Chemical reactor

A reactor and chemical technology, which is applied in the field of reactors for the production of other compounds, can solve the problems of difficult and difficult sieve plates, and achieve the effect of taking into account the filtering effect, convenient processing and high load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

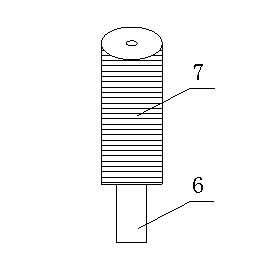

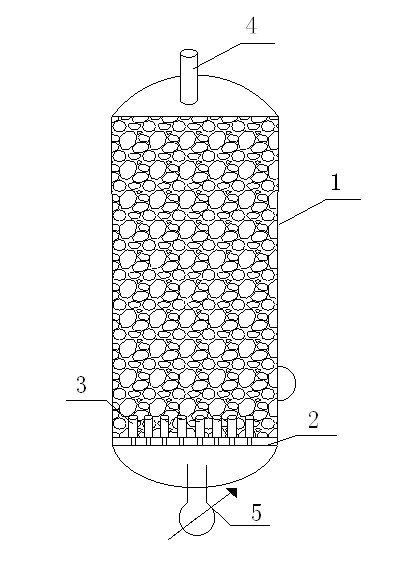

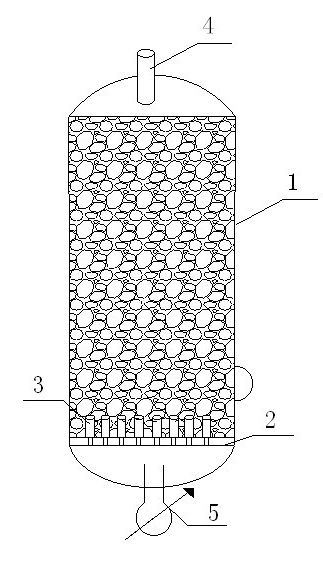

[0011] Such as figure 1 As shown, a kind of chemical reactor of the present invention comprises the reactor tank body 1 of bearing reactant and catalyst, and reactor tank body 1 top is provided with feed pipe 4, and the bottom has discharge pipe 5; The lower part of the inner cavity of the tank body 1 is provided with a catalyst / reactant separation device. The catalyst / reactant separation device includes a mounting plate 2, and mounting holes are arranged at intervals on the mounting plate 2, and water caps 3 are arranged in the mounting holes. Such as figure 2 , The water tap 3 includes a threaded pipe 6 matched with the installation hole, and a filter barrel 7 is installed on the top of the threaded pipe. The surface of the filter barrel 7 is a mesh structure with a gap smaller than the diameter of the catalyst.

[0012] This embodiment is a nonylphenol reactor. In this reactor, the resin catalyst is separated by the water cap 3 and the water cap mounting plate. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com