Patents

Literature

143 results about "Scale reading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CLPE Reading Scale Dependence to Independence. The Reading Scale describes the progression through the complex process of learning to read. It offers teachers ways of looking at and analysing their observations of children’s developing skills, knowledge and understanding of the reading process.

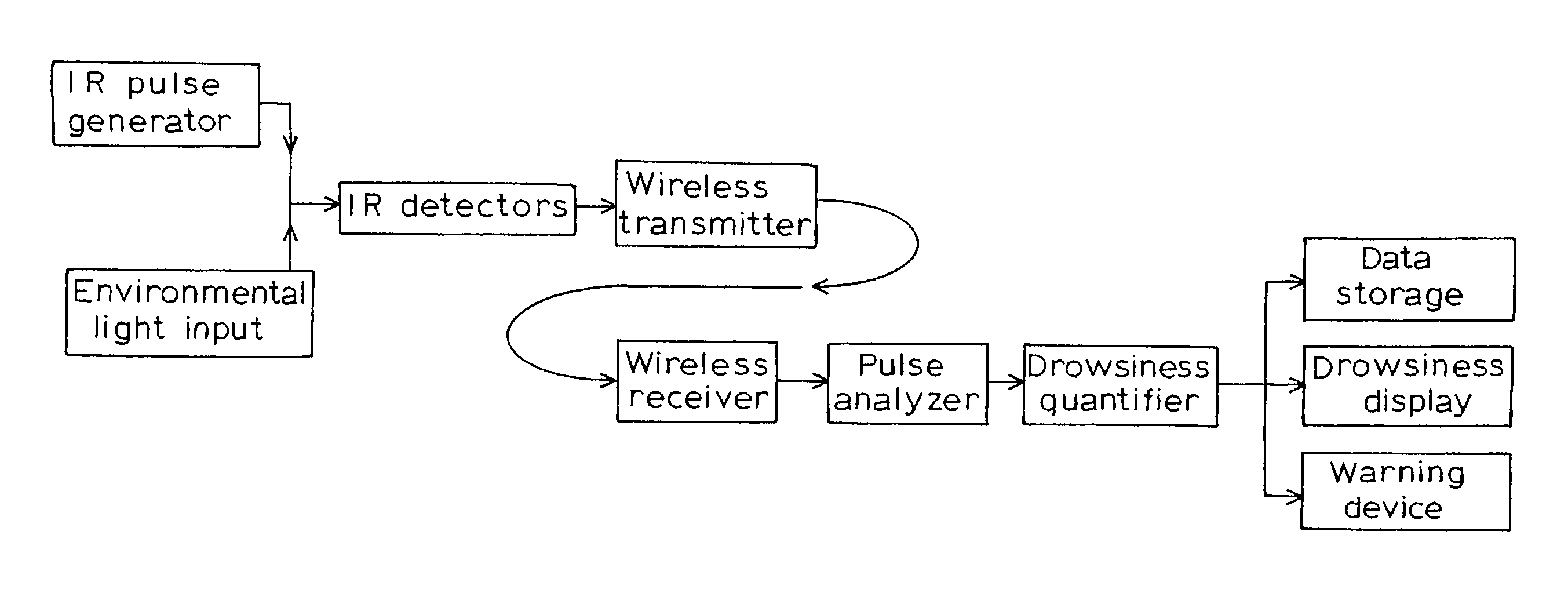

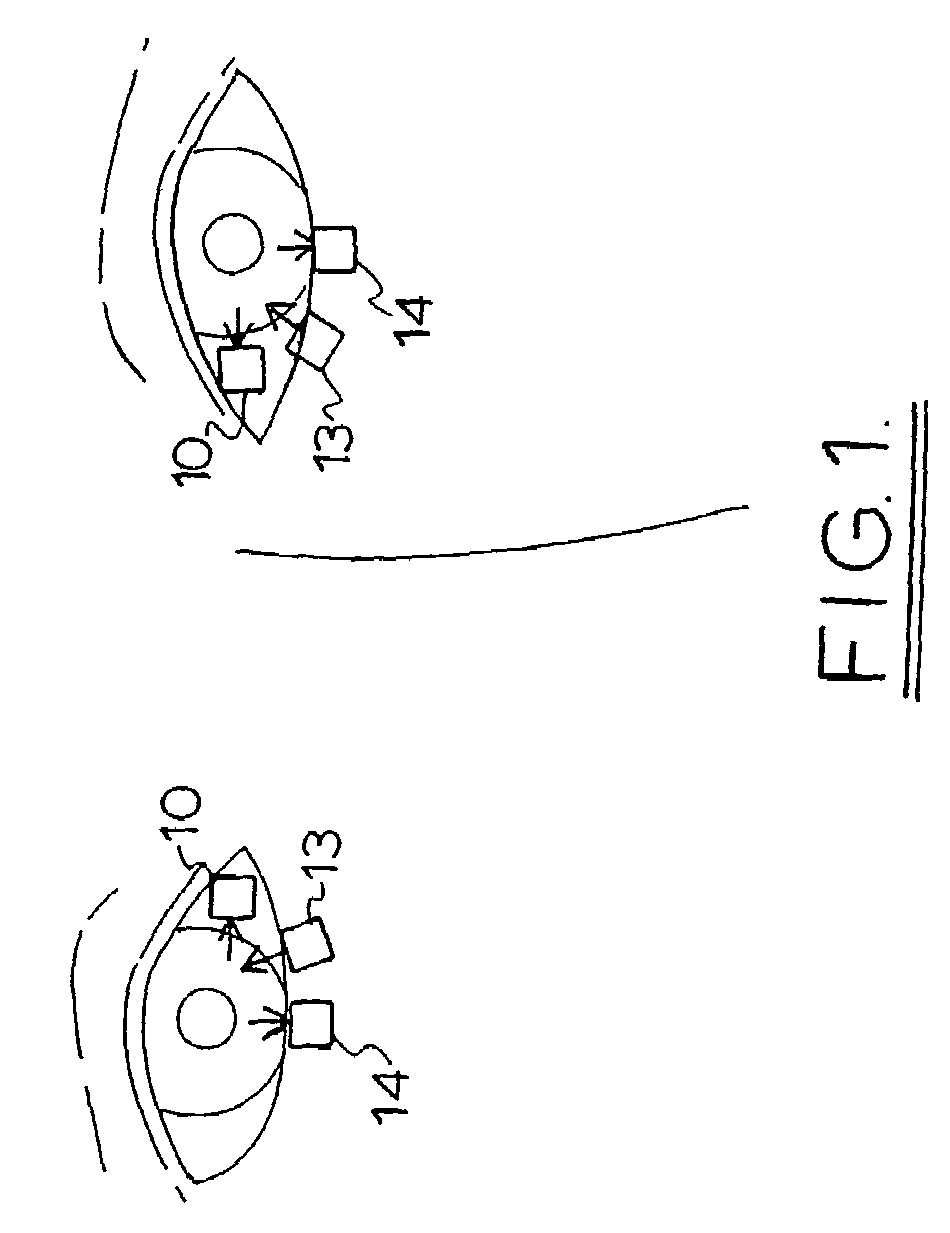

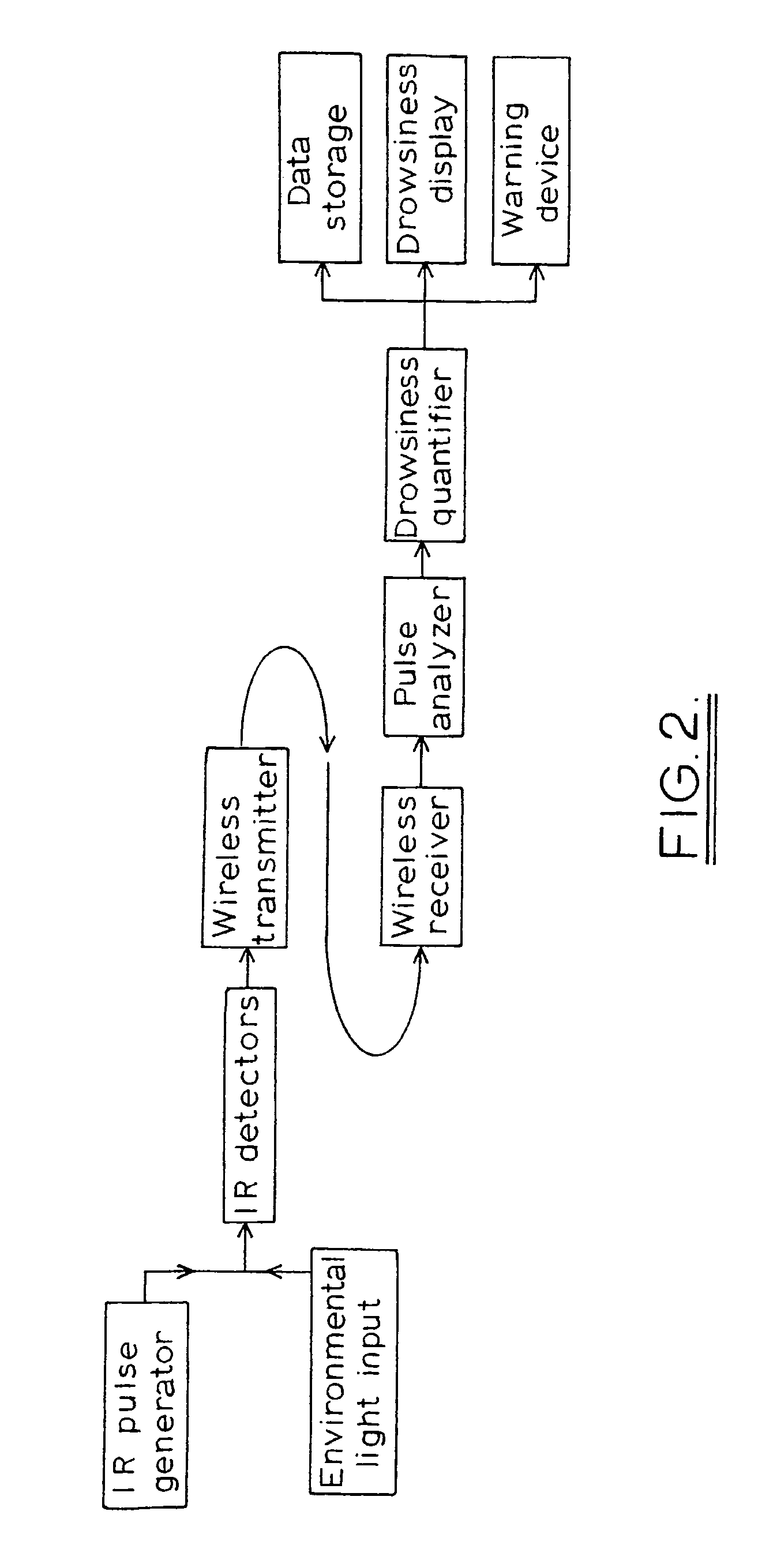

Alertness monitor

An alertness monitoring system includes: means to measure velocity and amplitude of eyelid and eye movement; and storage means to continuously record the measurements. A data processor calculates the blink amplitude to velocity ratio and / or the saccade amplitude to velocity ratio and compares the measurements against a predetermined scale. The scale is derived from averaged measurements of the eye and eyelid movement parameters for a sample population measured against predetermined incremental blood alcohol levels. The output of the system can include a display for showing the alertness measurement based on the scale, or an alarm means triggered by the scale reading reaching a predetermined limit based an the blood alcohol level scale.

Owner:SDIP HLDG

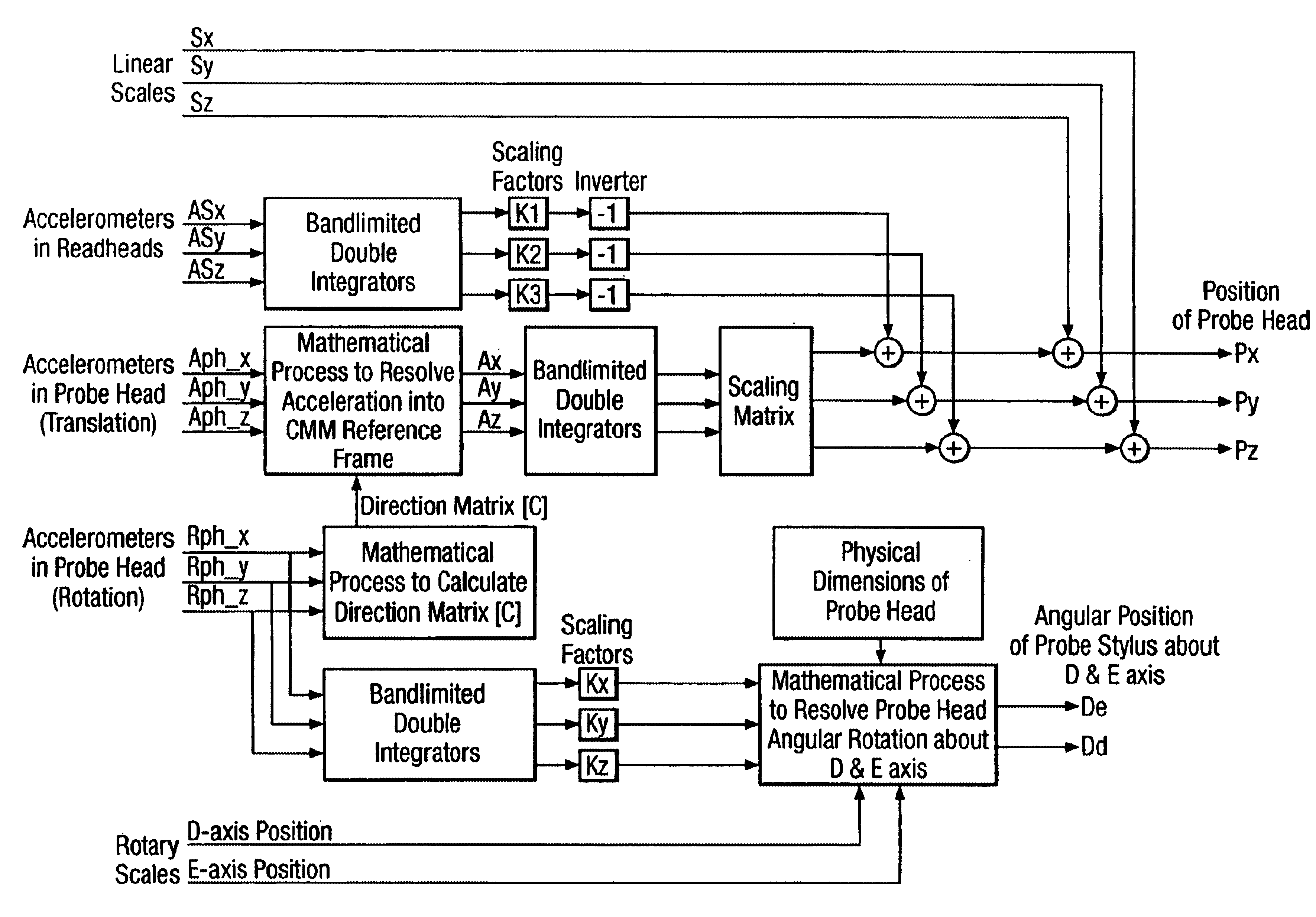

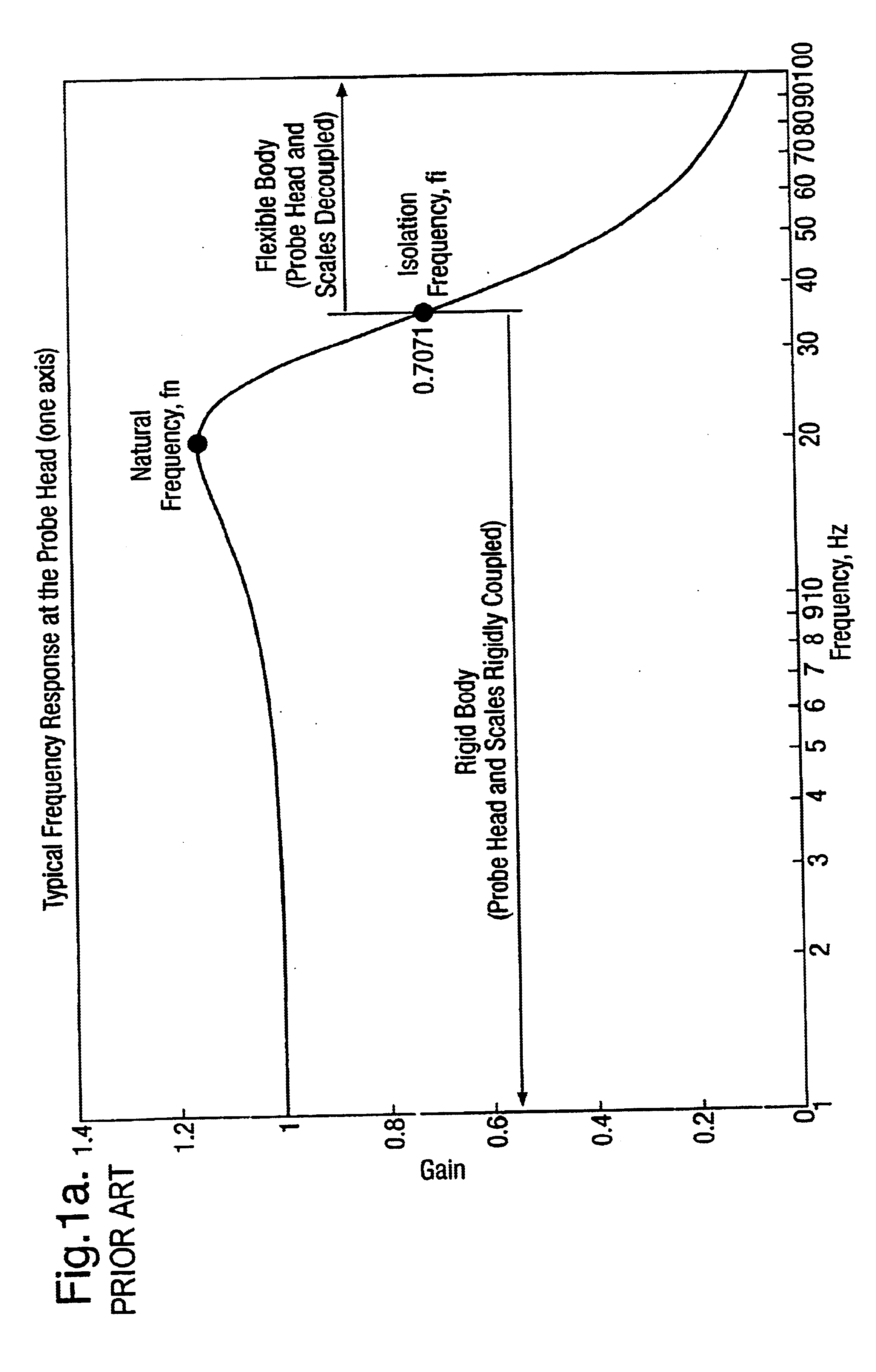

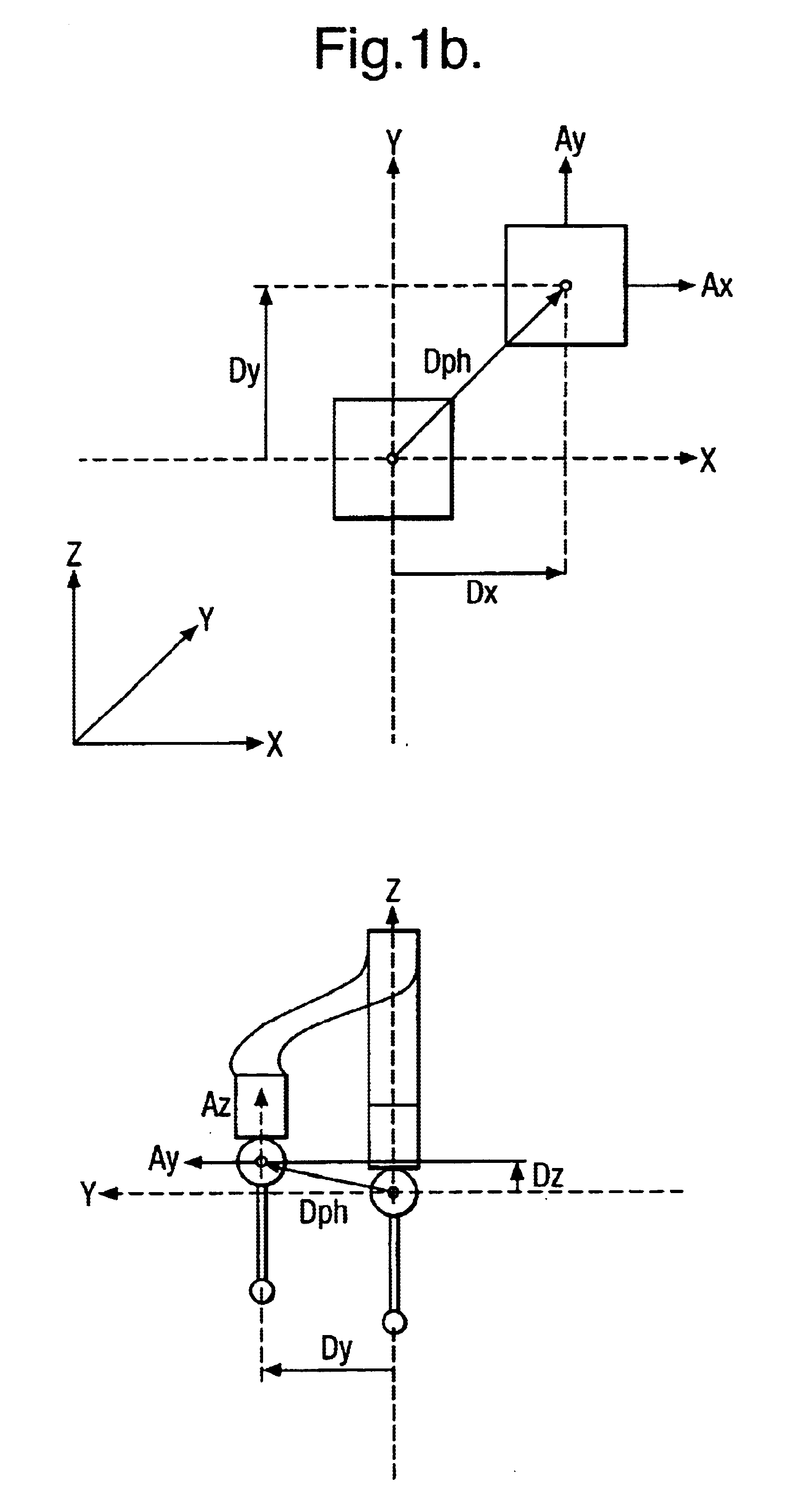

Method of and apparatus for correction of coordinate measurement errors due to vibrations in coordinate measuring machines (cmms)

InactiveUS6868356B2Acceleration measurement using interia forcesDigital computer detailsObservational errorAccelerometer

Accelerations of a probe or probe head due to vibrations of a machine during a measuring operation are measured using accelerometers placed in the probe or probe head. The acceleration signals are double integrated to determine the corresponding displacements of the probe or probe head and these are added to the readings of displacement of the machine taken from the machine scales using a data fusion algorithm to correct the scale readings for the vibration of the probe. Both linear and angular accelerations of the probe can be corrected in this way.

