Linseed husk and kernel separation device

A separation device, linseed husk technology, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve the problems of general overall effect and complex structure, and achieve simple structure and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

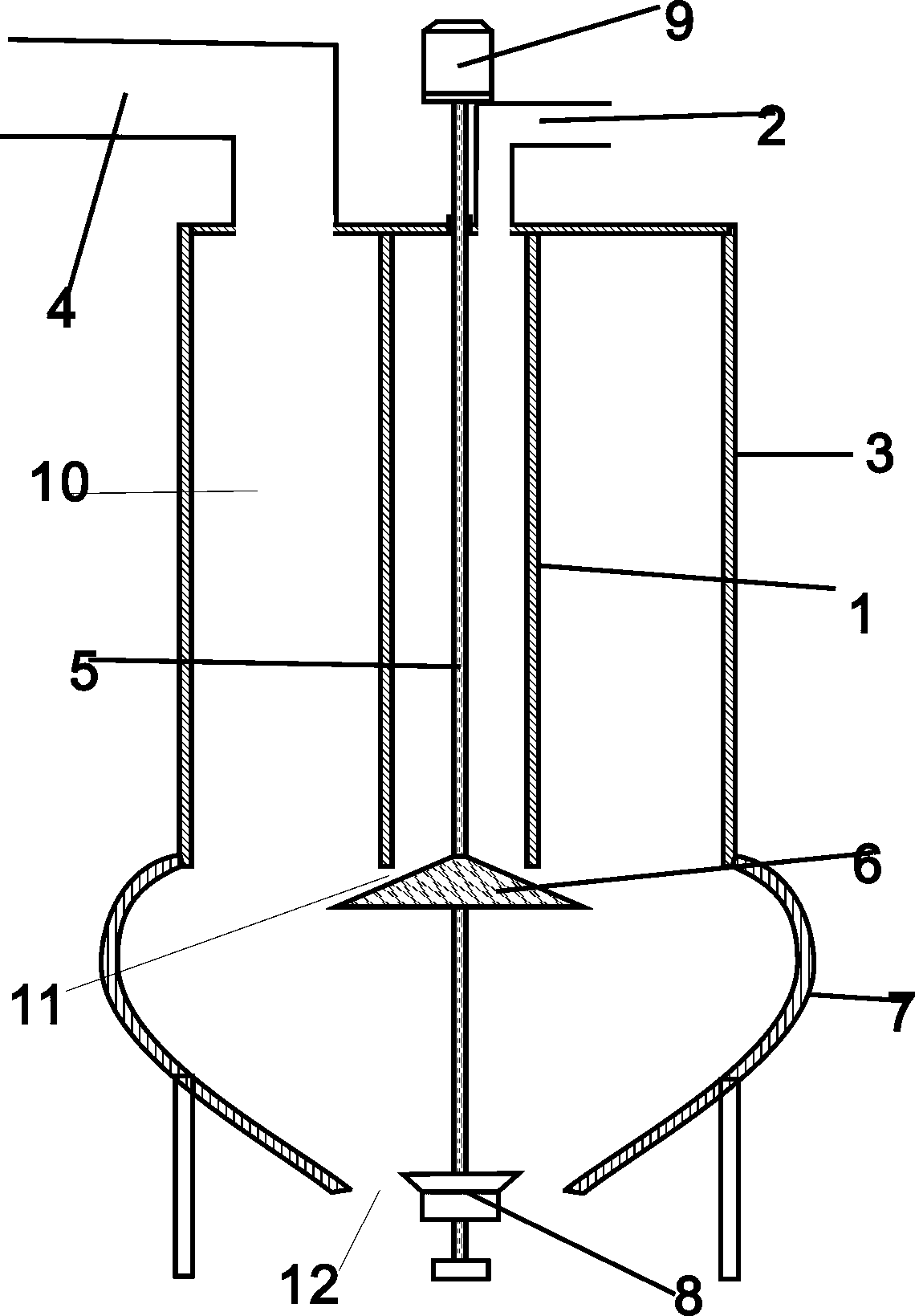

[0010] Linseed husk separation device, such as figure 1 As shown, it includes a vertically arranged feeding cylinder 1 with an open lower end, a feed inlet 2 is arranged on the top of the feeding cylinder 1, a rotating shaft 5 is longitudinally arranged along the axis of the feeding cylinder 1, and the rotating shaft 5 is advanced. A turntable 6 is fixed below the opening of the lower end of the material barrel 1, and a discharge gap 11 is formed between the turntable 6 and the lower end opening of the feeding barrel 1; The gap between forms a leather outlet 10, and a leather outlet 4 is provided on the upper part of the leather outlet 10 to connect with the exhaust fan; The protruding part 7 is located under the opening of the lower end of the feeding cylinder 1 . The upper surface of the turntable 6 is a conical surface. The taper of the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com