Young modulus measuring method achieved through metal wire drawing method

A technology of Young's modulus and measurement method, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of tape bending, difficulty in accuracy, measurement error, etc., and achieve cost saving and convenience Measuring, reducing the effect of conditioning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

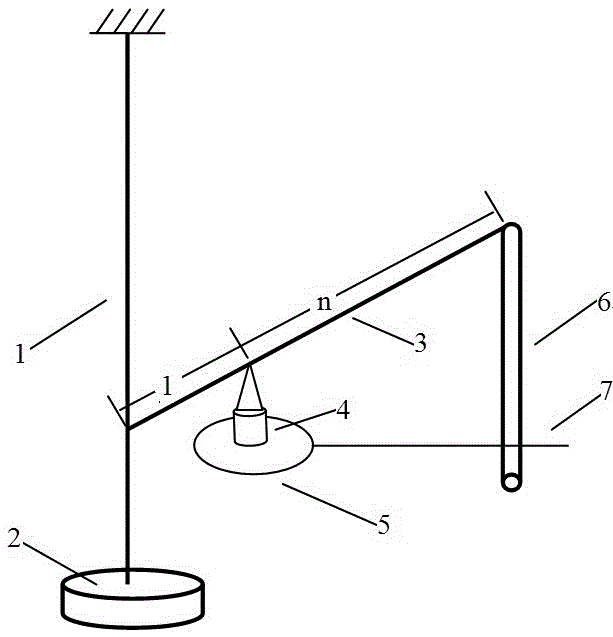

[0010] Metal wire stretching method Young's modulus measurement method, the upper end of a metal wire 1 (the object to be measured Young's modulus) is fixed on the support frame (that is, the upper end is fixed, the existing Young's modulus measurement, The upper end is generally fixed on the beam at the upper end of the support frame, and some are also fixed on the ceiling, which can be realized by the prior art), and a tray 2 is fixed on the lower end, and the tray 2 is used to add heavy objects (the prior art is to add or Reduce the weight, each weight is generally 1 kg), and the fixed point is located in the center of the tray.

[0011] A lever 3, one end of the lever 3 is clamped on the wire, because the lever itself is not strong, only a scale 6 (or called a scale) is hung on the right end, according to the similarity of the triangle, the purpose of the lever It only enlarges the elongation of the metal wire on the left, so the force between the lever and the metal wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com