Owner:RENISHAW PLC

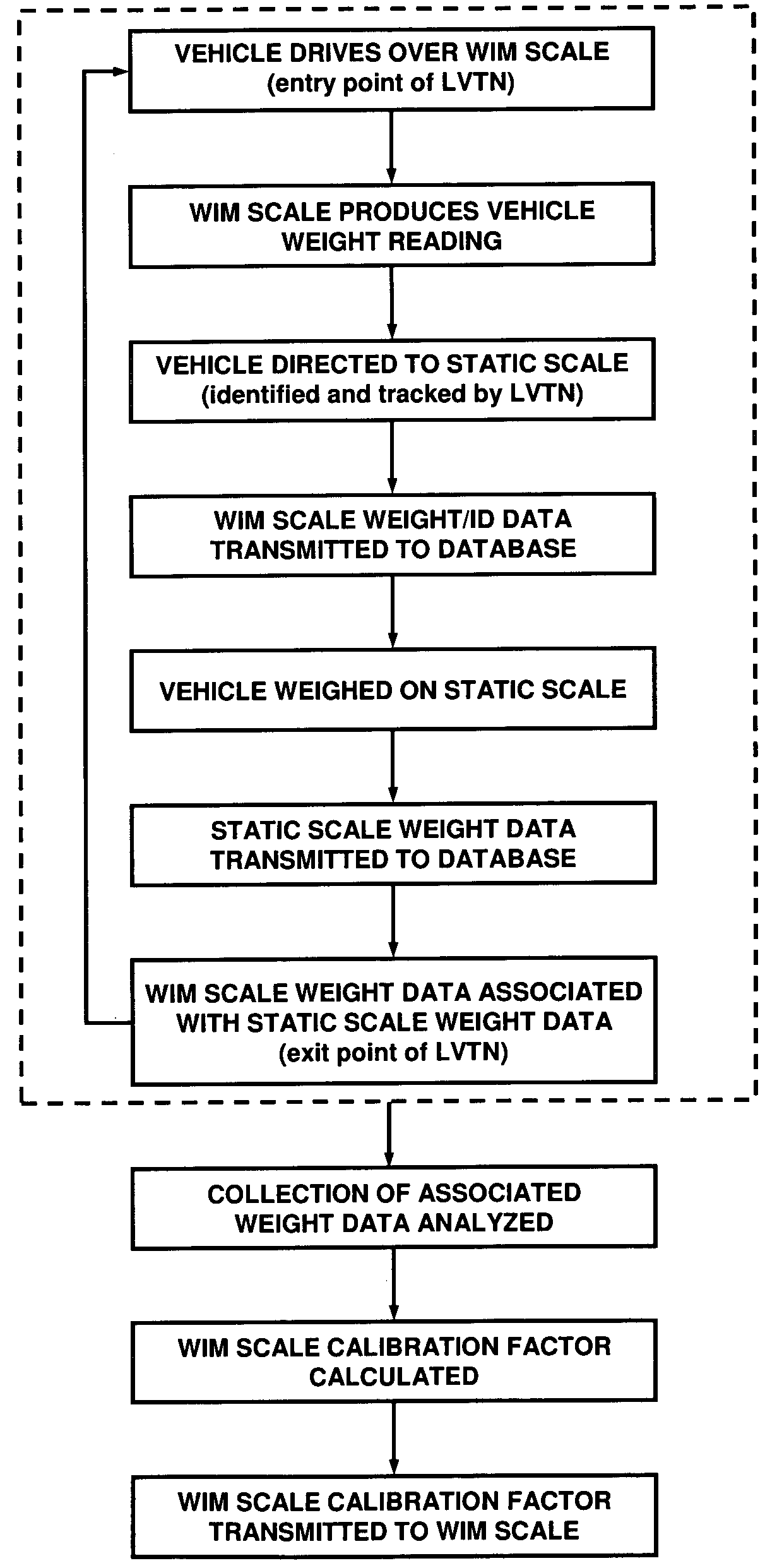

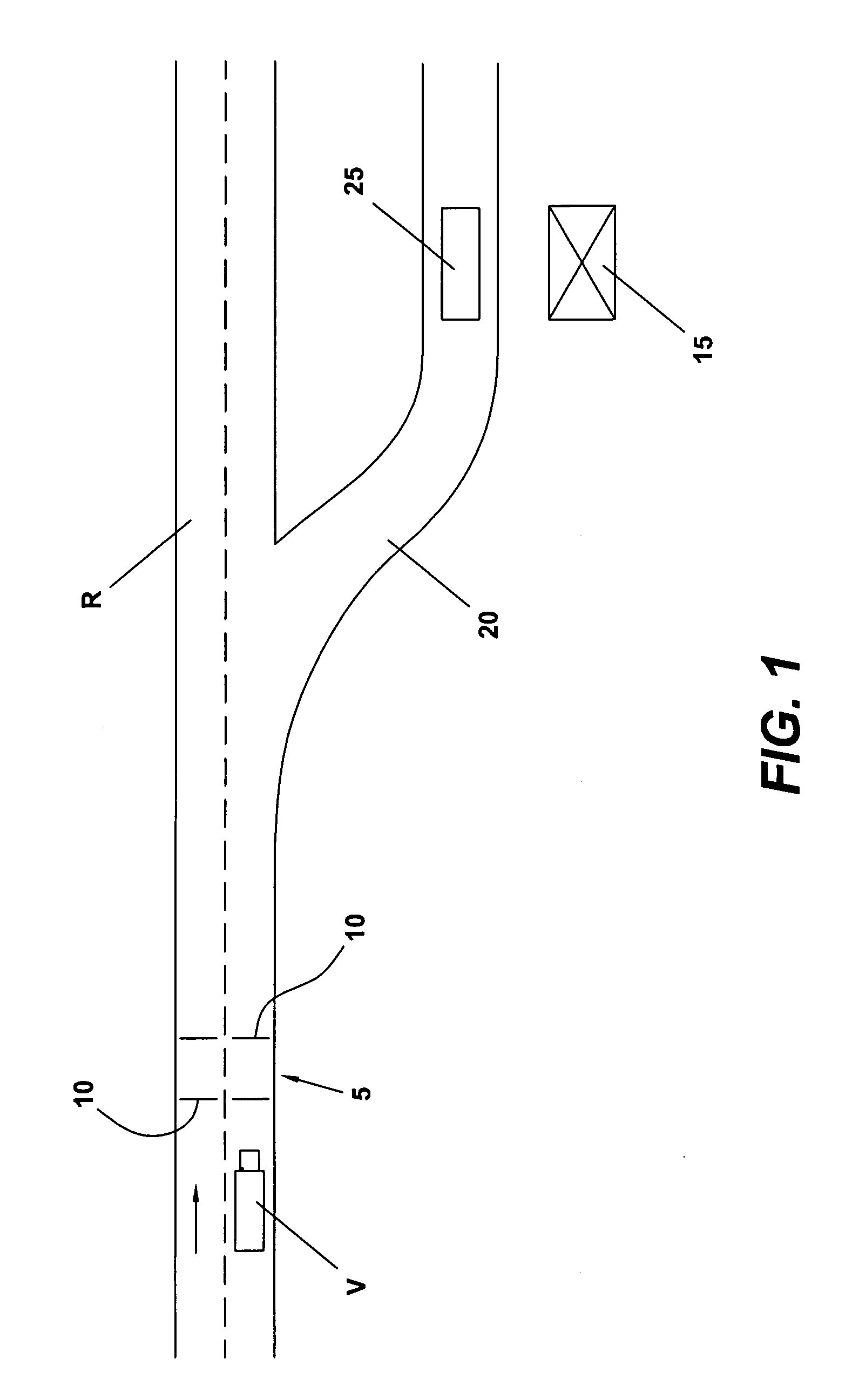

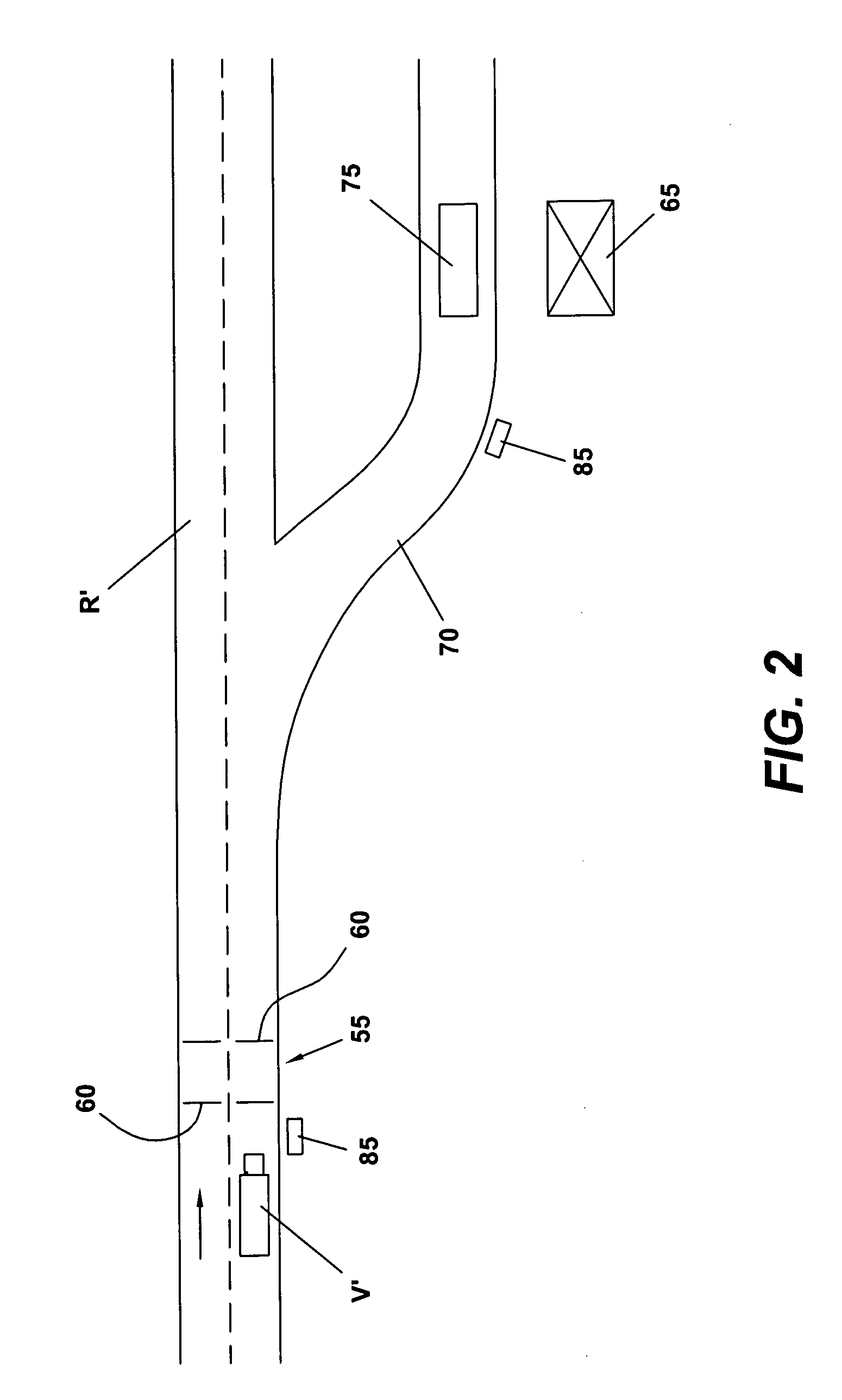

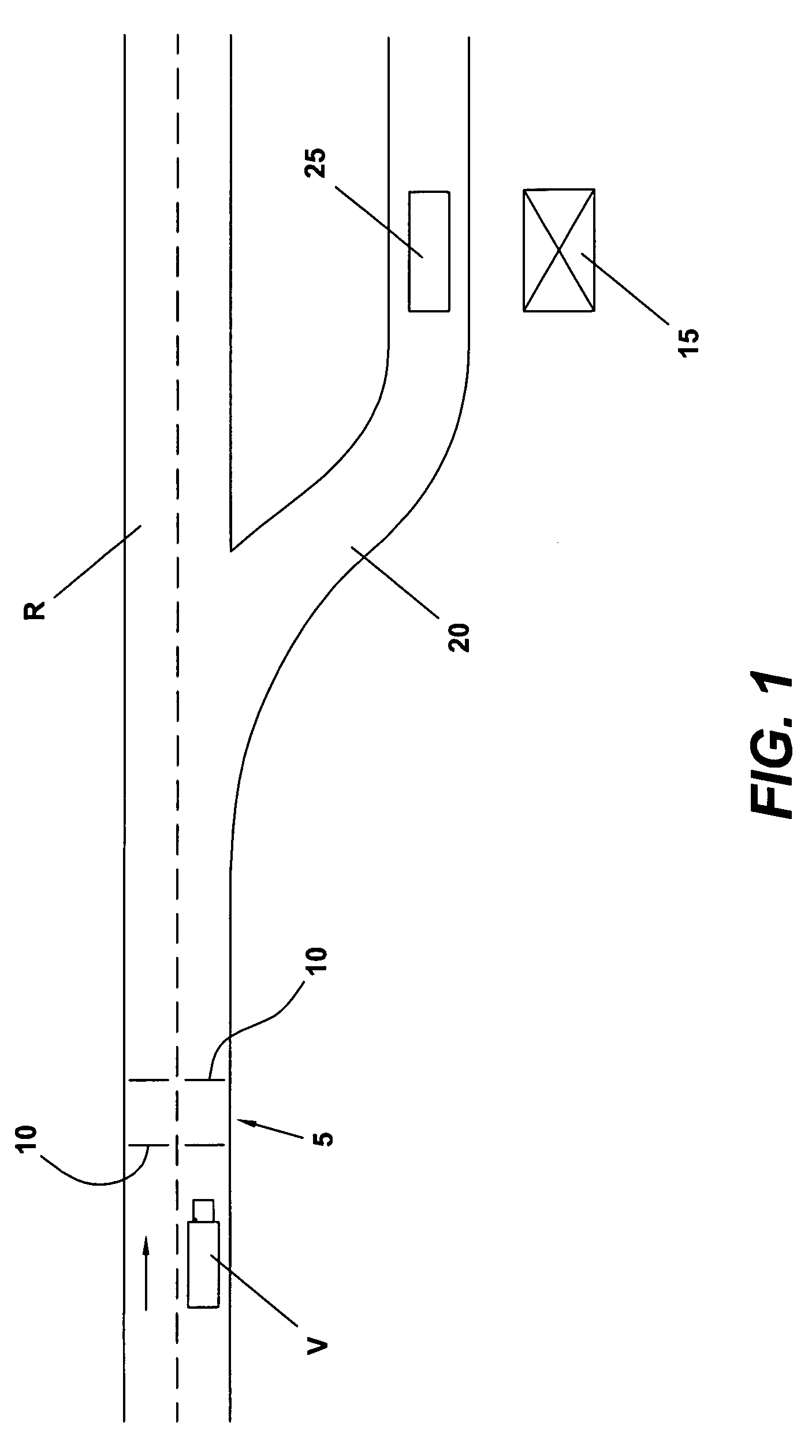

Weigh-in-motion system with auto-calibration

ActiveUS20090151421A1Accurate readingWeighing apparatus testing/calibrationSpecial data processing applicationsMobile vehicleComputer science

Weigh-in-motion (WIM) systems for weighing moving vehicles, the systems having the ability to automatically determine and periodically apply calibration factors to WIM scale readings. Auto-calibration may include transferring both WIM and static weight readings for the same vehicle to a database, associating the weight readings, collecting a number of such weight readings, and analyzing the differences between the WIM and static weight readings to calculate WIM scale calibration factors. The calibration factors may be based on vehicle characteristics such as vehicle weight, vehicle class and / or vehicle speed at the WIM scale.

Owner:METTLER TOLEDO INC

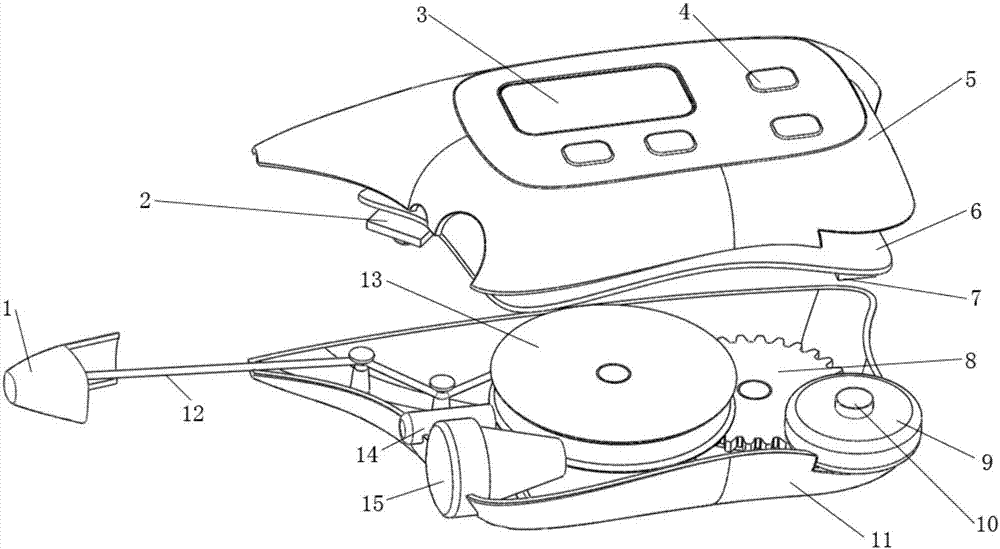

Vision-based pointer instrument automatic reading system and method

InactiveCN105550683AFree laborImprove work efficiencyCharacter and pattern recognitionHough transformVision based

The invention discloses a vision-based pointer instrument automatic reading system and method. The system comprises: a circle center acquiring module used for acquiring image data of a pointer instrument and searching for the center of a circle of the pointer instrument in the image data; a pointer acquiring module used for extracting pointers of the pointer instrument through a Houghline function of Hough transform; a dial acquiring module used for extraction of a dial of the pointer instrument, extraction of the dial is determined according to image color information, and an optimal threshold value of color is determined by use of values of RGB, thereby extracting the dial of the pointer instrument; and a scale reading module used for calculating and reading an indicated number through the acquired pointers of the pointer instrument and the dial of the pointer instrument. Readings are directly obtained according to processing of an algorithm and are transmitted to a command center, and the command center can observe whether the instrument works normally according to the data, which is convenient and rapid.

Owner:CHONGQING UNIV

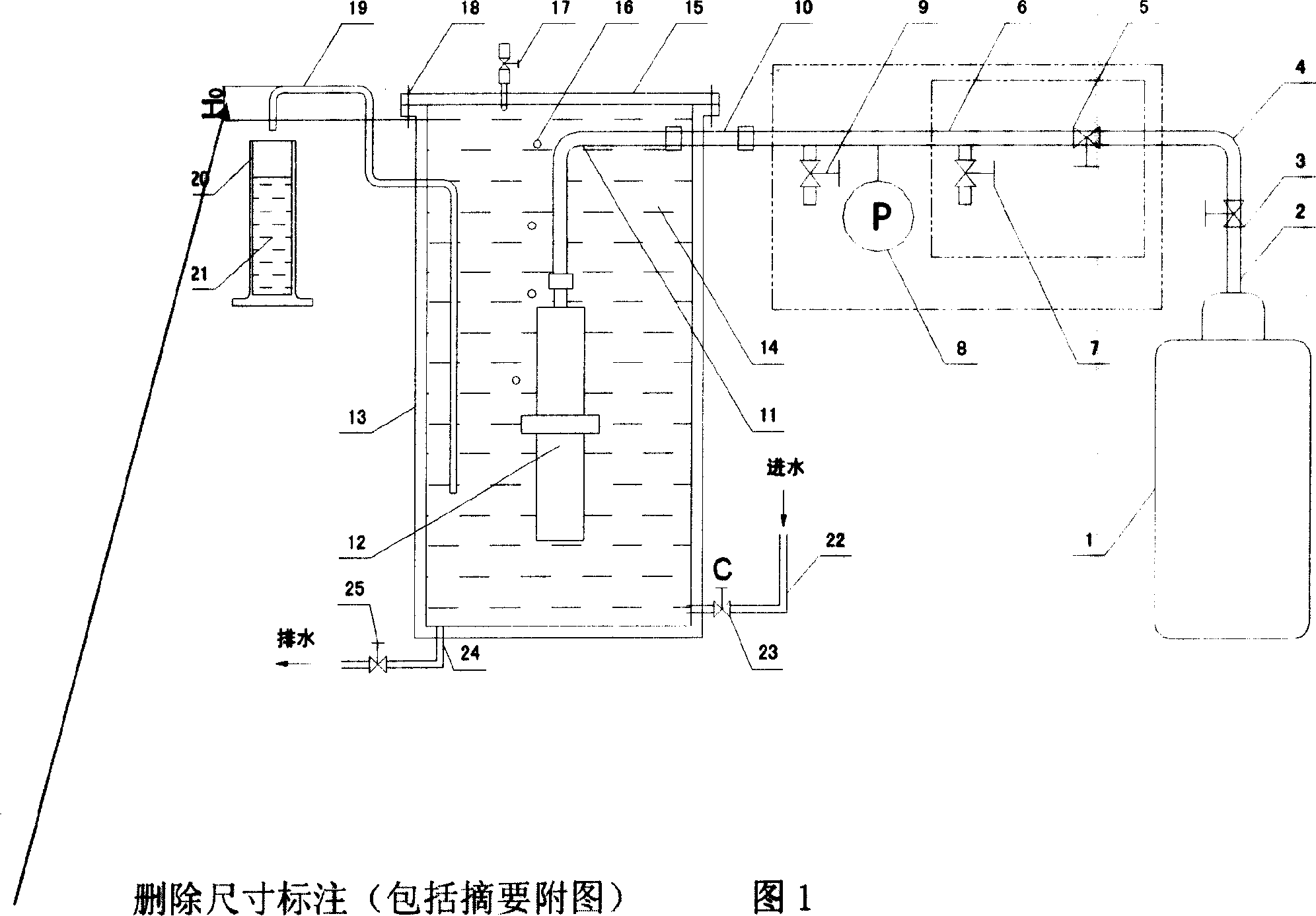

Airtight type tested pieces air-leakage detecting device

ActiveCN1932464AThe collection method is scientific and reliableEnsure consistencyDetection of fluid at leakage pointVolume measurement apparatus/methodsAir compressionWater storage

The invention discloses a detecting device for the leakage of gas-tight test piece including the aqua storage tank of the watertight test piece and the air compressing device to fill the pressure to the gas-tight test piece and the measuring cup to collect the leaking gas. The aqua storage tank is connected with the test piece inside and the conduit of the air compressing device in outside which is installed with the stabilizing voltage device. The water storage vessel has a flooding pipe connected to the out and a measuring cup. The invention transforms the reverse scale reading of the original air volume to the forward scale reading of the liquid volume by the liquid drained by leaking gas of the closed test piece. Therefore, it can assure the coherence of the reading and the fact leaking quantity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

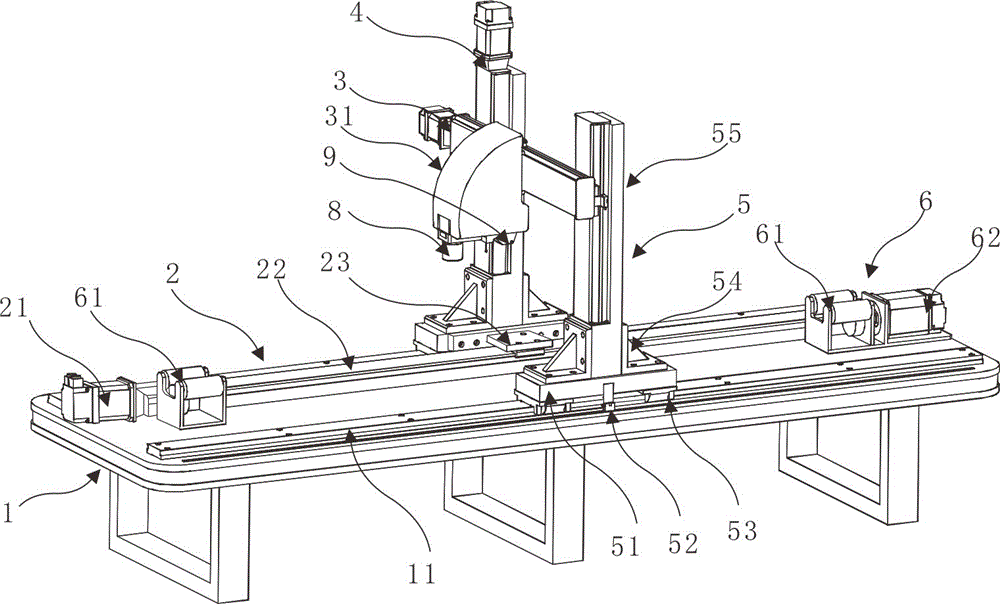

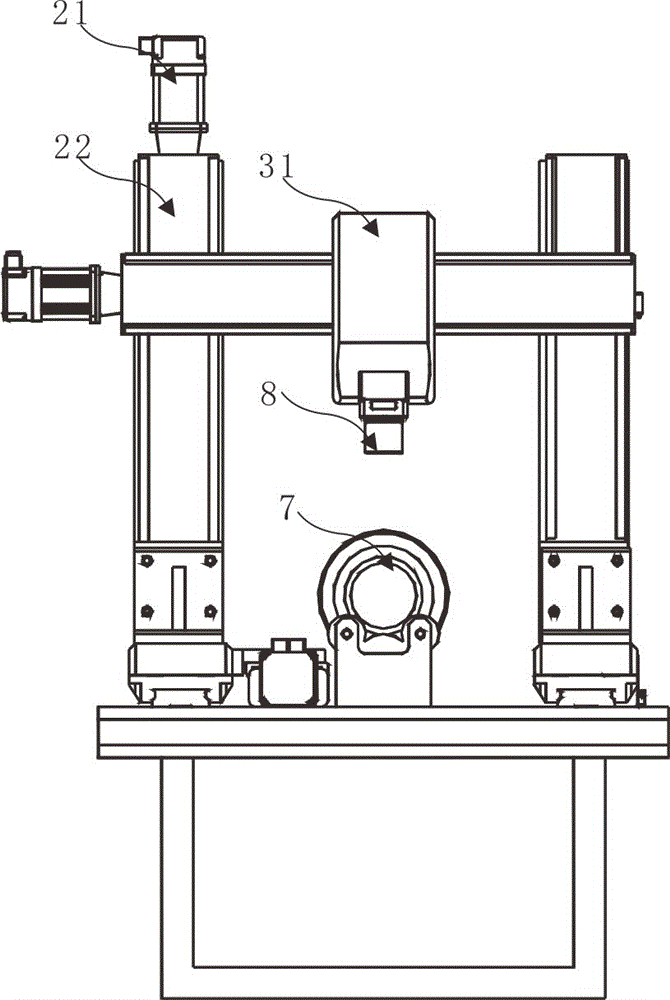

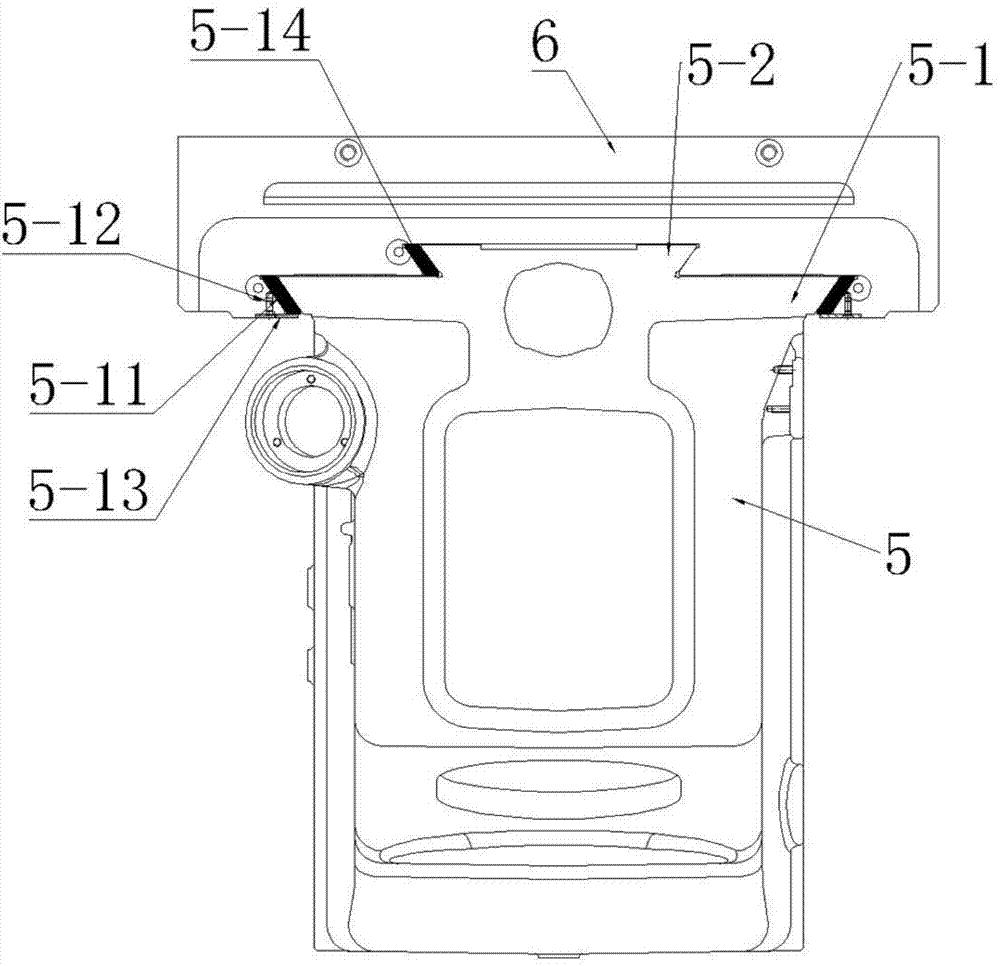

Analytic apparatus of surface profile damage of curve-surface parts and method thereof

ActiveCN106066333AAutomatic and accurate collectionMaterial analysis by optical meansUsing optical meansBall screwMechanical engineering

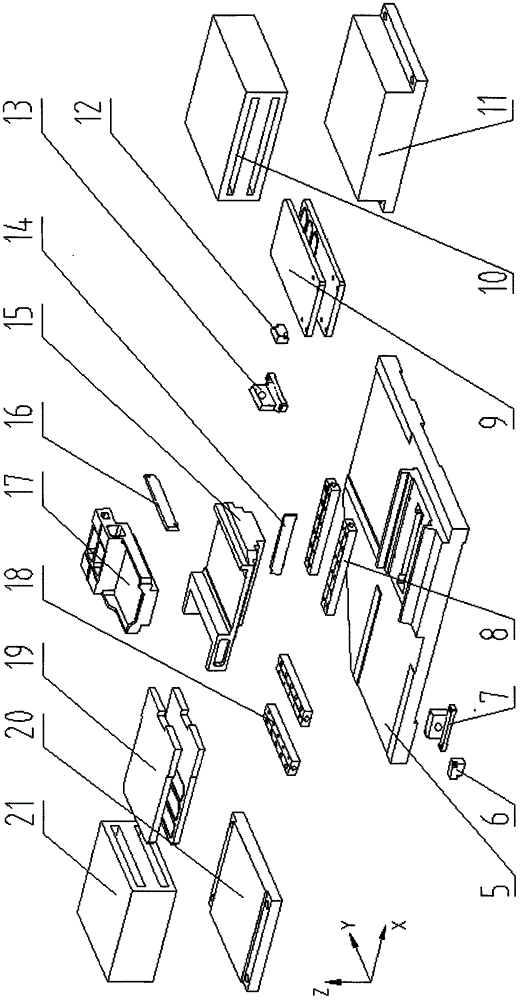

The invention discloses an analytic apparatus of surface profile damage of curve-surface parts and a method thereof. The analytic apparatus comprises a shake-proof bench on which an X-axis ball screw module, at least one slide rail and a rotary apparatus for driving the curve-surface parts to rotate are arranged. A Z-axis vertical column apparatus is movably arranged on the slide rail. A Z-axis vertical ball screw module is fixedly on the Z-axis vertical column apparatus. A Y-axis ball screw module is arranged on the Z-axis vertical ball screw module. A magnetic grid ruler, which is matched with a magnetic grid ruler scale reading head that is installed on each of the X-axis, Y-axis and Z-axis vertical ball screw modules, is arranged on each of the X-axis, Y-axis and Z-axis vertical ball screw modules. The Y-axis ball screw module is provided with a CCD image sensor and a laser 2D profile collection instrument; the CCD image sensor, the laser 2D profile collection instrument and the magnetic grid ruler scale reading heads are all connected to a detection module. The X-axis, Y-axis and Z-axis vertical ball screw modules and the rotary apparatus are all connected to a control module.

Owner:SOUTHWEST JIAOTONG UNIV

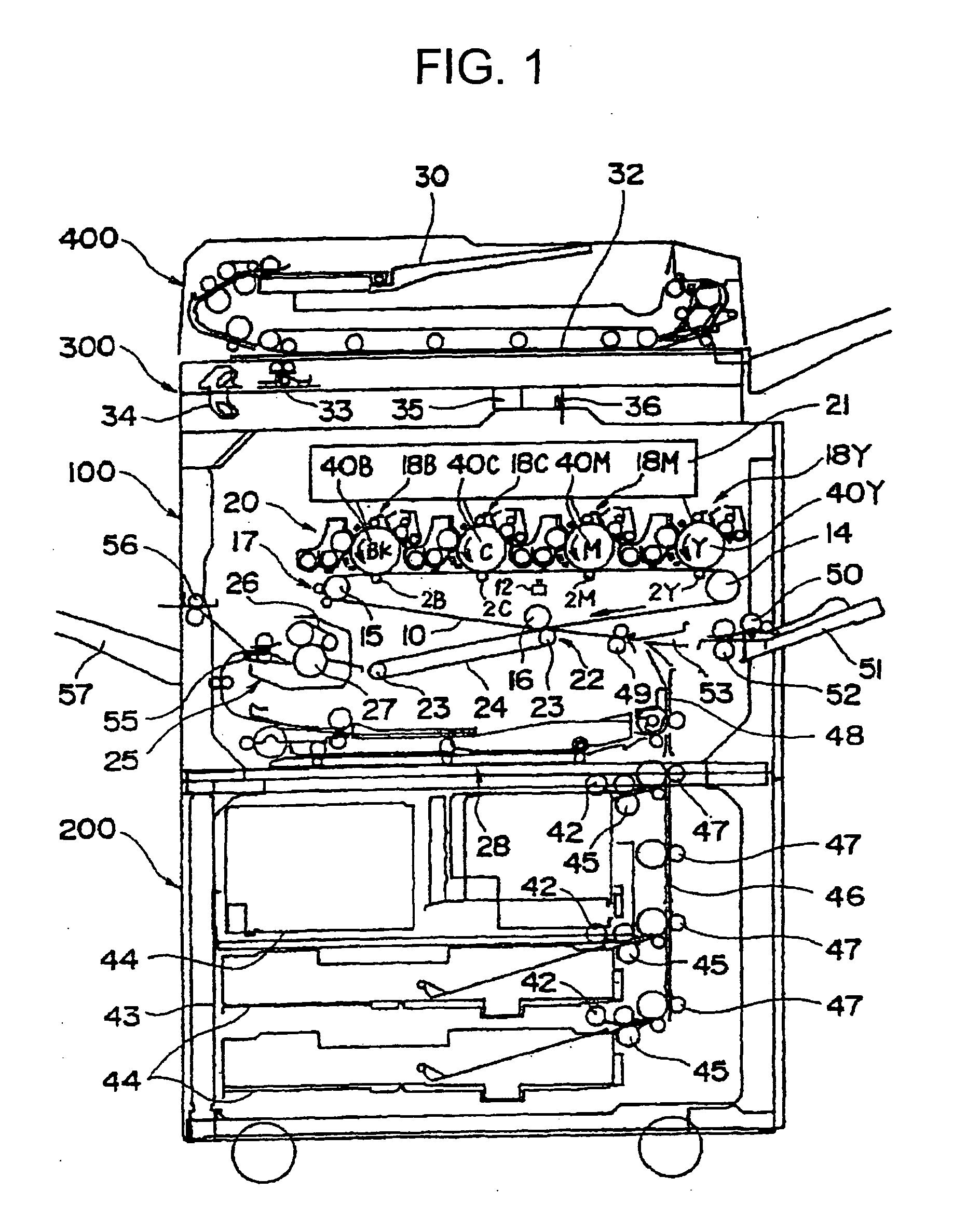

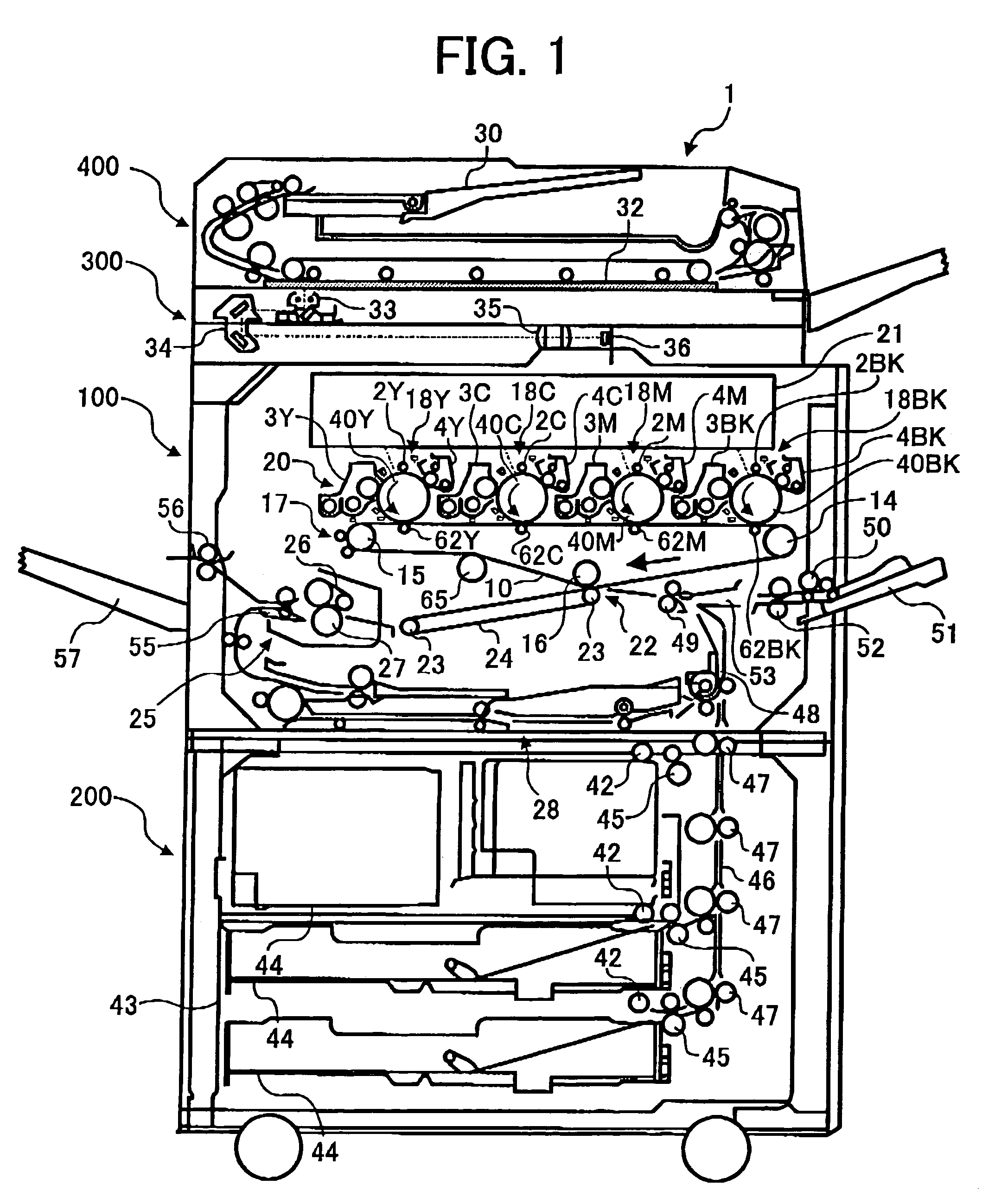

Image forming apparatus

ActiveUS20040114951A1Solve problemsElectrographic process apparatusArticle feedersImage formationEngineering

