Condensing gathering separator for separating lubricating oil from refrigerant

A separator and refrigerant technology, applied in the field of separators, can solve problems such as difficult to meet the requirements of oil separation effect, and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

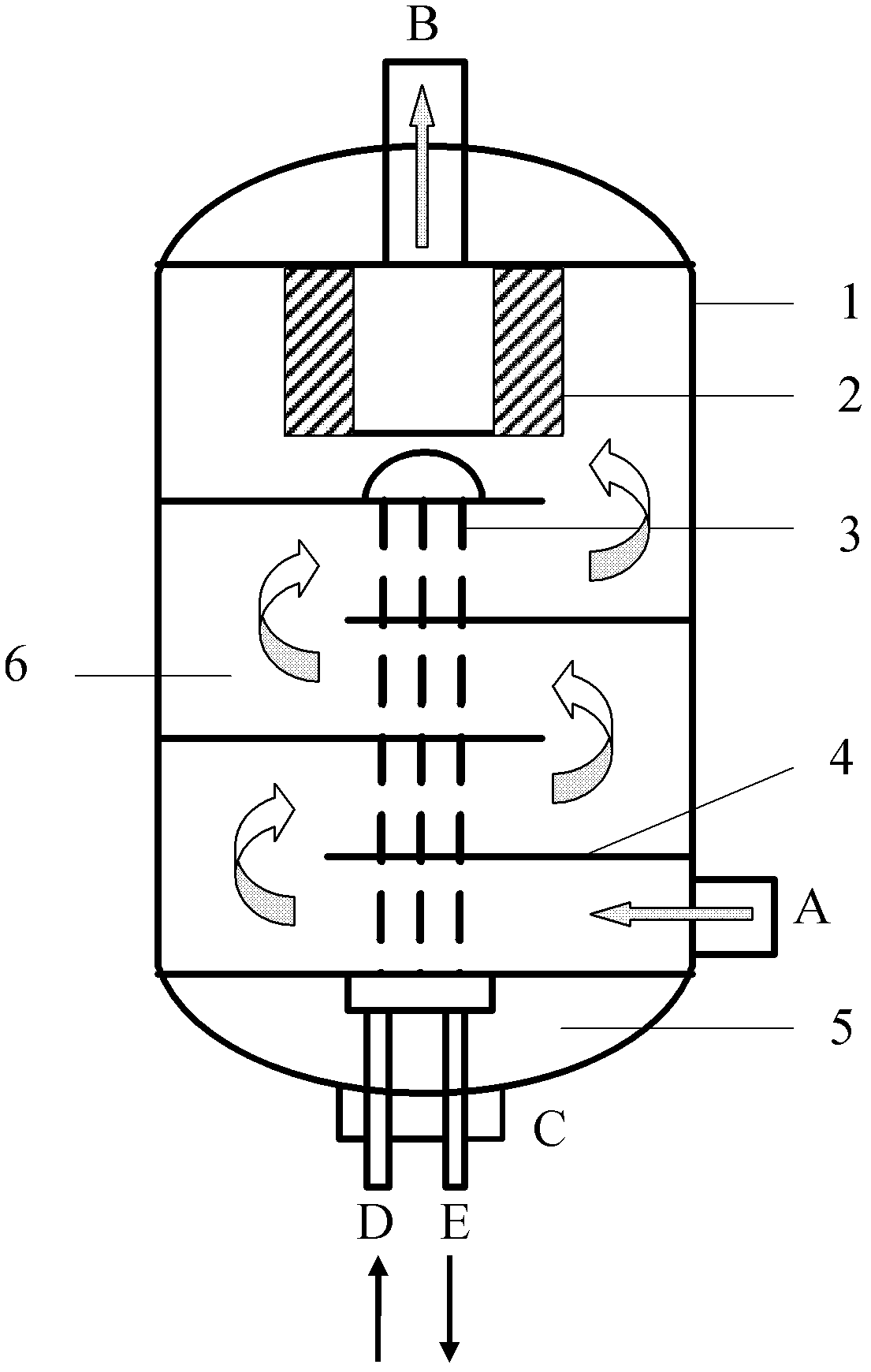

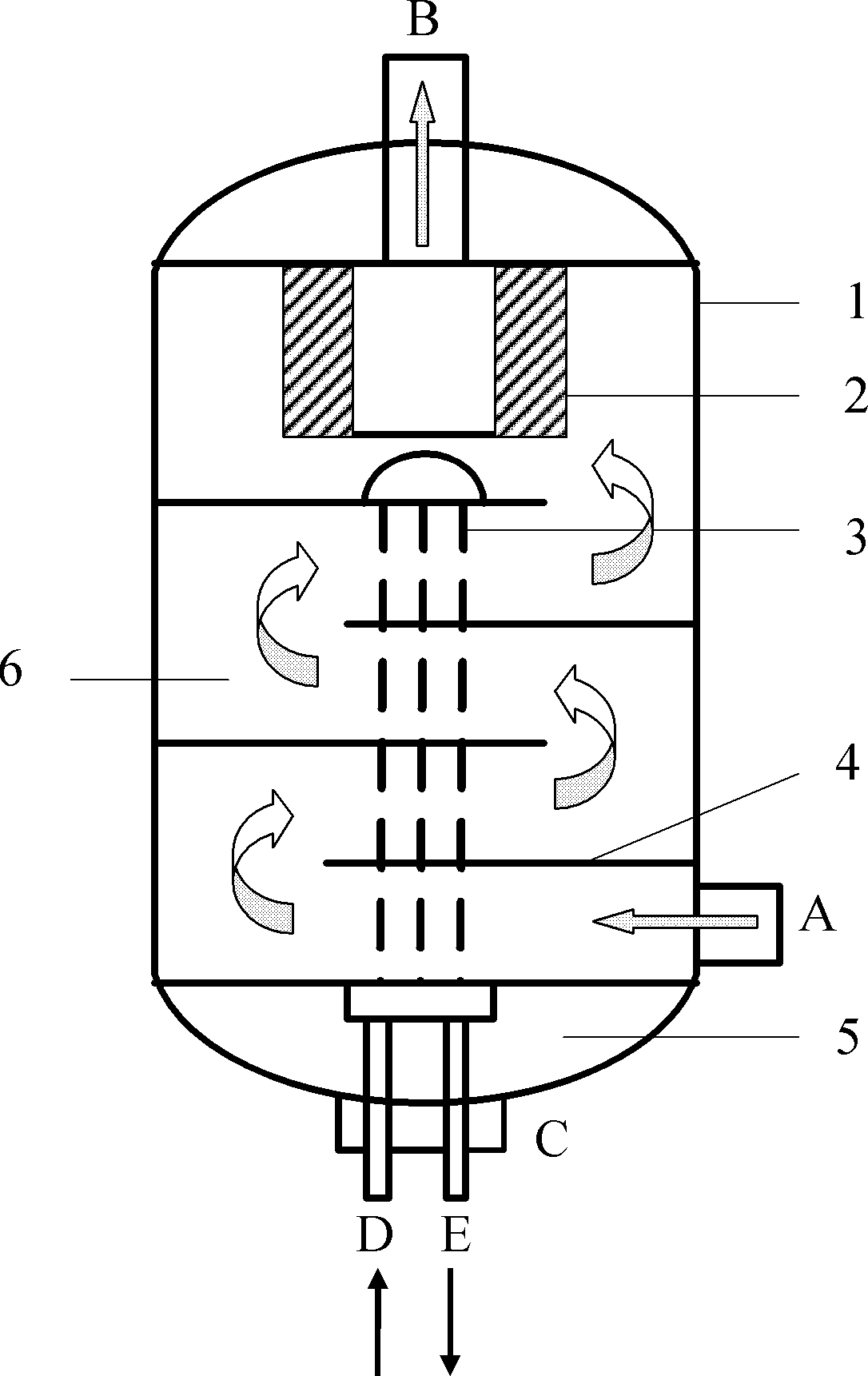

[0021] The upper and lower ends of the cylindrical separator housing 1 (with a diameter of 40 centimeters and a height of 1 meter) placed vertically in the axial direction of this embodiment are respectively equipped with a top cover and a bottom oil collection chamber 5; at the center of the lower end of the top cover A hollow annular adsorption filter 2 is installed, and the inner shell wall of the cylindrical separator housing 1 below the hollow annular adsorption filter 2 is equipped with 4 horizontal baffles 4 to prevent staggering, and the outer edges of the horizontal baffles 4 exceed all The radial center of the cylindrical separator housing 1; the cooling coil 3 penetrates through the lower end of the cylindrical separator housing 1 (or the bottom oil collection chamber 5), and then passes through the baffles from bottom to top in turn 4. After passing through the uppermost baffle plate, bend and pass through each baffle plate 4 from top to bottom in turn, and finally ...

Embodiment 2

[0025] The upper end face and the lower end face of the cylindrical separator housing 1 (diameter is 60 centimeters, height is 1.5 meters) of the axially vertical placement of present embodiment are respectively equipped with top cover and bottom oil collection cavity 5; Hollow top cover The lower end is equipped with a hollow annular adsorption filter 2, and 20 horizontal baffles 4 are installed on the inner shell wall of the cylindrical separator housing 1 below the hollow annular adsorption filter 2, and the outer edge of the horizontal baffle 4 exceeds the circle. The radial center of the cylindrical separator housing 1; the cooling coil 3 penetrates through the lower end of the cylindrical separator housing 1 (or the bottom oil collection chamber 5), and then passes through the baffles 4 from bottom to top in turn, After passing through the uppermost baffle plate, it is bent and passes through each baffle plate 4 from top to bottom in turn, and finally protrudes from the l...

Embodiment 3

[0027] This embodiment is basically the same, the difference is that there is one horizontal baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com