Airtight type tested pieces air-leakage detecting device

A technology of detection device and test piece, applied in measurement device, by detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., it can solve problems affecting test accuracy, poor reading accuracy, working Pressure instability and other problems, to achieve the effect of scientific and reliable bubble collection method, stable experimental pressure, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

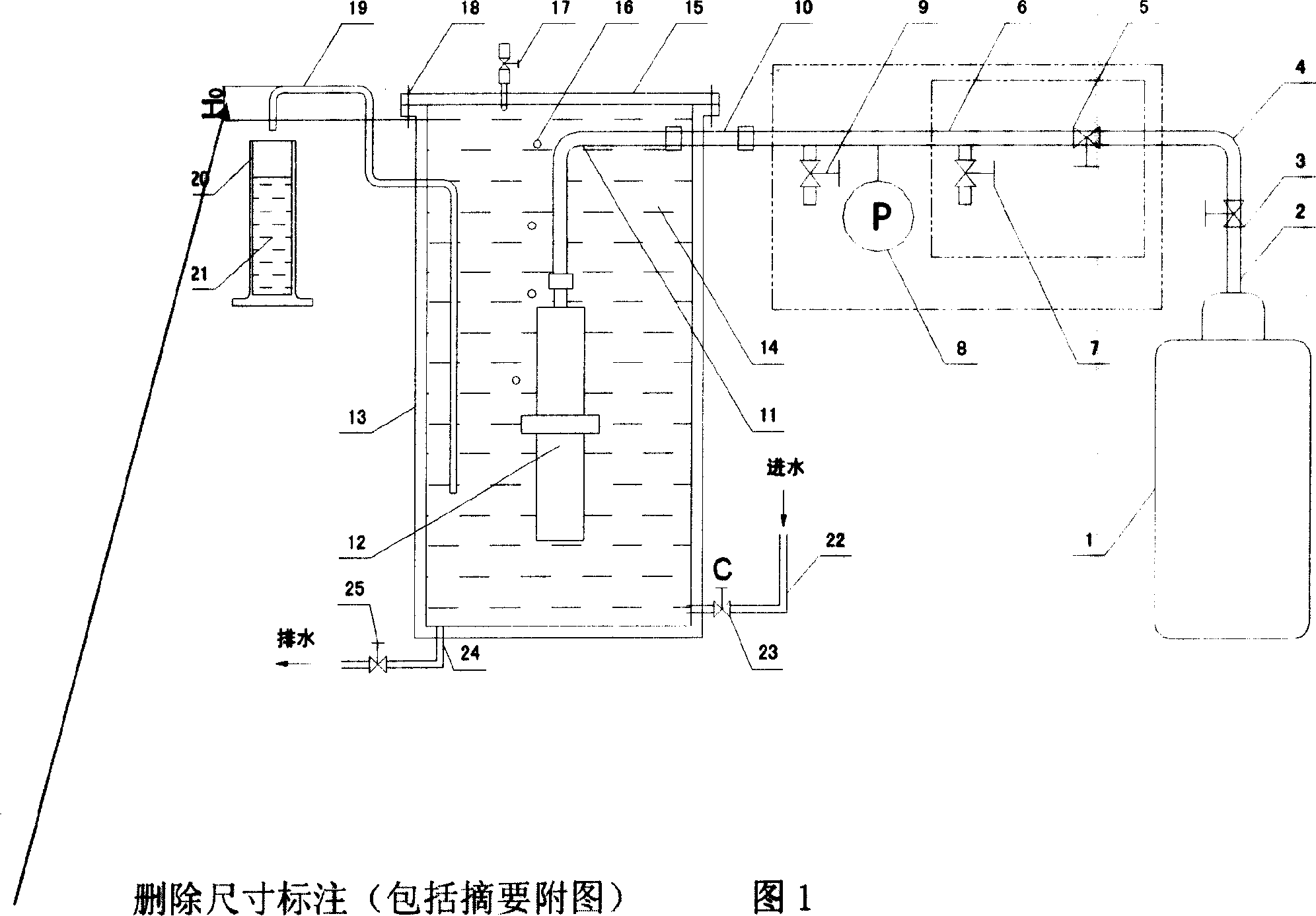

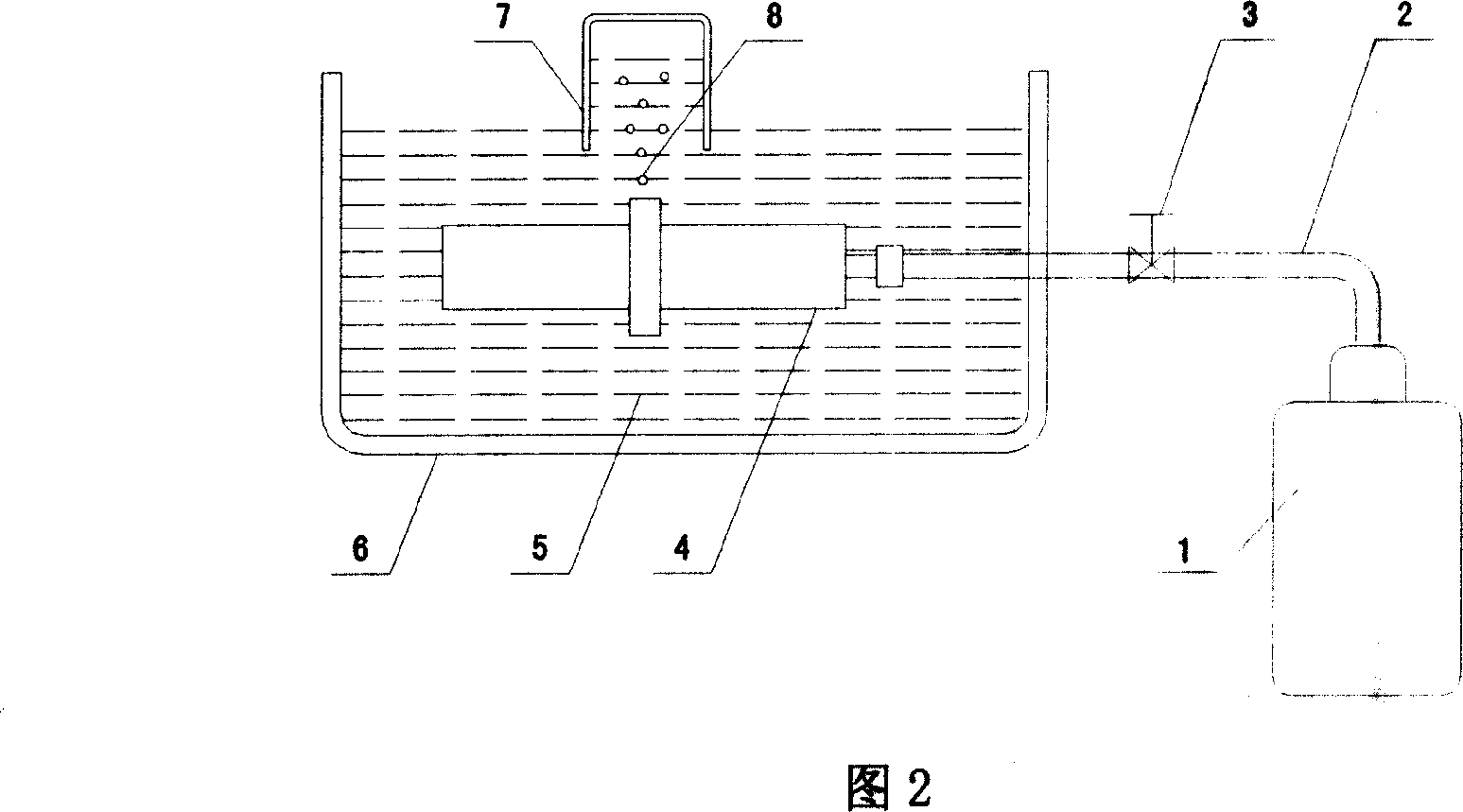

[0015] Figure 1 depicts a preferred embodiment of the invention. It mainly includes a water storage tank 13 for the watertight test piece, an air compression device 1 for charging the airtight test piece, and a measuring cup 21 for collecting air leakage from the watertight test piece. The air compression device can be a cylinder filled with compressed air, or an air source device from an air compressor. The water storage tank 13 that makes water storage container is formed on sealing port and passes through the sealing port cover 15 of bolt 18. During the test, the water-tight test piece is placed in the water storage tank 13 filled with water 14 to form a closed space. The test piece 12 is connected to the inner conduit 11, and is connected to the air compression device 1 through the outer conduit 10 connected to the outside. The outer conduit 10 is equipped with a pressure stabilizing mechanism, which mainly includes a pressure reducing valve 5 connected to the gas passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com