Owner:RICOH KK

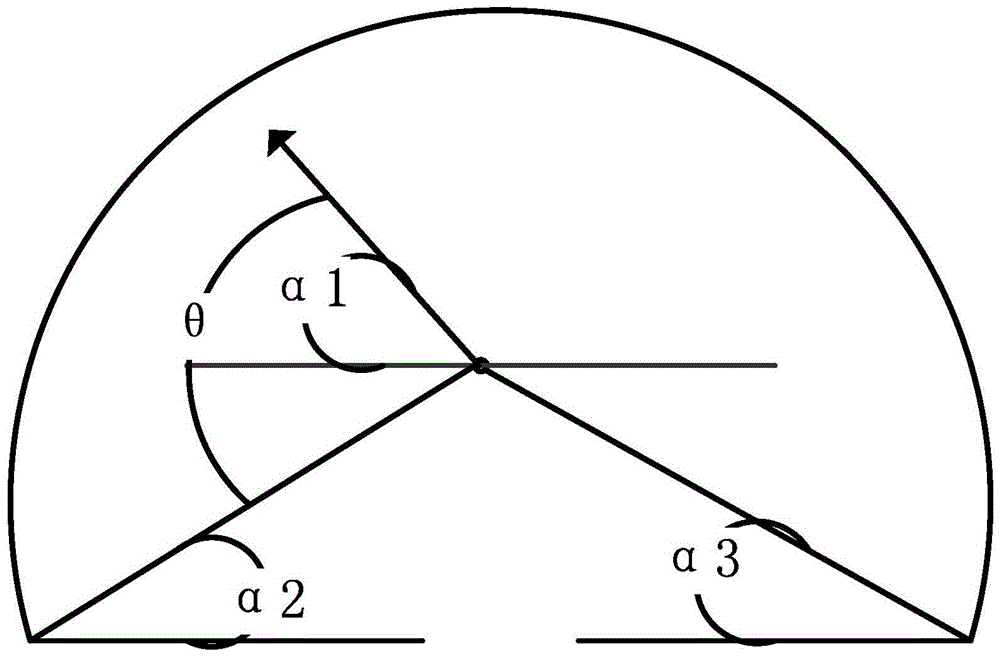

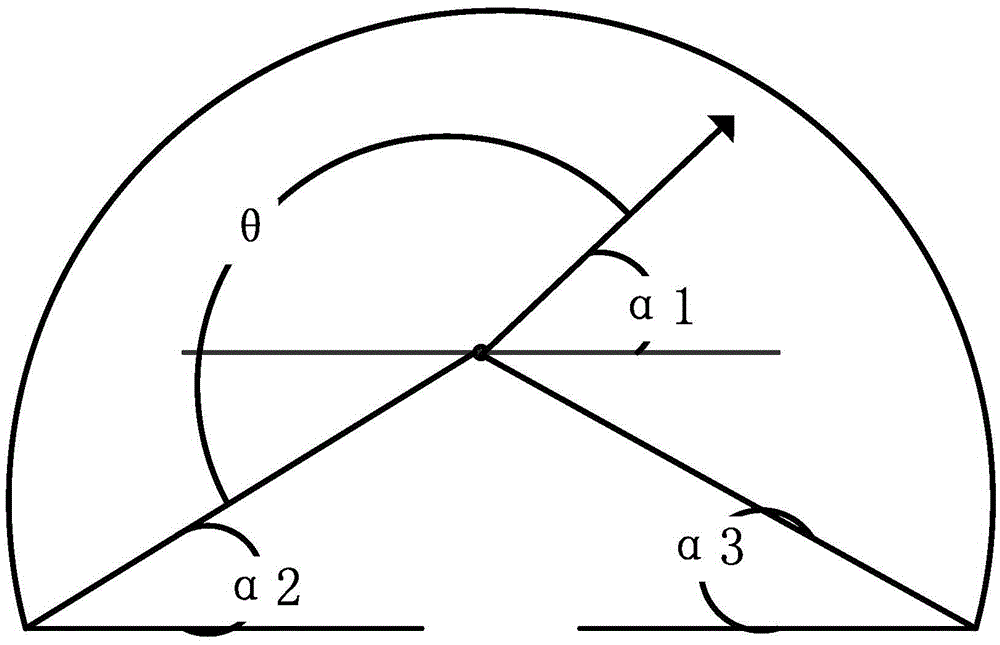

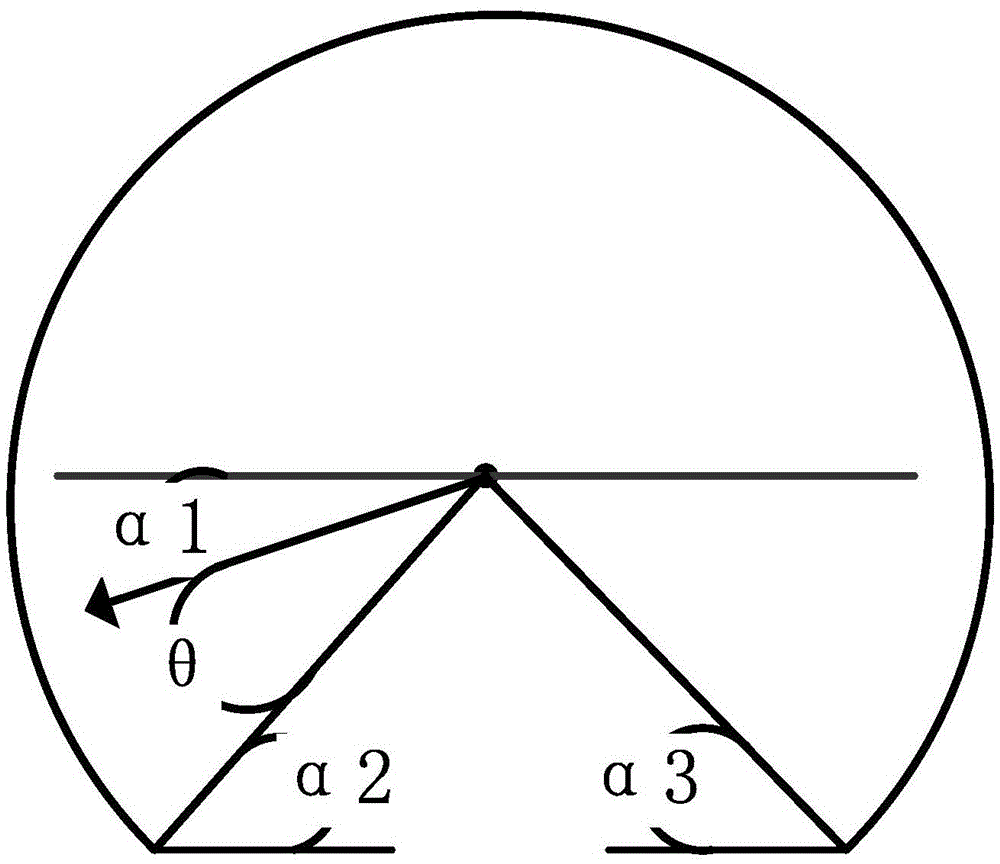

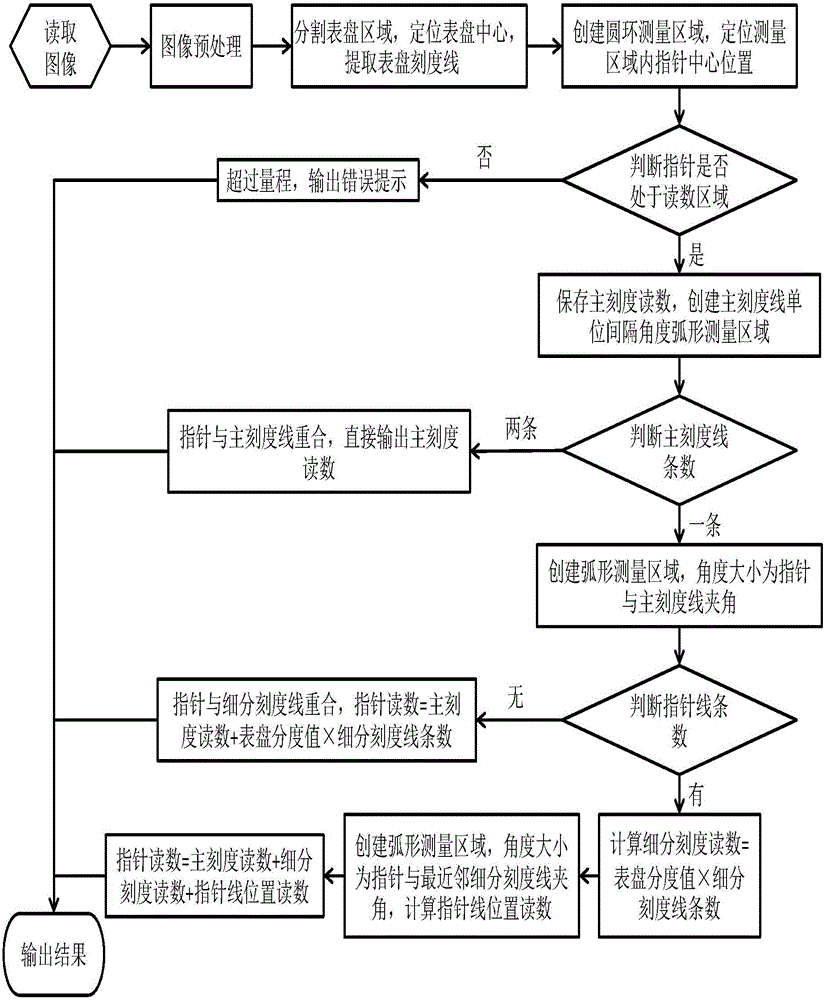

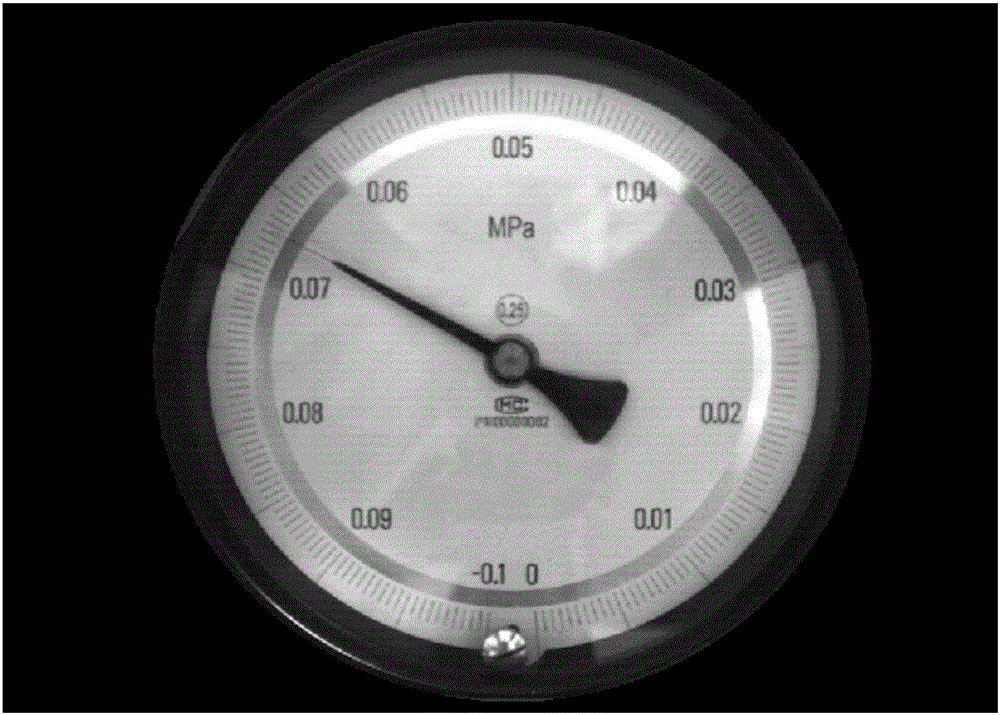

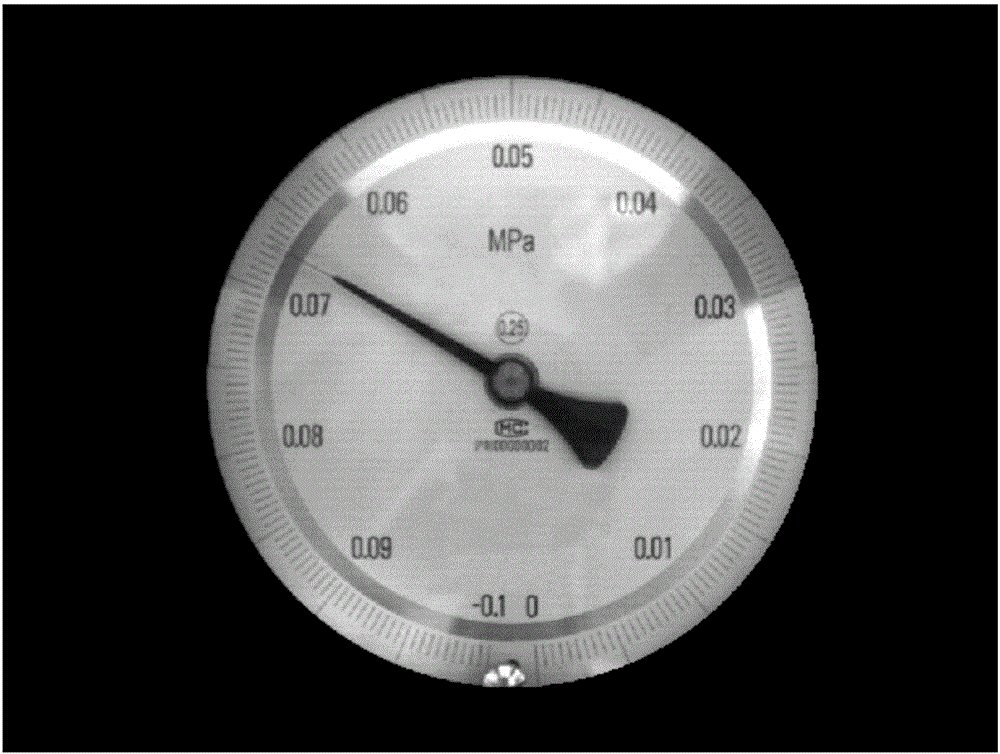

Method for automatically identifying reading of pointer type pressure meter

InactiveCN105741307AImprove the accuracy of automatic identificationIncrease contrastImage enhancementImage analysisImage contrastComputer science

The invention discloses a method for automatically identifying reading of a pointer type pressure meter, comprising steps of collecting a pressure meter dial image through an industrial camera, performing pre-processing on the image, enhancing the image contrast, reducing noise, improving the accuracy of automatic identification by the pressure meter in the later stage, performing segmentation on the dial zone, enabling each zone to correspond to the main scale reading; determining the position condition of the pointer between the scale lines;and separately calculating the main scale, the subdivision scale and the pointer line position reading so as to obtain the final reading of the pointer. The method is simple in algorithm principle, good in robustness and high in identification accuracy and can be widely applied in the instrument calibration technology.

Owner:SHENZHEN YUANQI INTELLIGENT TECH CO LTD

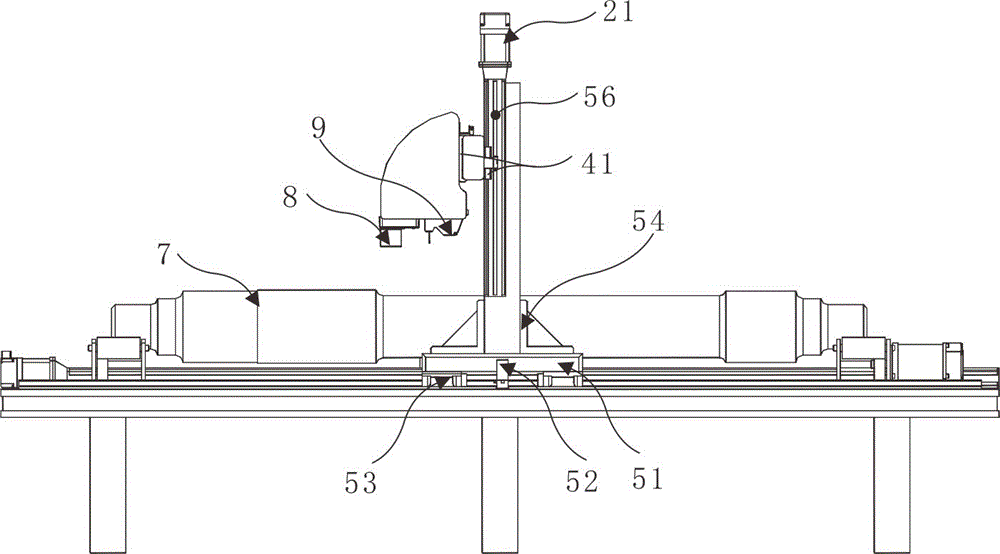

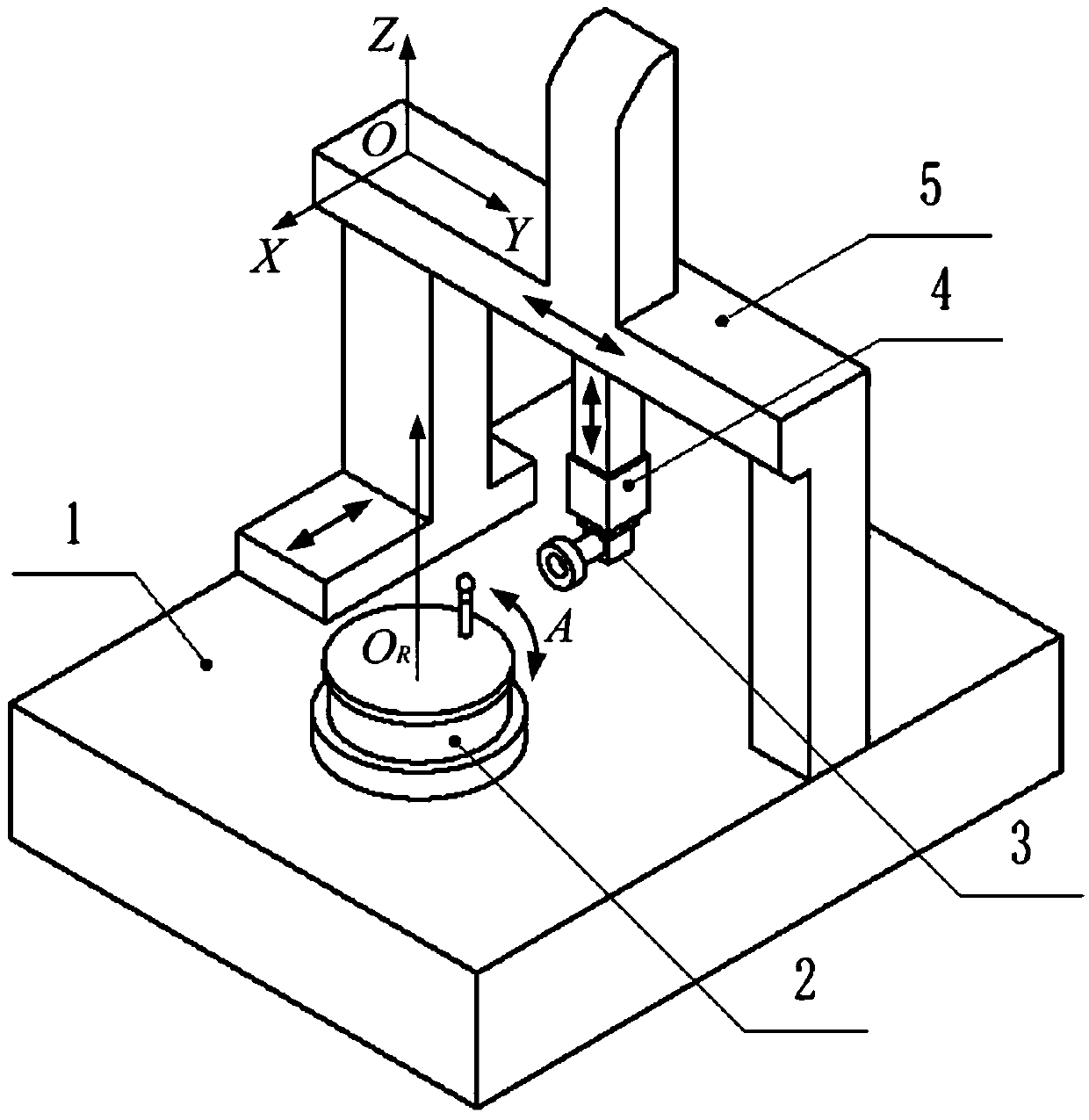

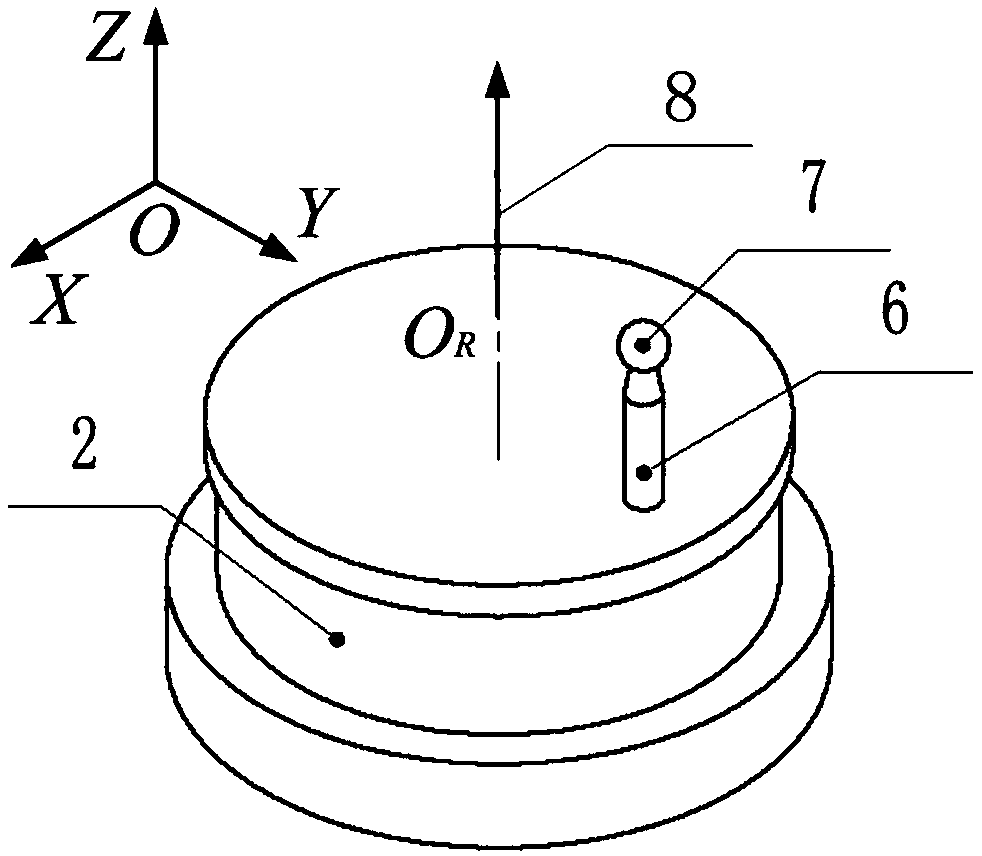

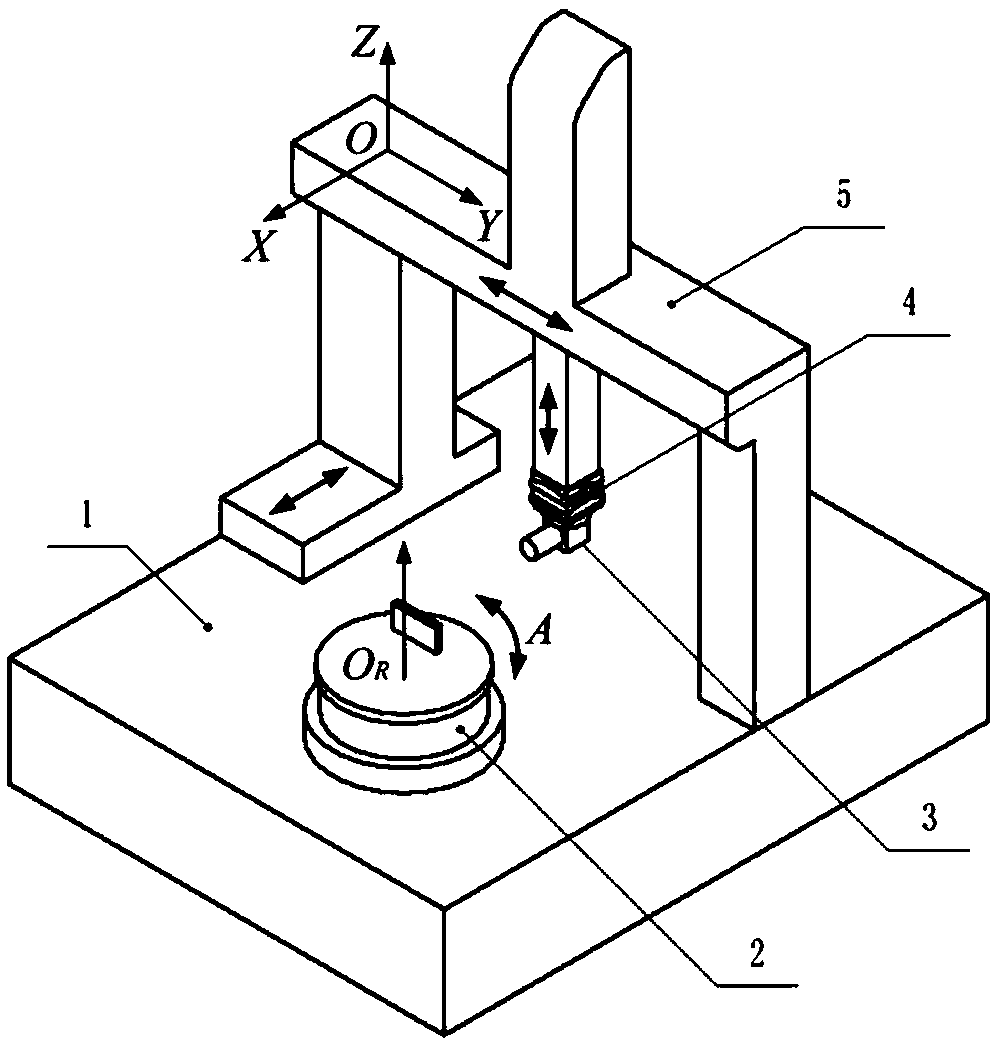

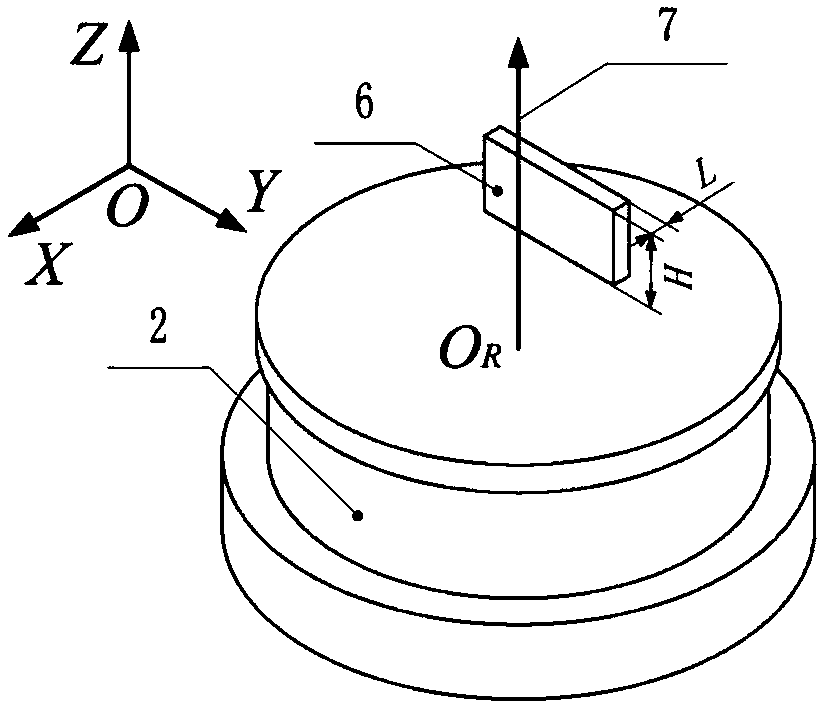

Method for calibrating origin position of center axis of rotary table based on visual measurement

