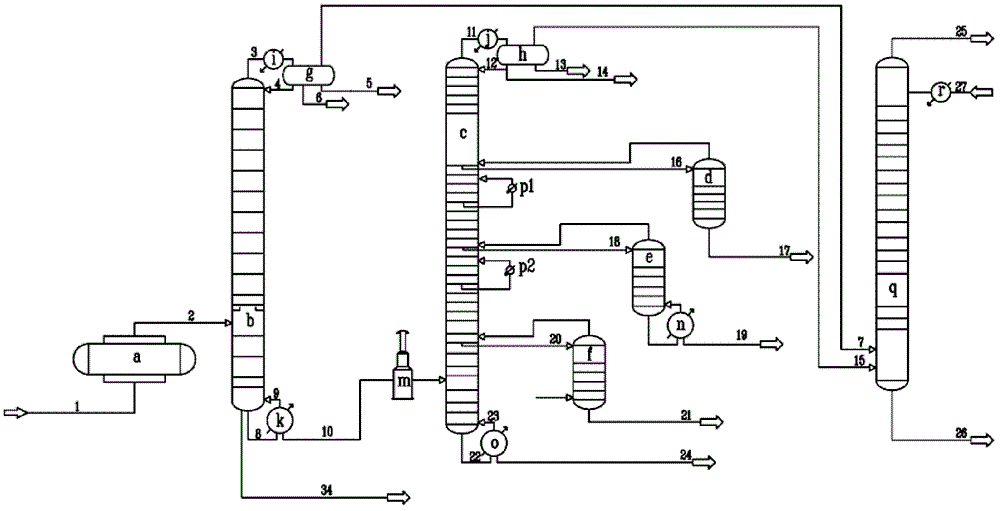

A system and method for processing condensate

ActiveCN102876359BEfficient separationSimple processTreatment with plural serial refining stagesOil processingReboiler

The invention discloses a system and a method for processing condensate oil. The system comprises a primary tower and an atmospheric tower; the bottom of the primary tower is provided with a primary tower reboiler; and the bottom of the atmospheric tower is provided with an atmospheric tower reboiler. The method comprises the following steps of: heating one part of primary tower bottom oil by using the primary tower reboiler, returning the heated oil to the primary tower bottom, heating the other part of primary tower bottom oil by using an atmospheric heating furnace; and heating one part of atmospheric tower bottom oil by using the atmospheric tower reboiler, returning the heated oil to the atmospheric tower bottom, and discharging the other part of atmospheric tower bottom oil, which serves as a heavy oil product. The system and the method can overcome a processing difficulty that light hydrocarbon content is high in the condensate oil processing process, are suitable for a production device which does not have a requirement for recycling a liquefied gas product in the condensate oil, and have the advantages of simple operation and low energy consumption.

Owner:CHINA PETROCHEMICAL CORP +1

Coin classifying and counting device and using method thereof

ActiveCN105976486AImprove classification speedImprove classification efficiencyCoin/paper handlersModularityScale reading

The invention relates to a coin classifying and counting device, specifically relates to a device which has a simple structure and classifies and counts coins according to the coin diameter and a using method thereof, and belongs to the technical field of mechanical classifying devices. Coins are pre-arranged using a roller structure, so the coins can go into a coin feeding slot and a coin classifying track in sequence. The process is smooth, and the speed and efficiency of coin classification are improved. By adjusting the speed of the roller, the drop speed of coins can be controlled, and thus the classification efficiency is adjusted. The number of coins is acquired based on scale reading, which is intuitive and accurate. Modular coin separation can be realized. By changing the number of sets of wedge blocks, hoppers and coin storage tanks and the arrangement positions thereof, the device can meet the separation requirements of more types of coins, and can be used to separate coins with different diameters from all over the world.

