Rubber leveling machine tool

A machine tool and rubber technology, applied in the field of machine tools, can solve the problems of low recycling rate of waste tires, restricting the recycling and utilization of waste tires, low degree of automation, etc., and achieves the effect of simple structure, reduced reprocessing cost, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

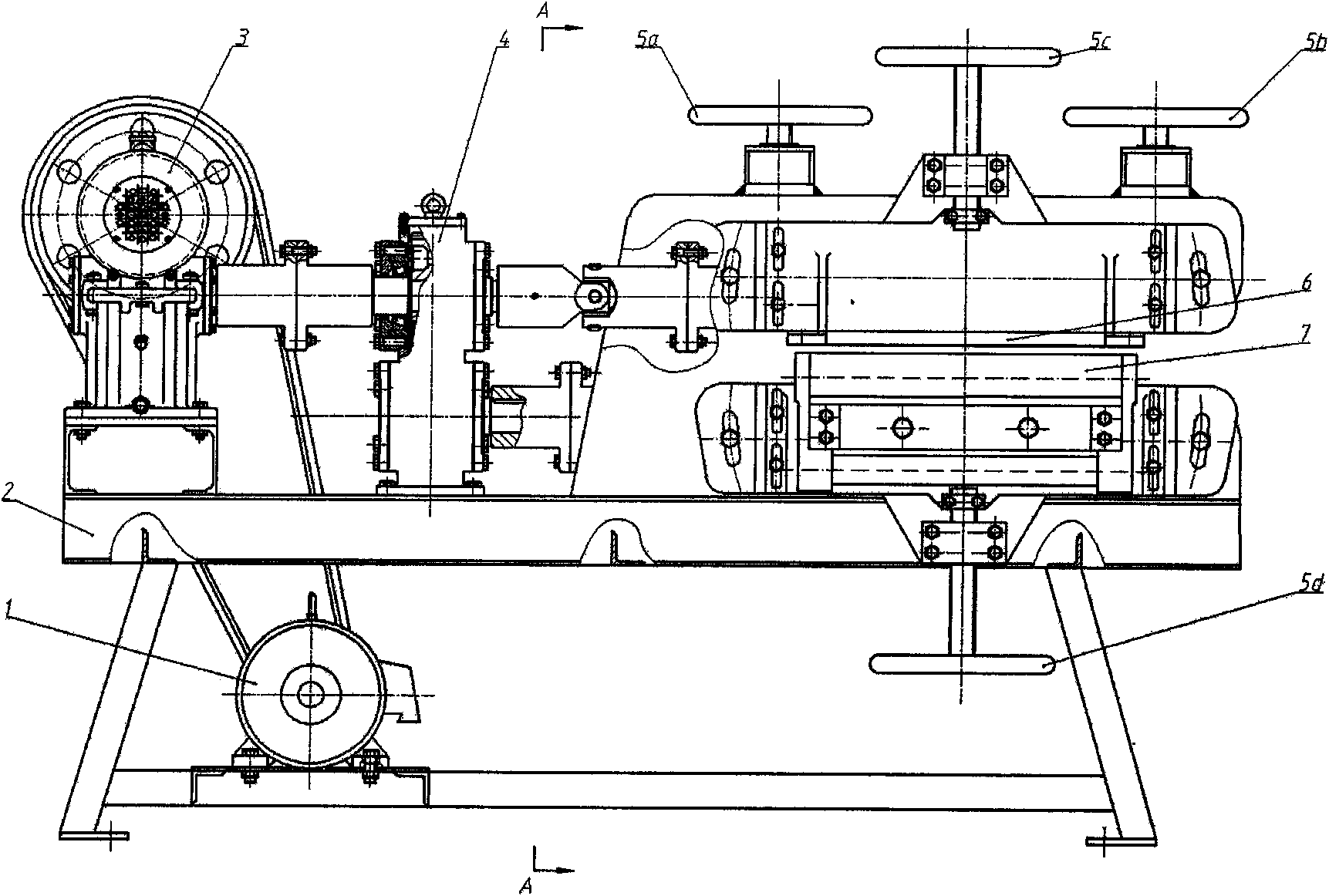

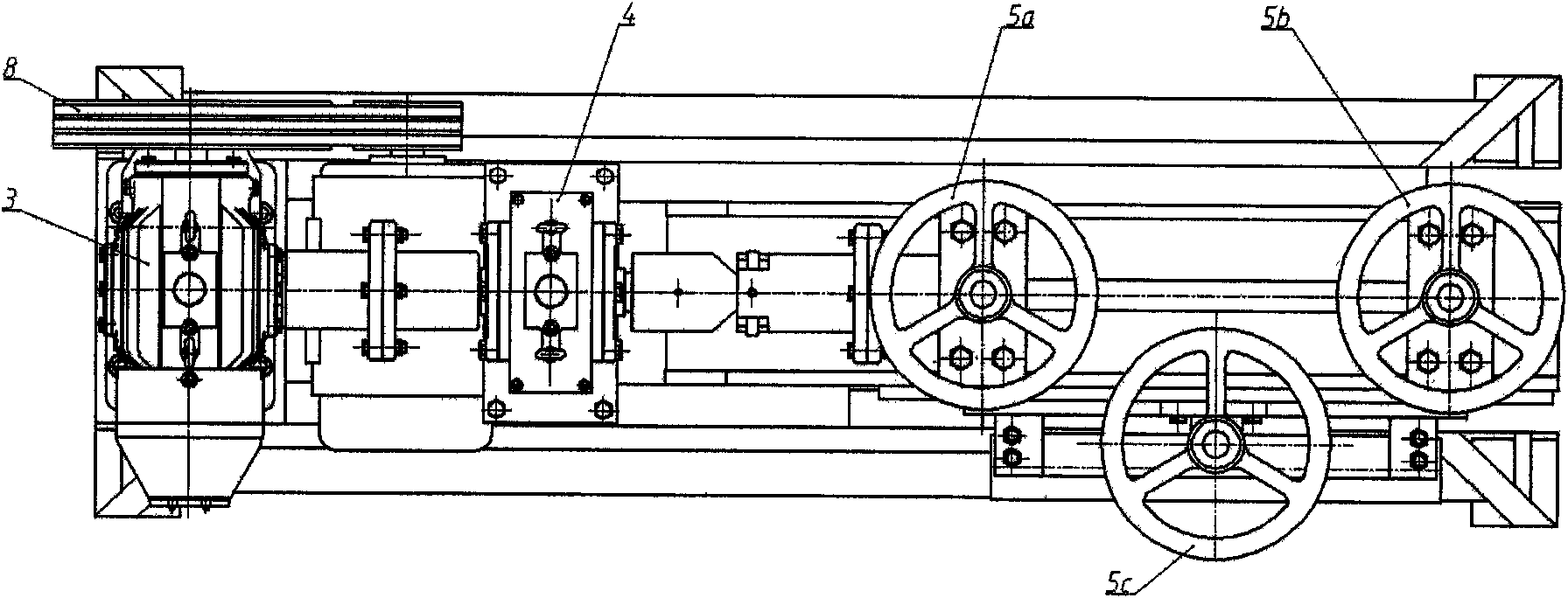

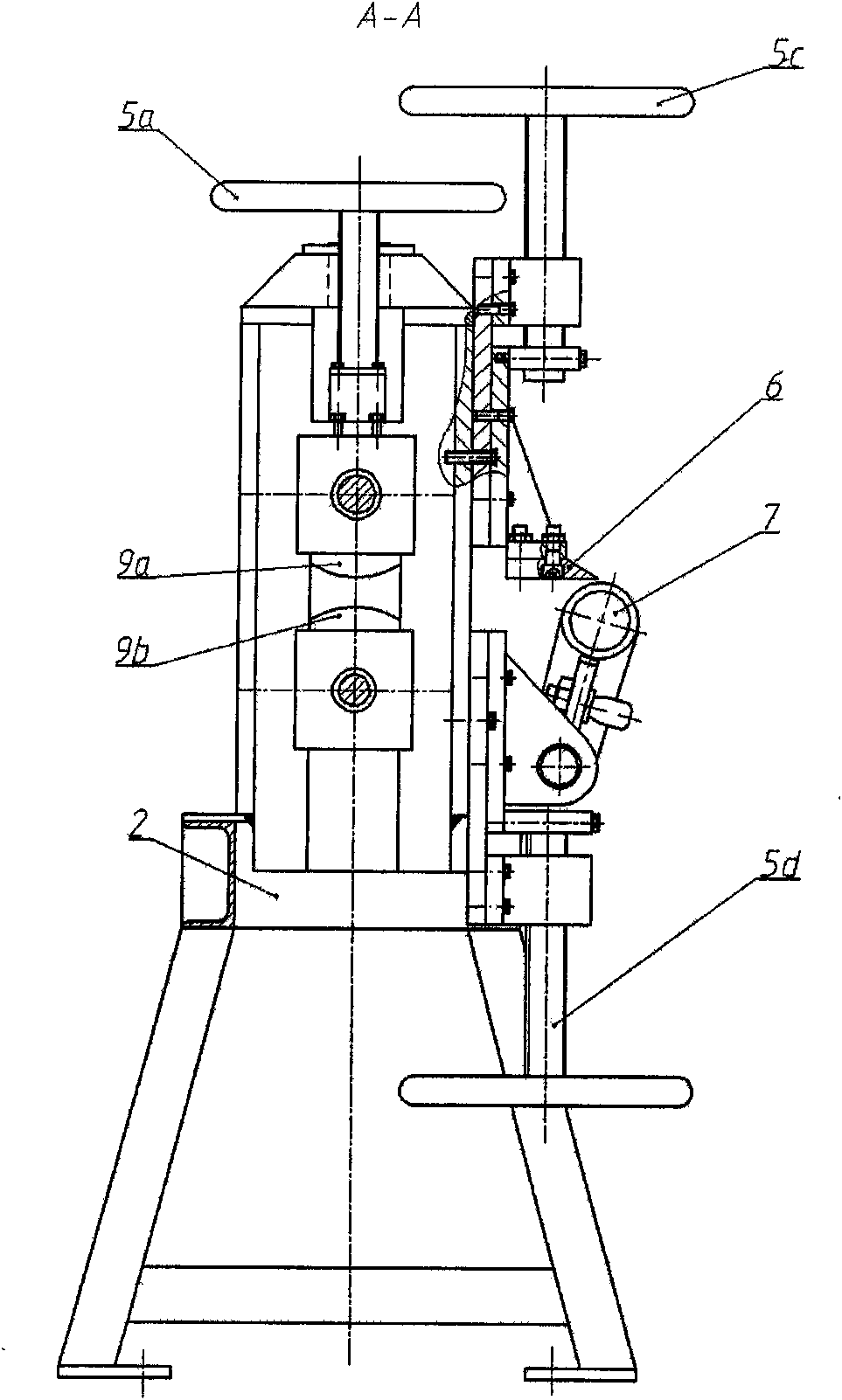

[0011] The present invention proposes a rubber leveling machine tool, such as figure 1 , figure 2 and image 3 As shown, the machine tool includes a frame 2, a diverter 4 fixed on the frame 2, two gear adjustment devices connected to the diverter 4, a tool rest mechanism and a drive worm gear reduction device arranged in front of the gear adjustment device The motor 1 of the worm reducer 3, the worm reducer 3 is driven by the V-shaped pulley 8 driven by the motor 1, the reversing device 4 is installed on the right side of the worm reducer 3 and connected with the frame 2, and the output of the reversing device 4 turns to the opposite direction The two drive shafts are respectively driven to form two toothed rollers 9 side by side up and down. The two toothed rollers 9 with opposite directions not only clamp the side of the tire left by removing the middle tread part of the waste tire, but also drive the side of the tire to rotate around a center of circle. It presents a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com