InactiveCN109596073AImprove measurement accuracy and measurement efficiencySolving Critical Problems in Vision MeasurementUsing optical meansRotary stageCLARITY

The invention provides a method for calibrating an origin position of a center axis of a rotary table based on visual measurement. The method comprises the following steps of: 1, fixing an integral component consisting of a calibration ball and a ball arm to the table-board of the rotary table, and deviating from the center axis of the rotary table; 2, rotating the rotary table to various angularpositions, driving an image acquisition device by a three-dimensional moving bridge to align the calibration ball and collect an image of the calibration ball with the same clarity degree and positioncentered, and record scale readings of three linear axes of X, Y and Z at each position at this time; and 3, performing least square fitting on the recorded data, and then calculating the origin coordinates of the center axis of the rotary table in a machine coordinate system of a visual measuring device, thereby determining a space position of the origin coordinates in the machine coordinate system. The method for calibrating the origin position of the rotary table center axis based on the visual measurement has simple principle, is convenient to apply, and solves the key problems in the visual measurement of the parts of the rotary body.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

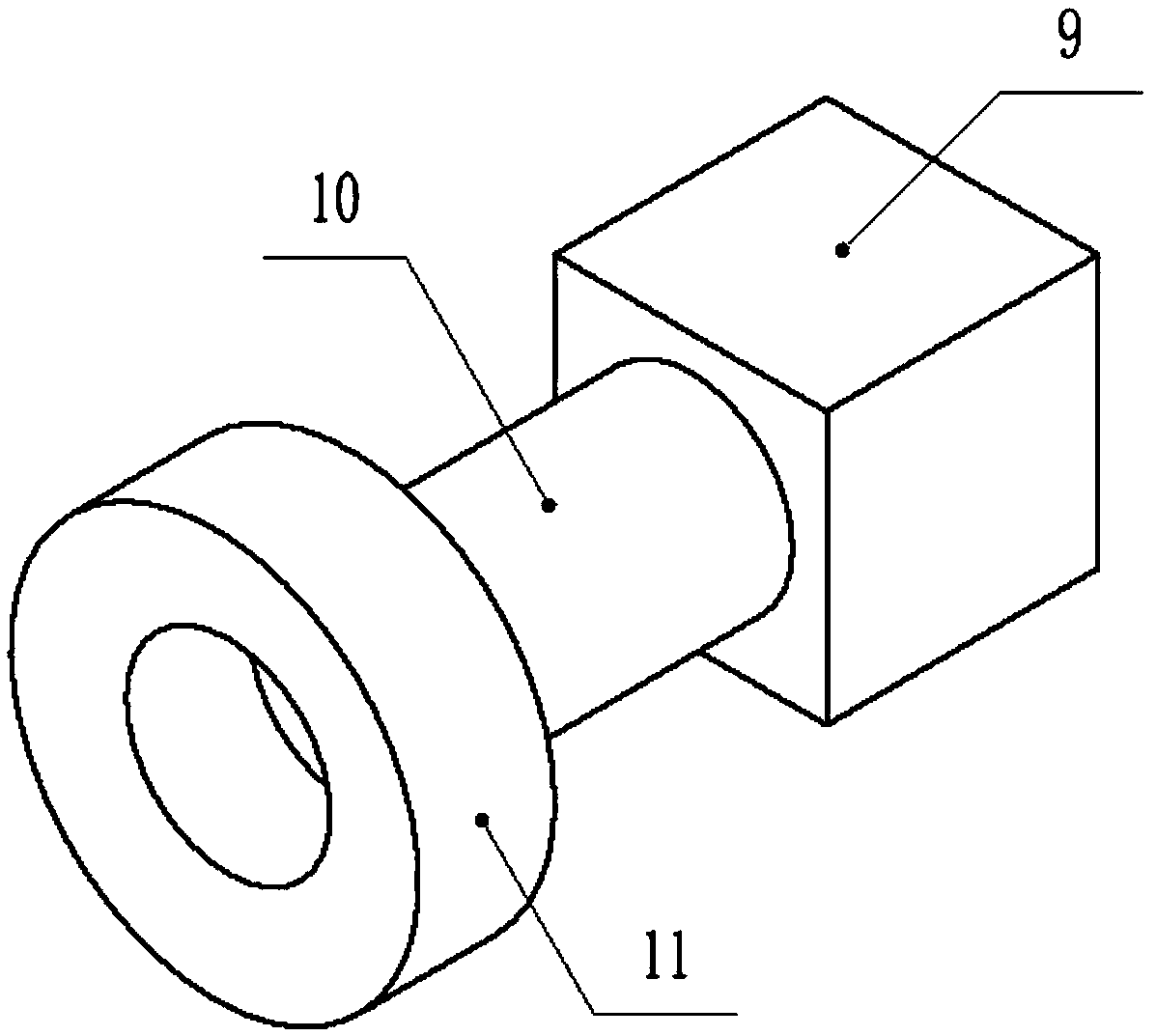

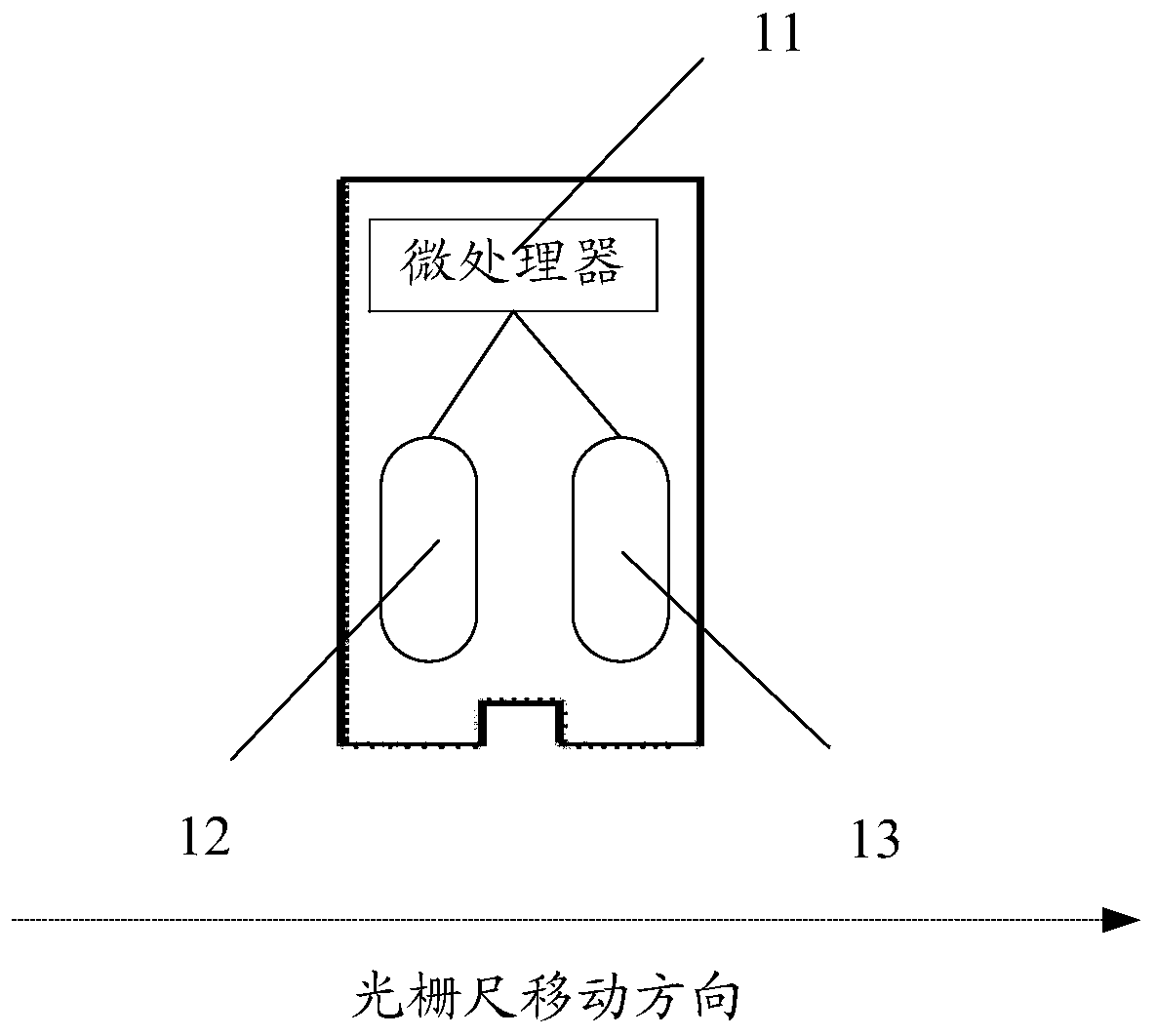

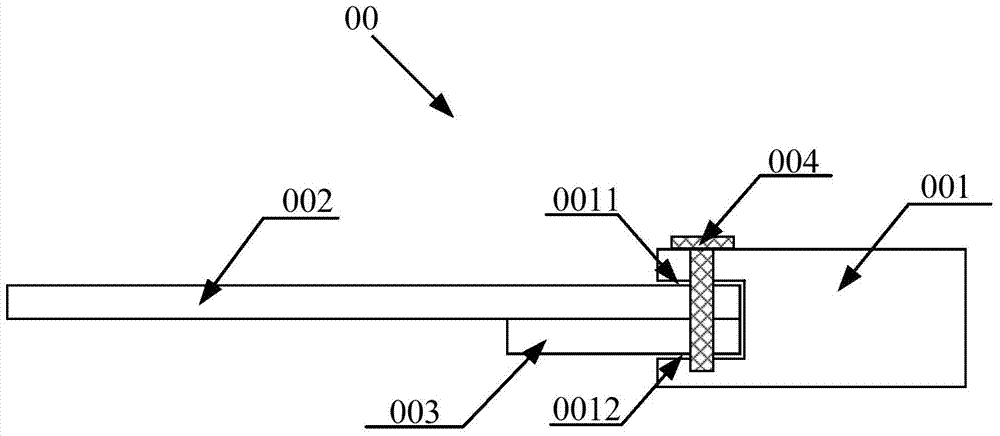

Grating scale reading head, grating scale joint and grating scale displacement sensor

The embodiment of the invention discloses a grating scale reading head, a grating scale joint and a grating scale displacement sensor. The grating scale reading head comprises a microprocessor, and afirst reading sensor and a second reading sensor which are connected with the microprocessor and arranged in the movement direction of a grading scale. The microprocessor is configured to determine that the displacement value of a current grating scale needs gap compensation according to the movement displacement values read by the first reading sensor and the second reading sensor, the actual movement displacement value of the grating scale is calculated according to the movement displacement values read by the first reading sensor and the second reading sensor and the movement direction of the grating scale, and the grating scale reading head is applied to a grating scale displacement sensor by employing a plurality of scale gratings spliced to a grating scale main body and allowing thelength values of the gaps at the connections of the scale gratings being twice larger than the distances of the grating grooves so as to improve the displacement measurement of the grating scale displacement sensor and facilitate achievement of increasing of the measurement range of the grating scale displacement sensor through increasing of the scale grating length.

Owner:GUANGDONG UNIV OF TECH

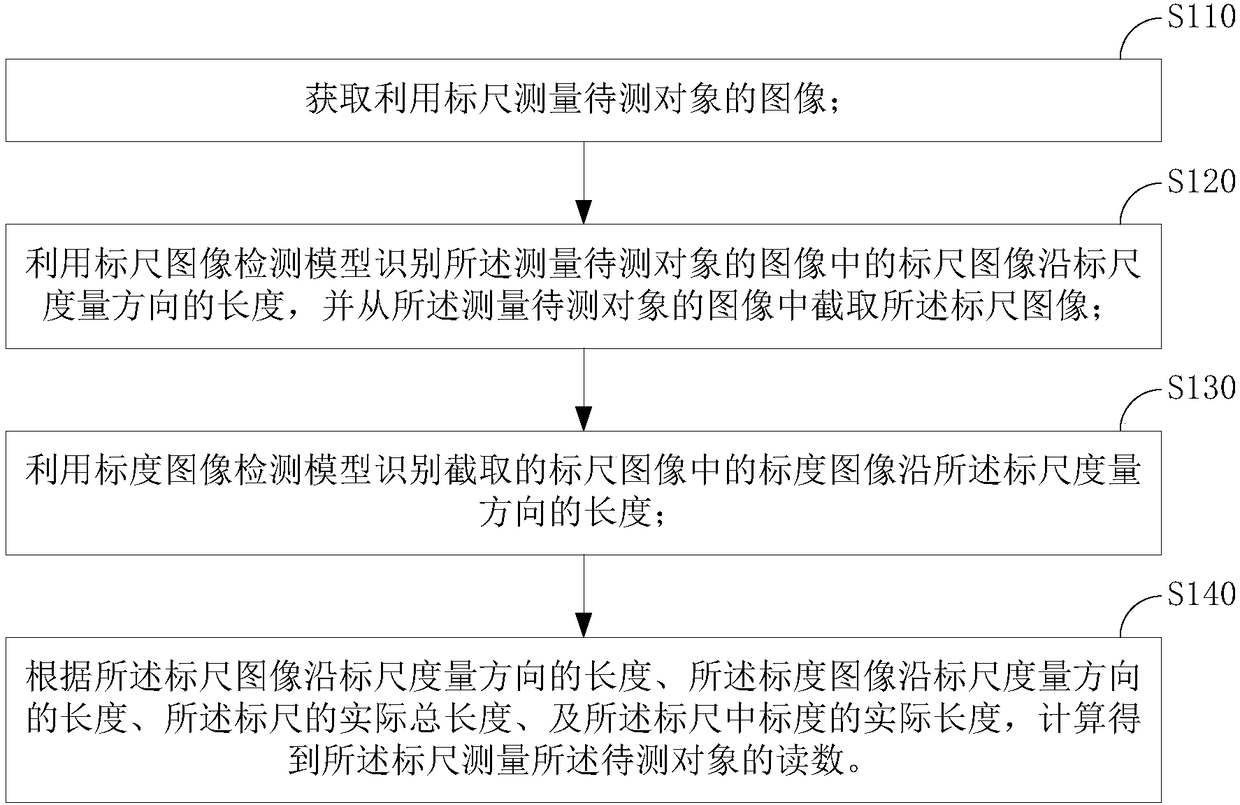

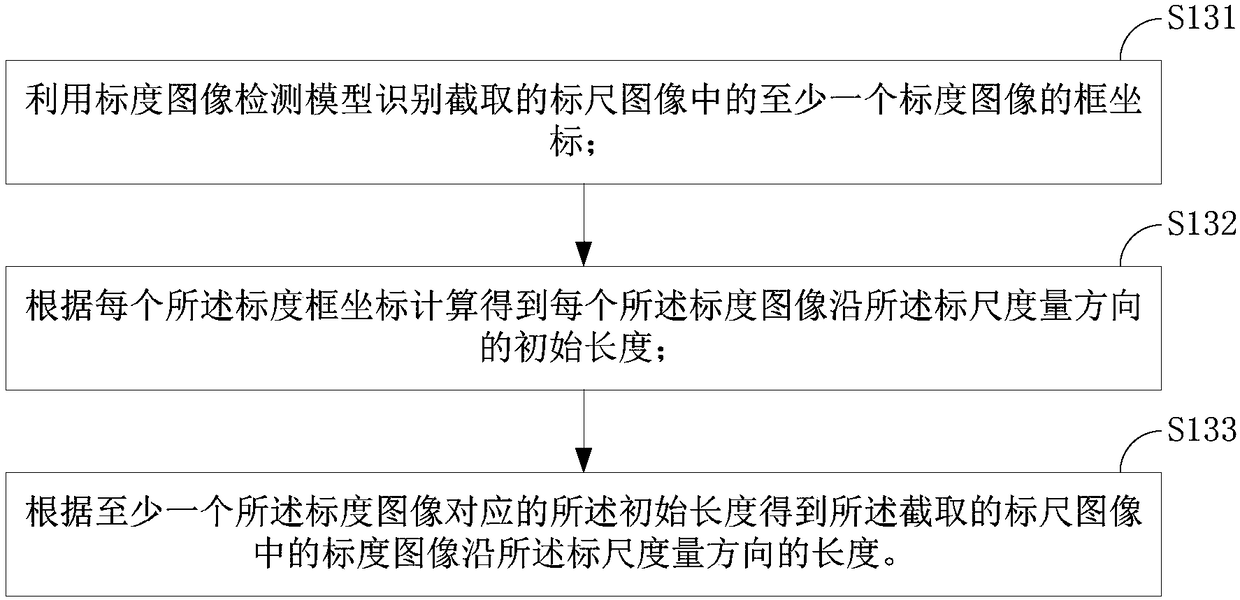

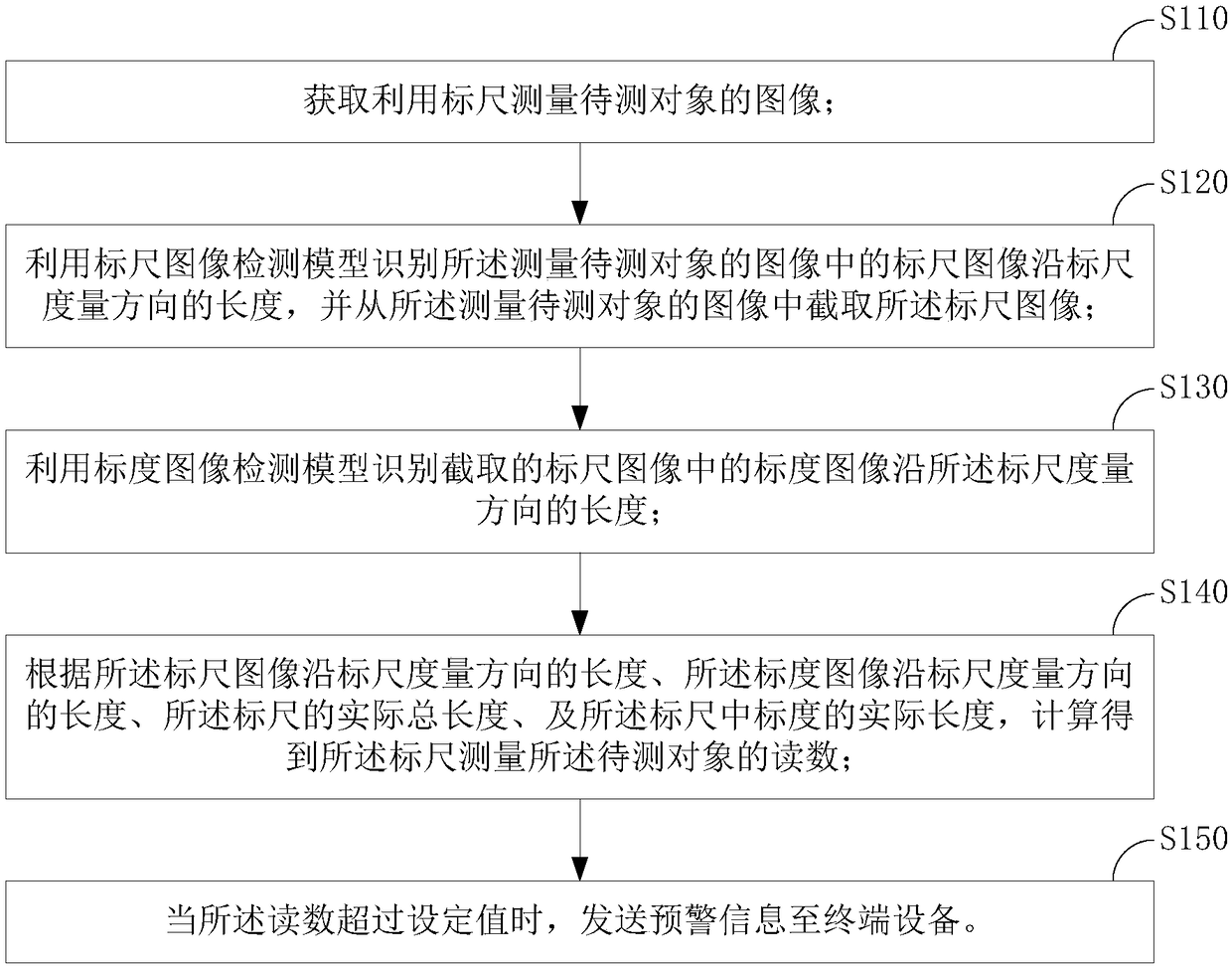

Image recognizing method and device for ruler reading

ActiveCN108596221AImprove adaptabilityCharacter and pattern recognitionComputer graphics (images)Computer vision

The invention provides an image recognizing method and device for ruler reading. The method comprises the following steps of: acquiring an image of measuring a to-be-measured object by using a ruler;recognizing the length of a ruler image in the image of the to-be-measured object along the ruler measurement direction by using a ruler image detecting model and intercepting the ruler image from theimage of measuring the to-be-measured object; recognizing the length of a ruler scale image in the intercepted ruler image along the ruler measurement direction by using a ruler scale image detectingmodel; and calculating the reading of measuring the to-be-measured object by the ruler according to the length of the ruler image along the ruler measurement direction, the length of the ruler scaleimage along the ruler measurement direction, the actual total length of the ruler and the actual length of the ruler scale in the ruler. The measurement reading of the ruler is calculated through therecognized lengths of the ruler and the ruler scale, so that the adaptability of the scale image recognizing to complex environments can be increased.

Owner:坤御(北京)技术有限公司

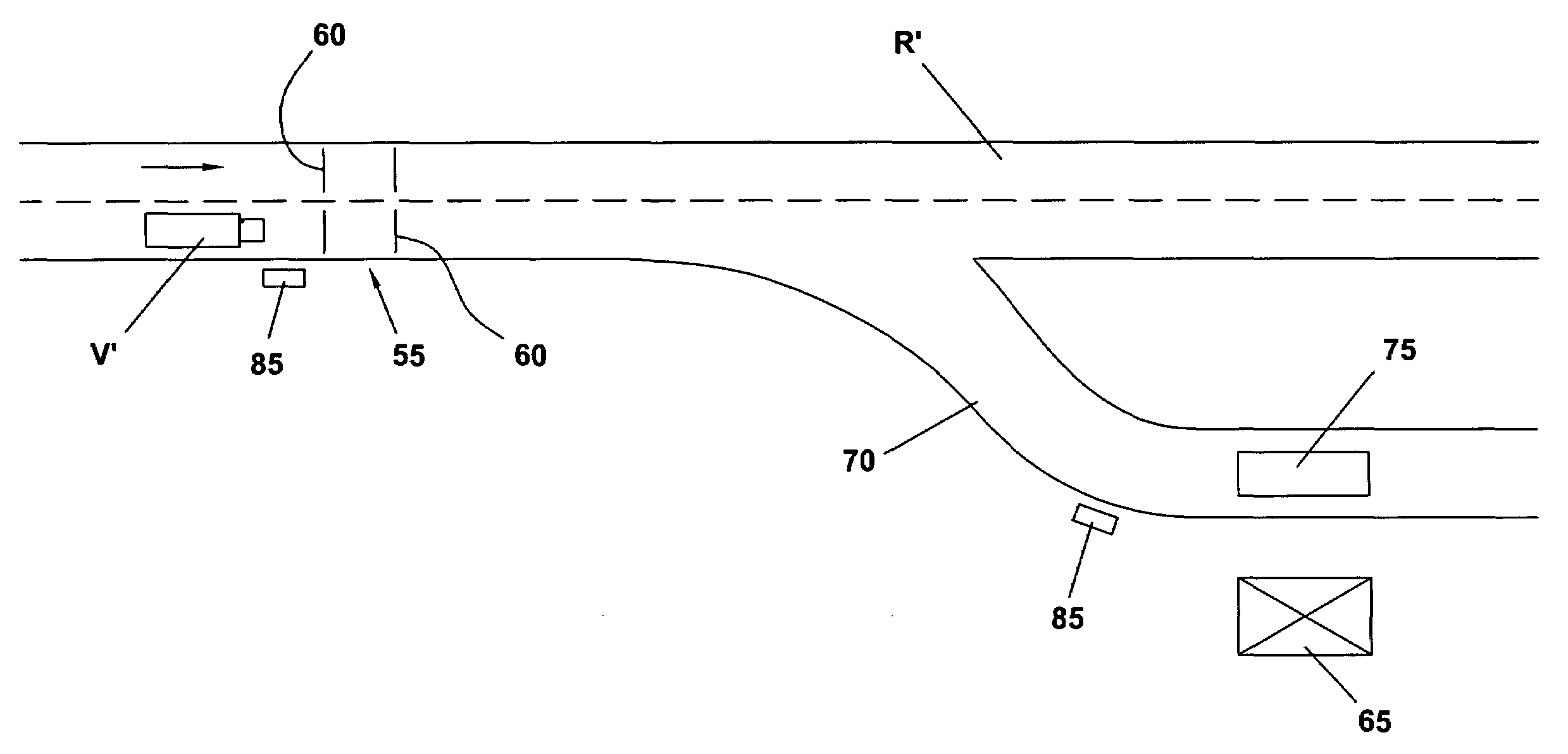

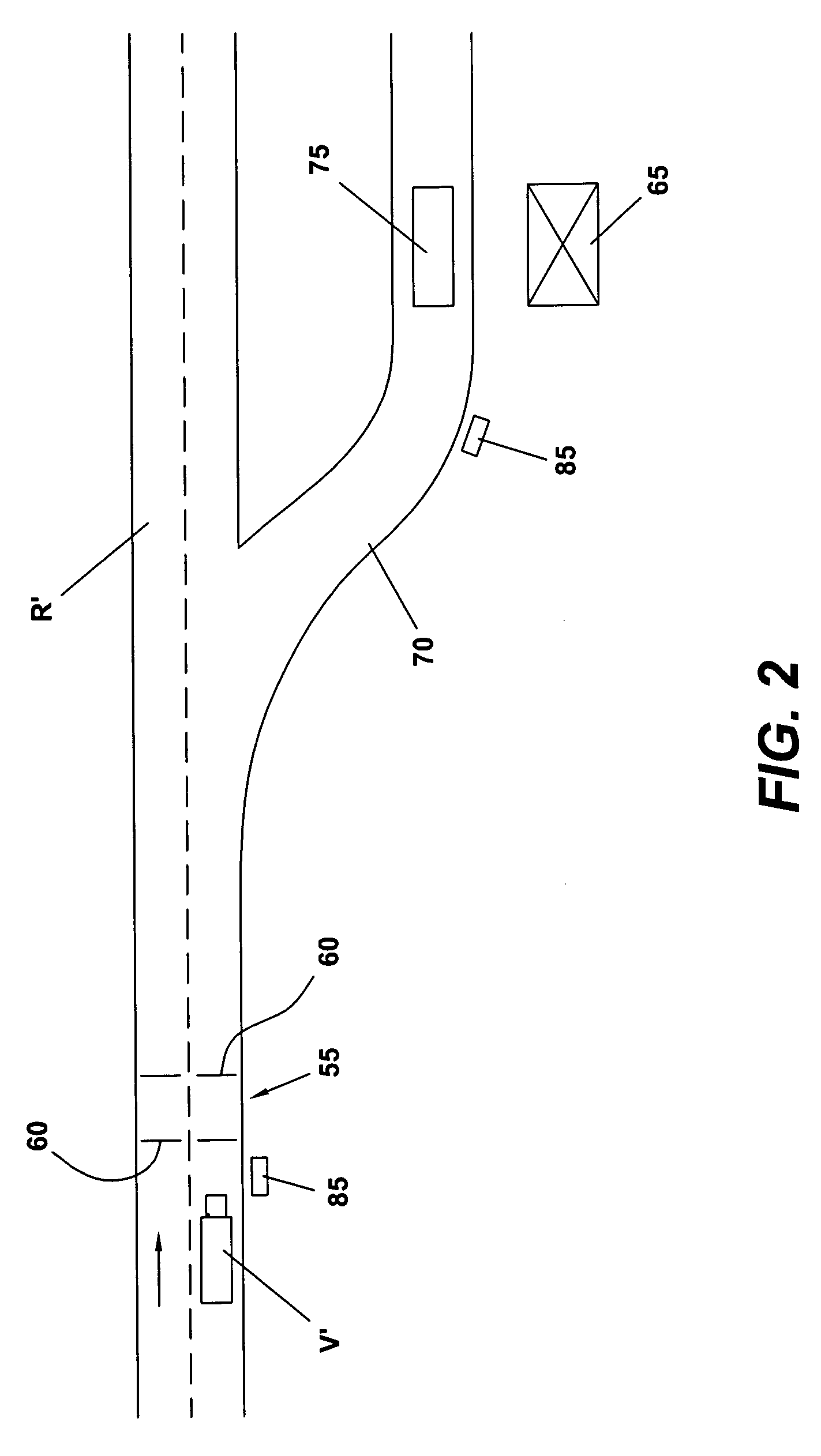

Weigh-in-motion system with auto-calibration

ActiveUS7684946B2Accurate readingWeighing apparatus testing/calibrationSpecial data processing applicationsMobile vehicleComputer science

Weigh-in-motion (WIM) systems for weighing moving vehicles, the systems having the ability to automatically determine and periodically apply calibration factors to WIM scale readings. Auto-calibration may include transferring both WIM and static weight readings for the same vehicle to a database, associating the weight readings, collecting a number of such weight readings, and analyzing the differences between the WIM and static weight readings to calculate WIM scale calibration factors. The calibration factors may be based on vehicle characteristics such as vehicle weight, vehicle class and / or vehicle speed at the WIM scale.