Owner:CHANGZHOU UNIV

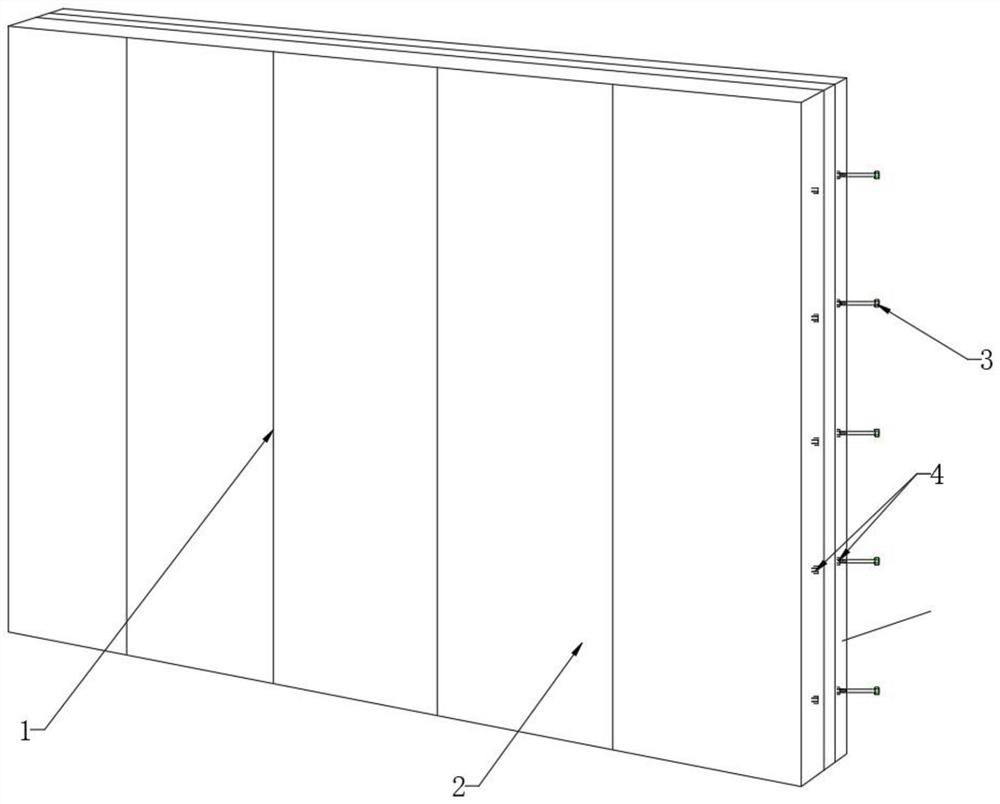

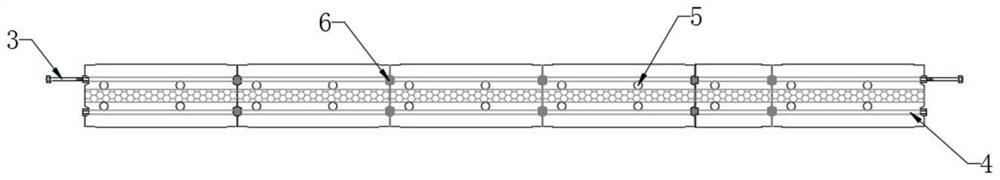

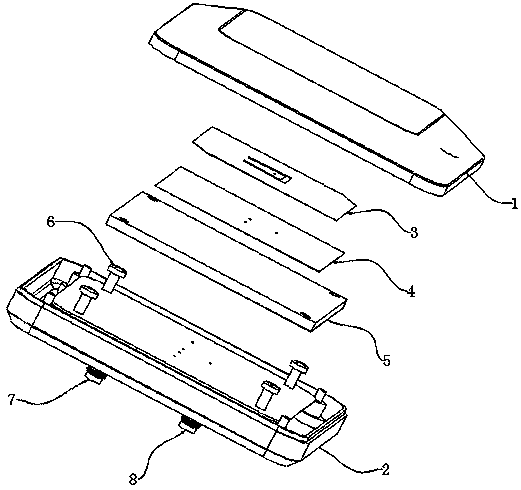

Prefabricated ceramsite foamed concrete sandwich thermal insulation external wall panel

InactiveCN114108867AHigh compressive strengthWon't hurtWallsClimate change adaptationSolid wallThermal insulation

The invention discloses a prefabricated ceramsite foamed concrete sandwich thermal insulation external wall panel, and particularly relates to the technical field of fabricated novel wall bodies, the prefabricated ceramsite foamed concrete sandwich thermal insulation external wall panel comprises a plurality of layers of outer enclosure walls distributed in a rectangular shape, each outer enclosure wall comprises a plurality of longitudinally arranged unit plates, and a plurality of reserved pipeline holes are longitudinally formed in the vertical surfaces of the unit plates; and a plurality of separating walls are mounted between the outer enclosure walls which are distributed in a rectangular manner. When an earthquake comes, the junction of the wallboard and the structure is broken in advance without damaging the structure, and the situation that life is hurt due to breaking and collapsing like masonry is avoided; the unit plates are excellent in moisture resistance, so that the phenomena of moisture regain and mildewing of the block wall body are avoided; double concave-convex seams are adopted, so that the common building problem of water seepage of a block wall is solved; the wall body is light and low in cost; compared with a traditional clay brick, the effects of energy conservation and emission reduction can be achieved; and each wallboard is vertically provided with a reserved pipeline core hole, so that the characteristics of the solid wallboard are ensured, water and electricity pipelines can conveniently penetrate through the wallboard, and the pipeline separation requirement of a fabricated building is met.

