Method for refining mixed alcohol by rectification-pervaporation coupling process

A technology of pervaporation and mixing alcohol, applied in the field of separation, can solve the problems of not complying with energy saving and environmental protection, the number of rectification towers used is large, and the energy consumption is high, achieving clean production, saving reprocessing costs, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

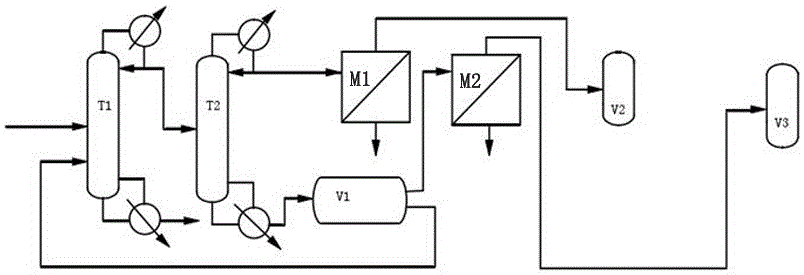

[0028] The rectification-pervaporation coupling process refines the method for mixed alcohol, and its specific steps are as follows:

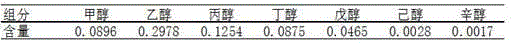

[0029] 1) A mixed alcohol solution with a water content of 93.8wt% and a feed flow rate of 15L / h, the reflux ratio of the dehydration tower is 1, the feed is fed in the middle, and it is dehydrated by rectification and dehydration in the dehydration tower T1. Distillate composition is as shown in table 1;

[0030] 2) The top product enters the crude separation tower T2, the reflux ratio of the crude separation tower is 3, and the middle part feeds; the content of the tower top product is shown in Table 2, and the content of the tower bottom product is shown in Table 3; the obtained tower bottom product enters the separation Phase device V1, the temperature of the phase separator is 50°C, the oil phase product enters the pervaporation device M2 for further dehydration; the top product of the crude separation tower directly enters the pervaporati...

Embodiment 2

[0032] Fischer-Tropsch synthetic wastewater mixed alcohol refining process coupled with rectification-pervaporation process, the specific steps are as follows:

[0033] 1) A mixed alcohol solution with a water content of 93.8wt% and a feed flow rate of 15L / h. The reflux ratio of the dehydration tower is 1, and the feed is fed in the middle. It is dehydrated by rectification and dehydration in the dehydration tower T1. Composition is as shown in table 1;

[0034] 2) The top product enters the crude separation tower T2, the reflux ratio of the crude separation tower is 3, and the middle part feeds; the content of the tower top product is shown in Table 2, and the content of the tower bottom product is shown in Table 3; the obtained tower bottom product enters the separation The phase separator V1, the temperature of the phase separator is 50°C, the oil phase product enters the pervaporation device M2 for further dehydration; the top product directly enters the pervaporation devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com