Owner:METTLER TOLEDO INC

Multifunctional electronic tape

PendingCN107144195AEasy to useSmall sizeUsing optical meansMechanical measuring arrangementsObservational errorLiquid-crystal display

The invention relates to a multifunctional electronic tape, which comprises a shell, a wire-pulling distance measurement device, a liquid crystal display, a PCB and a battery, wherein the liquid crystal display is embedded in the shell, the PCB and the battery are fixed in the shell, the PCB is provided with a single-chip microcomputer, the wire-pulling distance measurement device comprises a wire pulling head, a wire and a wire winding device, the shell is further fixedly provided with two guide columns at the corners, one end of the wire is wound on the wire winding device, the other end of the wire sequentially bypasses the two guide columns and then penetrates out from one corner of the shell, the other end of the wire is fixed with the wire pulling head with a magnet, and the shell is further internally provided with an optical image sensor at the position between the two guide columns. According to the invention, multiple functions are integrated, the multifunctional electronic tape can be independently used, the measured length is displayed in the mode of a numerical value, the trouble of scale reading is saved, the measurement precision is higher than that of a traditional steel tape, he measurement error is less than 1mm, and intelligent tape data can be transmitted to a mobile phone in real time through an APP so as to be convenient for recording and consulting.

Owner:HANGZHOU RUIYU INDAL

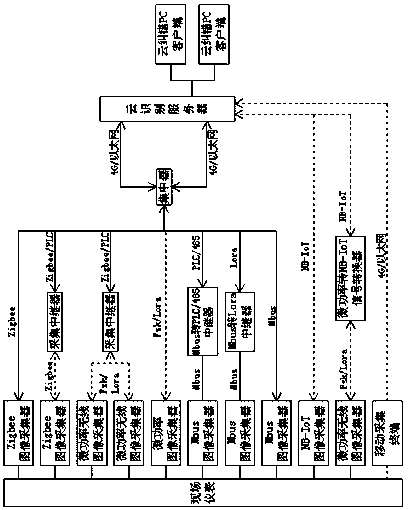

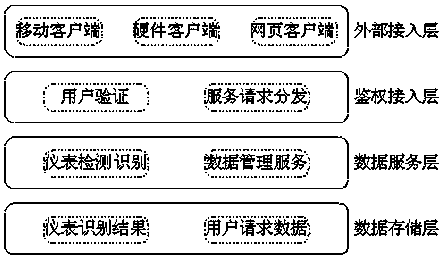

Cloud recognition meter reading system based on structure of Internet of Things

InactiveCN108898813AIncrease the level of automationReduce human and material resources inputElectric signal transmission systemsCharacter and pattern recognitionData interfaceData store

The invention discloses a cloud recognition meter reading system based on a structure of Internet of Things in the field of image recognization. The cloud recognition meter reading system comprises animage collecting system and a cloud recognizing server which are mutually matched so as to finish the functions of the system, wherein the image collecting system comprises an image collector, a relay, a concentrator and a mobile collecting terminal and is used for finishing the collection and uploading of field meter images; the cloud recognizing server comprises a data interface module, an authentication access module, a data processing and recognizing service module, a data storage module and a cloud recognizing correction module and is used for finishing the access, service request issuing, data processing and recognition, data storage and cloud recognition correction of meter image data. The cloud recognition meter reading system has the characteristics of low cost, good expandability, objective and accurate data and the like, and large-scale reading data stored in the cloud recognizing server can be conveniently analyzed and excavated, so that the cloud recognition meter readingsystem can be applied to data supervision and the providing of individual services.

Owner:深圳市云识科技有限公司 +1

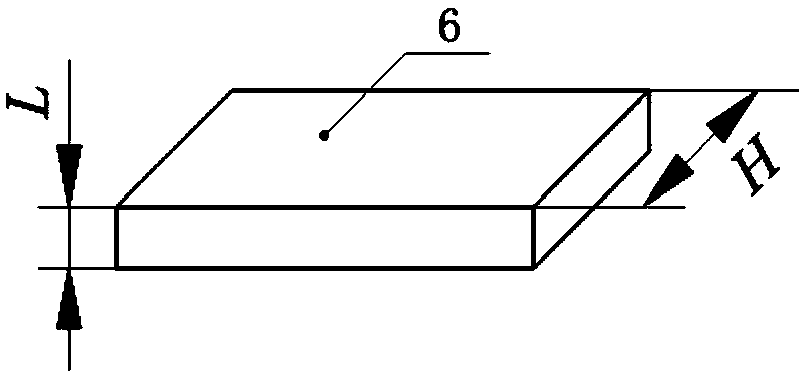

Method for determining spatial coordinates of rotation center of turntable

The invention provides a method for determining the spatial coordinates of the rotation center of a turntable. The method is based on a visual coordinate measuring system which is composed of a worktable, a turntable, an imaging device, an attitude adjustment mechanism and a three-dimensional moving bridge and has three linear motion axes X, Y, Z and a rotary motion axis A. By means of a cuboid calibration block made of hard alloy steel, the method accomplishes image acquisition for edges of the calibration block at different angular positions through the spatial linear motion of the three-dimensional moving bridge and the rotary motion of the turntable, the grating scale reading of each linear motion axis is recorded at the same time, and finally the three-dimensional spatial coordinatesof the rotation center of the turntable in a machine coordinate system of the multi-axis visual coordinate measuring system are solved by combining the thickness and height of the calibration block according to an image processing technology. The method is simple in principle and convenient in application, solves key problems in multi-axis visual coordinate measurement of rotary parts, and has great practicability and practical application values.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

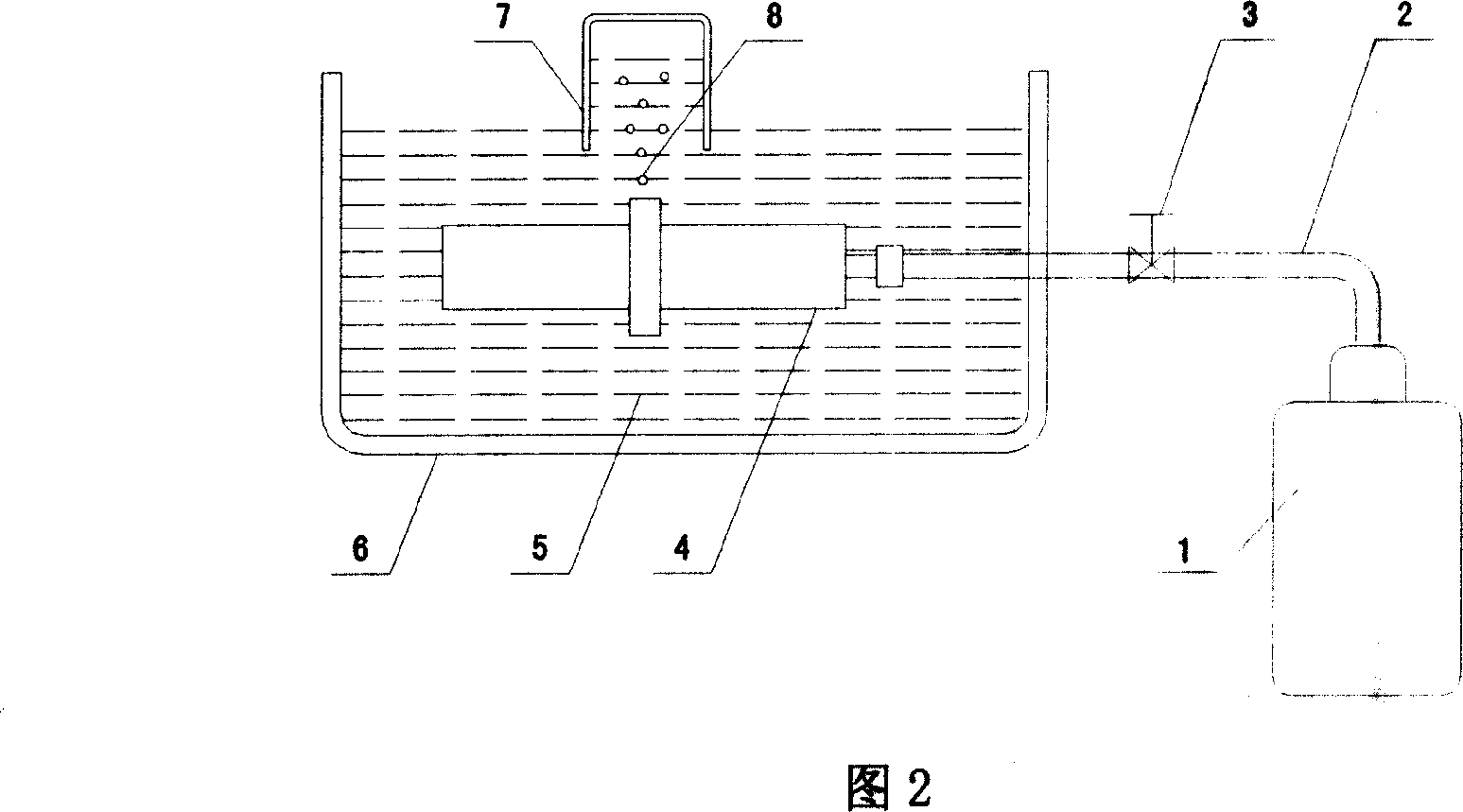

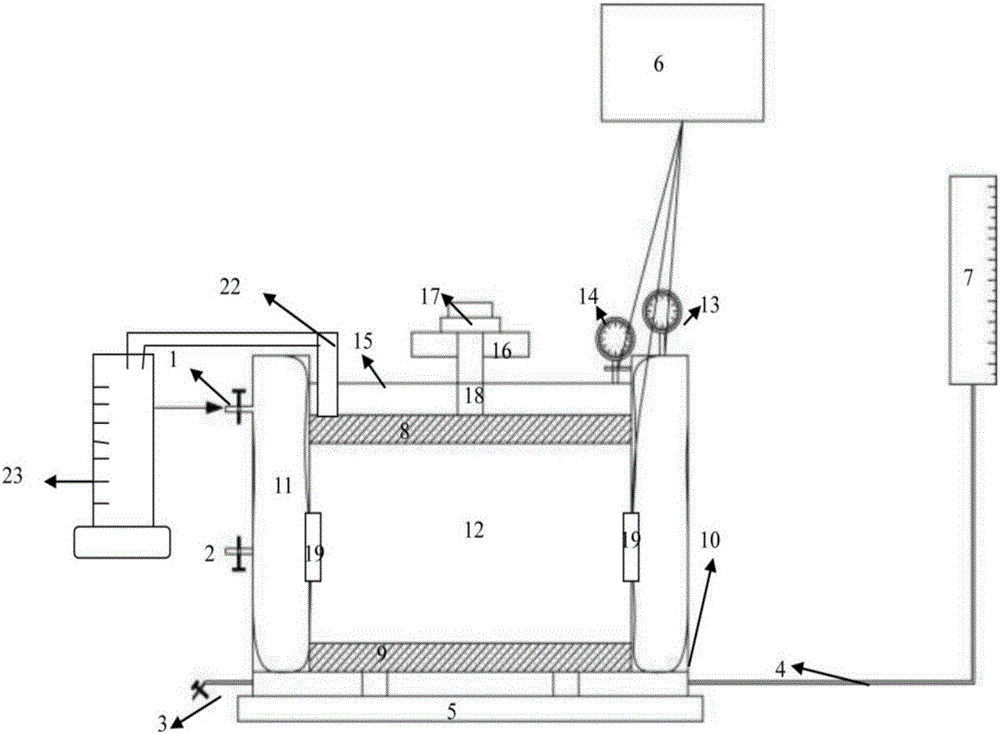

Rock soil penetration air pressure solidification testing method

InactiveCN106769500ASmall footprintEasy loadingMaterial strength using tensile/compressive forcesPermeability/surface area analysisGraduated cylinderExhaust valve

The invention discloses a rock soil penetration air pressure solidification testing method. An adopted solidification instrument comprises a base 5, a cover plate 15, a scale water storage tank 7, a measuring cylinder 23, a pressure application device and a computer 6, wherein the cover plate 15 is supported on the base 5 through a supporting piece. The testing method comprises the following steps: before a test, turning on the computer, filling the scale water storage tank with water, recording a scale reading, sheathing soil samples with soft sheaths, and placing the soil samples between an upper permeable stone and a lower permeable stone; emptying air in the cavity of the base; switching off an exhaust valve of the base, and switching on an air inlet valve and an air suction valve so as to enable an air bag in an air bag cavity to be in contact with a wall of the air bag cavity, wherein an air gauge displays the value of the applied confining pressure; enabling the bottom of a pressure application shaft to be in full contact with the upper permeable stone, and applying weights on a jack; determining the solidification time according to geo-technical testing procedures; and after the test is over, recording the water yield in unit time, and calculating the permeability coefficient according to the Darcy law.

Owner:TIANJIN UNIV

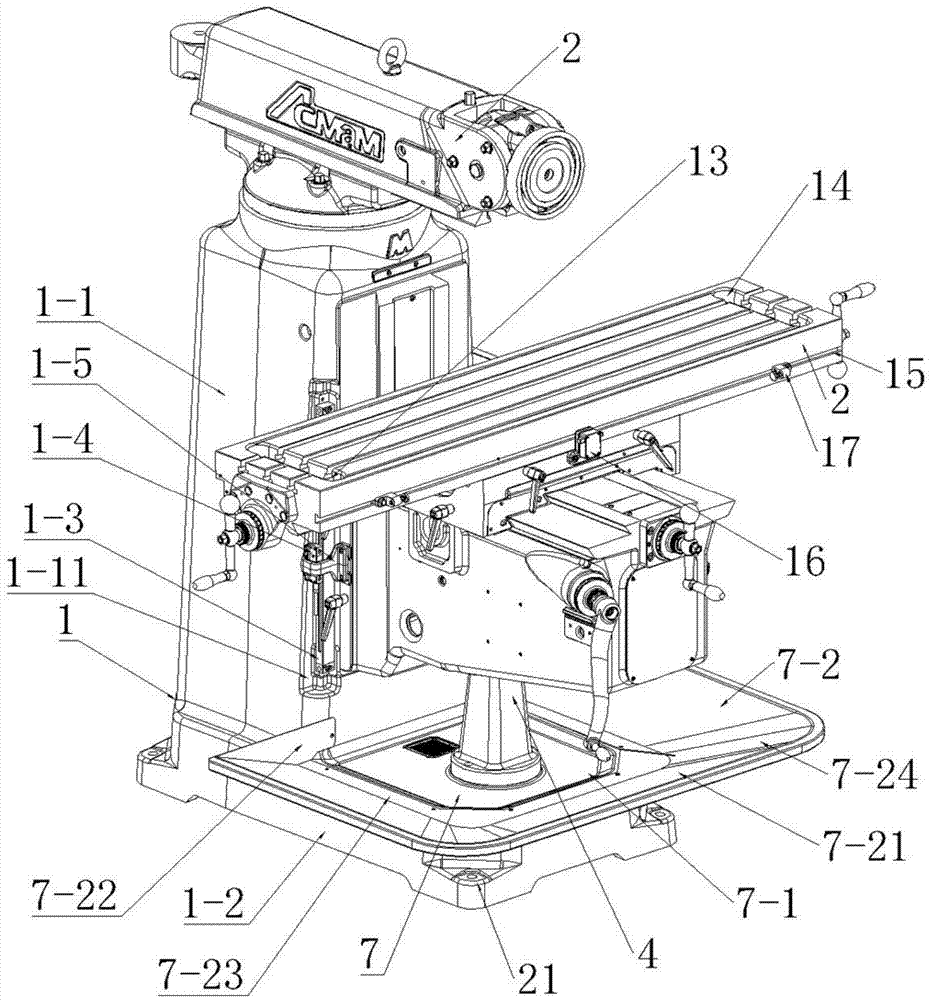

CNC milling machine

InactiveCN103934697AReduce labor intensityReduce cloggingMeasurement/indication equipmentsMilling machinesNumerical controlGrating

The invention discloses a CNC milling machine. The CNC milling machine comprises a numerical control device, a machine body, a milling mechanism, a workbench, a transverse feeding mechanism, a lifting table and a cooling and lubricating system, wherein the milling mechanism, the workbench, the transverse feeding mechanism, the lifting table and the cooling and lubricating system are arranged on the machine body. The machine body is composed of a lifting table seat and a milling machine base. The milling mechanism is mounted on the top of the lifting table seat through a rotary disk. The milling machine base is provided with a liquid receiving groove. The CNC milling machine is characterized in that the milling machine base is provided with a liquid collection tank, a filtering device, a circulating pipeline and a circulating water pump, the liquid collection tank, the filtering device and the circulating pipeline are connected with the liquid receiving groove, and the circulating water pump is connected with the circulating pipeline; the lifting table seat is provided with a grating scale, a grating scale reading head and a reading head seat, the grating scale reading head is arranged on the reading head seat, the reading head seat is arranged on the lifting table, and the lifting table seat is provided with a recess for containing the grating scale; a guide rail seat is provided with a dovetail rail, and the dovetail rail is provided with a dovetail guide portion; a carrying table is arranged at the front end of the workbench, and a stop mechanism is arranged at the rear end of the workbench; the four corners of the lifting table seat are respectively provided with an L-shaped supporting leg. The CNC milling machine is simple in structure, convenient to use and high in production efficiency.

Owner:FOSHAN FENGBAO PRECISION MACHINE

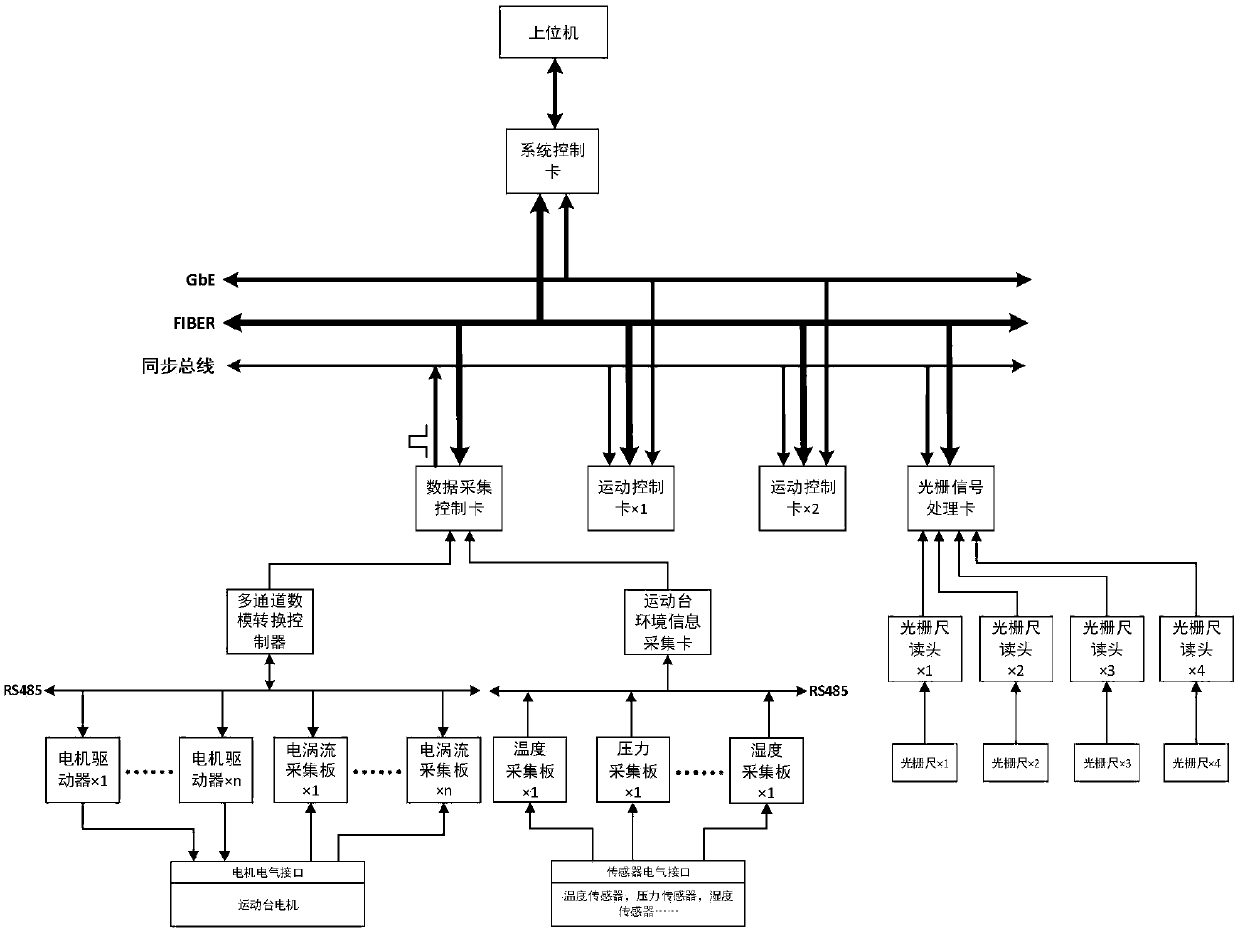

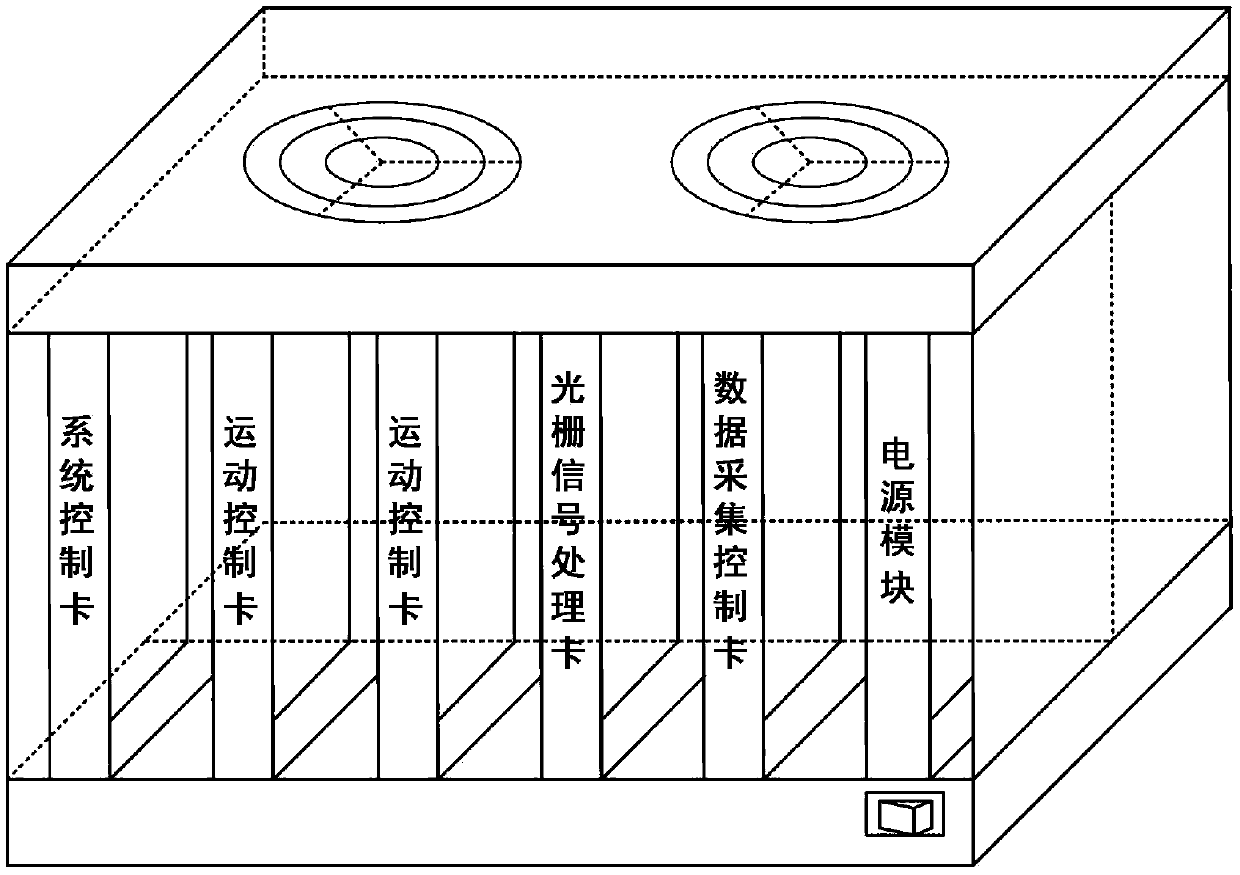

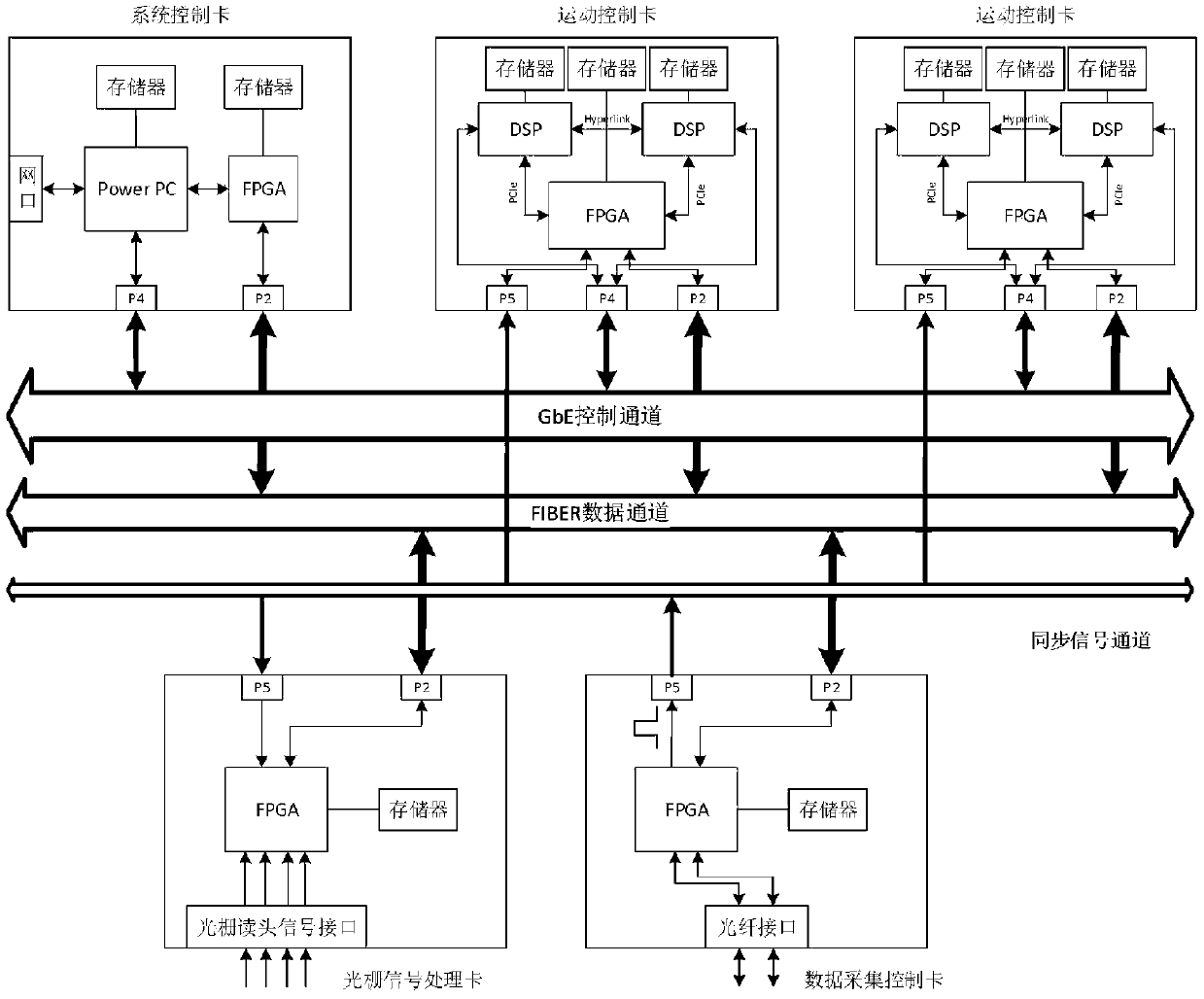

Open VPX based synchronous motion control system and method of high-precision high-speed motion platform

The invention provides an Open VPX based synchronous motion control system of a high-precision high-speed motion platform. The system comprises a system control card, a motion control card, a data collection control card, a grating signal processing card, a multichannel digital to analog conversion controller, a motion platform environment information collection card, a motor driver, a current vortex collection board, a sensor information collection plate, a grating scale reading head and a host computer. Open VPX supports VITA66.4 optical interconnection backboard bus protocols, a used fiberconnector supports multichannel fiber interconnection, the single-channel data transmission rate can reach 14Gbps, an optical interconnection backboard bus is used for data transmission, and the requirements of constant improvement of the high servo frequency, large data bulk and high instantaneity for the synchronous control system of the motion platform of the high-end photo-etching machine canbe met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