Owner:浙江汇腾新型建筑材料有限公司

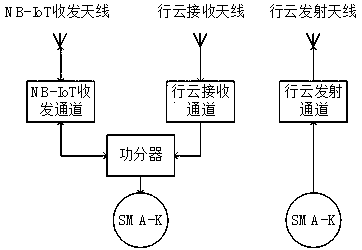

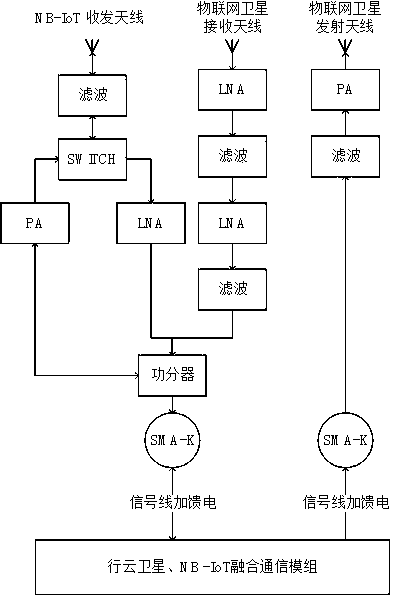

NB-IoT and Internet-of-Things satellite fusion antenna

PendingCN111180907ACompatible with miniaturization requirementsMeet the requirements of integrationRadiating elements structural formsRadiating element housingsTransceiverActive antenna

The invention relates to an NB-IOT and Internet-of-Things satellite fusion antenna. The fusion antenna comprises an NB-IOT transceiver antenna (3), a row cloud receiving antenna, a row cloud transmitting antenna, a power divider, an A-path SMA-K port (7) and a B-path SMA-K port (8). The NB-IOT transceiver antenna is connected to a NB-IOT transceiver channel, the row cloud receiving antenna is connected to a row cloud receiving channel, and the NB-IOT transceiver channel and the row cloud receiving channel are combined and connected to the A-path SMA-K port (7) through the power divider; and the row cloud transmitting antenna is connected to the row cloud transmitting channel. According to the scheme, the NB-IOT transceiver antenna and the row cloud transmitting and receiving antenna are integrated in one antenna, so that the occupied space is smaller, the antenna adopts an active antenna design, the requirement of integration of a celestial body and a terminal can be met, and the requirement of separation of the antenna and the terminal can also be met.

Owner:CHENGDU CORESAT TECH CO LTD +1

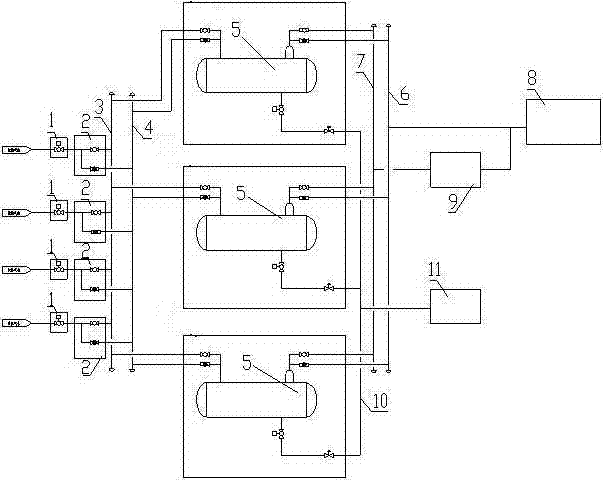

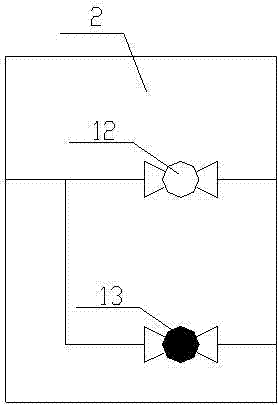

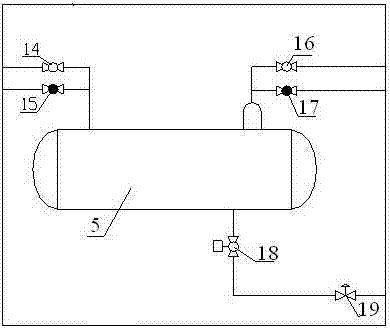

Ground high-low pressure mixed gas-liquid separation system based on multi-reservoir commingling production gas field

The invention provides a ground high-low pressure mixed gas-liquid separation system based on a multi-reservoir commingling production gas field. The ground high-low pressure mixed gas-liquid separation system comprises a gas inlet pipeline and a gas-liquid separator; an in-station block valve is arranged on the gas inlet pipeline; the outlet end of the in-station block valve is communicated with a high-low flow switching valve bank; the high-low flow switching valve bank is composed of a high-pressure flow control valve and a low-pressure flow control valve, the two of which are communicated in parallel to the outlet end of the in-station block valve. The ground high-low pressure mixed gas-liquid separation system is capable of simultaneously meeting the natural gas-liquid separation requirements in different production manners such as total high-pressure production, high-low pressure mixed production and total low-pressure production.

Owner:XIAN CHANGQING TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com