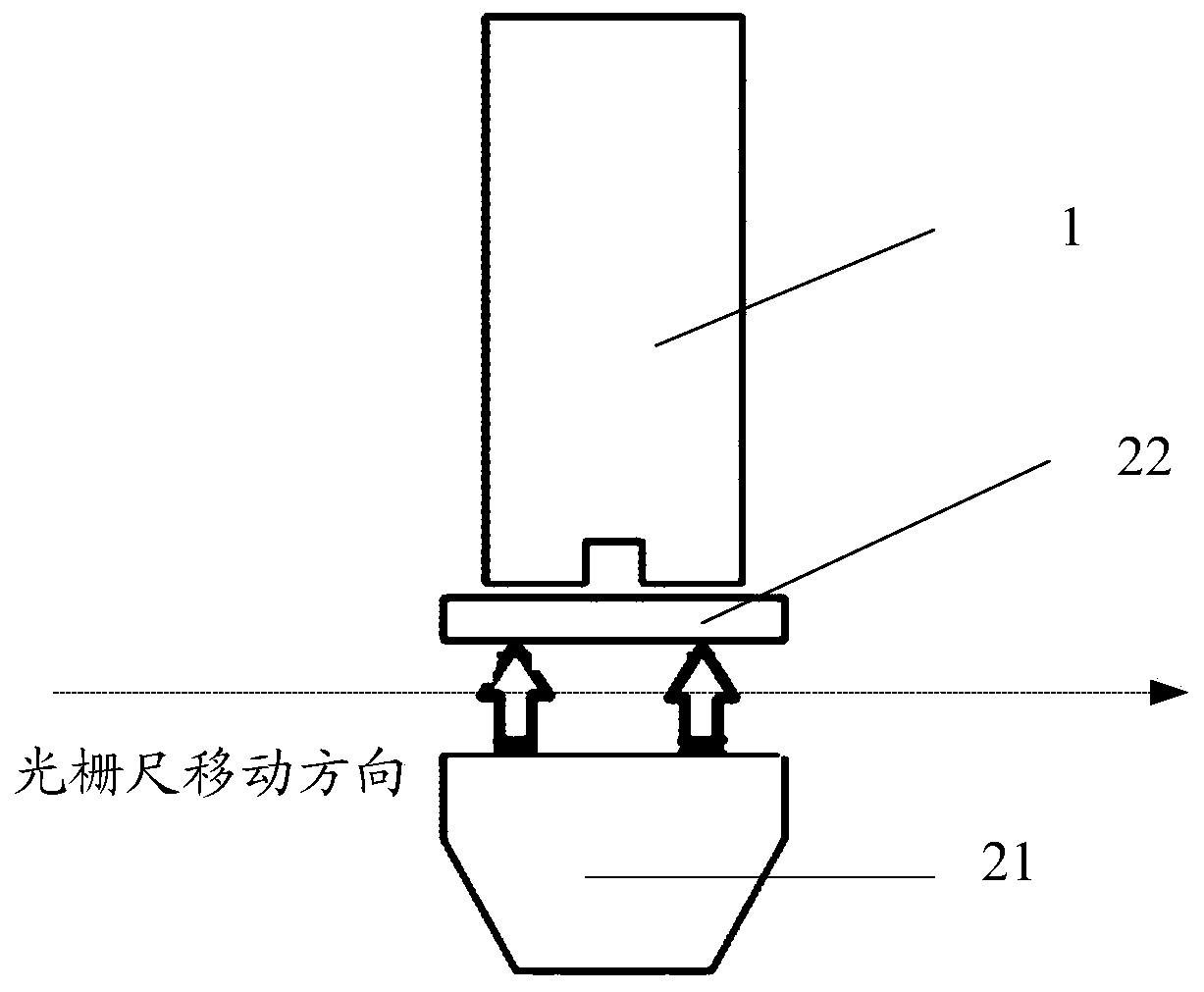

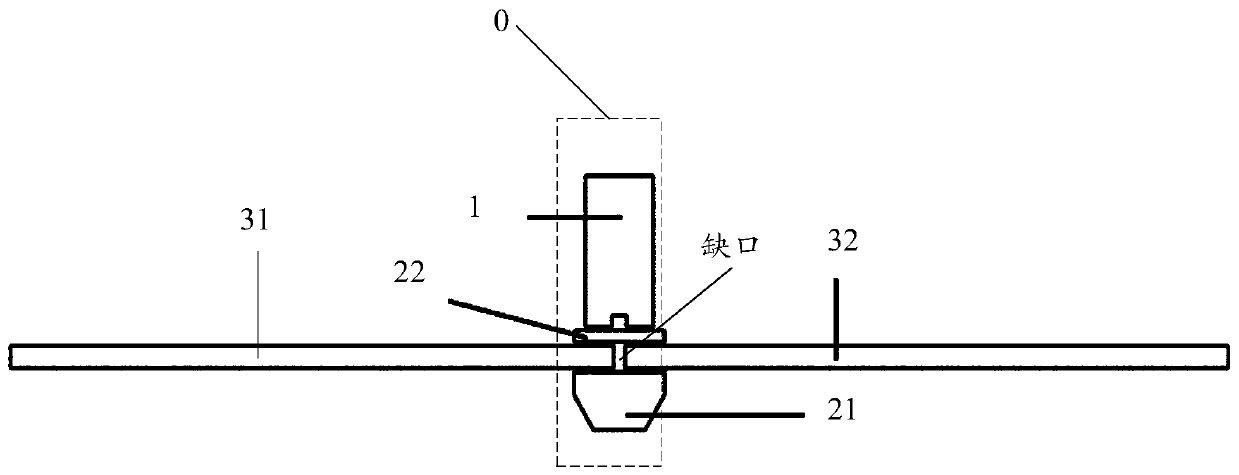

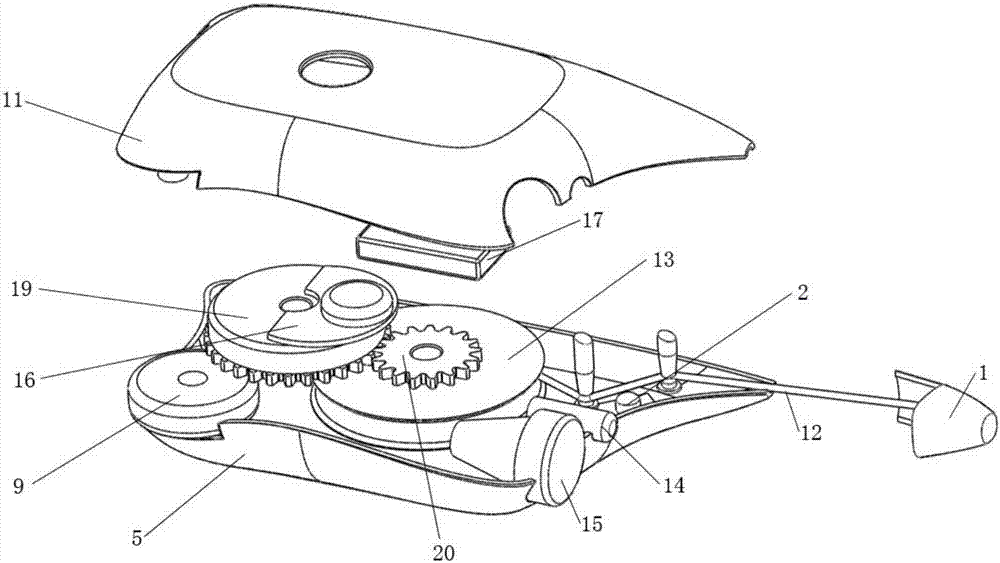

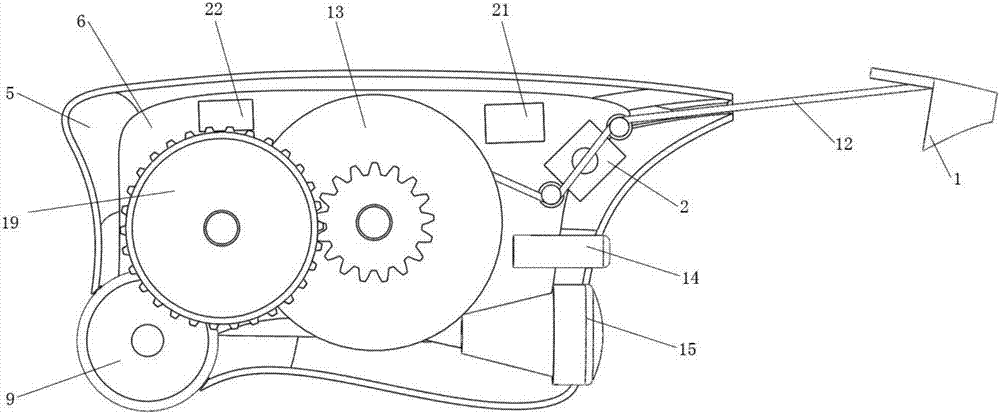

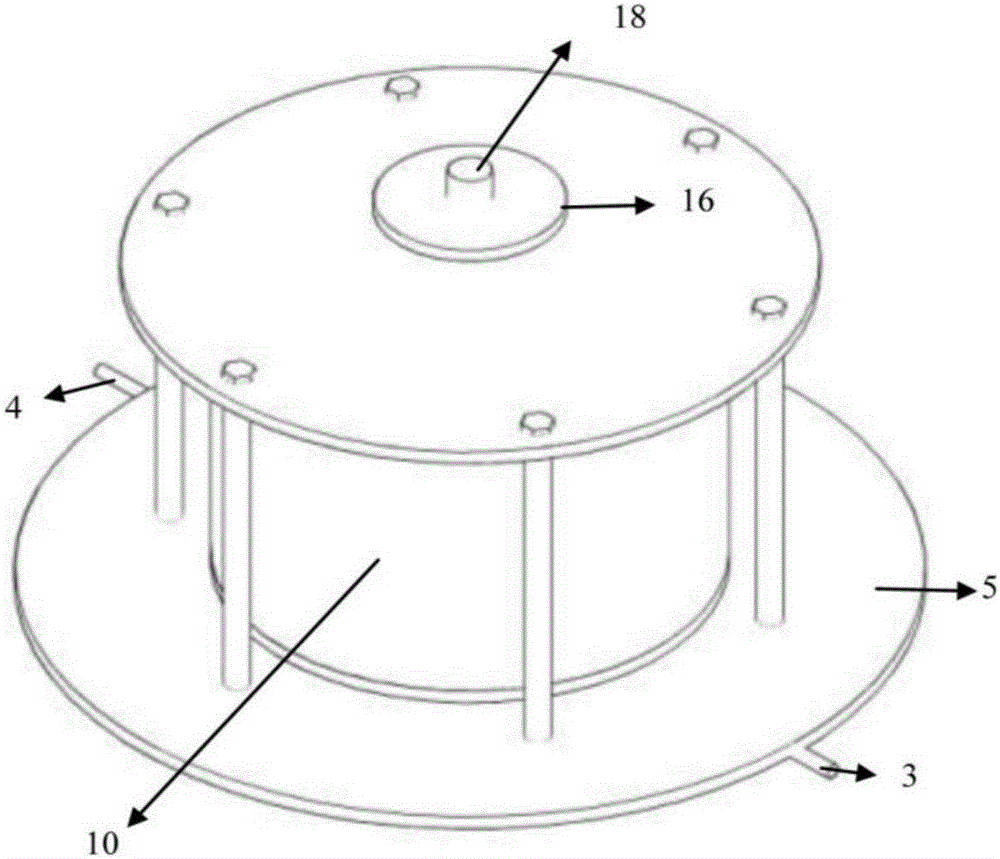

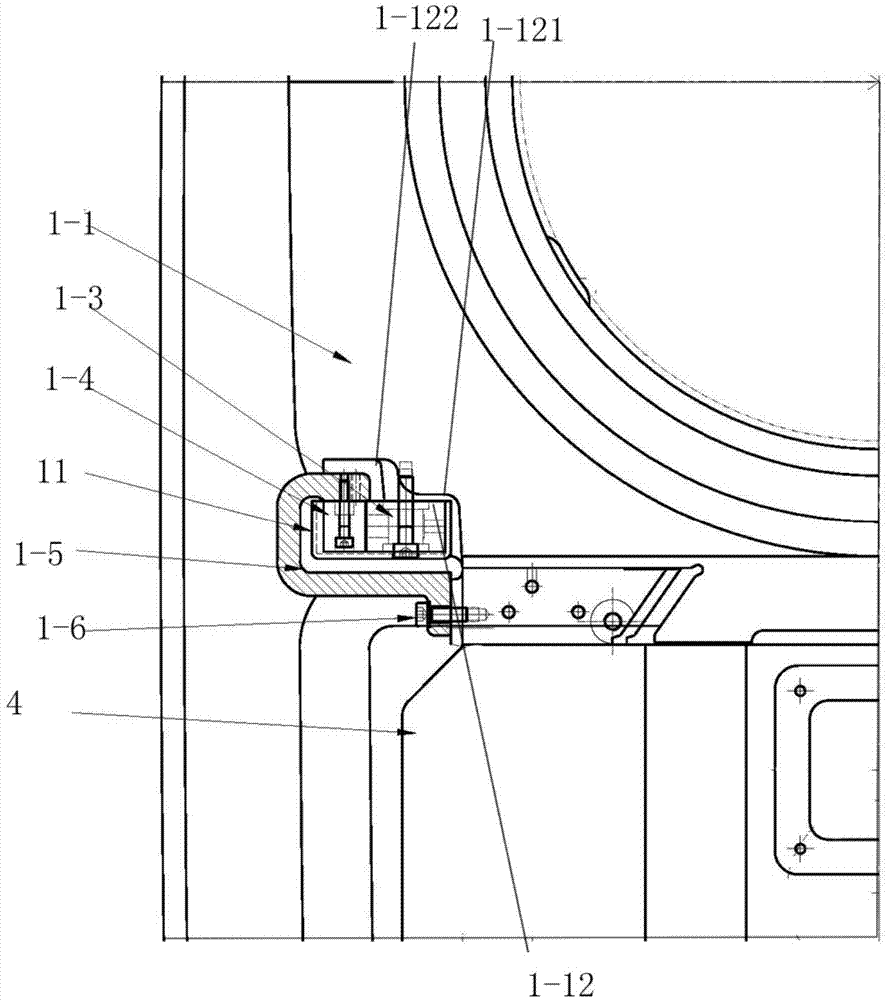

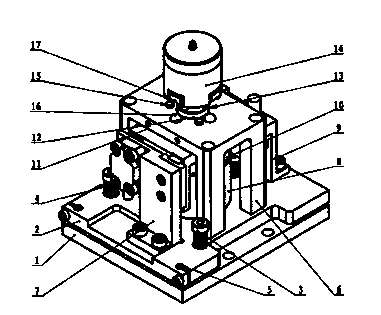

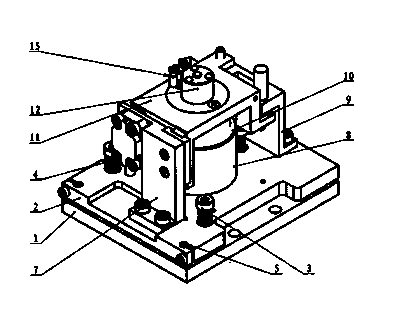

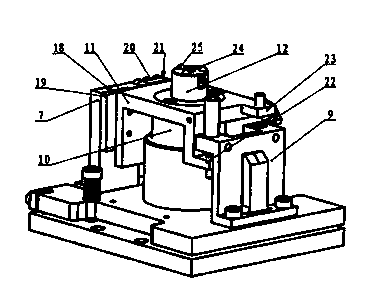

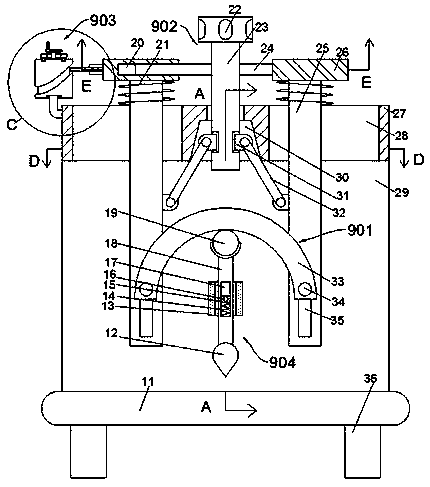

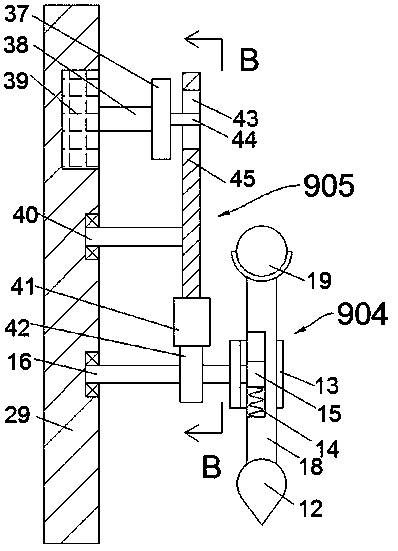

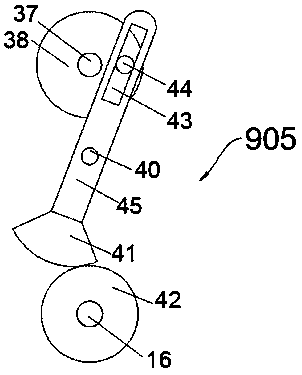

Wafer chip jacking mechanism

ActiveCN103633006AFast jacking processReliable jacking processSemiconductor/solid-state device manufacturingGratingActuator

The invention discloses a wafer chip jacking mechanism. By the aid of the wafer chip jacking mechanism, the problem of difficulty in replacing ejector pins in existing wafer chip stripping mechanisms can be solved. The wafer chip jacking mechanism comprises a motor stator fixing plate (2). A voice coil motor stator (8) is fixedly arranged on the motor stator fixing plate (2), an inverted-L-shaped lifting plate (11) is arranged on the top of a voice coil motor rotor (10), a lifting guide rail groove (19) is formed in the inner side surface of a reading head mounting frame (7), a grating scale reading head (20) is arranged on the inner side surface of the reading head mounting frame (7), a lifting slider (18) and a grating scale (21) are respectively arranged on the outer side of an upright plate of the inverted-L-shaped lifting plate (11), a lifting cylinder (12) is arranged on the top surface of a horizontal plate of the inverted-L-shaped lifting plate (11), pull-in magnets (15) of an ejector pin actuator (14) are respectively arranged on the outer side of a through hole (13), and an ejector pin mounting seat pull-in magnet (24) and three ejector pin mounting seat support balls (25) are respectively arranged on the top surface of the lifting cylinder (12). The wafer chip jacking mechanism is applicable to wafer chip stripping mechanisms with the requirement of frequently replacing wafer chips with different sizes.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

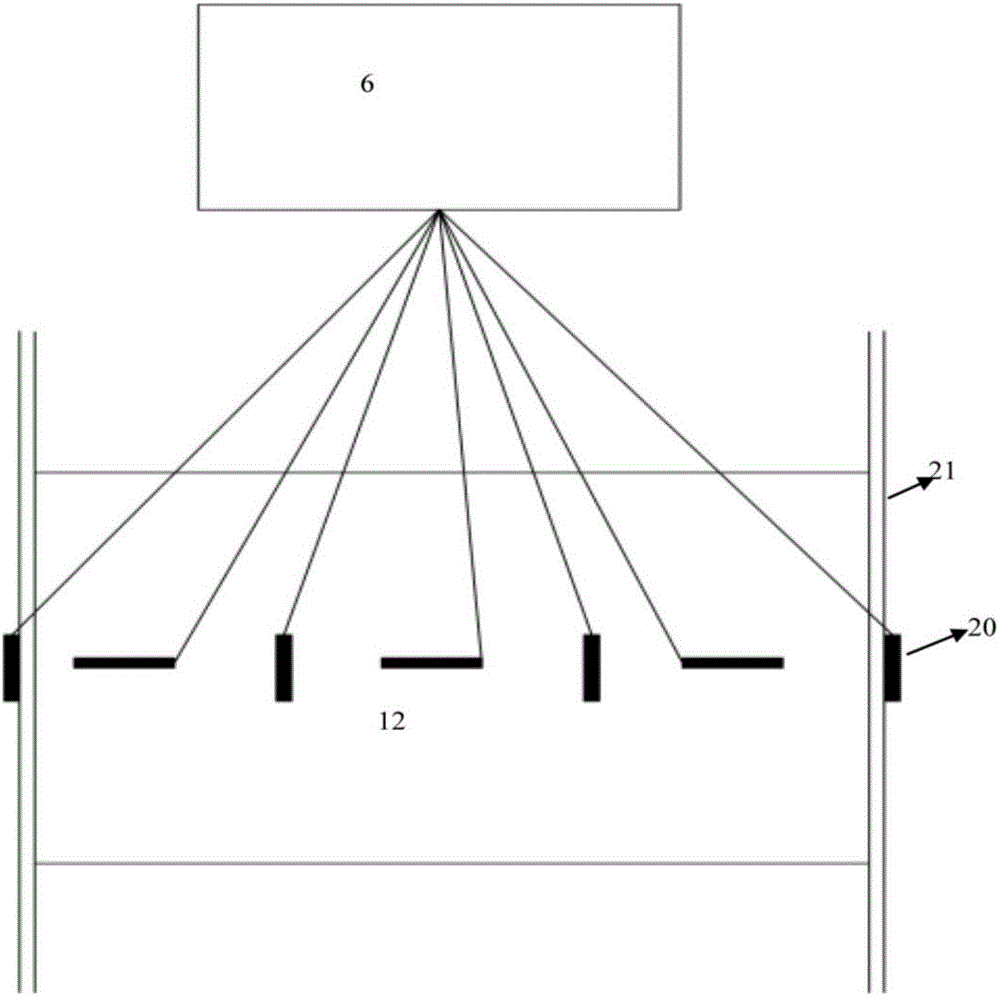

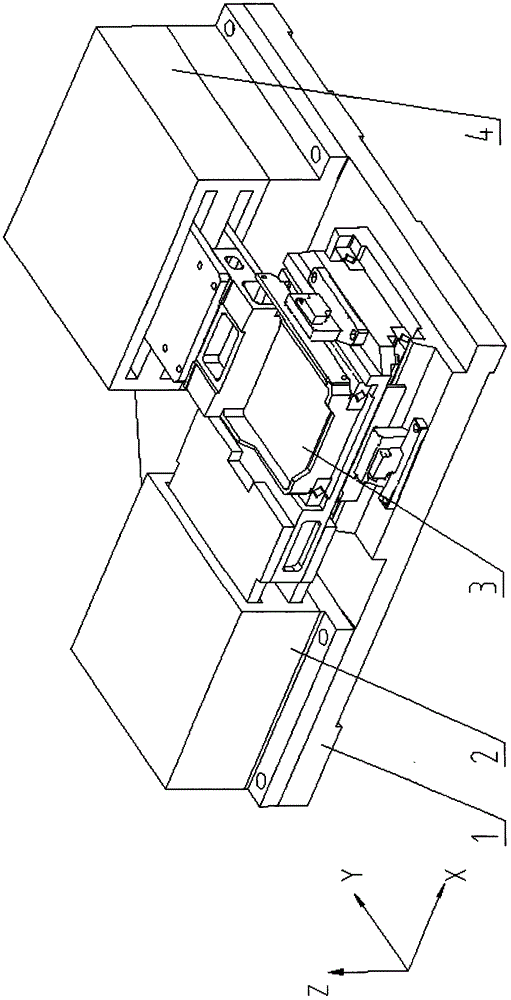

XY motion platform driven by double-layer linear motor

InactiveCN102723296AGreat driving forceHigh speedSemiconductor/solid-state device manufacturingMultiple dynamo-electric motors speed regulationProduction lineLinear motor

The invention provides an XY motion platform driven by a double-layer linear motor. The XY motion platform comprises a bottom plate component (1), an X-axis linear motor component (2), a motion platform component (3), a Y-axis linear motor component (4), a bottom plate (5), an X-axis grating scale reading head (6), an X-axis precision motion guide rail (8), a Y-axis linear motor rotor (9), a Y-axis grating scale reading head (12), a Y-axis precision motion guide rail (18), an X-axis linear motor rotor (19) and the like. The XY motion platform driven by the double-layer linear motor has high driving capacity, high motion speed, reasonable linear motor decoupling mode and small structure size, and is suitable for high-speed packaging operation of a semiconductor integrated chip performed on a production line and in other narrow spaces.

Owner:HARBIN INST OF TECH

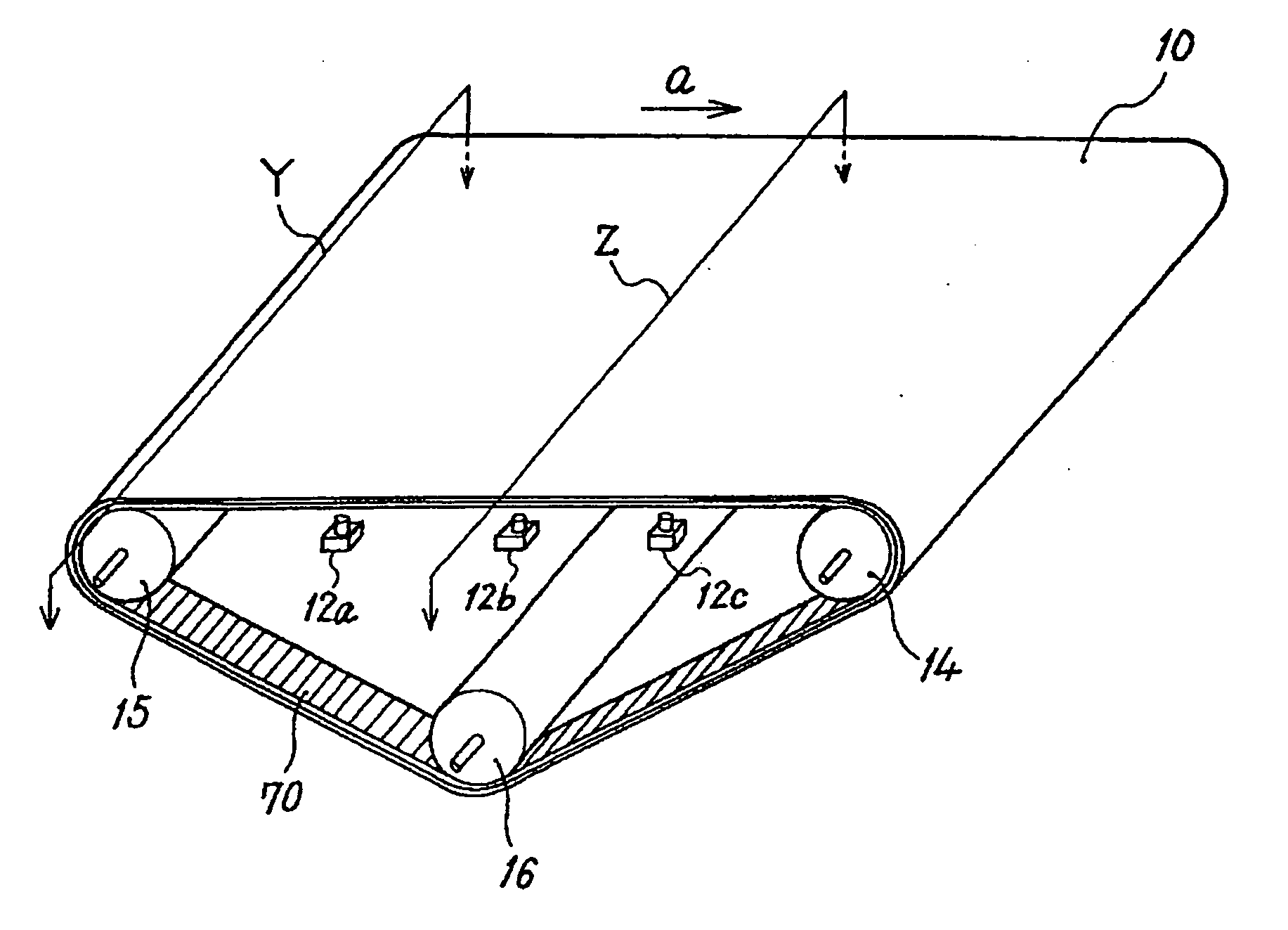

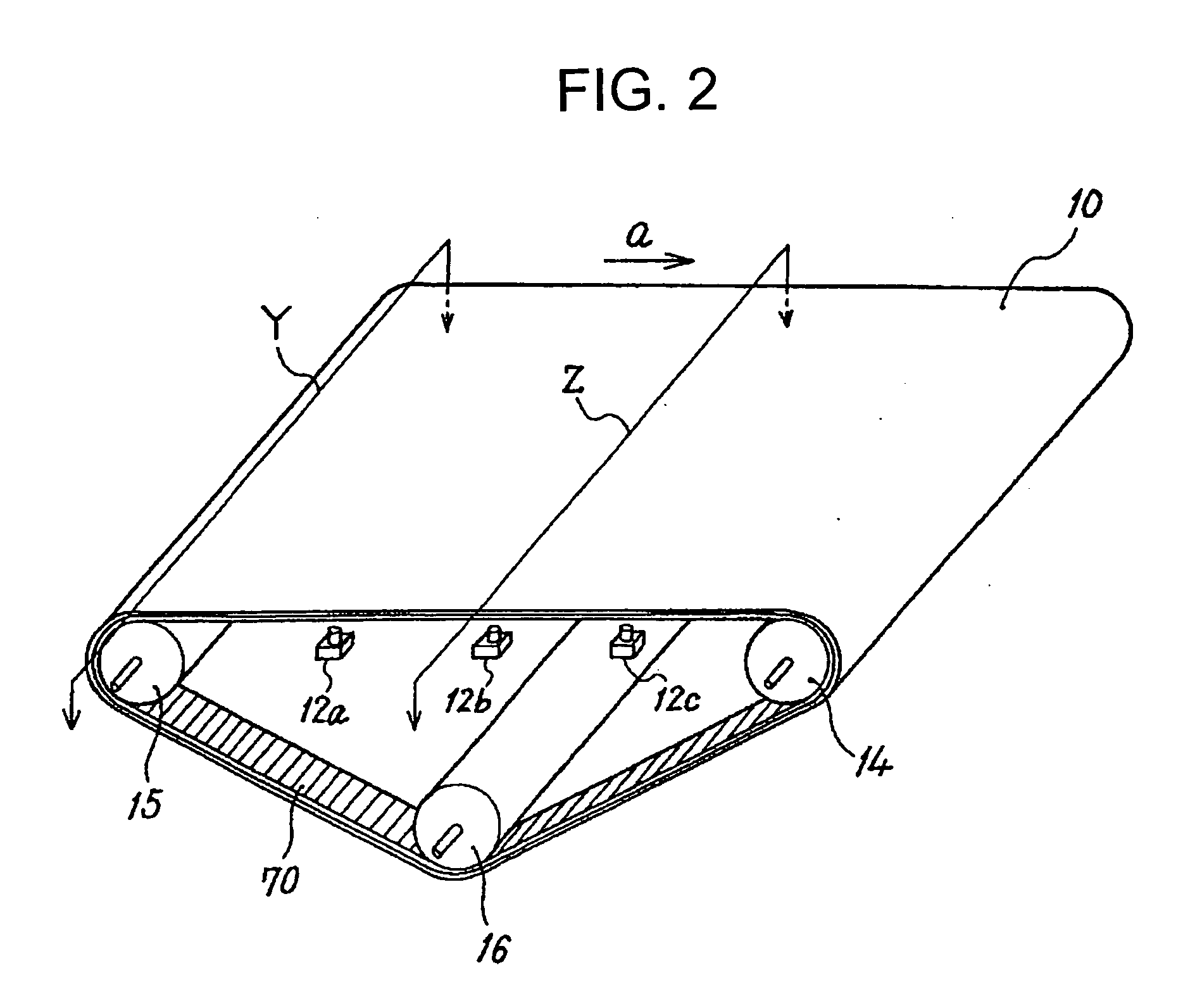

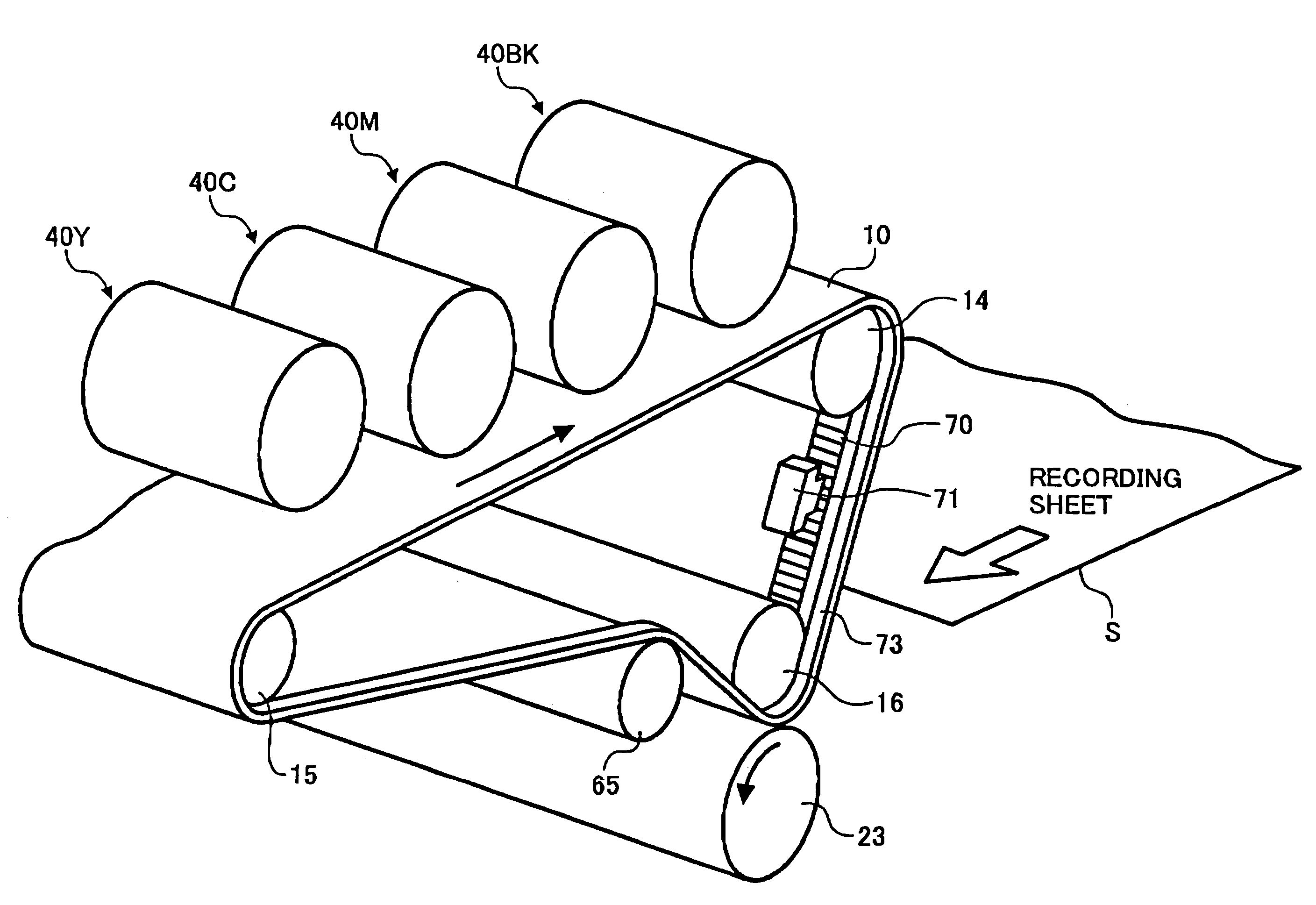

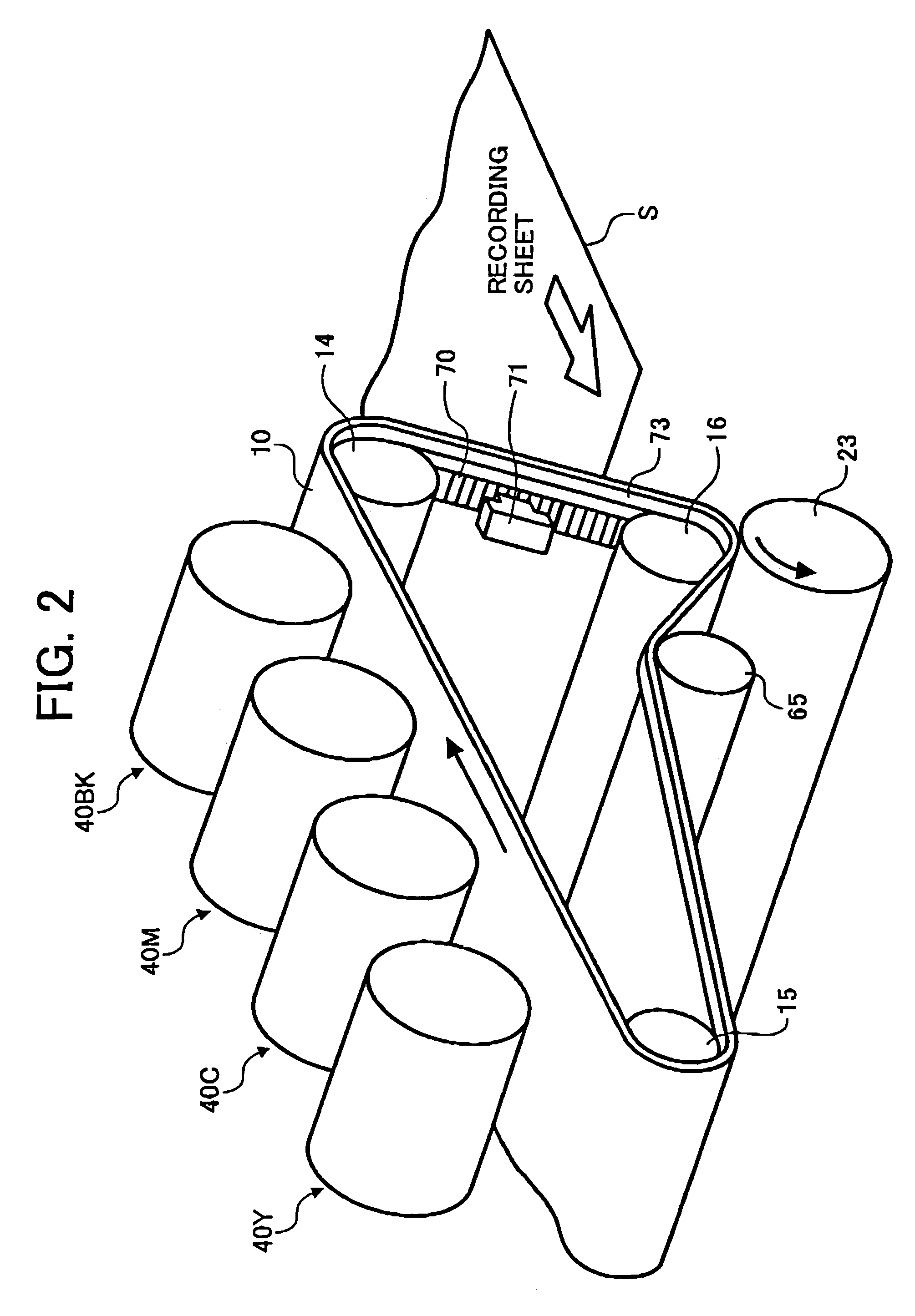

Method and apparatus of image forming capable of suitably controlling transfer characteristic

InactiveUS7245863B2Recording apparatusElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus includes a rotating member, a drive mechanism, a scale, and a scale reading mechanism. The rotating member is configured to carry an image. The drive mechanism is configured to rotationally drive the rotating member. The scale is provided around an entire perimeter of a surface of the rotating member. The scale reading mechanism is configured to read the scale and arranged in a region where the rotating member is prevented from wavering or being distorted. A rotating drive of the rotating member is controlled based on information read by the scale reading mechanism.

Owner:RICOH KK

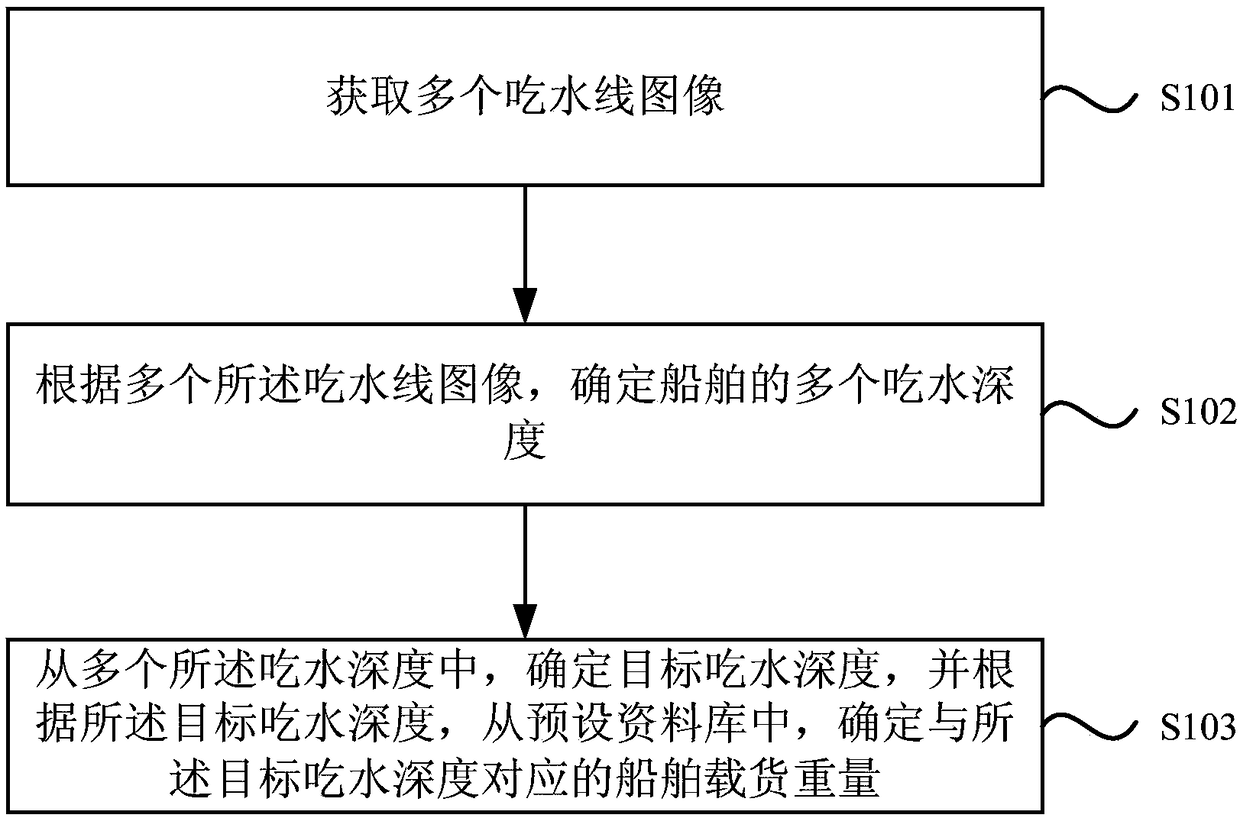

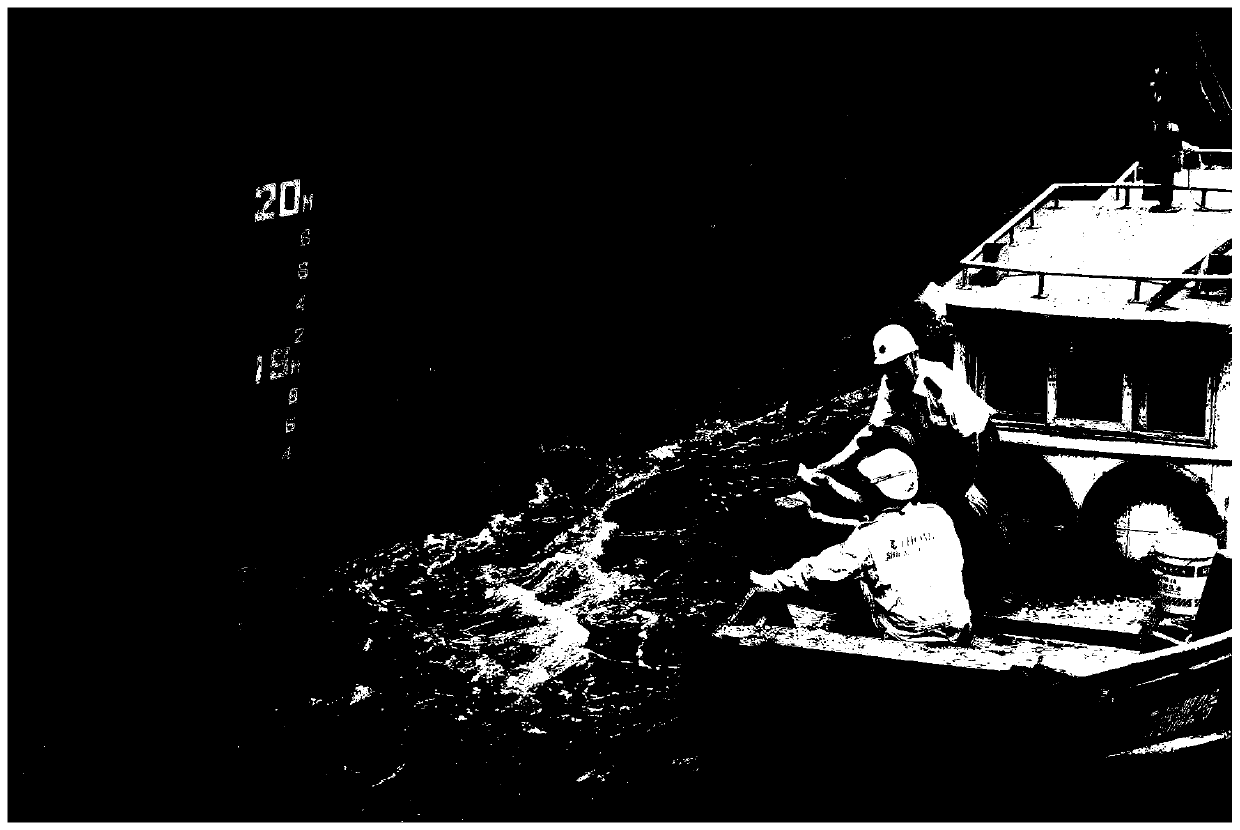

Ship cargo weight determining method and device

ActiveCN108423136AOvercome errorOvercome time-consuming technical issuesCharacter and pattern recognitionWeighing apparatus using fluid action balancingMarine engineeringVisual inspection

The embodiment of the invention discloses a ship cargo weight determining method and device. The ship cargo weight determining method comprises the steps that multiple waterline images are obtained; according to the multiple waterline images, multiple immersion depths of a ship are determined; the immersion depth of a target is determined, and the ship cargo weight corresponding to the immersion depth of the target is determined from the multiple immersion depths, and the ship cargo weight corresponding to the immersion depth of the target is determined from a preset data bank according to thetarget immersion depth. By adopting the technical scheme, the technical problem is solved that large errors and long consumed time likely occurred due to water gauge scale reading through traditionalmanual visual inspection under the situation that the ship is disturbed and affected by stormy waves and waves are large, subjective errors brought by manual reading are avoided, the measurement precision and working efficiency are improved, and the ship cargo weight determining method is safe in operation, convenient, capable of saving time and good in practicability.

Owner:英飞智信(北京)科技有限公司 +1

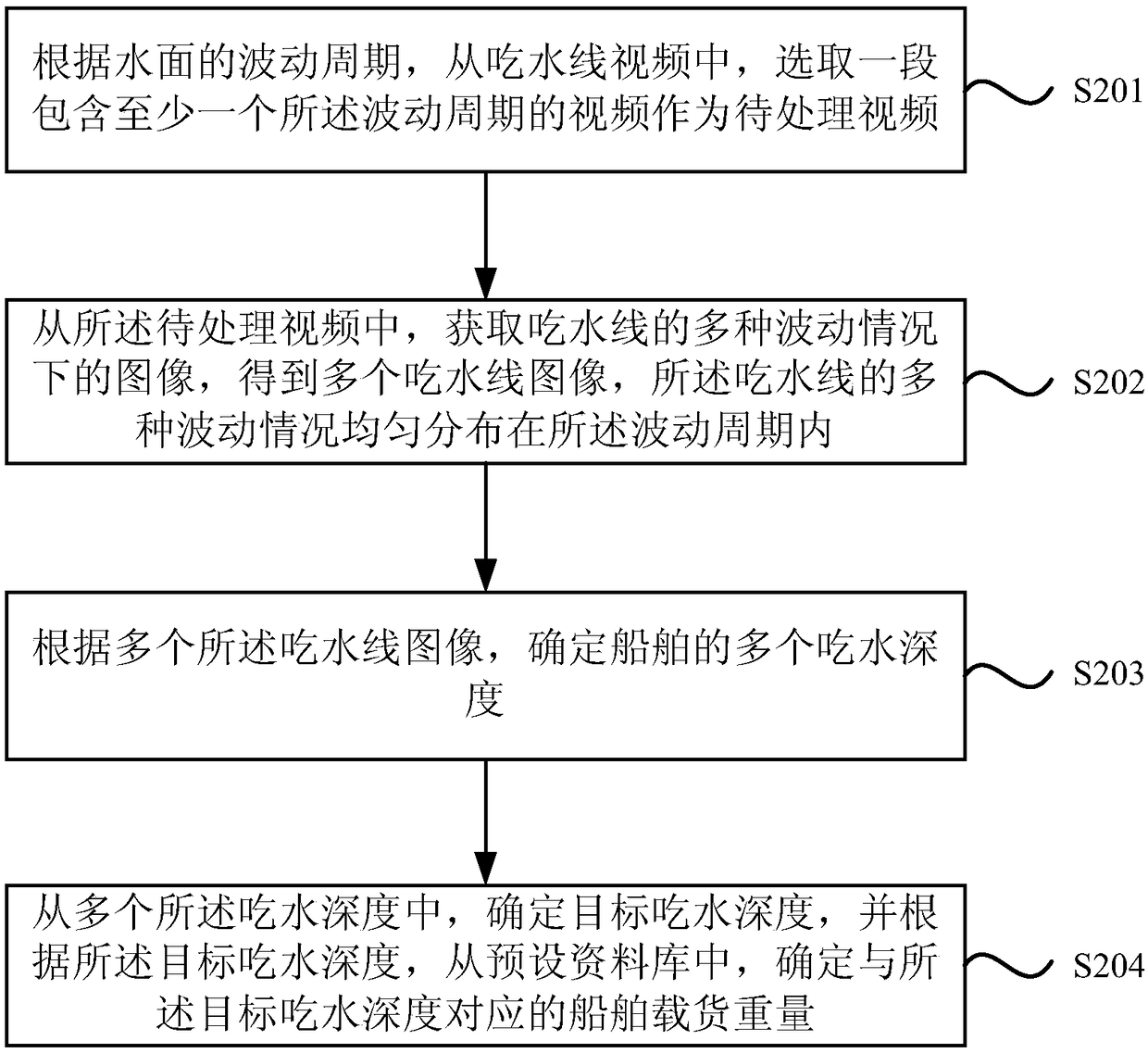

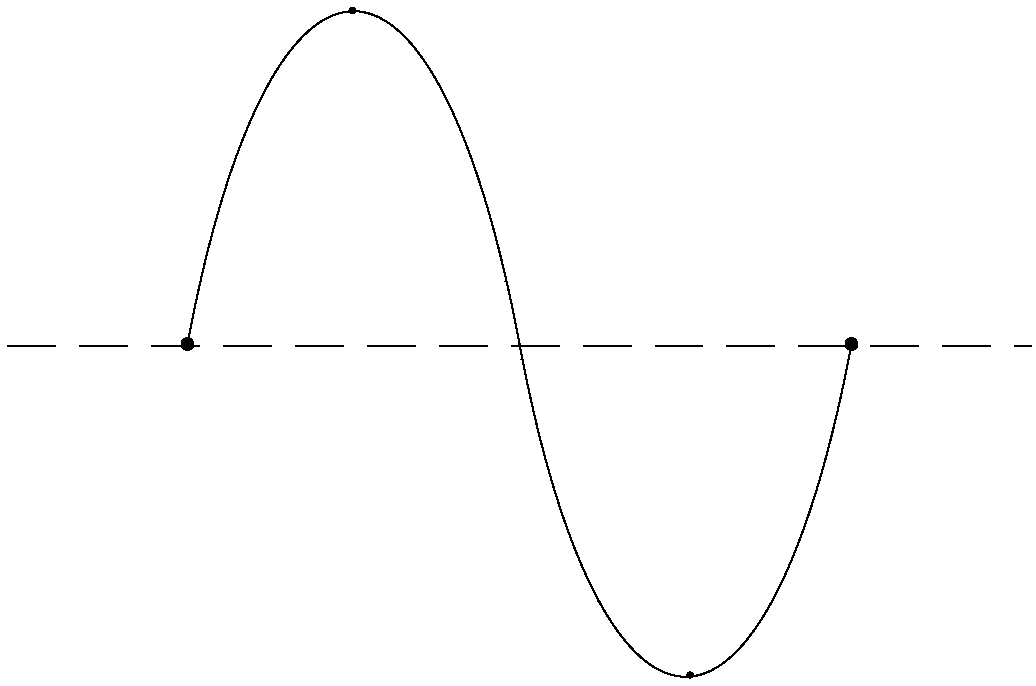

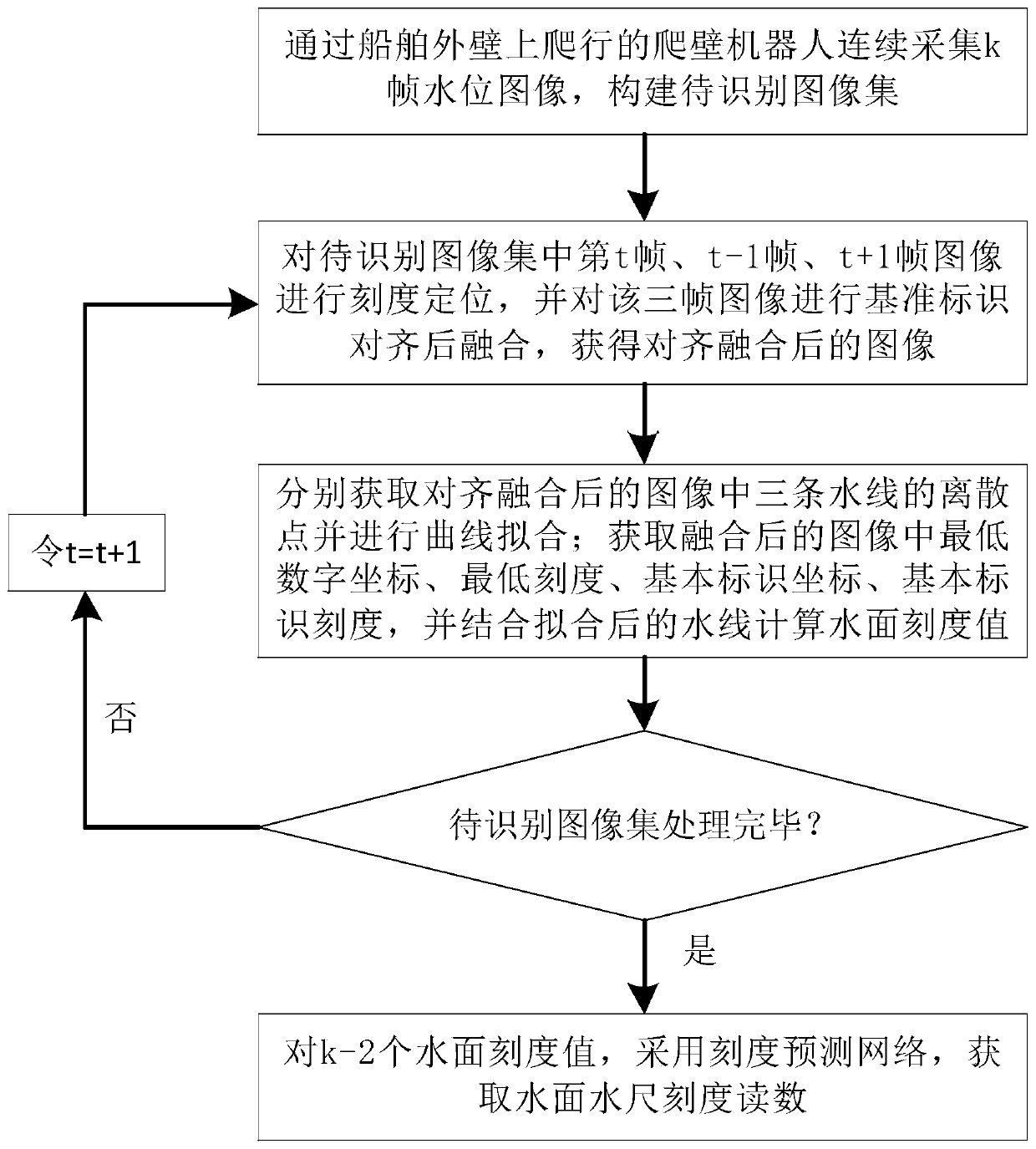

Ship water gauge identification method, system and device based on wall-climbing robot

ActiveCN110334680AShooting stabilityEliminate distracting factorsCharacter and pattern recognitionVessel stability improvementShortest distanceCurve fitting

The invention belongs to the technical field of ship measurement, particularly relates to a ship water gauge identification method, a ship water gauge identification system and a ship water gauge identification device based on a wall-climbing robot. The invention aims to solve the problems that an existing water gauge identification method is not easy to perform water gauge reading in a short distance and data reading is inaccurate. The method comprises the steps that carrying out scale calibration and reference identification coordinate alignment on the t frame, the t-1 frame and thet+1 frame of collected continuous k frames of water level images to obtain a fused image; performing curve fitting on the waterline discrete points of the fused image; obtaining the image parameters of the fused image, and calculating water surface scale values in combination with a fitting waterline; obtaining water surface water gauge scale readings based on k-2 water surface scale values. According to the invention, the wall-climbing robot is adopted to acquire video data at a short distance and read the scales of the image water gauge, so that the danger is reduced. The labor cost is saved. The efficiency and accuracy are improved. The systematic management is realized, and storage, management and search are easy in operation.

Owner:南京海豚梦智能科技有限公司

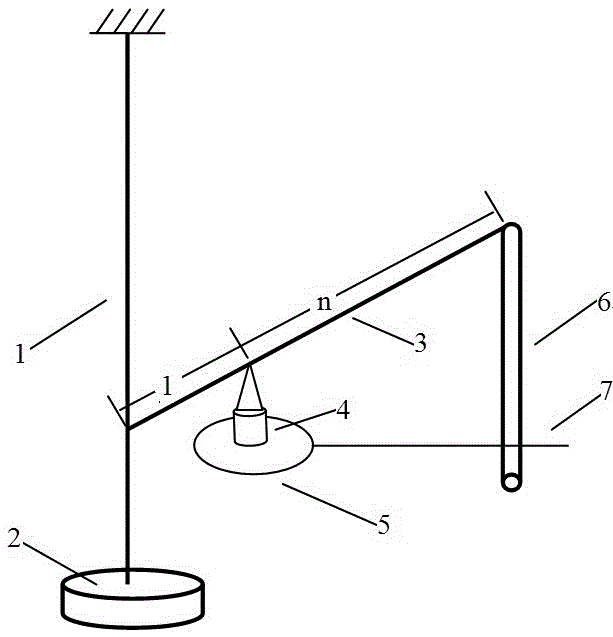

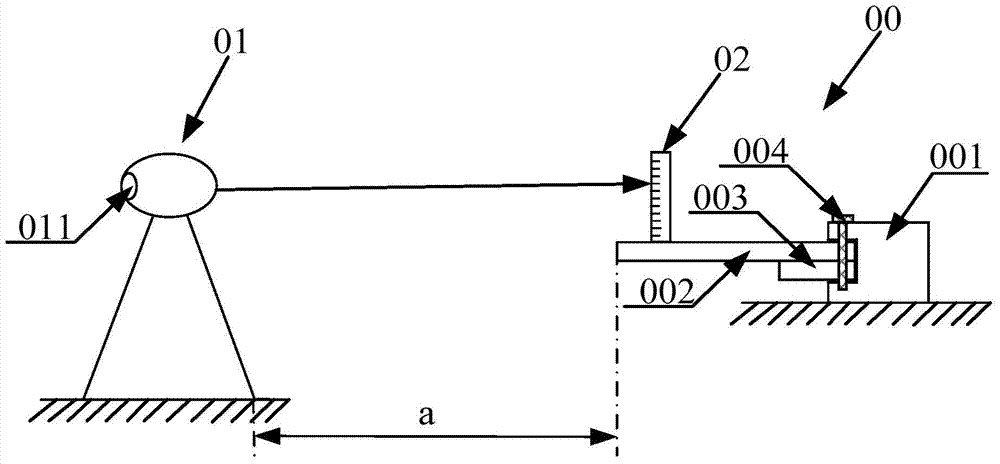

Young modulus measuring method achieved through metal wire drawing method

InactiveCN106018116AEasy to measureLow costMaterial strength using tensile/compressive forcesYoung's modulusRead through

The invention provides a Young modulus measuring method achieved through a metal wire drawing method, and relates to physical parameter measuring. According to the technical scheme for simplifying Young modulus measuring, the upper end of a metal wire is fixed, and a tray is fixed to the lower end of the metal wire; one end of a lever is clamped on the metal wire, a support point of the lever is fixed to the upper end of a support, and the lever can rotate around the support point; a cylindrical scale is hung at the tail end of the lever; a horizontal slender rod stretches out of a fixing platform, and the tail end of the right side of the horizontal slender rod is in a cylindrical shape and is used as a reading pointer; the diameter d of the metal wire is measured, the distance L between the fixing point of the lever on the metal wire and the upper end fixing point of the metal wire is measured, the magnification times n of the lever is measured, the reading number x1 of the scale is read through the position where the slender rod points, a weight with the mass of m is added on the tray, the scale reading number x2 of the position where the slender rod points is read again, and then the Young modulus Y=4 m*g*n*L / (pi*d<2>*|x2-x1|) is obtained, wherein g is the gravity acceleration, and pi is the circumference ratio. The method has the advantages that the cost is reduced, and regulation is convenient.

Owner:SICHUAN UNIV

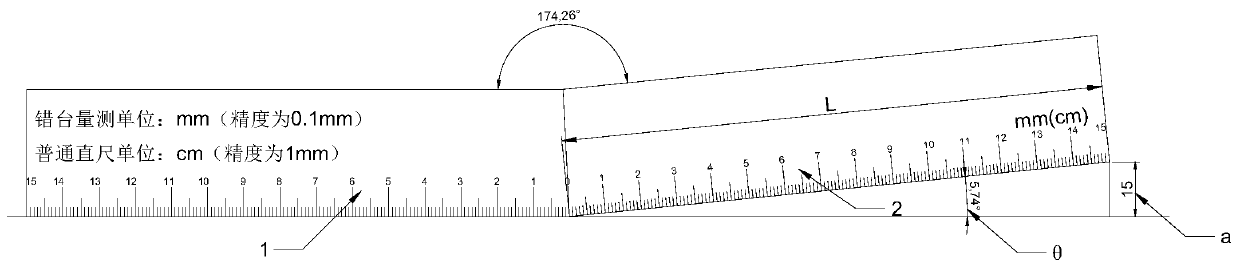

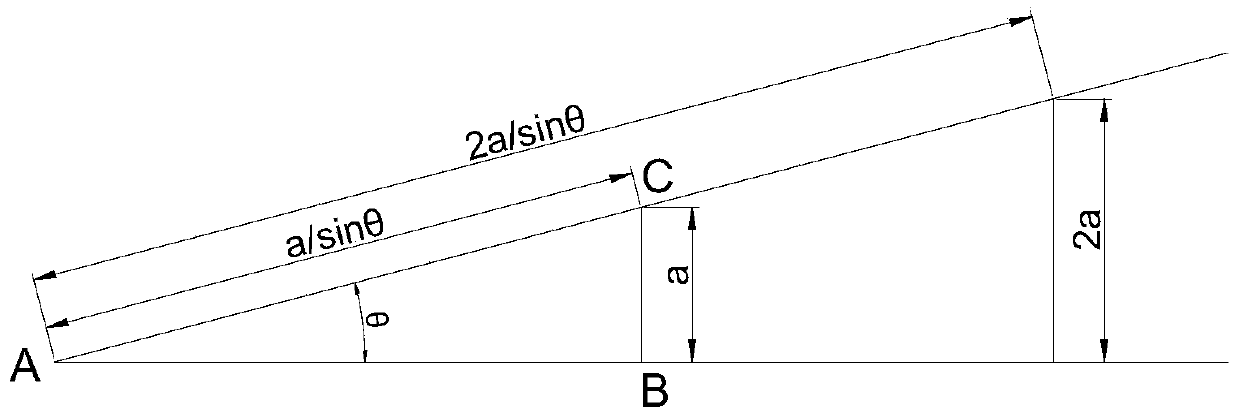

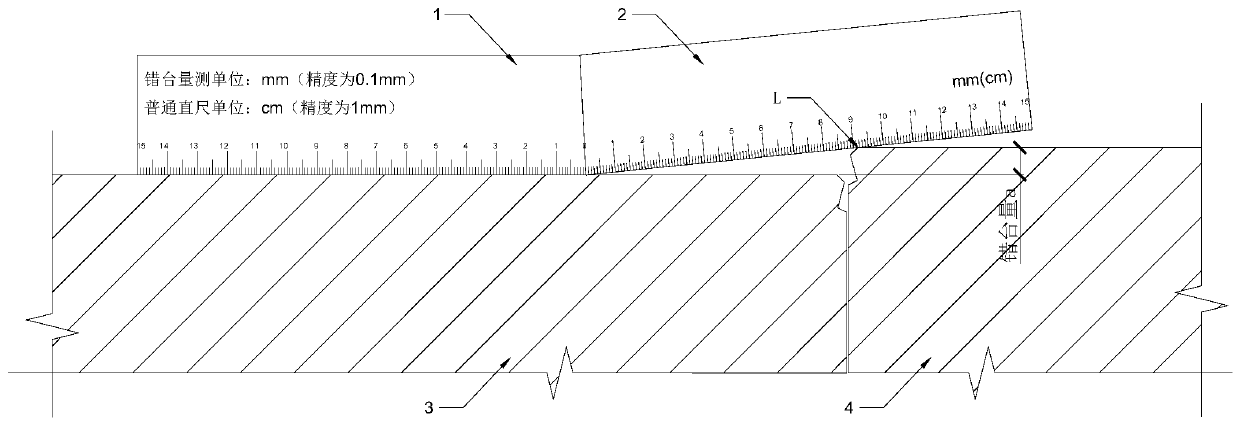

Segment dislocation measuring device and method

PendingCN109900184AImprove efficiencyHigh precisionMechanical measuring arrangementsNuclear energy generationUltimate tensile strengthMeasuring ruler

The invention discloses a segment dislocation measuring device and method. The device comprises a first measuring ruler (1) and a second measuring ruler (2); the first measuring ruler and the second measuring ruler are both rulers with scale marks; the 0 scale mark end of the first measuring ruler is connected with the 0 scale mark end of the second measuring ruler; an angle between the first measuring ruler and the second measuring ruler is 180 degrees-theta; and a dislocation quantity a is equal to a scale reading L*sin (180 degrees-theta). The method includes the following steps that: the scale mark side of the first measuring ruler is attached onto a first segment (3); step 2, the first measuring ruler slides along the first segment toward a second segment, so that the scale mark sideof the second measuring ruler contacts with the edge of the upper end of the second segment; and step 3, the dislocation quantity a is calculated through the scale reading L. With the device and method of the invention adopted, measurement errors and measurement work intensity can be decreased, accurate and timely dislocation data are provided for a shield formed tunnel, the analysis of the causeof dislocation is assisted, construction parameters are adjusted, and a preliminary basis is provided for high-quality formed tunnels.

Owner:中建八局轨道交通建设有限公司

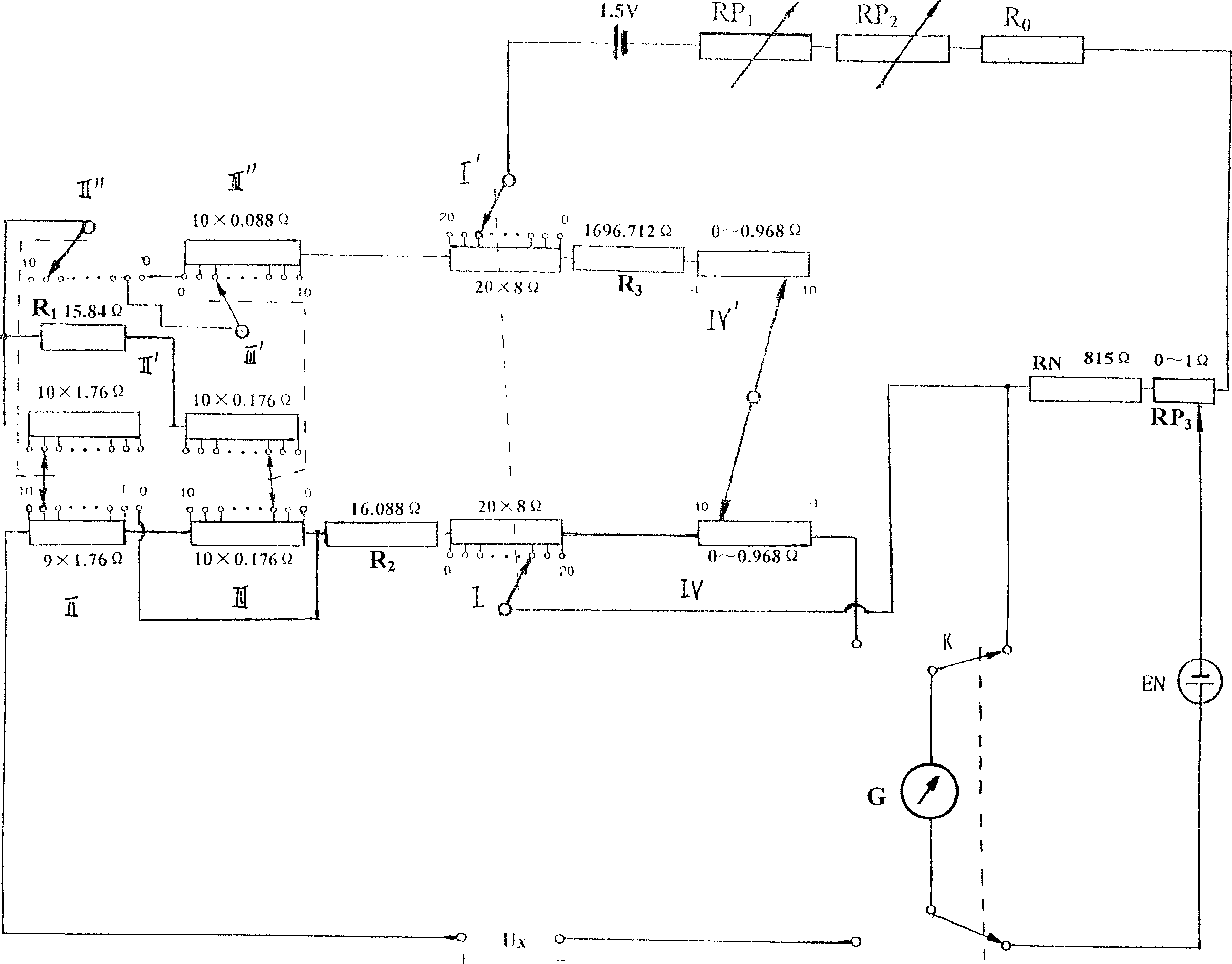

Direct current potentiometer having five scale readings

InactiveCN1991387AGood repeatabilityAc/dc potentiometric measuring arrangementsElectrical resistance and conductanceEngineering

The invention provides a DC potentiometer with five-digit reading for DC voltage measurement, and comprises three measuring discs of 20X8 Omega, 9X1.76 Omega, 10X0.176 Omega and a 0-0.968 Omega slide discs for providing five-digit reading system, all the resistors for measurement are connected directly with wires, thereby eliminating the contact resistance and variation difference of the step switch from the measurement result.

Owner:骆乃光

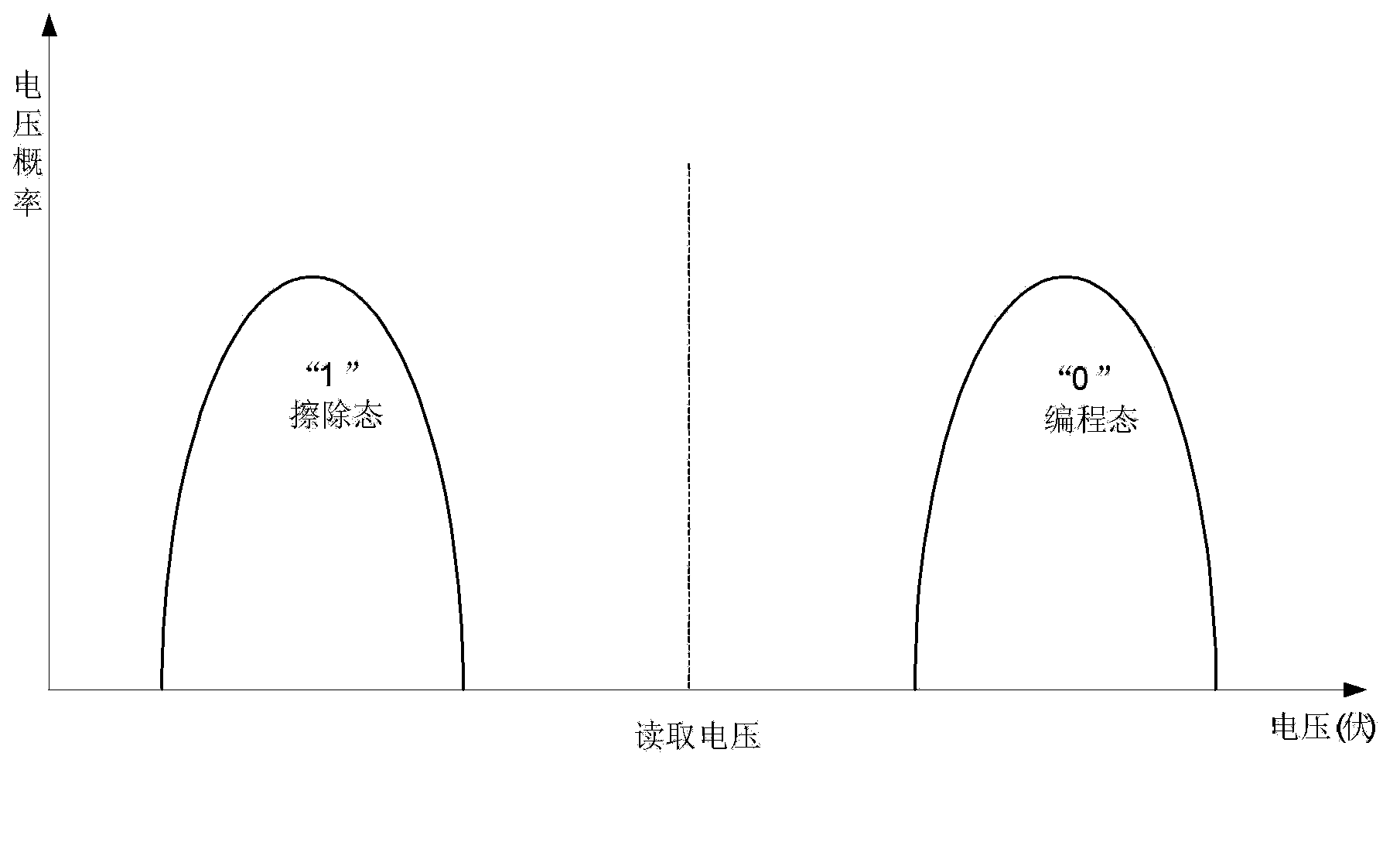

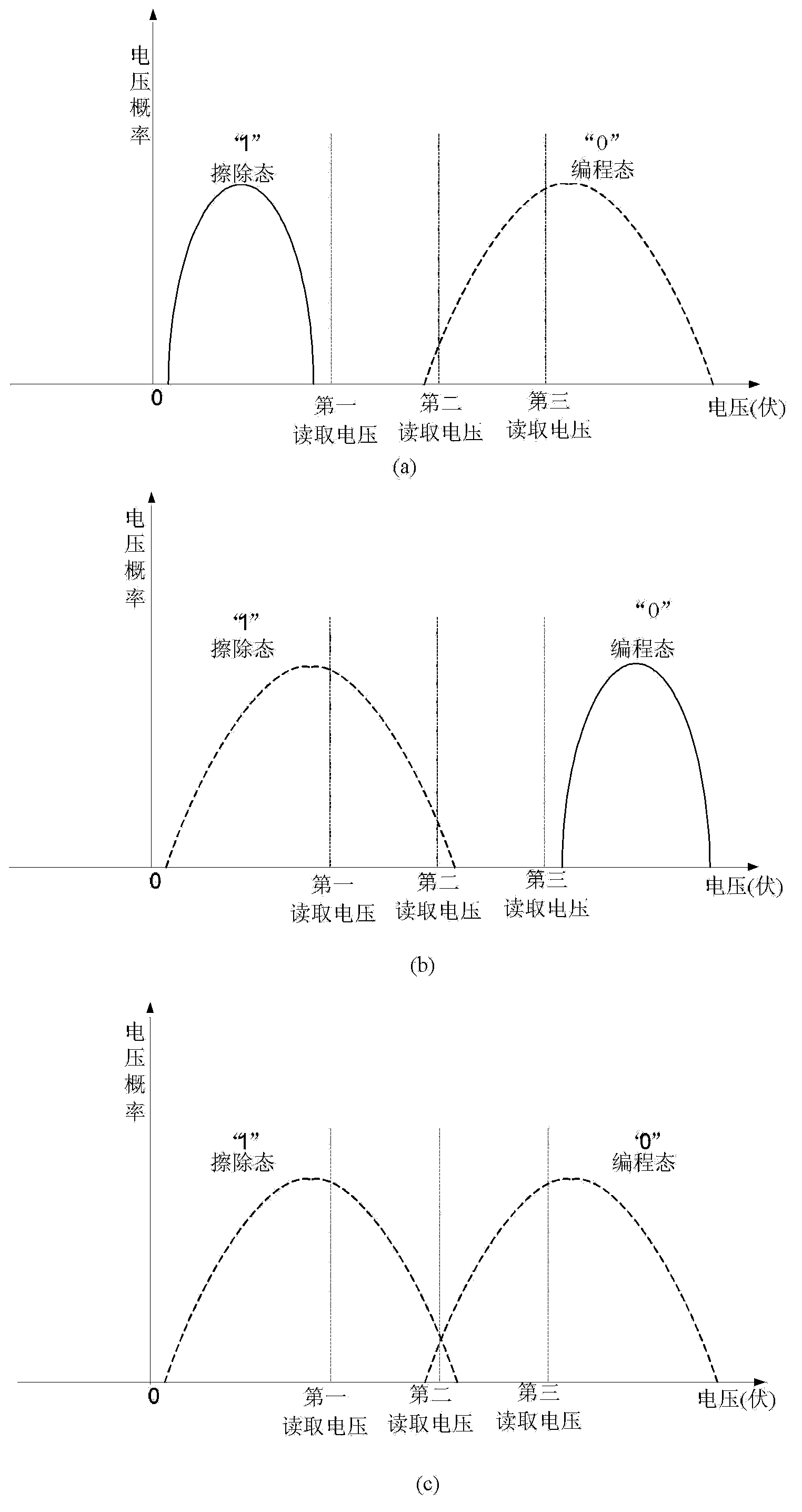

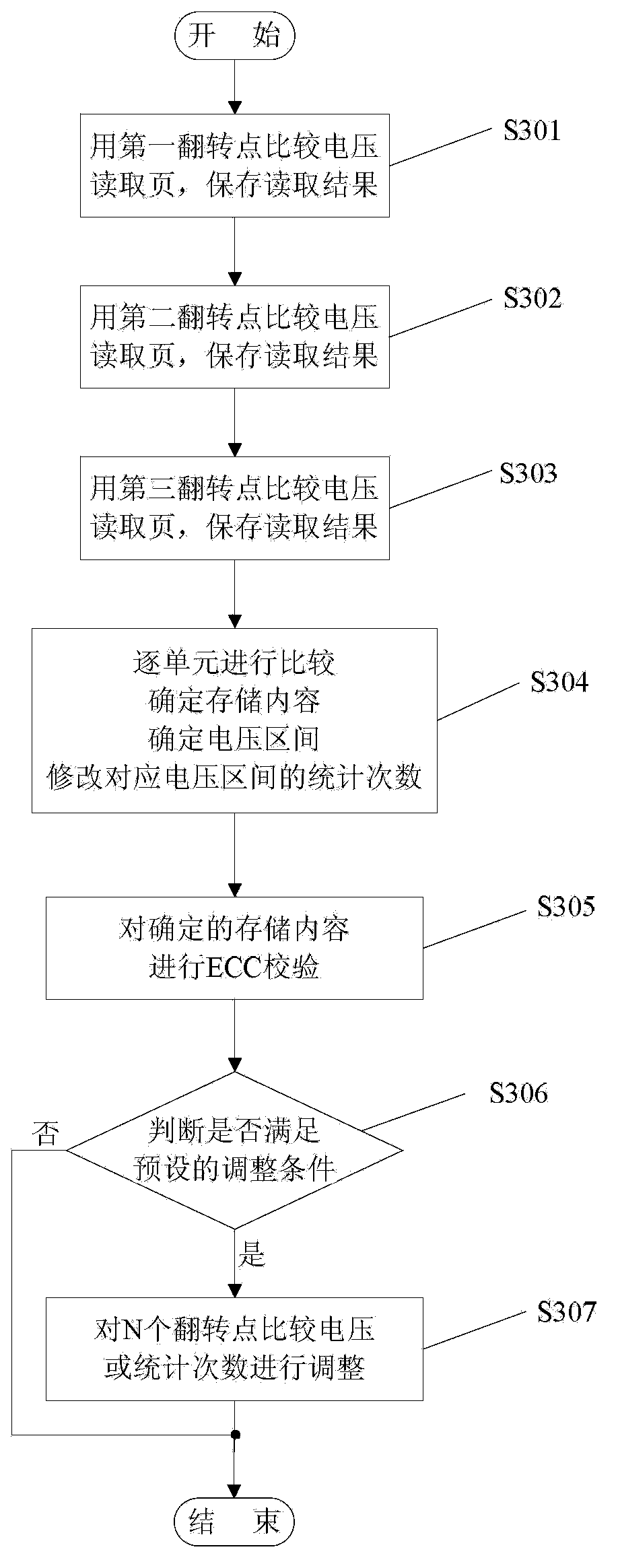

High-reliability NAND Flash reading method and system

ActiveCN103811070AImprove accuracyReduce the probability of false readsRead-only memoriesDependabilityComputer science

The invention relates to the technical field of data storage, and discloses a high-reliability NAND Flash reading method and system. The method comprises the following steps: storing N turnover point comparison voltages in a peripheral circuit, wherein the N turnover point comparison voltages are arranged to form N+1 voltage intervals by size, the number of statistic times of the voltage intervals are respectively stored in the peripheral circuit of the NAND Flash, and N is an odd number which is greater than 1; when receiving a reading command, acquiring N reading results by respectively using the storage states of the storage units in the N turnover point comparison voltage reading page; and sequentially determining the storage states and voltage intervals of the storage units, determining the reading result of the page, and adjusting the N turnover point comparison voltages. By adopting the multiple-reading mode, temporarily storing and comparing the reading results each time and combining ECC (error correction code) verification, the method and system can effectively reduce the probability of error reading in large-scale reading and enhance the accuracy of the reading operation.

Owner:GIGADEVICE SEMICON (BEIJING) INC

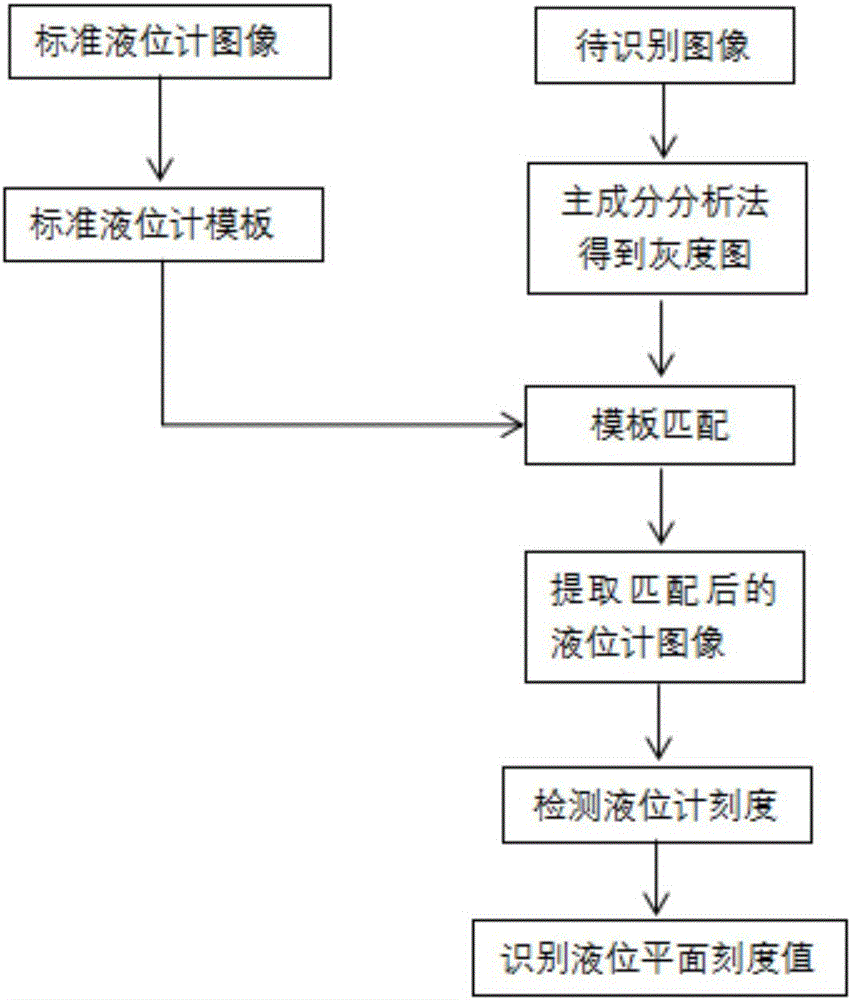

Method for accurately recognizing liquid level by template matching

ActiveCN106643965AEfficient identificationHigh speedImage analysisMachines/enginesTemplate matchingGray level

The invention discloses a method for accurately recognizing a liquid level by template matching. The method comprises the following steps that step 1, a standard liquid level meter image is taken and a liquid level meter standard template is established; step 2, an image containing a liquid level meter is taken, an optimum projection gray level diagram of the liquid level meter is obtained by principal component analysis; step 3, the liquid level meter standard template is matched with the optimum projection gray level diagram of the liquid level meter; step 4, a liquid level meter image after matching is extracted; step 5, the scale position of the liquid level meter image after matching is recognized, the highest and lowest points of liquid level meter scales are read out, and the scale reading is determined by the proportion relation; the method for accurately recognizing the liquid level by template matching solves the technical problem in traditional measurement methods that the accuracy and speed are not satisfied in liquid level detection in substations.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

Adjustable wood curved slot processing equipment

ActiveCN110293612AEasy to processPrecise processingDovetailed workProfiling/shaping machinesEngineeringMechanical engineering

The invention discloses adjustable wood curved slot processing equipment. The adjustable wood curved slot processing equipment comprises a processing table, wherein the upper end of the processing table is fixedly equipped with vertical plates; the upper ends of the vertical plates are fixedly equipped with rail plates; slide paths which are symmetrical left and right are arranged in the rail plates in a communication mode; and a variable rail device is arranged in the slide paths. According to the adjustable wood curved slot processing equipment disclosed by the invention, limitation reverseto a cutting edge cutting and rotating direction is adopted, a swing arm connected to a cutting edge is guided by an adjustable limiting plate, and rotates along with an arc surface for limiting platefolding, so that processing for curved slots with non-irregular angles is accomplished; a tool is adjusted by lifting to control feeding depth of curved slots in a wood surface, so that the tool is protected from shallow to deep; moreover, up-down reciprocating movement is realized through positive and negative rotation for processing wavy curved slots, so that processing ability of the equipmentis strengthened; and the bending angle and the feeding depth are specifically changed through scale readings, so that processing is more precise.

Owner:徐州光头强木业有限公司

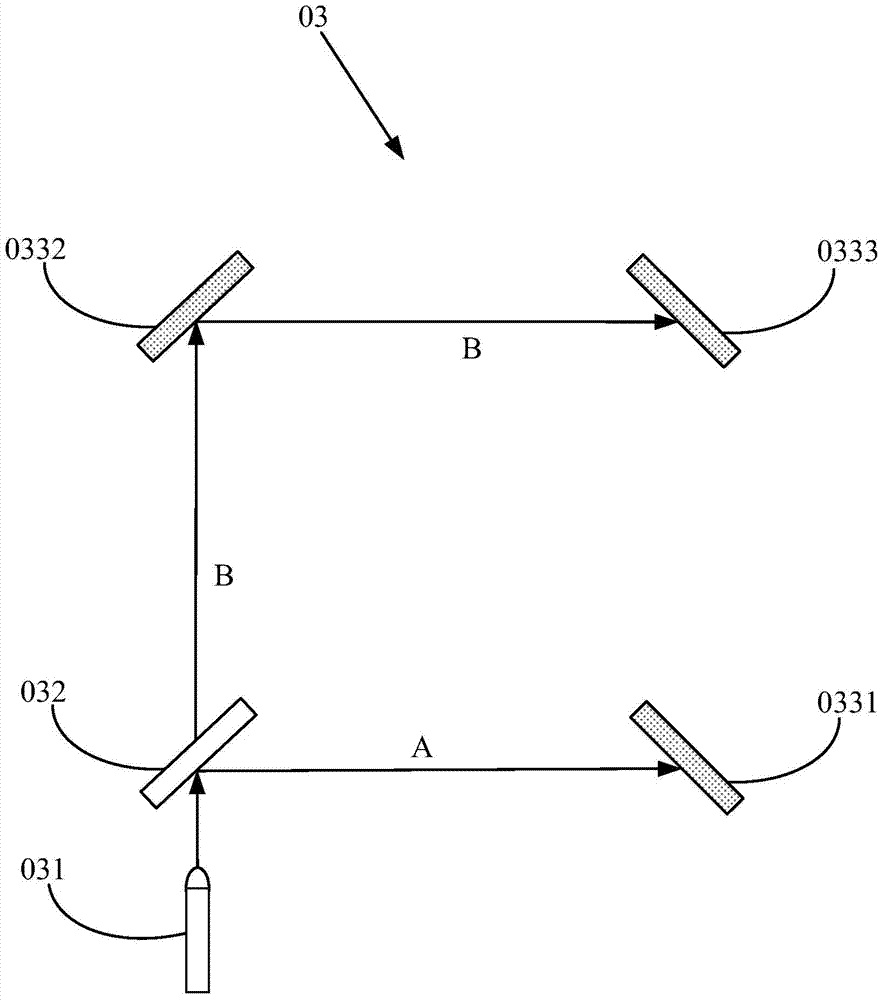

Levelness detection device and method and levelness regulation device and method

InactiveCN104776838AEasy to operateImprove detection accuracySurveying instrumentsManipulatorAcousticsLiquid crystal

The invention discloses a levelness detection device and method and a levelness regulation device and method, and belongs to the field of liquid crystal panel manufacturing. The levelness detection device comprises a light emitter, a half reflecting and half transmitting mirror, a first reflecting mirror, a second reflecting mirror and a third reflecting mirror, and the half reflecting and half transmitting mirror and the reflecting mirrors are provided with scales; a ray emitted by the light emitter are divided into two emergent rays through the half reflecting and half transmitting mirror, one emergent ray is emitted to the first reflecting mirror, the other emergent ray is emitted to the second reflecting mirror, the second reflecting mirror reflects the other emergent ray to the third reflecting mirror, and the scale readings on the half reflecting and half transmitting mirror and the reflecting mirrors are read and compared to detect the levelness. According to the levelness detection device and method and the levelness regulation device and method, the problems that in the prior art, the operation process is complex and artificial errors are prone to occurring are solved, and the effects of simplifying the operation process and improving the detection precision are achieved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com